Patents

Literature

35results about How to "Achieve punching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

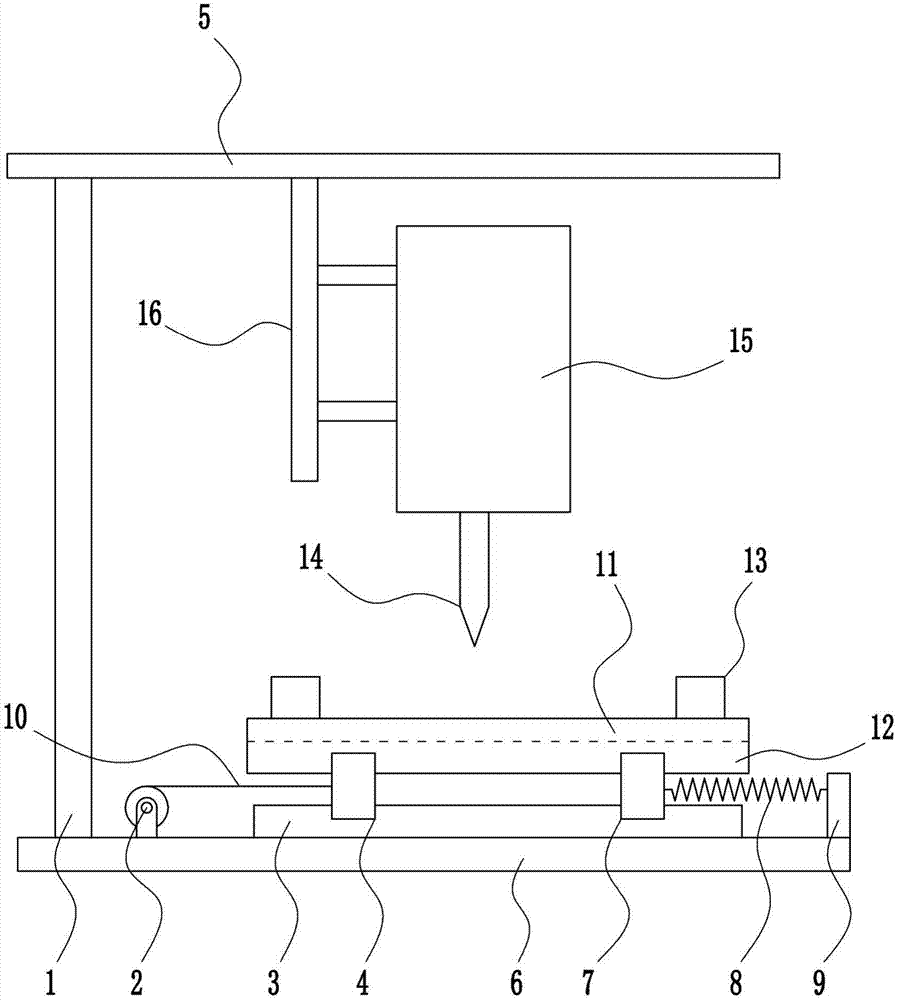

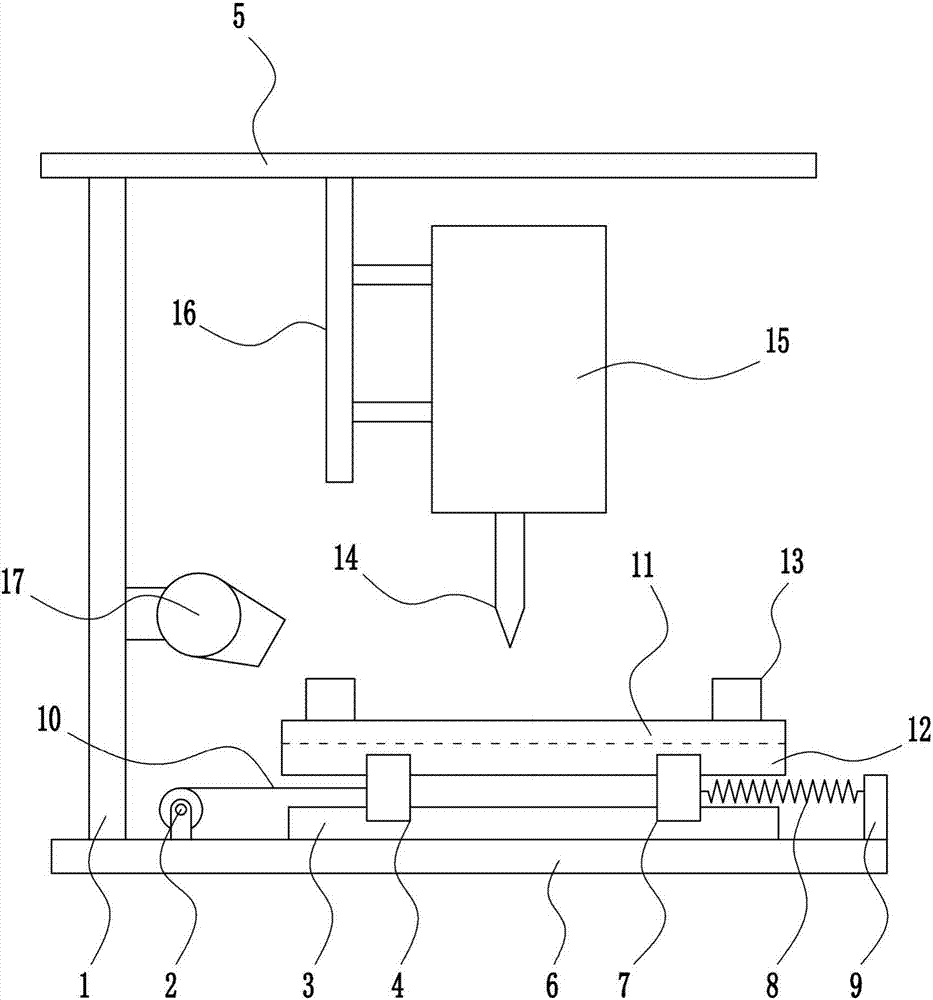

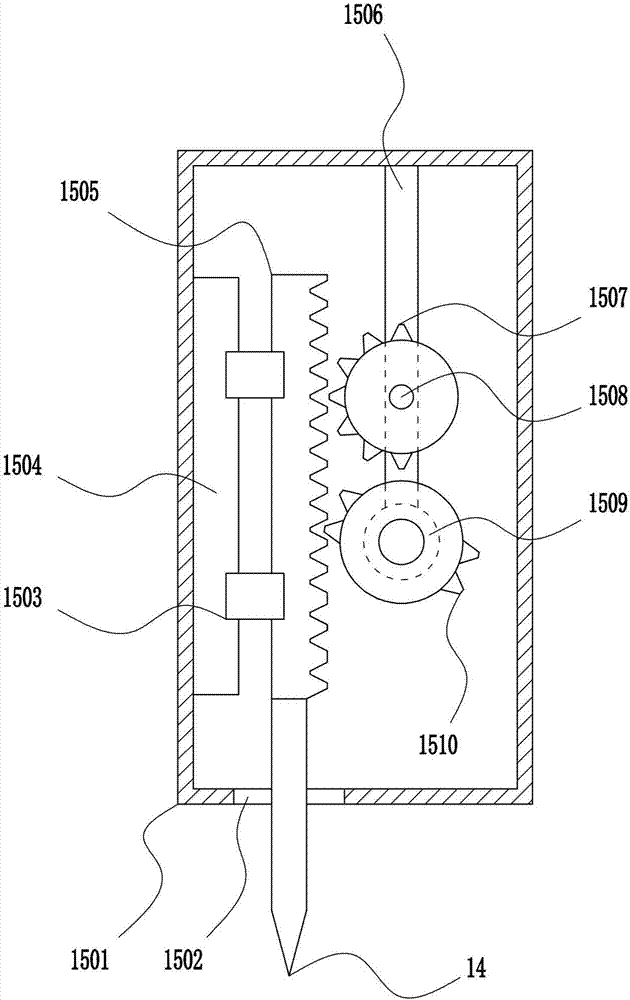

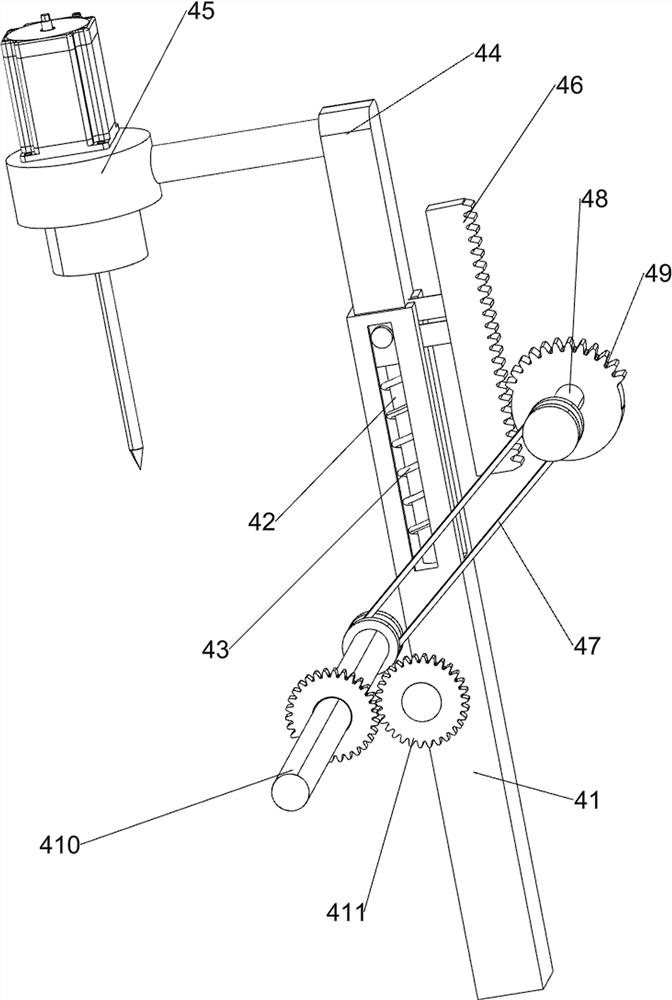

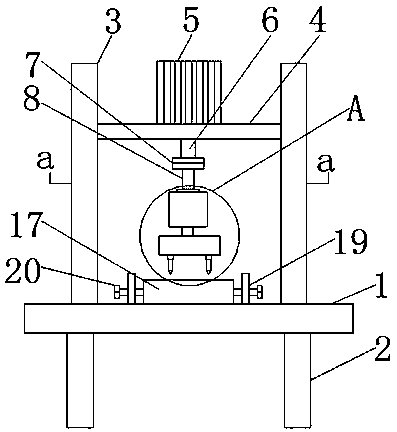

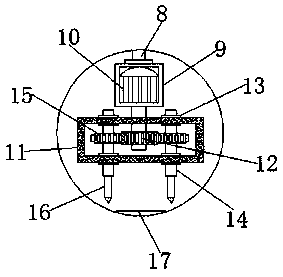

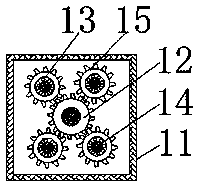

Quick footwear upper punching device for shoe production

InactiveCN106889702ARealize up and down movementAdjustable positionShoemaking devicesHeelsPunchingEngineering

The invention relates to a punching device, in particular to a quick footwear upper punching device for shoe production. According to the technical aims, the quick footwear upper punching device for shoe production is convenient to operate and high in punching efficiency. In order to achieve the technical aims, the quick footwear upper punching device for shoe production comprises a left frame, an electric winding wheel, a first sliding rail, a first sliding block, a top plate, a bottom plate, a second sliding block, a first spring, a baffle, a stay wire, an operating platform, a fixing device and the like; the left frame is welded to the left side of the top of the bottom plate, the first sliding rail is connected to the middle of the top of the bottom plate in a bolted joint mode, and the first sliding block and the second sliding block are connected to the upper end of the first sliding rail in a sliding mode. According to the footwear upper punching quickly device for shoe production, due to the fact that a rotating motor is controlled to run and a first notched gear and a second notched gear are matched with a rack, a vertical motion of the rack is achieved so that punching operation of a footwear upper can be conducted through the vertical motion of a drill head.

