Multi-piece solid golf ball

a golf ball and multi-piece technology, applied in the field of multi-piece solid golf balls, can solve the problems of loss of fair play and significant drawbacks of low-hs players, and achieve the effect of reducing the distance traveled by the ball and reducing the distan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

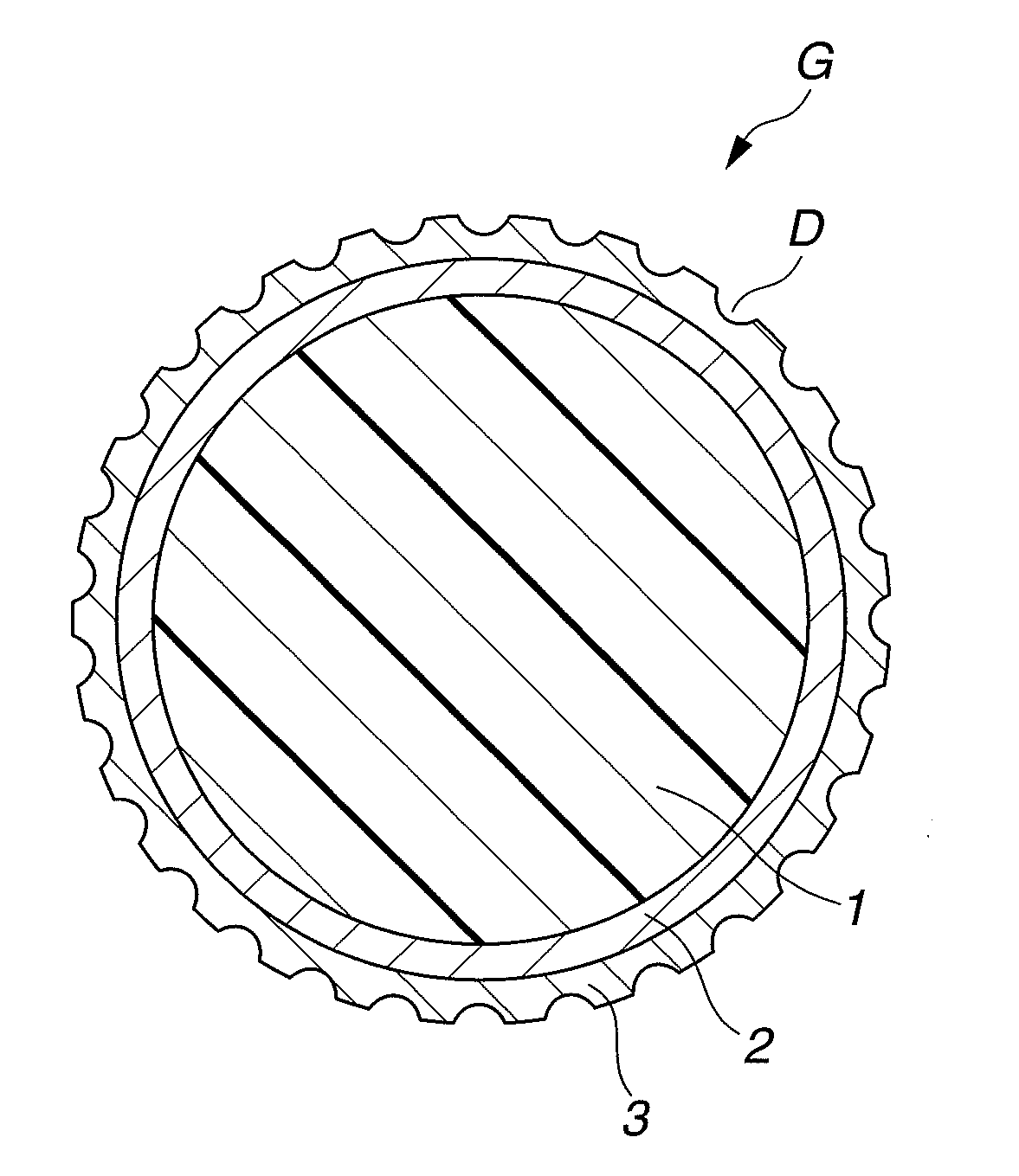

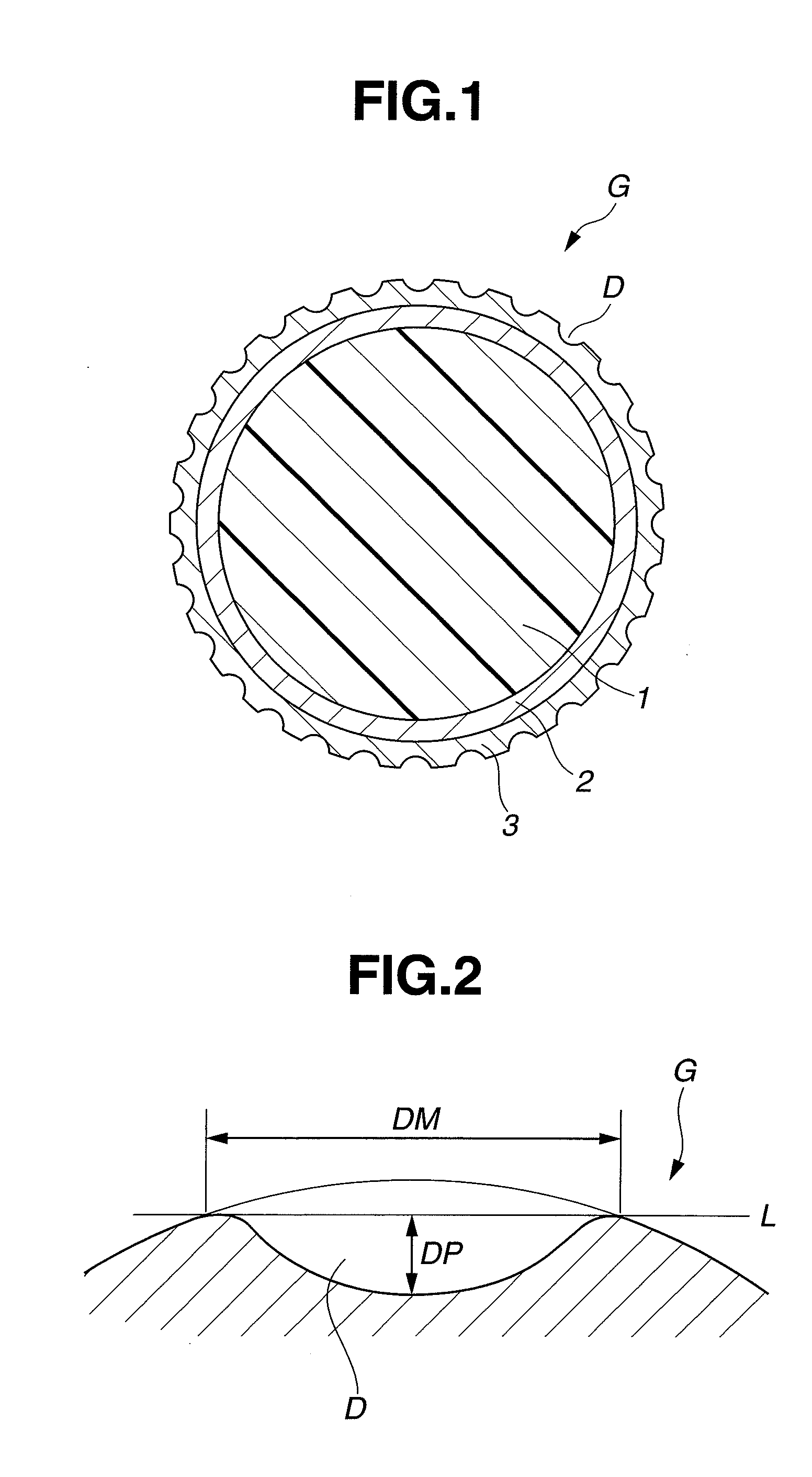

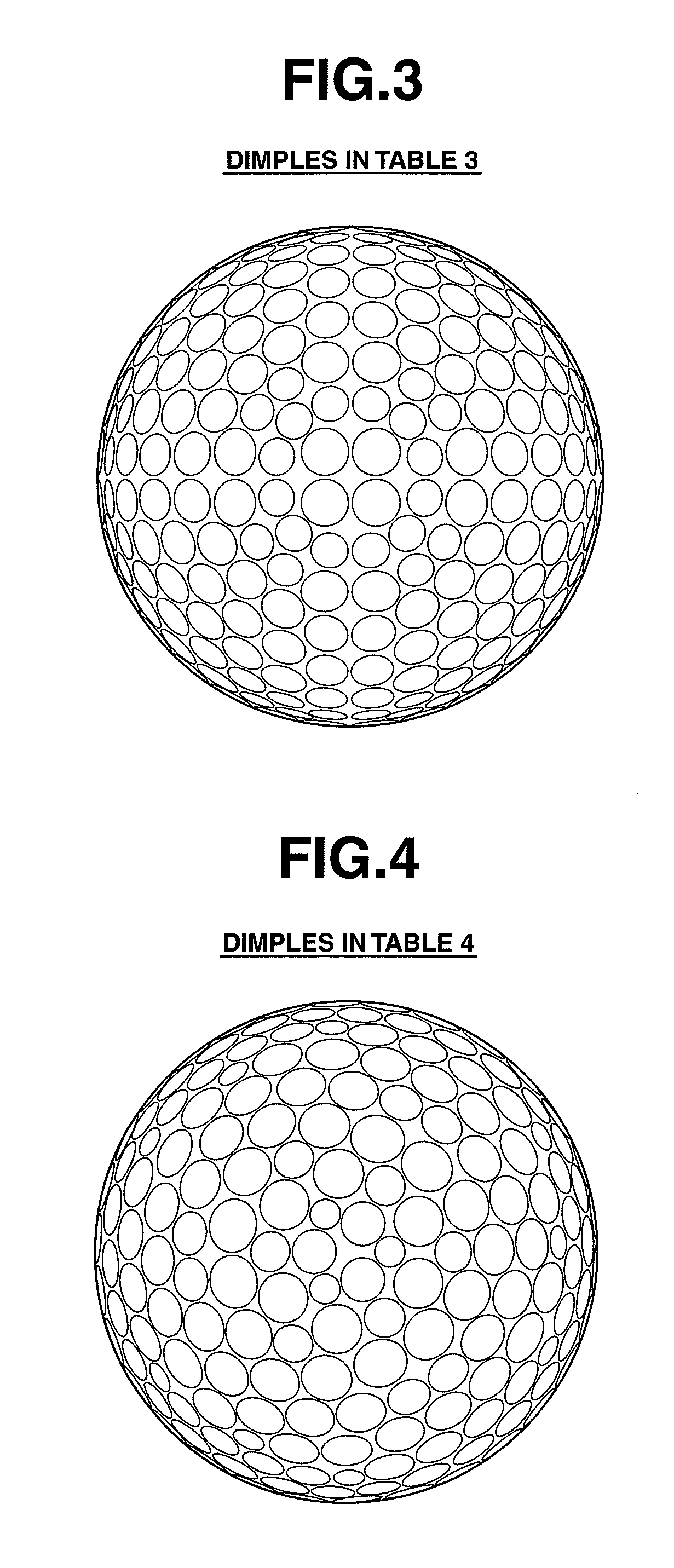

Image

Examples

examples

