Auxiliary combustion device using tail gas waste heat to gasify alcohol

An auxiliary combustion and exhaust gas technology, which is applied in the direction of exhaust devices, fuel supply devices, and noise reduction devices, can solve the problems of high cost, failure to recycle energy, and inability to popularize and apply high-power fuel oil units, etc., and achieve strong heat storage capacity , The technical means are simple and easy to implement, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

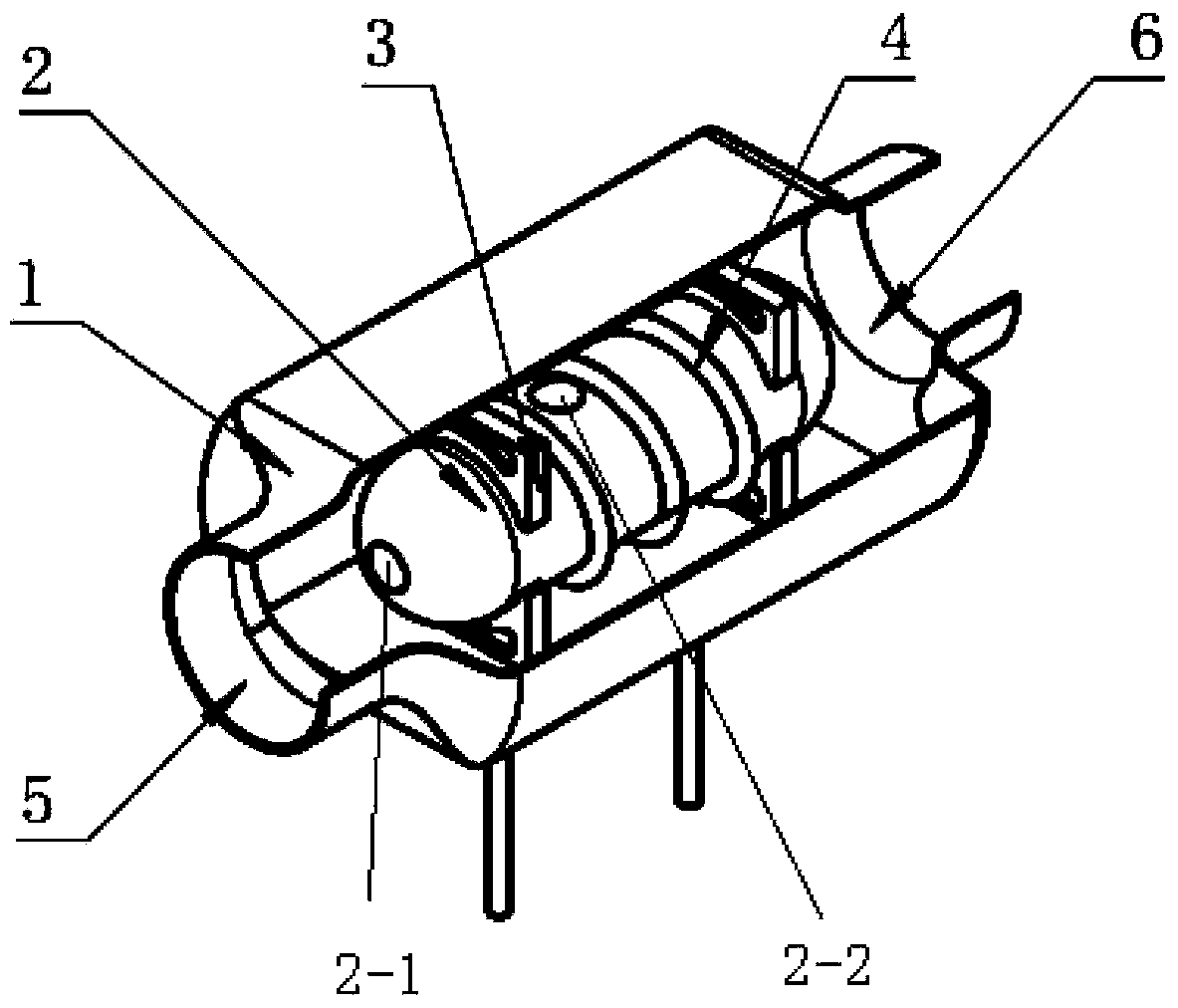

[0023] Such as figure 1 shown. The auxiliary combustion device for gasifying alcohols by using exhaust waste heat in the present invention comprises a housing 1, an inner tank 2 placed in the housing 1, a bracket 3 placed in the housing 1 for fixing the inner tank 2, and an inner tank wrapped around the 2 copper pipe 4 on the outer wall, exhaust gas inlet 5 for connecting the exhaust pipe and exhaust gas outlet 6 for exhausting exhaust gas; there is a gap between the outer wall of the inner tank 2 and the inner wall of the housing 1;

[0024] The two ends of the copper tube 4 pass through the housing 1, one end is used to inhale external liquid alcohol (referring to methanol or ethanol), and the other end is used to connect the engine intake pipe. The copper tube 4 is made of copper with high thermal conductivity, and is wound around the outer wall of the inner tank 2 in a spiral shape, which increases the heating area and is beneficial to the gasification of liquid alcohol i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com