Owner:林永贵

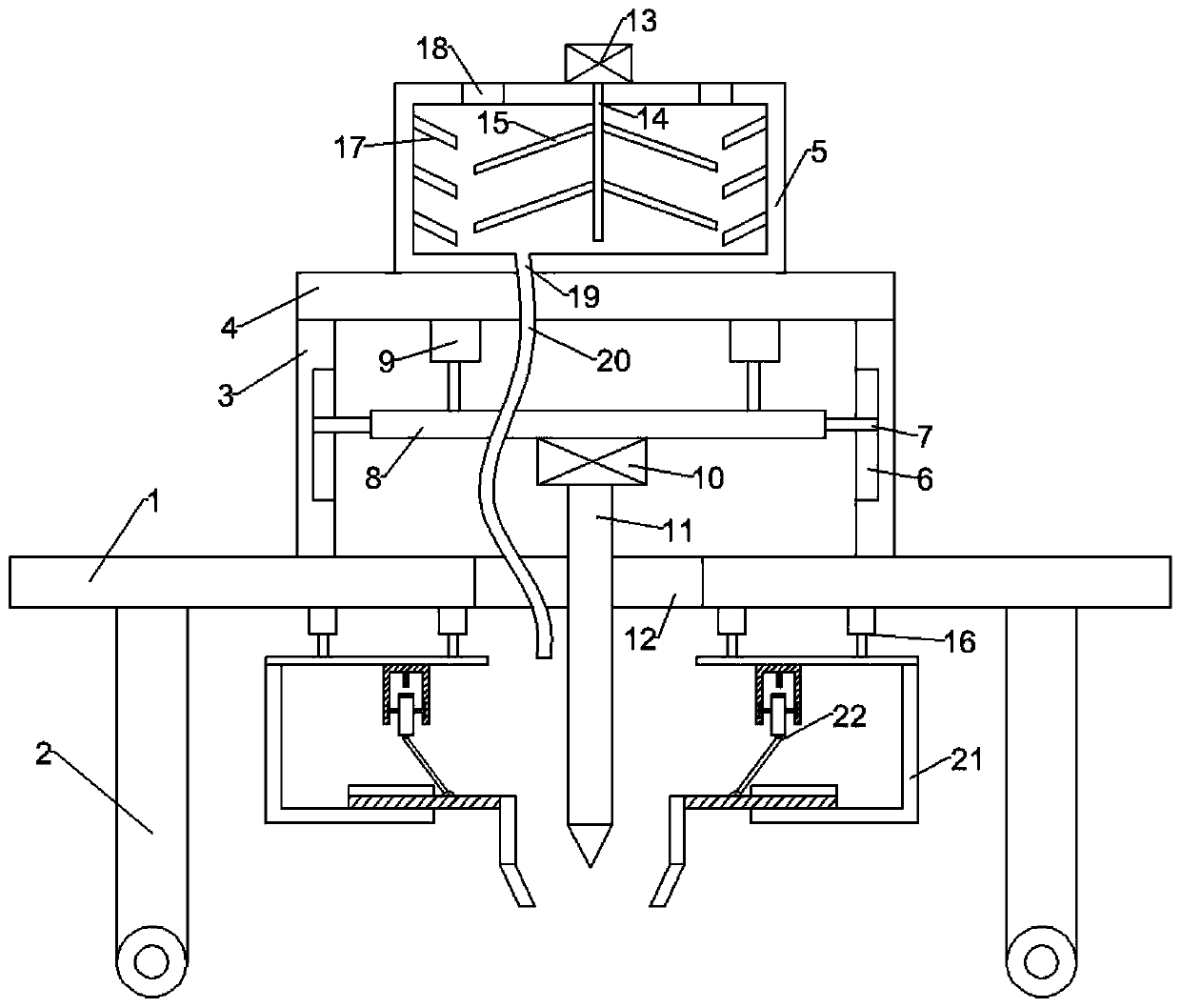

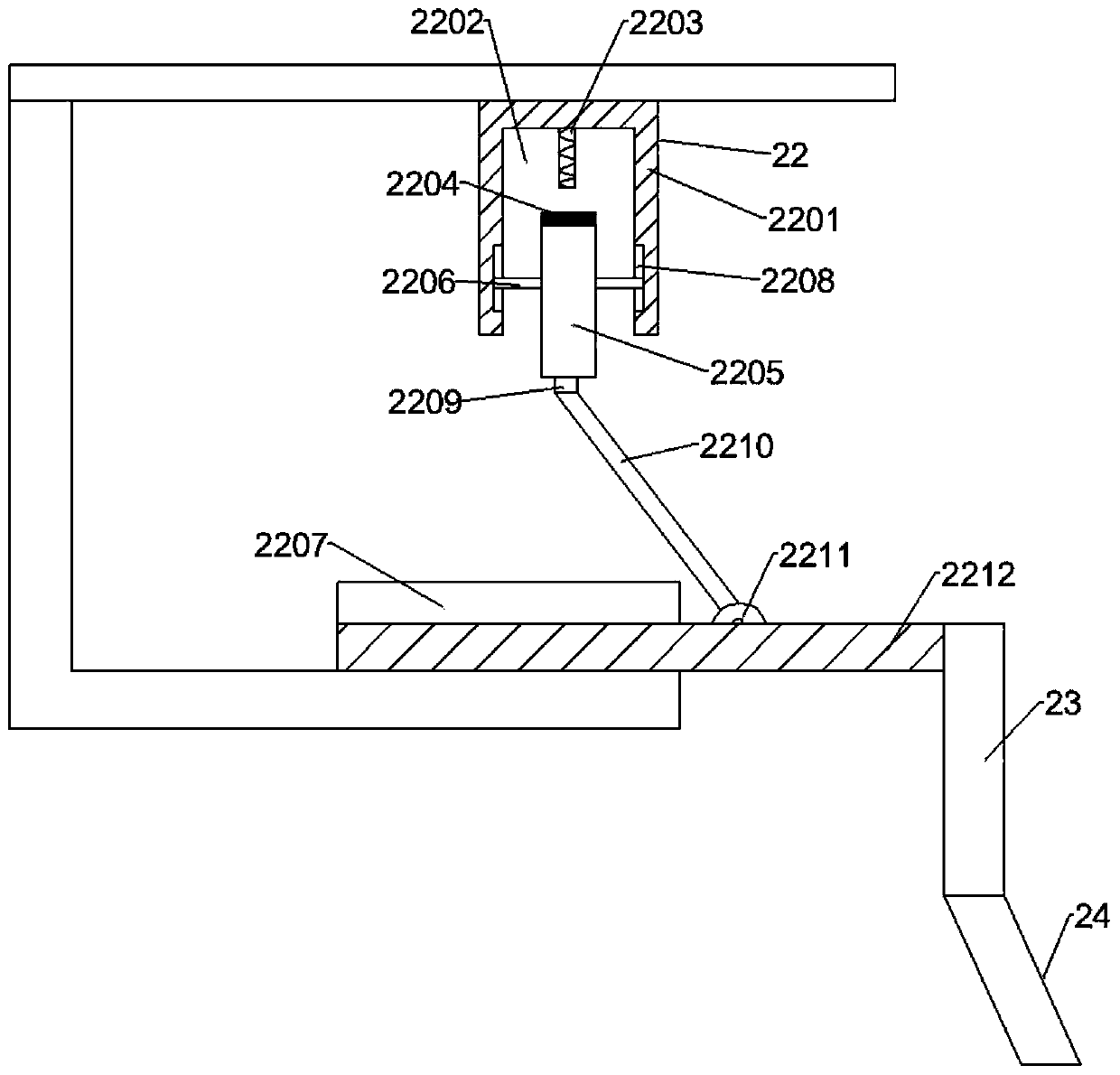

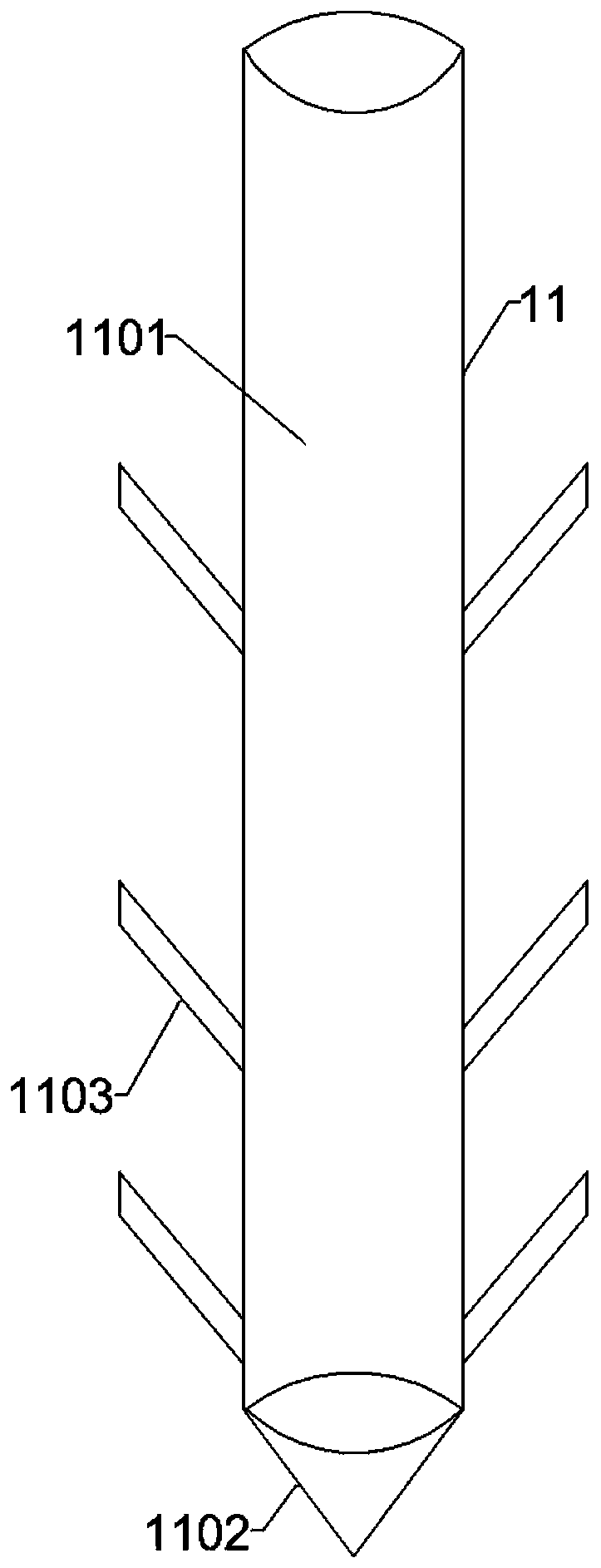

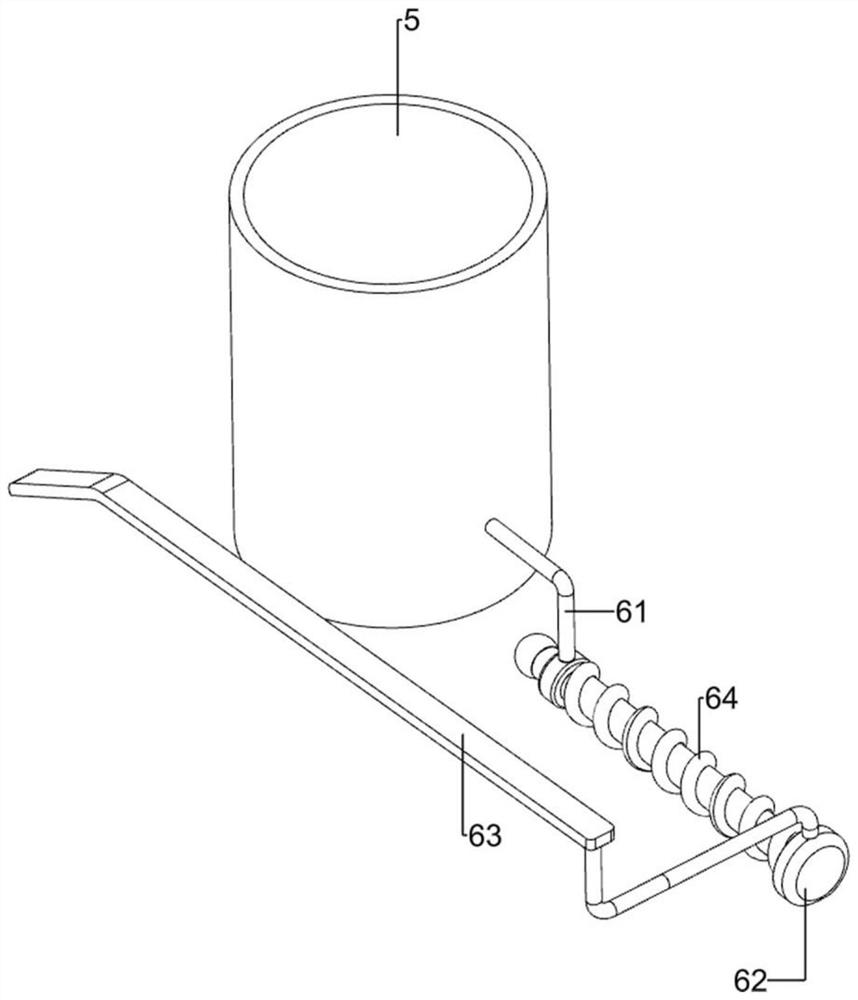

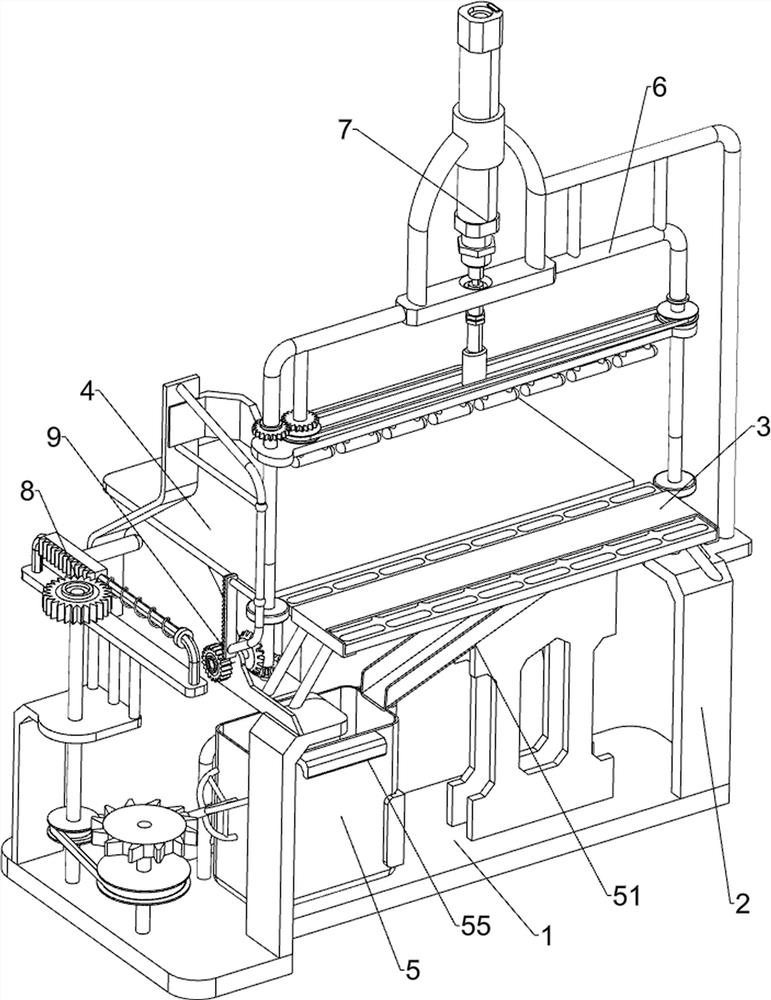

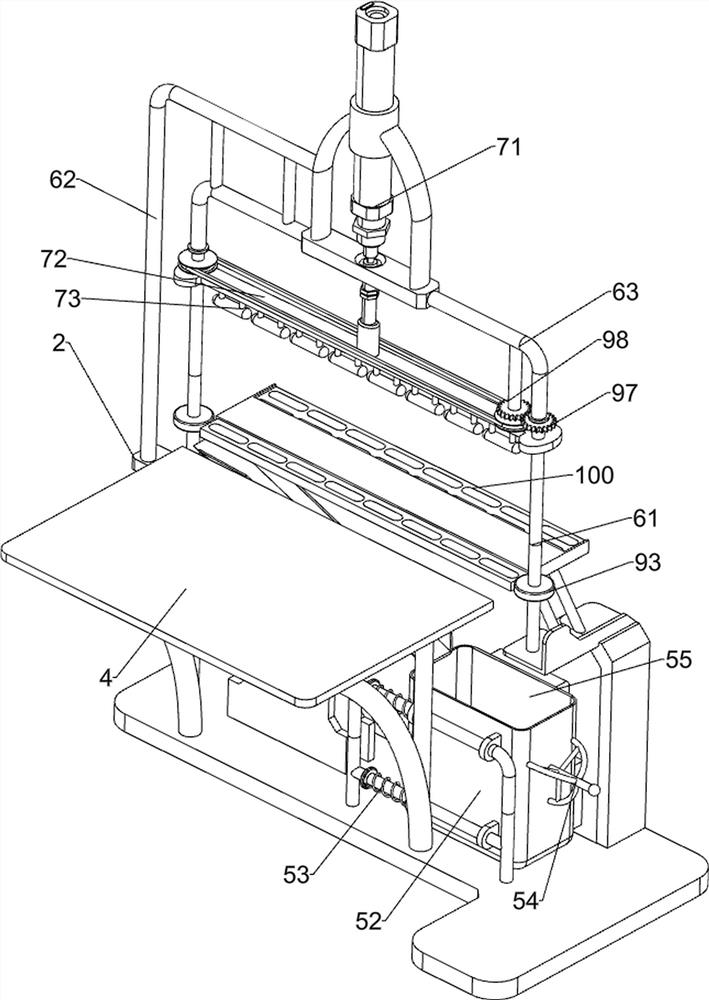

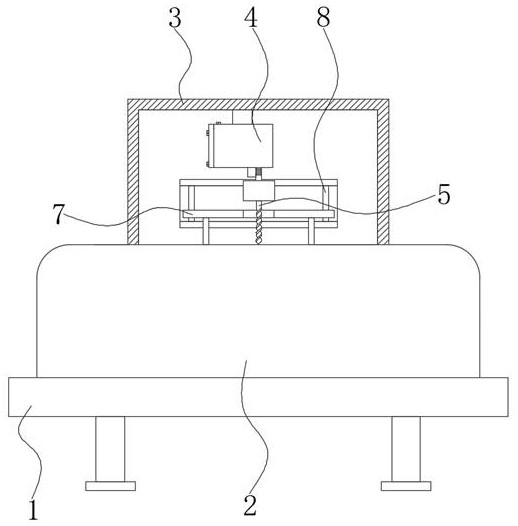

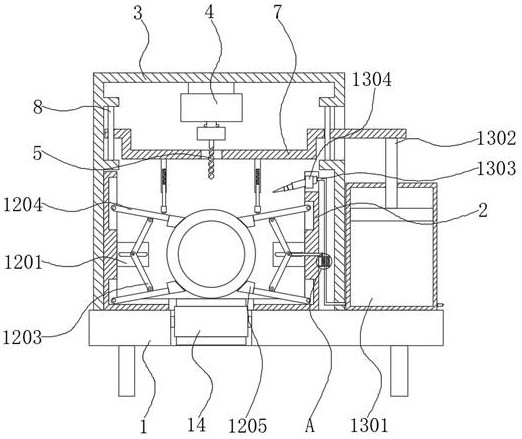

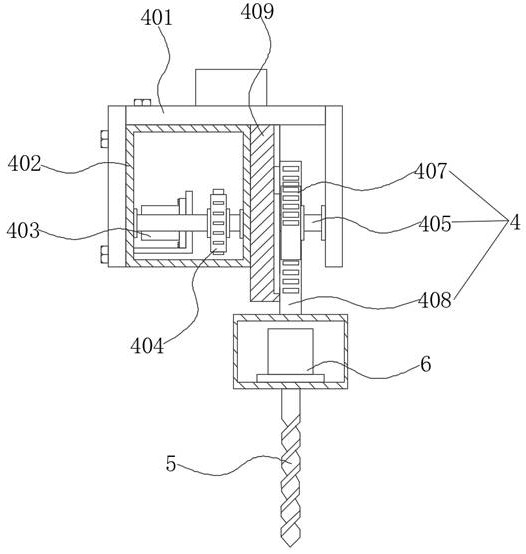

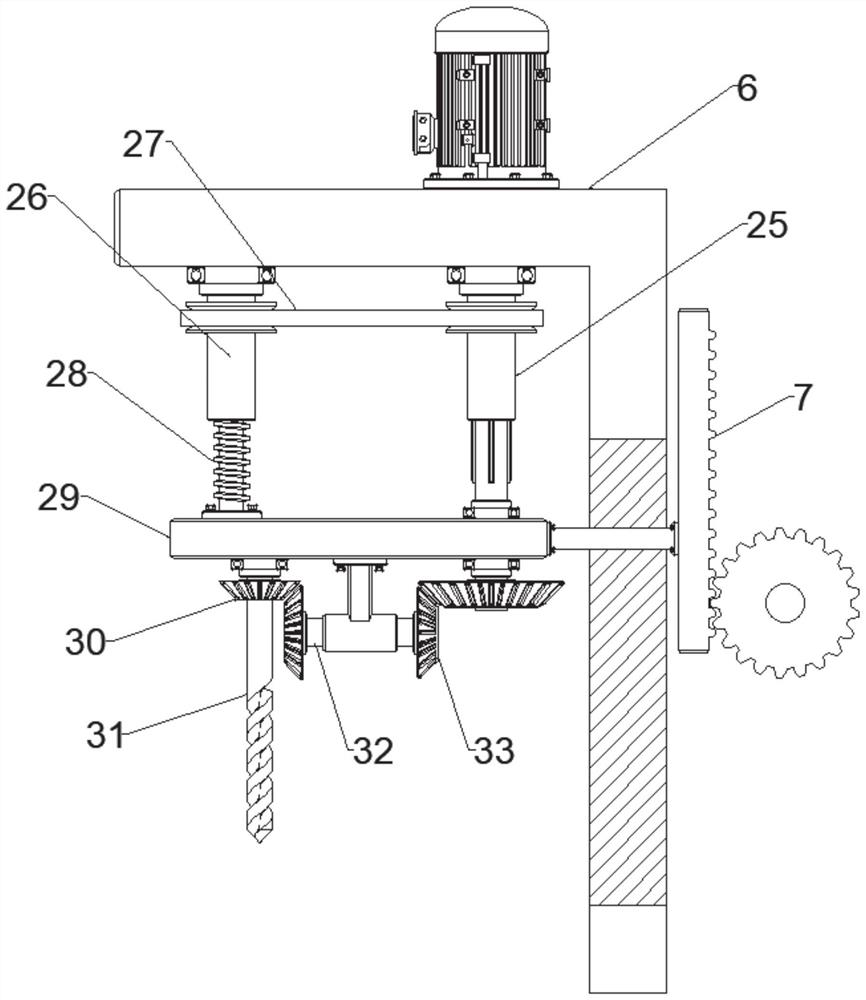

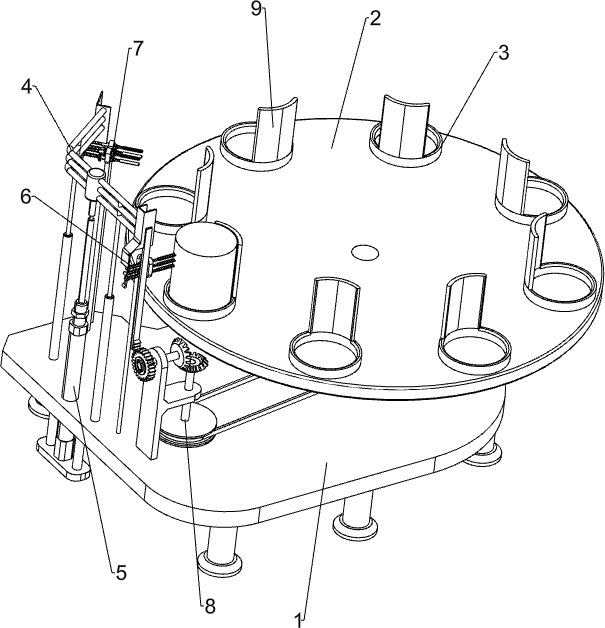

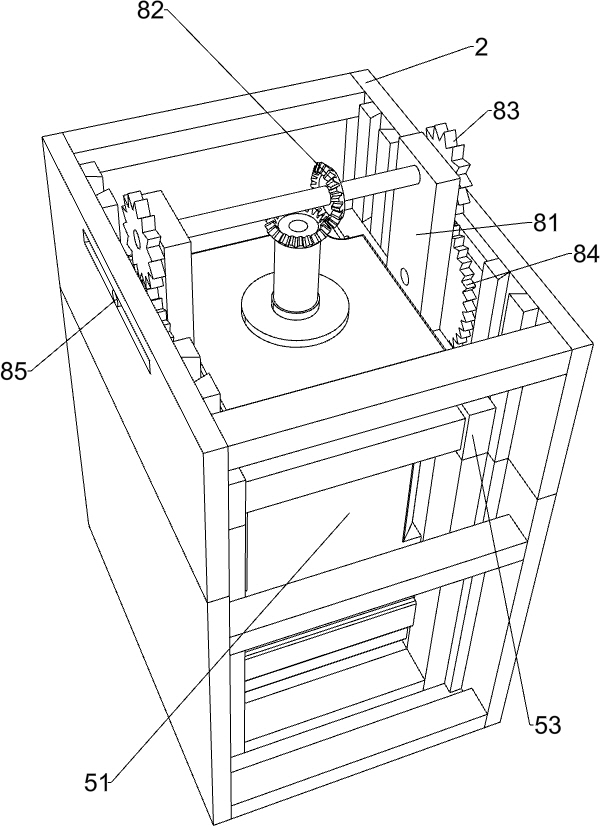

