Singling device and a singling method

a technology of singling device and singling method, which is applied in the direction of conveying parts, de-stacking articles, and article separation, etc., can solve the problem of requiring a comparatively long tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

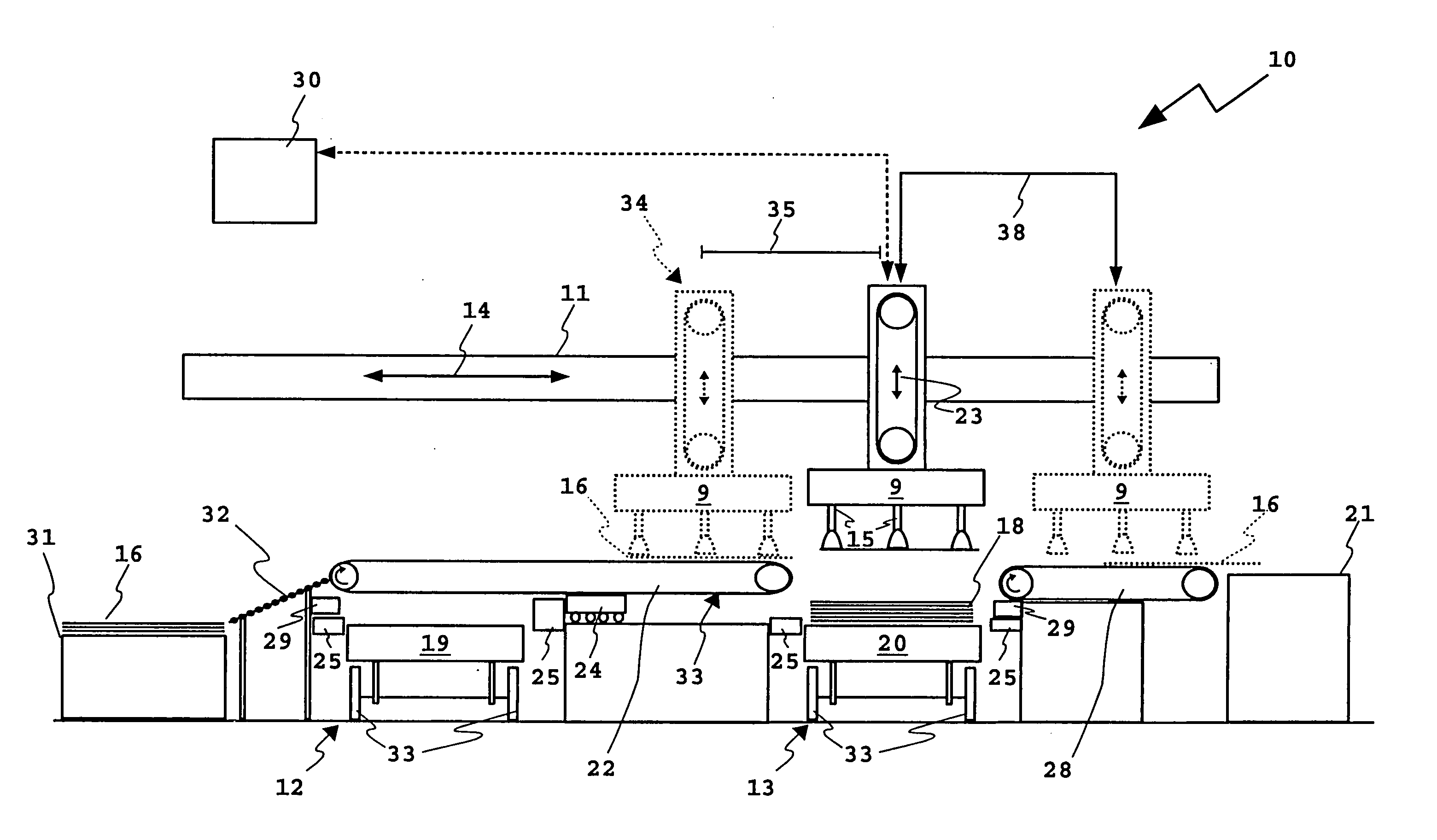

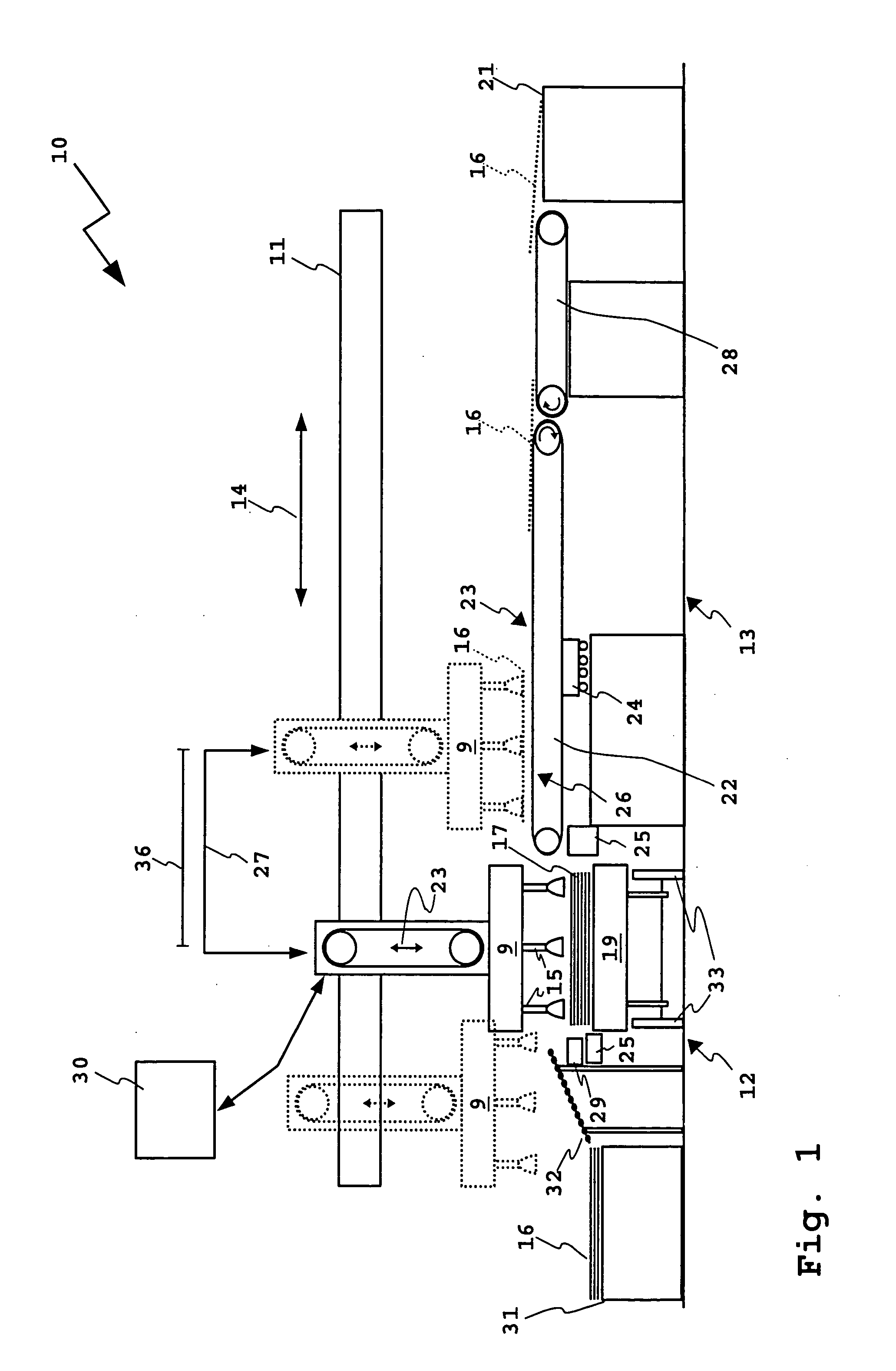

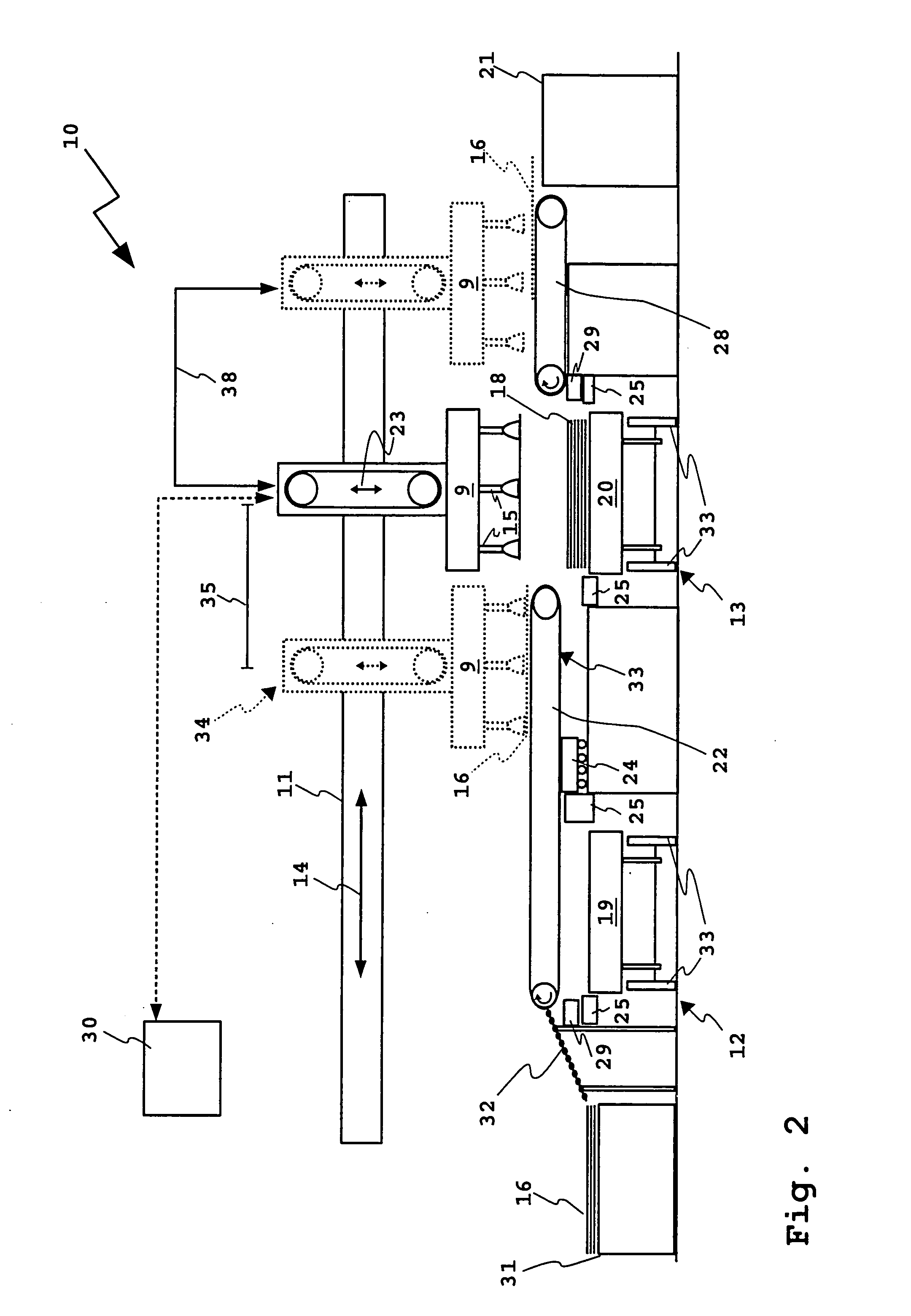

[0022] A lifting means 9 of a singling device 10 is mounted on a guide means 11 for longitudinal movement thereon. It can be reciprocated between a first and a second tendering position 12 and 13 in the longitudinal direction 14. Underneath it on the lifting means 9 there are suction means 15, with which the lifting means 9 can lift sheet metal panels 16 from the sheet metal panel stacks 17 and 18 to the two tendering positions 12 and 13. The sheet metal panel stacks 17 and 18 are held on transport carriages 19 and 20, which may be moved into the singling device 10 in the transverse direction and constitute transverse conveying means.

[0023] When a sheet metal panel stack 17 or 18 has been dealt with so that one of the transport carriages 19 or 20 is free, the respective transport carriage 19 or 20 is moved out of the singling device 10, reloaded with sheet metal panels 16 and returned to the respective tendering position 12 or 13. The lifting means 9 alternatively handles sheet meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com