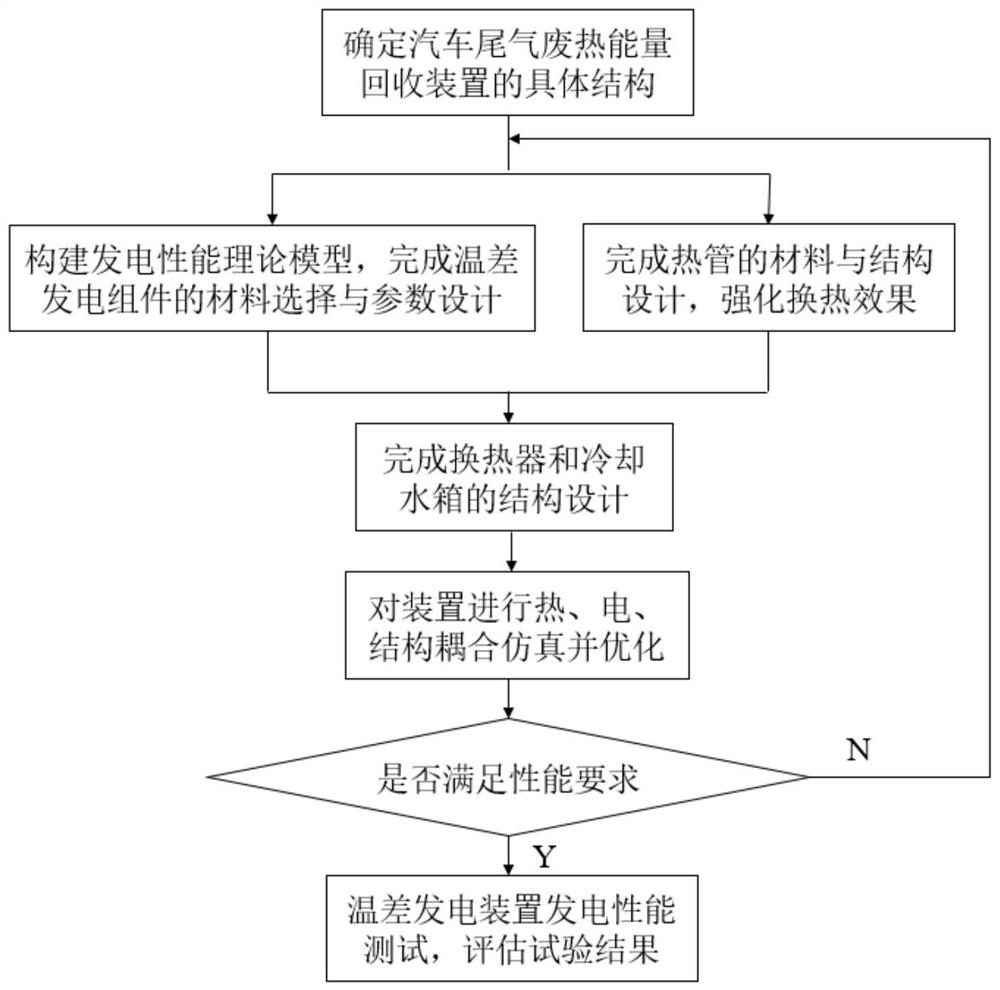

Automobile exhaust waste heat efficient energy recovery device and design method

A technology of energy recovery device and automobile exhaust, which is applied in exhaust device, muffler device, computer-aided design, etc., to achieve the effect of increasing the temperature difference between the hot and cold ends, flexible layout, and improving the effect of energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