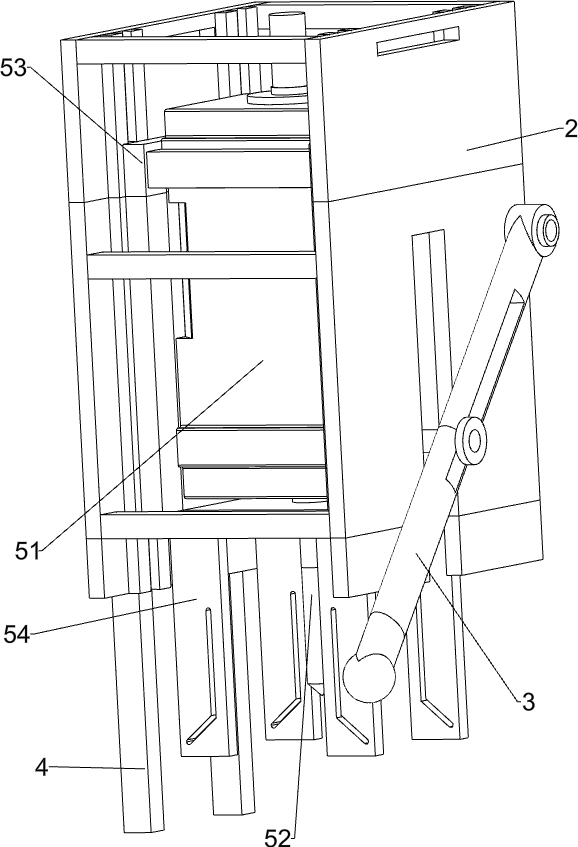

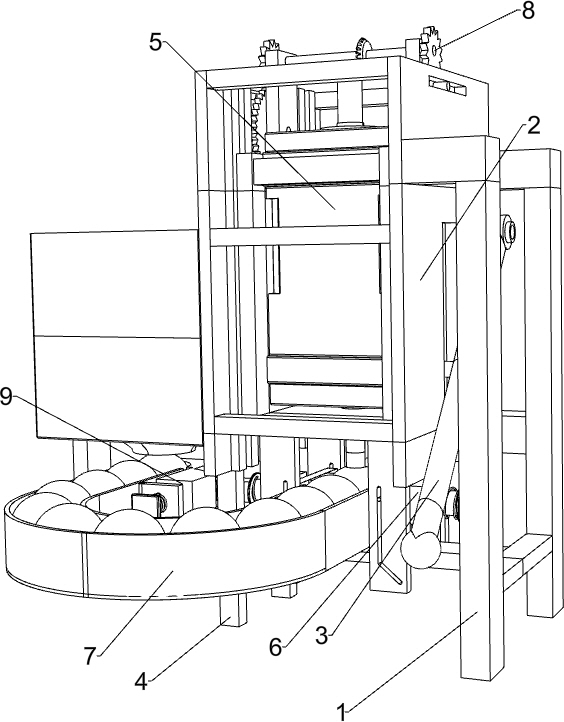

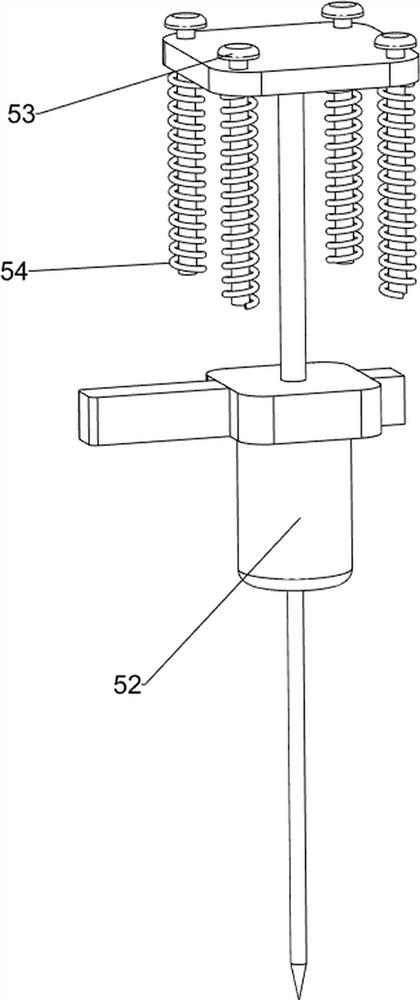

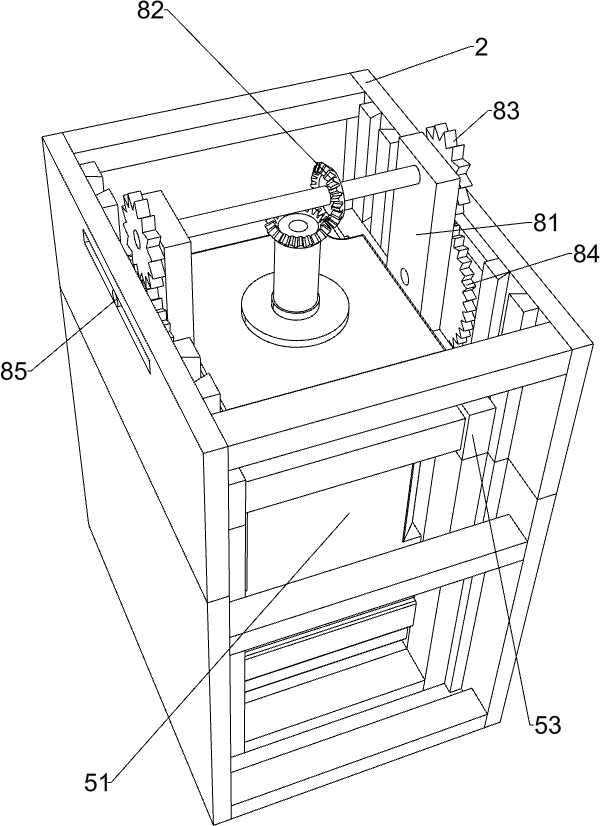

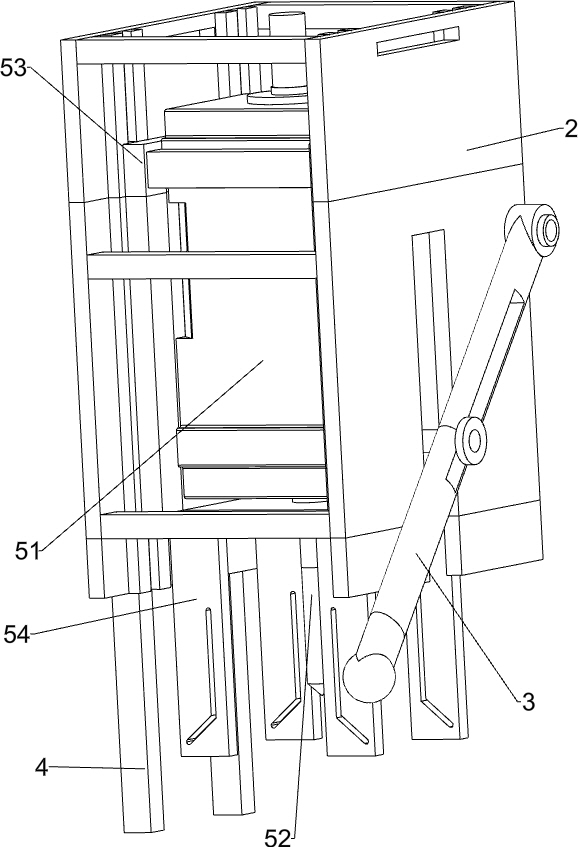

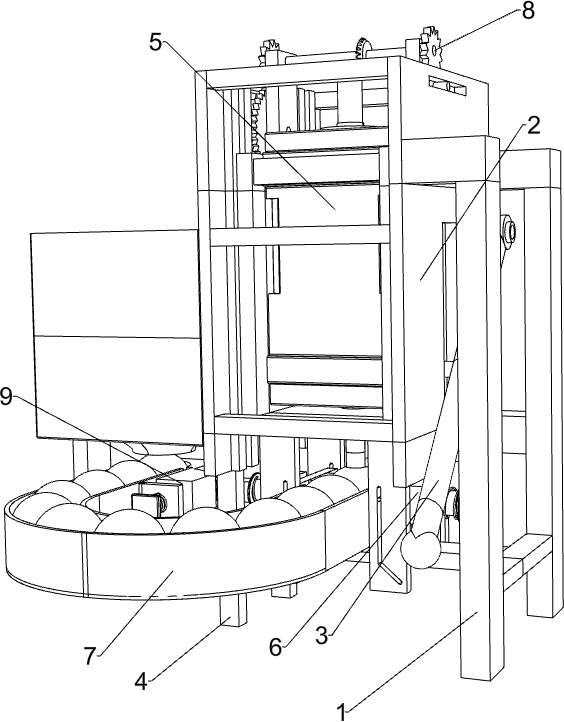

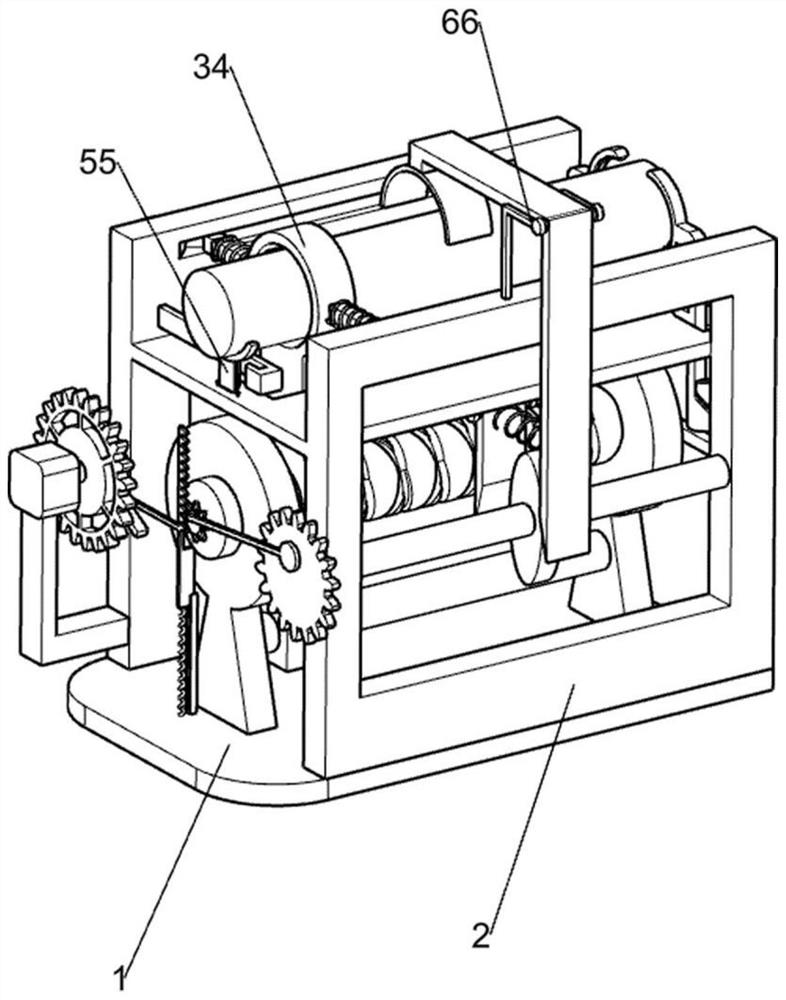

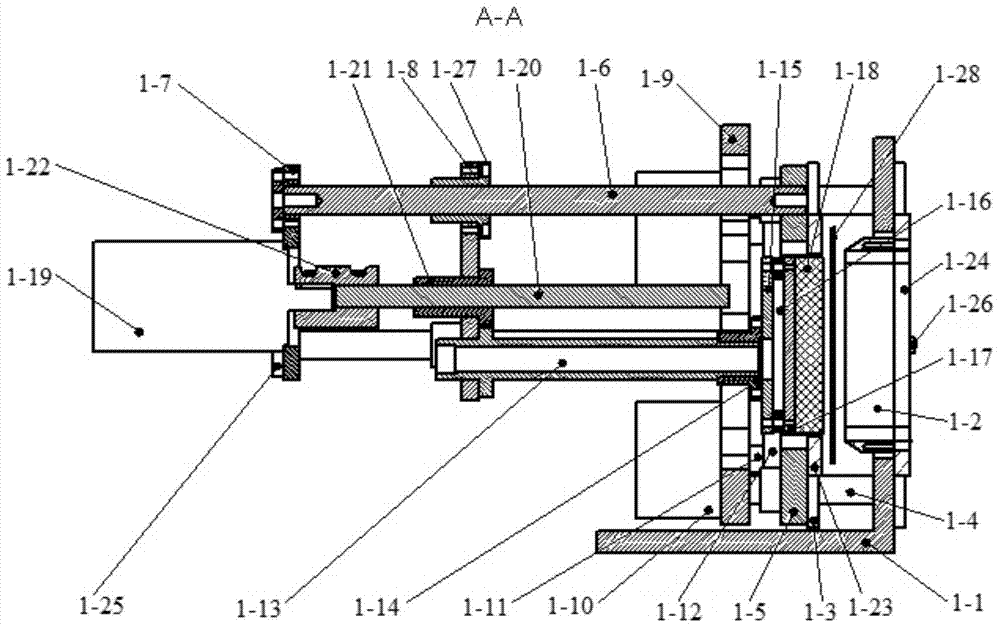

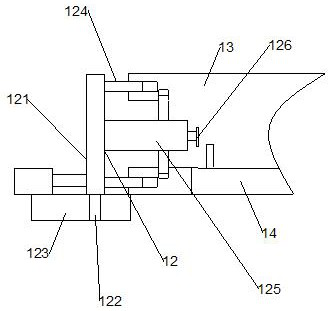

Perforating machine for agaric planting wood

InactiveCN112060215AAchieve punching effectAchieve full hole punchingStationary drilling machinesAgricultural scienceAgricultural engineering