[0153]The following Examples and Comparative Examples are provided by way of illustration and not by way of limitation.

examples 1 to 3

, Comparative Examples 1 to 5

[0154]The rubber compositions shown in Table 1 were prepared, then molded and vulcanized at 155° C. for 15 minutes to produce solid cores. Numbers in the table indicate parts by weight.

TABLE 1ABCPolybutadiene rubber 11001000Polybutadiene rubber 200100Zinc acrylate30.031.528.0Peroxide1.21.21.2Zinc oxide444Barium sulfate20.12118.7Calcium carbonate005Antioxidant0.10.10.1Zinc salt of pentachlorothiophenol0.60.60Specific gravity1.1861.1941.186

[0155]Trade names of the materials in the table are as follows.[0156]Polybutadiene rubber 1:[0157]Available under the trade name “BR 730” from JSR Corporation.[0158]Polybutadiene rubber 2:[0159]Available under the trade name “BR 01” from JSR Corporation.[0160]Zinc acrylate: Available from Nihon Jyoryu Kogyo Co., Ltd.[0161]Peroxide: 1,1-Bis(t-butylperoxy)cyclohexane; available under the trade name “Perhexa C-40” from NOF Corporation.[0162]Zinc oxide: Available from Sakai Chemical Industry Co., Ltd.[0163]Barium sulfate: Av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com