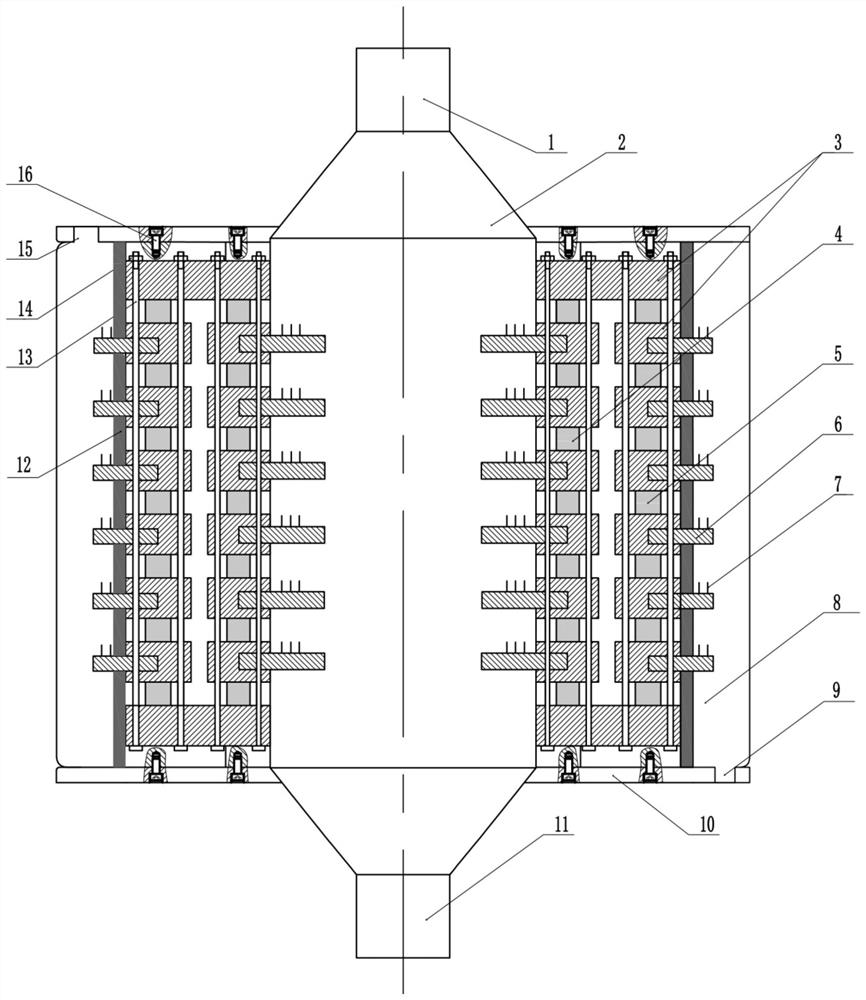

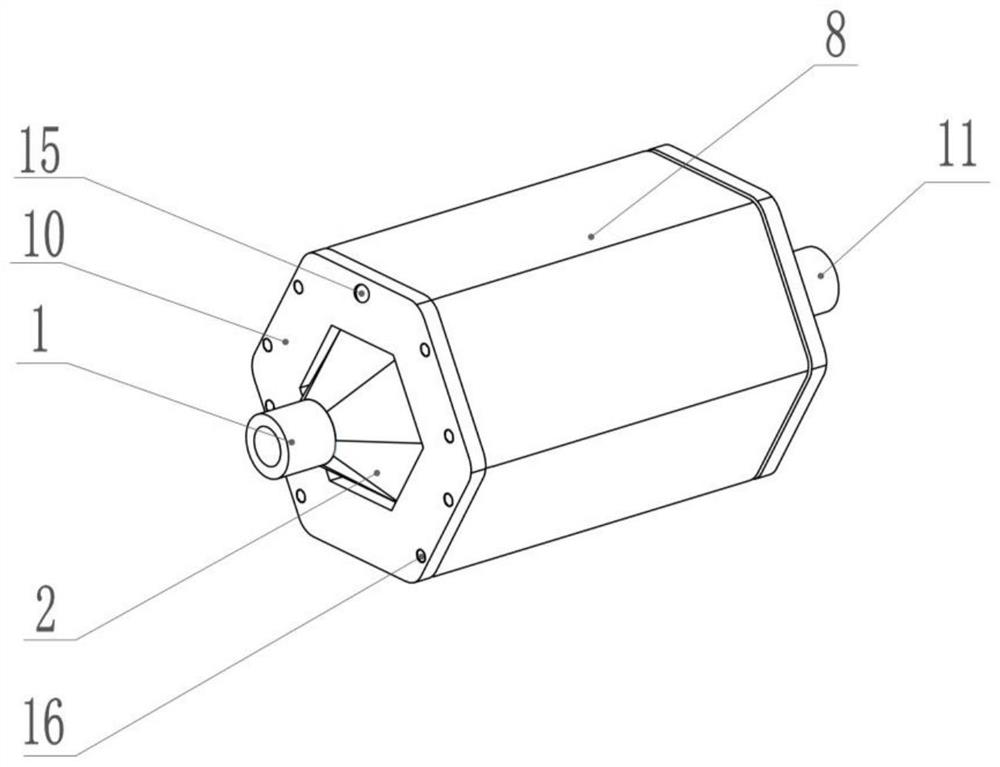

[0038] Attached below Figure 1-3 As well as the specific examples, the present invention will be further described. It should be pointed out that the technical solution and design principle of the present invention will be described in detail below only with an optimized technical solution, but the protection scope of the present invention is not limited thereto.

[0039] Such as Figure 1-3 As shown, a high-efficiency energy recovery device and design method for waste heat from automobile exhaust adopts a regular hexagonal cylindrical structure, including an air inlet 1, a heat exchanger 2, a heat-conducting copper plate 3, a high-temperature thermoelectric power generation piece 4, and a low-temperature thermoelectric power generation piece 5 , Heat pipe 6, copper fin 7, cooling water tank 8, water inlet 9, end cover 10, air outlet 11, foam glass 12, long screw 13, nut 14, water outlet 15, bolt 16.

[0040] The plurality of heat-conducting copper plates 3 are arranged in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com