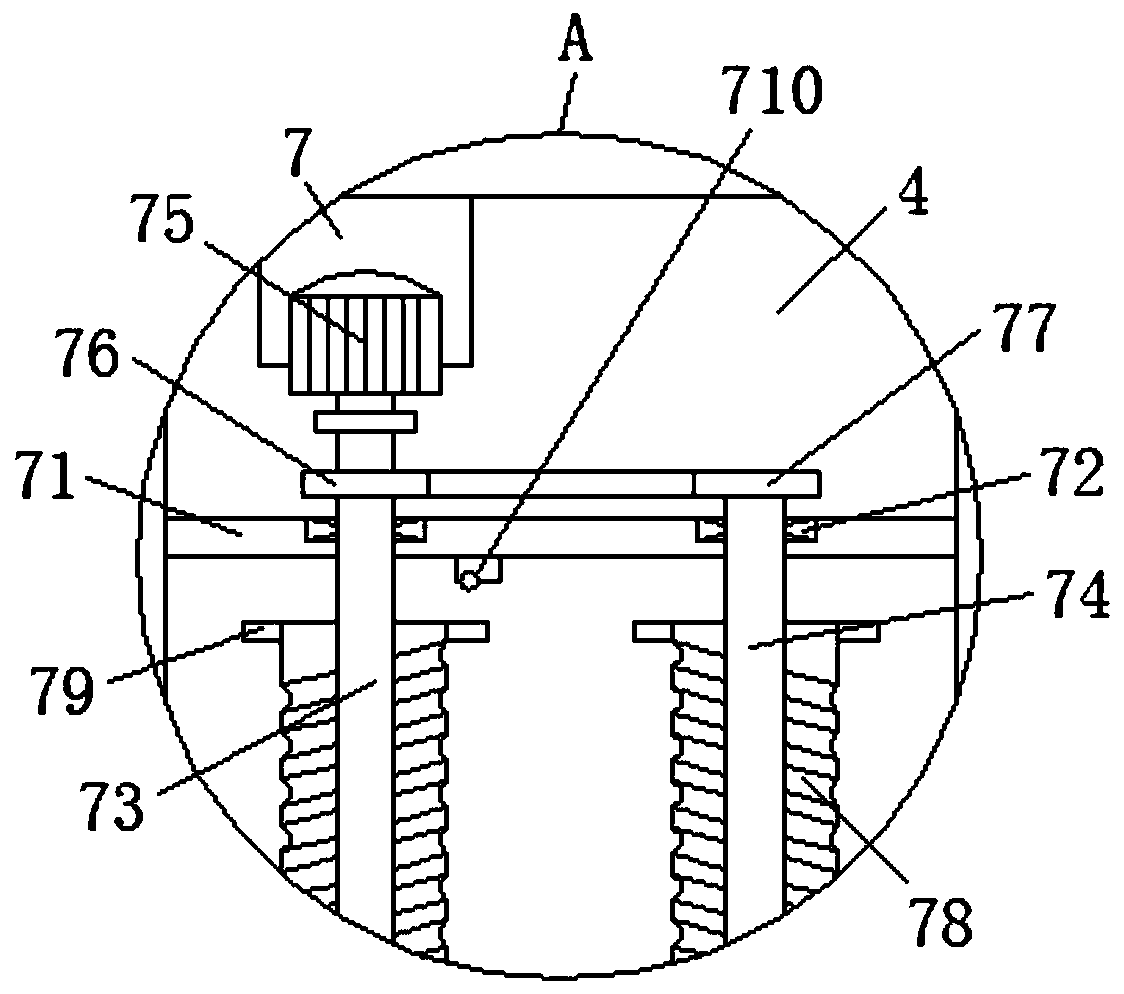

The invention relates to a perforating machine, in particular to a perforating machine for agaric planting wood. The perforating machine for the agaric planting wood can achieve continuous rotating and moving of the wood, continuously carries out perforating, and saves time and labor. The perforating machine for the agaric planting wood comprises bases, a workbench, a drilling mechanism and a rotating mechanism, wherein the workbench is arranged at the top of the base, and a motor is arranged on one side of the top of the workbench; the drilling mechanism is connected between an output shaft of the motor and the workbench; and the top of the workbench is connected with the rotating mechanism. By the cooperation of the motor, the drilling mechanism and the rotating mechanism, the wood can be fixed, the effect that the wood is perforated can be continuously achieved, comprehensive perforating is achieved by continuously rotating the wood, and therefore the working efficiency of people can be improved.

