Dual bypass for piston-type flushometer

A flushing valve and piston technology, applied in the field of flushing valves, can solve the problems of increasing flushing volume, increasing operating costs, etc., and achieve the effects of reducing flushing volume, reducing travel distance, and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

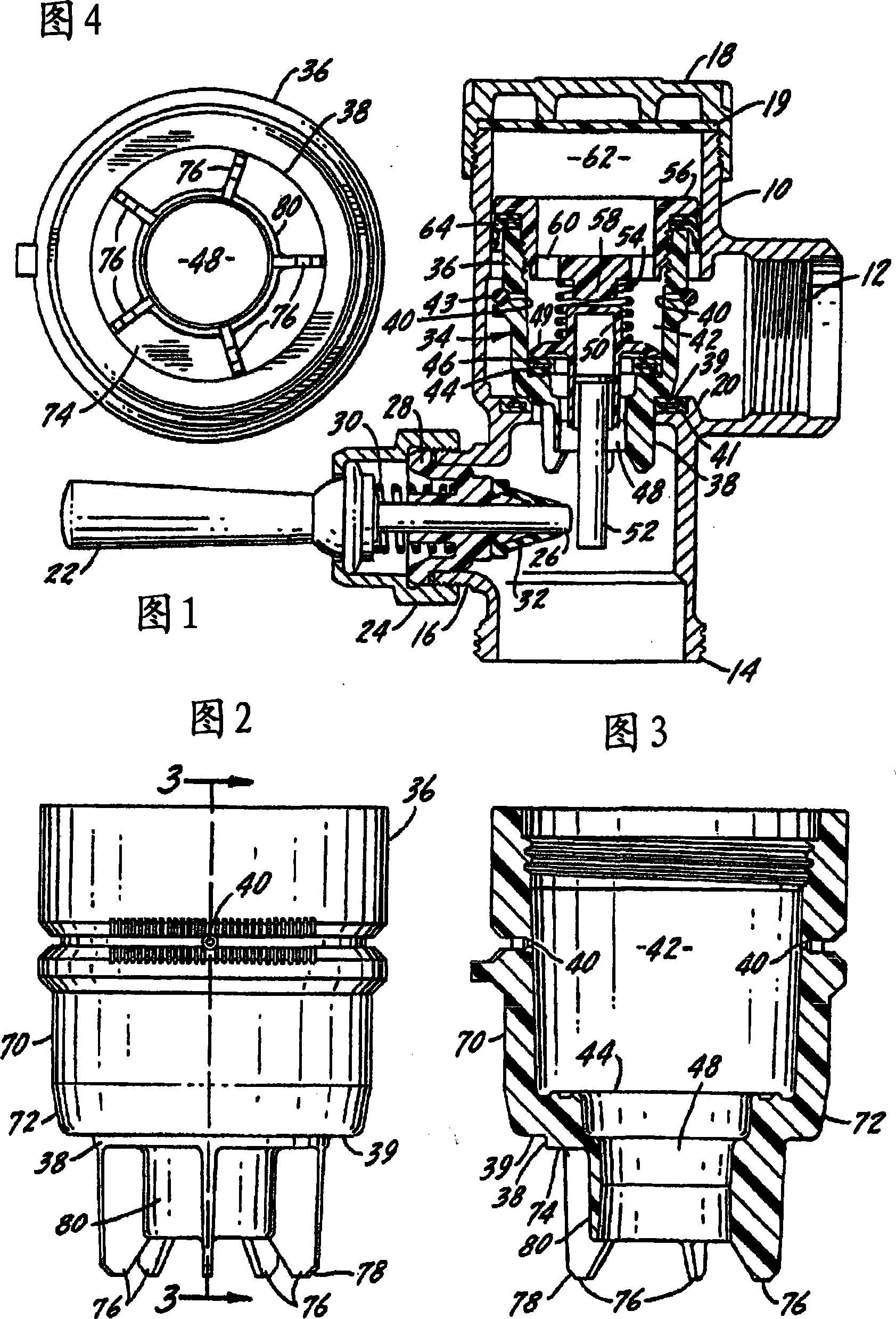

[0014] The piston of the present invention is conventionally used with flush valve assemblies for urinals or toilets. The flush valve piston is designed to control the flow of water through the flush valve in order to provide a specific amount of water for each flush operation, while the water passes through the flush valve at a high rate even when the water pressure is at the low end of the water pressure range commonly found in the United States. Although the present invention states that the desired water volume for each flush is 1.6 gallons or 6 liters, it should be understood that the size of the various components can be modified to provide a different water volume for each flush.

[0015] The flushing valve shown in the drawings has a generally hollow valve body 10 including an inlet connection portion 12, an outlet connection portion 14 and a handle connection portion 16. The top of the valve body is closed by a valve cover 18, and there may be a sealing element 19 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com