Owner:何勇

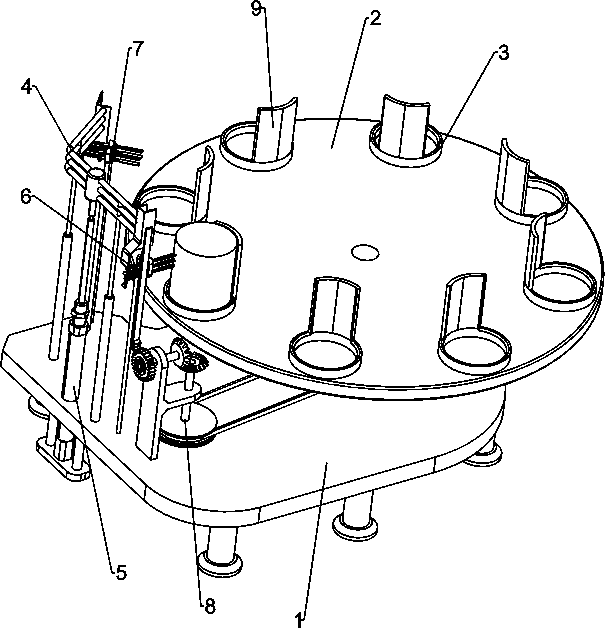

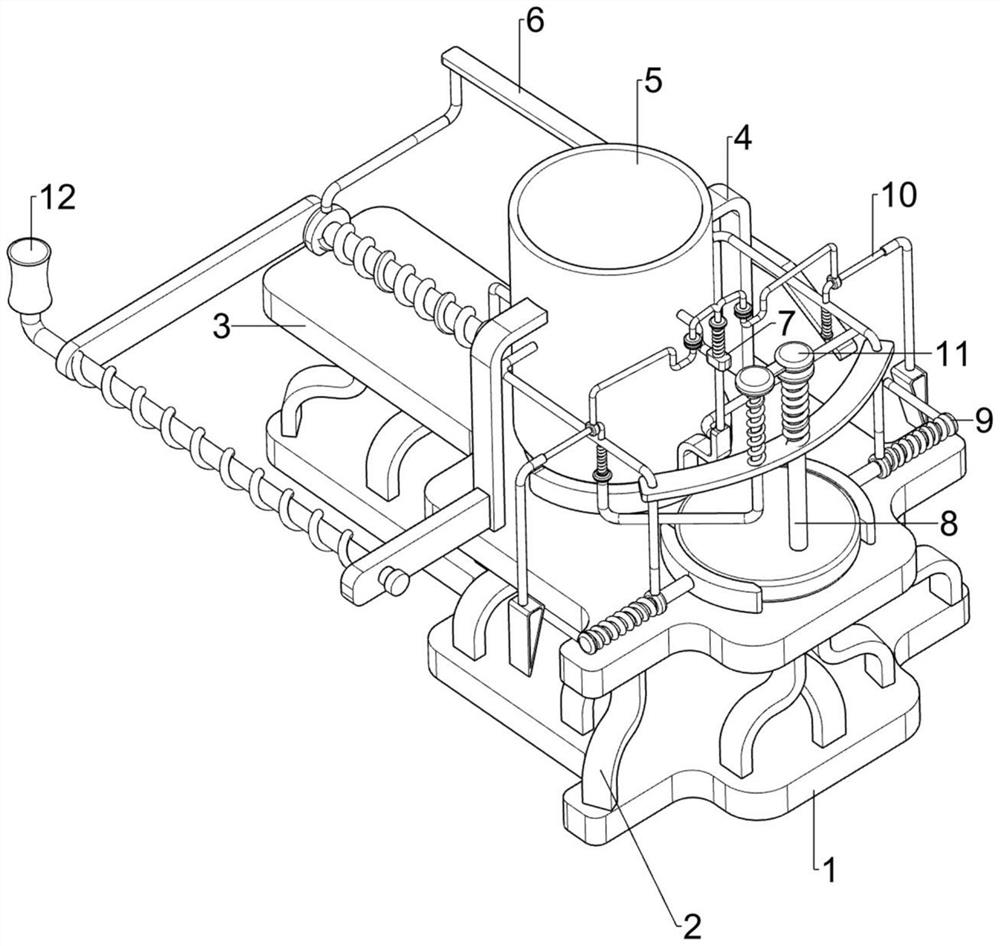

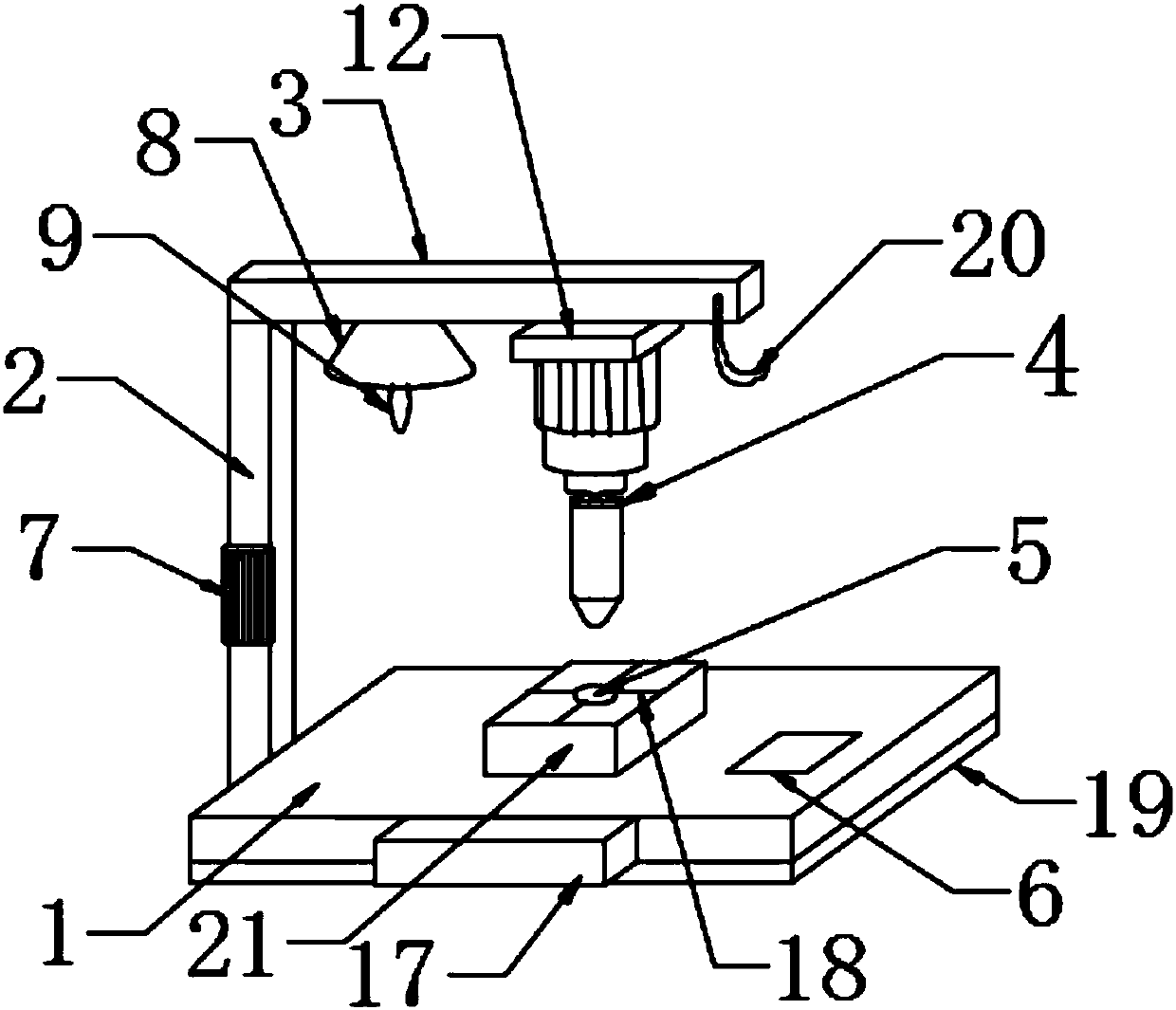

Dark-red enameled pottery water outlet punching device for pottery clay process

ActiveCN111590736AAchieve punching effectSave human effortCeramic shaping apparatusDomestic vesselsPunchingEngineering

The invention relates to a punching device, in particular to a dark-red enameled pottery water outlet punching device for a pottery clay process. The technical problem to be solved is to provide the dark-red enameled pottery water outlet punching device for the pottery clay process, which can save manpower during operation and is simple to operate. In order to solve the technical problem, the dark-red enameled pottery water outlet hole punching device for the pottery clay process comprises a supporting seat, a lifting frame and an air cylinder; the supporting seat is rotationally connected toone side of the top of the supporting seat, and multiple placing rings are evenly connected to a rotating disc in the circumferential direction at intervals; the lifting frame is slidably connected tothe other side of the top of the supporting seat; and the air cylinder is arranged on the side, close to the lifting frame, of the top of the supporting seat, and a telescopic rod of the air cylinderis connected with the supporting seat. According to the device, dark-red enameled pottery is subjected to punching through cooperative operation between a first punching assembly and a second punching assembly, and therefore the effect of punching on the dark-red enameled pottery is achieved.

Owner:柏顺娇

Boring device with fertilizing function

InactiveCN109997452AEasy to looseWon't gatherManure treatmentPlantingTransverse planeMechanical engineering

The invention relates to a boring device with a fertilizing function, comprising a bored mounting seat. Rollers are arranged symmetrically below the bored mounting seat; vertical plates are arranged symmetrically above the bored mounting seat; the top ends of the vertical plates are jointly fixedly connected with a transverse plate; a fertilizer box is arranged above the transverse plate; each vertical plate is provided with a movement groove which is connected with a moving plate through a slider; the top of the moving plate is connected with the transverse plate through first electric telescopic bars; a first driving motor is arranged below the moving plate; an output shaft of the first driving motor is connected with a boring mechanism; the boring mechanism penetrates a through hole ofthe bored mounting seat. Soil divider structures are employed, the boring mechanism is modified, and therefore, the technical problems are solved effectively.

Owner:合肥卓畅农业科技有限公司

Light transmission device punching equipment for vehicle-mounted microscope

ActiveCN112828999ARealize the push effectRealize the effect of opening and closingMetal working apparatusIn vehicleEngineering

The invention relates to punching equipment, in particular to light transmission device punching equipment for a vehicle-mounted microscope. According to the light-transmitting device punching equipment for the vehicle-mounted microscope, automatic punching is achieved, manual punching errors are reduced, and operation is convenient. The light transmission device punching equipment for the vehicle-mounted microscope comprises a first supporting plate, first supporting frames arranged on the first supporting plate, a second supporting plate arranged between the tops of the first supporting frames, second supporting frames arranged at the tops of the two sides of the middle of the second supporting plate, and a discharging frame arranged between the second supporting frames at the two sides. According to the light transmission device punching equipment, a first long block frame is manually pushed to move rightwards, so that a pusher is driven to move rightwards, a first spring is compressed, the pusher moves rightwards to push out a light transmission device, and the material pushing effect is achieved.

Owner:上饶市鑫锐光电有限公司

Punching and deburring device for polyethylene resin film

InactiveCN112123441AAchieve punching effectImprove work efficiencyMetal working apparatusPolymer sciencePunching

The invention provides a punching and deburring device for a polyethylene resin film, and relates to the field of plastics. The punching and deburring device for the polyethylene resin film is used for conveying the plastic film, and comprises a workbench, wherein two traction rollers are arranged on the workbench, and a support plate is arranged on the workbench. According to the punching and deburring device for the polyethylene resin film, needle holes are formed in the workbench, steel needles are installed on a transverse plate, and electric push rods electrically drive the transverse plate to lift so that the steel needle can puncture the plastic film, so that the plastic film is punched; an air pump, air bags, expanding rods and rubber bands are matched mutually, so that the overalldiameters of the steel needles are changed so as to punch the holes with different specifications, and the application range of the whole device is improved; a sliding strip, a spring, a cutting block, a steel wire and a motor are matched mutually so that the cutting block can move back and forth to smooth burrs generated by punching, so that the manual operation steps are reduced, and the laborcost is further reduced; and moreover, the burrs are processed while punching, so that the working efficiency is improved.

Owner:诸暨市惠中智能科技有限公司

Automatic punching device for breeding nursing bed

PendingCN112265056AAchieve punching effectSave human effortMetal working apparatusPunchingEngineering

The invention relates to a punching device, in particular to an automatic punching device for a breeding nursing bed. The device aims to solve the technical problem of how to design a automatic punching device of a nursing bed for breeding, and the device can push out more excess materials at a time, which improves the working efficiency and saves manpower. In order to solve the technical problem,the invention provides the automatic punching device for the breeding nursing bed. The device comprises a base, a placing frame, a placing plate and a material receiving assembly; fixing plates are connected with the two sides of the top of the base; the placing frame is connected between the tops of the fixing plates at the two sides; the placing plate is connected with the top of the base, andthe top of the placing plate is slightly lower than the placing frame; and the material receiving assembly is arranged on the base. According to the automatic punching device for the breeding nursingbed, the material collecting assembly, a mounting assembly and a punching assembly are matched to punch a breeding nursing bed plate, so that the effect of punching the breeding nursing bed plate is achieved.

Owner:龙锦明

Steel pipe drilling equipment

InactiveCN114289755AAchieve punching effectExtended service lifeFeeding apparatusPositioning apparatusHand heldBar pressing

The invention discloses steel pipe drilling equipment which comprises a base, a mounting seat and a support, the mounting seat and the support are arranged at the top of the base, a driving mechanism is arranged at the top of the inner wall of the support, a drill bit is arranged at the bottom of the driving mechanism, a pressing plate is movably arranged in the support, vertical rods are sleeved with the two ends of the pressing plate, and connecting cylinders are arranged at the two ends of the bottom of the pressing plate. A reset spring is arranged in the connecting cylinder, a pressing rod is arranged at the bottom of the reset spring, a pressing mechanism is arranged in the mounting base, and a cooling mechanism is arranged at one end of the top of the base. According to the steel pipe drilling device, the driving structure is arranged and used in cooperation with the conveying mechanism, the effect of automatically drilling a steel pipe is achieved, meanwhile, under the action of the pressing mechanism, the steel pipe is fixed, mechanical and rapid drilling of the steel pipe is achieved through the device, traditional manual handheld drilling is replaced, meanwhile, the drilling accuracy is guaranteed, and the production efficiency is improved. And the effects of improving the working efficiency and realizing batch production are achieved.

Owner:合肥宏程机械科技有限公司

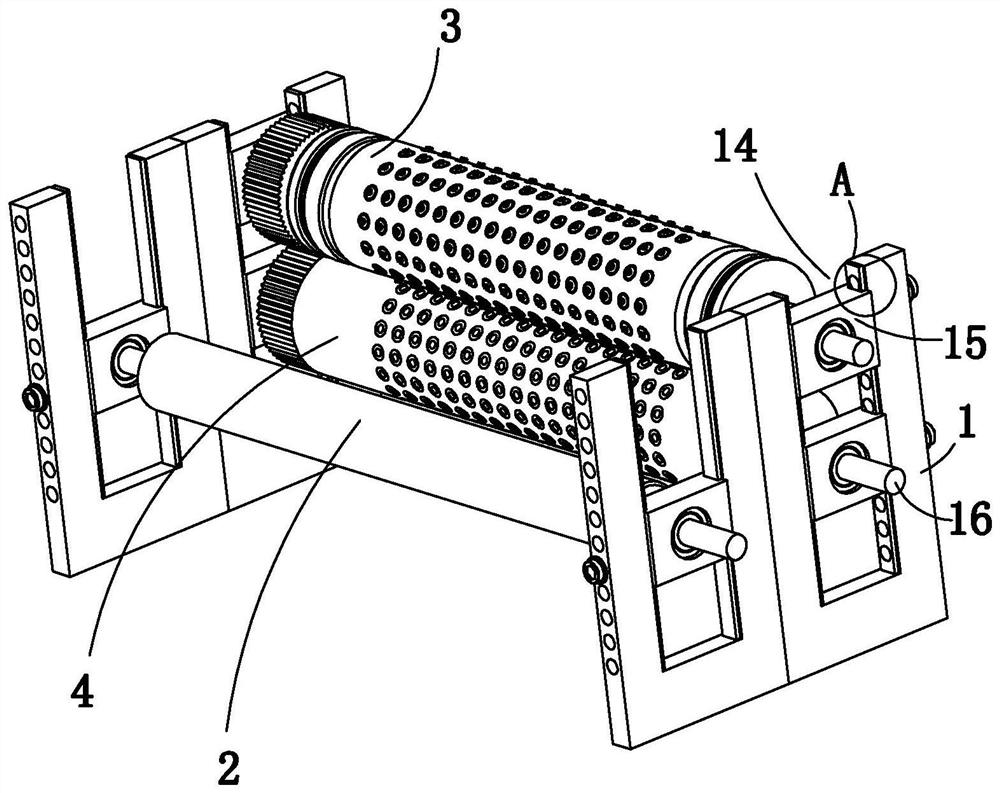

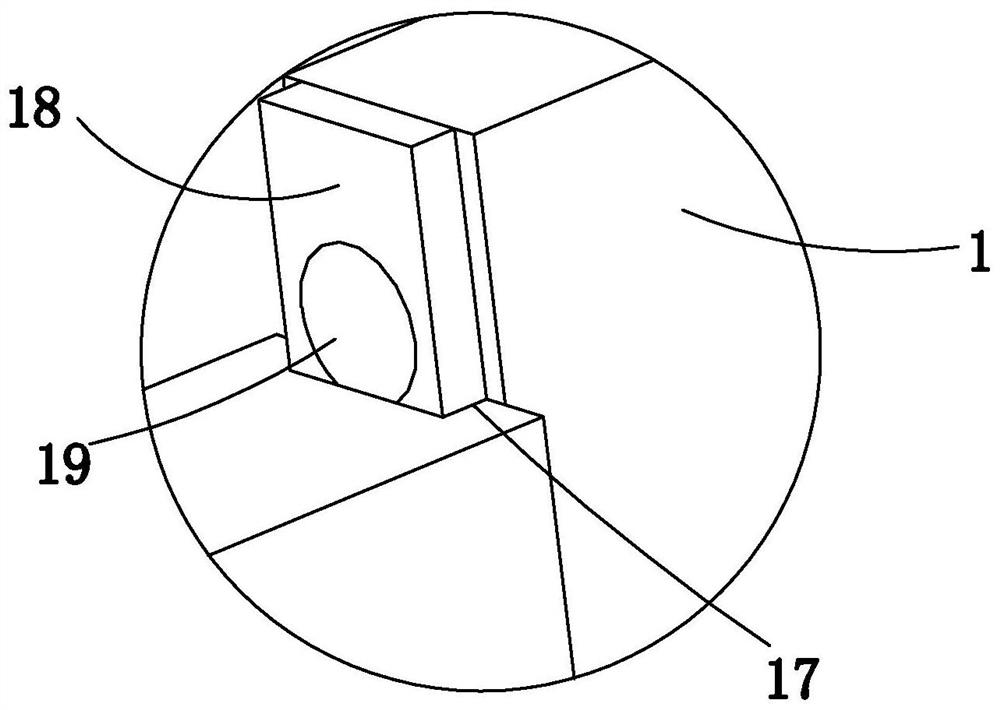

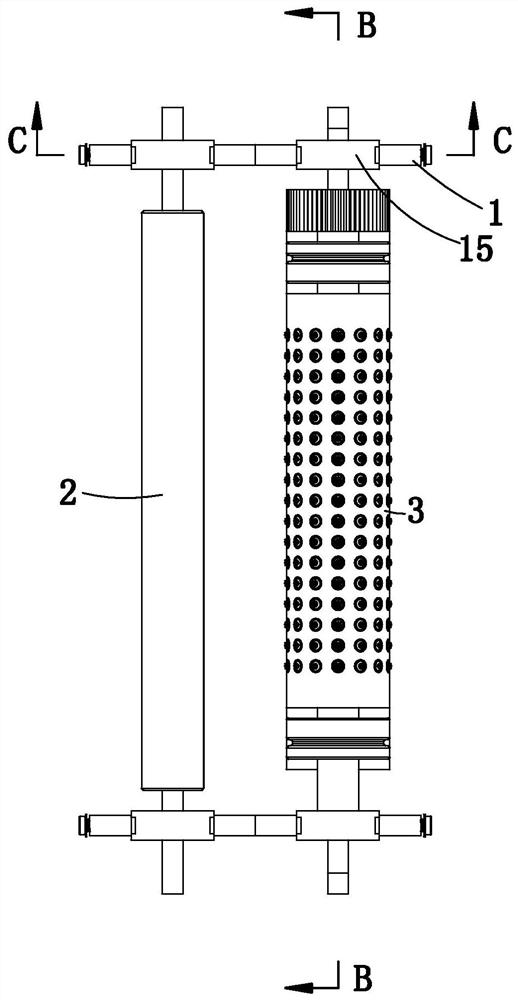

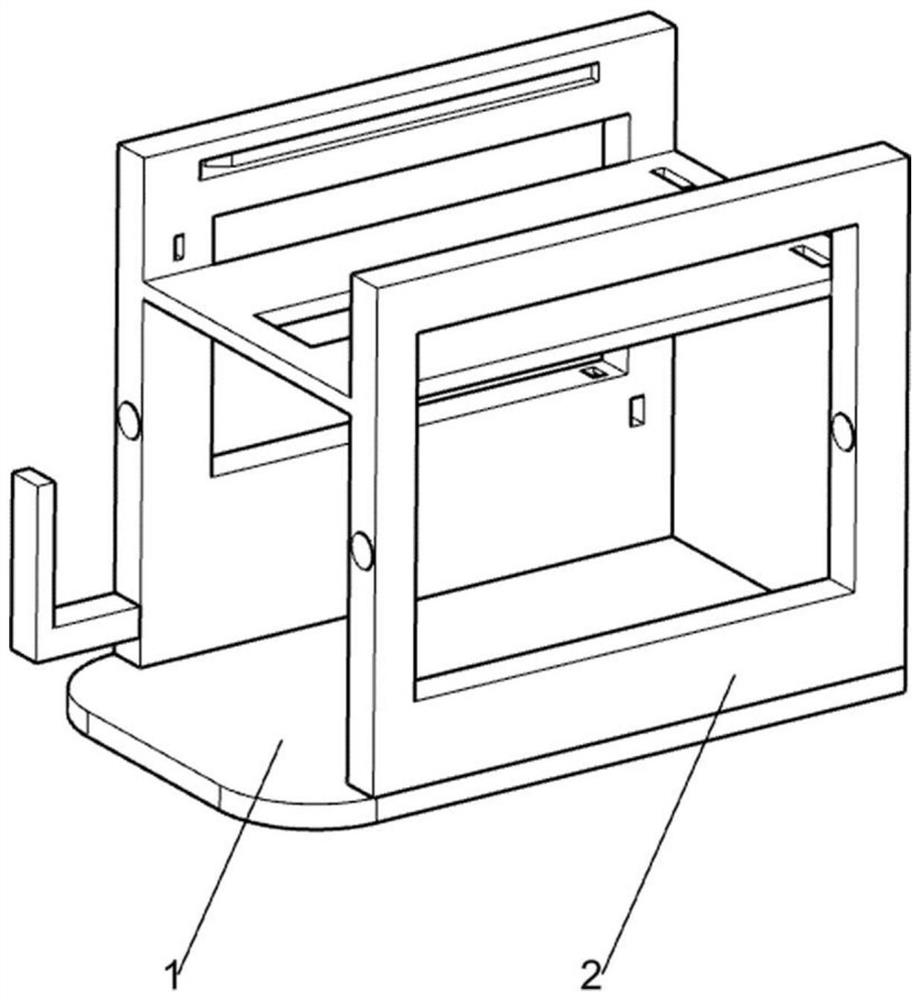

Paper punching device

PendingCN114670279AAchieve punching effectEasy to adjust the number of holesMetal working apparatusPunchingStructural engineering

The invention discloses a paper punching device. The paper punching device aims at solving the problem that according to an existing punching device, the punching number is inconvenient to replace. According to the technical scheme, the device is characterized by comprising a device body, the device body comprises a rack, a conveying roller rotationally connected to the rack, a first roller, a second roller and a driving device used for driving the conveying roller, the first roller and the second roller to rotate, and a plurality of first mounting grooves and second mounting grooves are formed in the surface of the first roller and the surface of the second roller correspondingly; a first connecting block is detachably connected into the first mounting groove through a connecting piece, and a second connecting block is connected into the second mounting groove in a threaded mode. Through cooperative work of the driving device, the first roller, the second roller, the protruding block on the first connecting block and the groove in the second connecting block, the effect of punching paper is achieved, and through cooperative work of the first mounting groove, the second mounting groove and the connecting piece, the punching number can be conveniently adjusted.

Owner:浙江本源纸塑科技有限公司

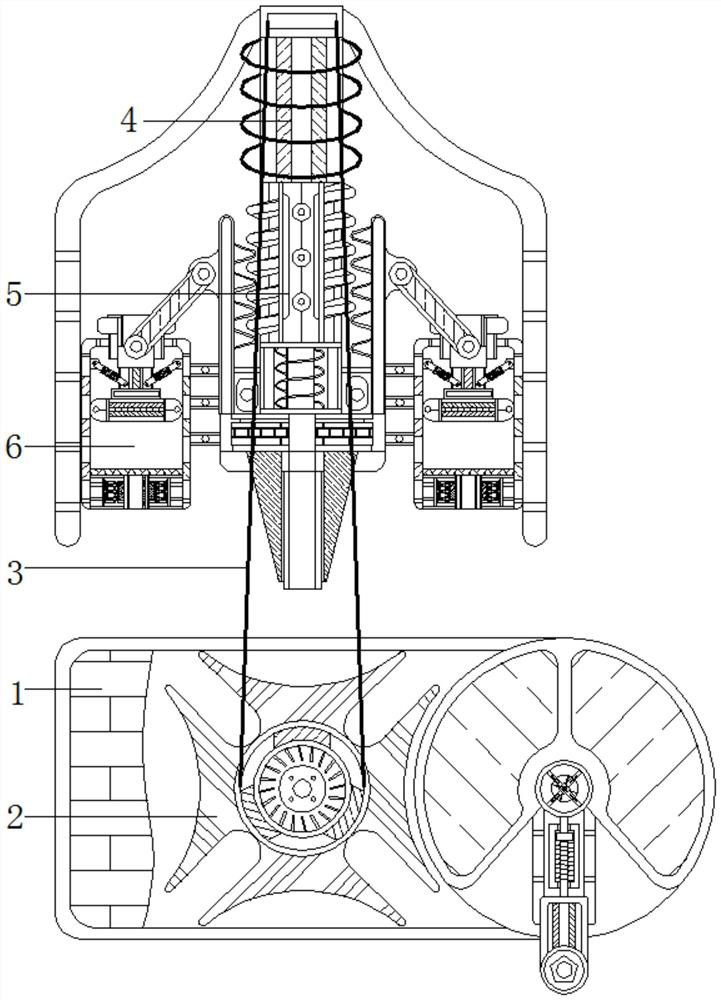

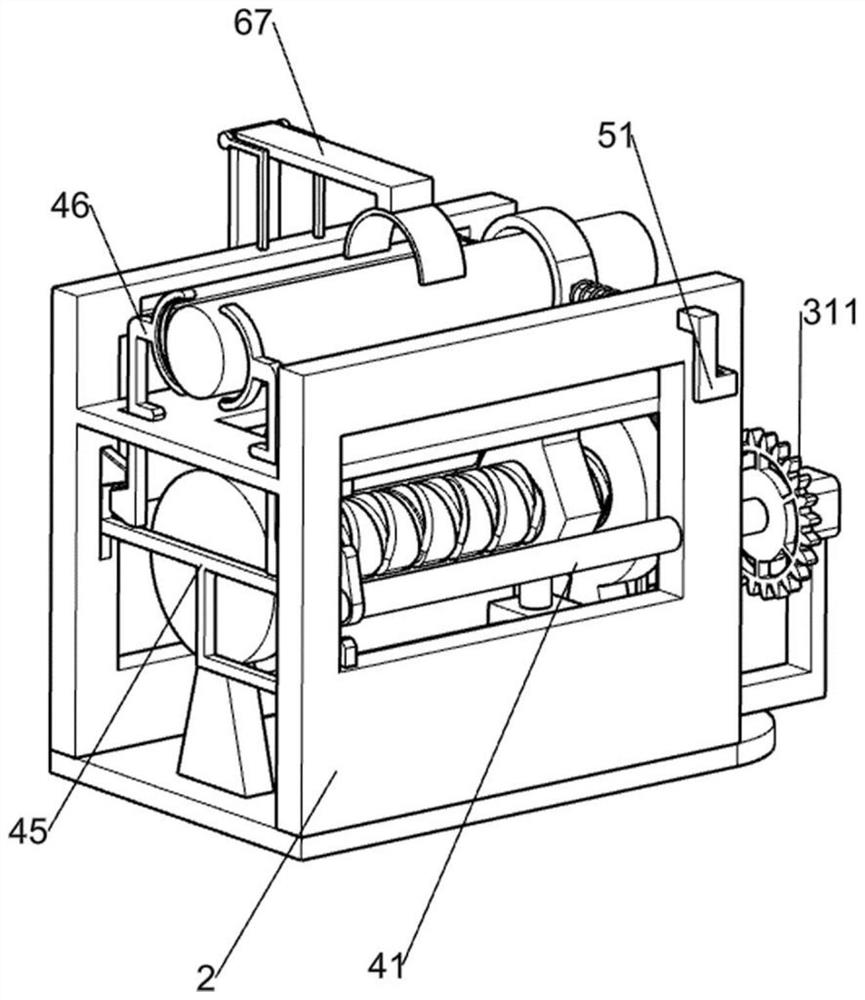

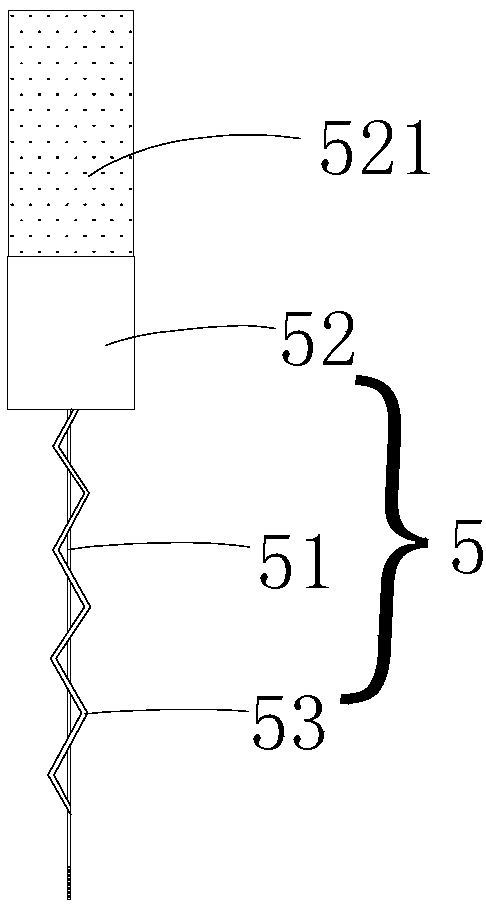

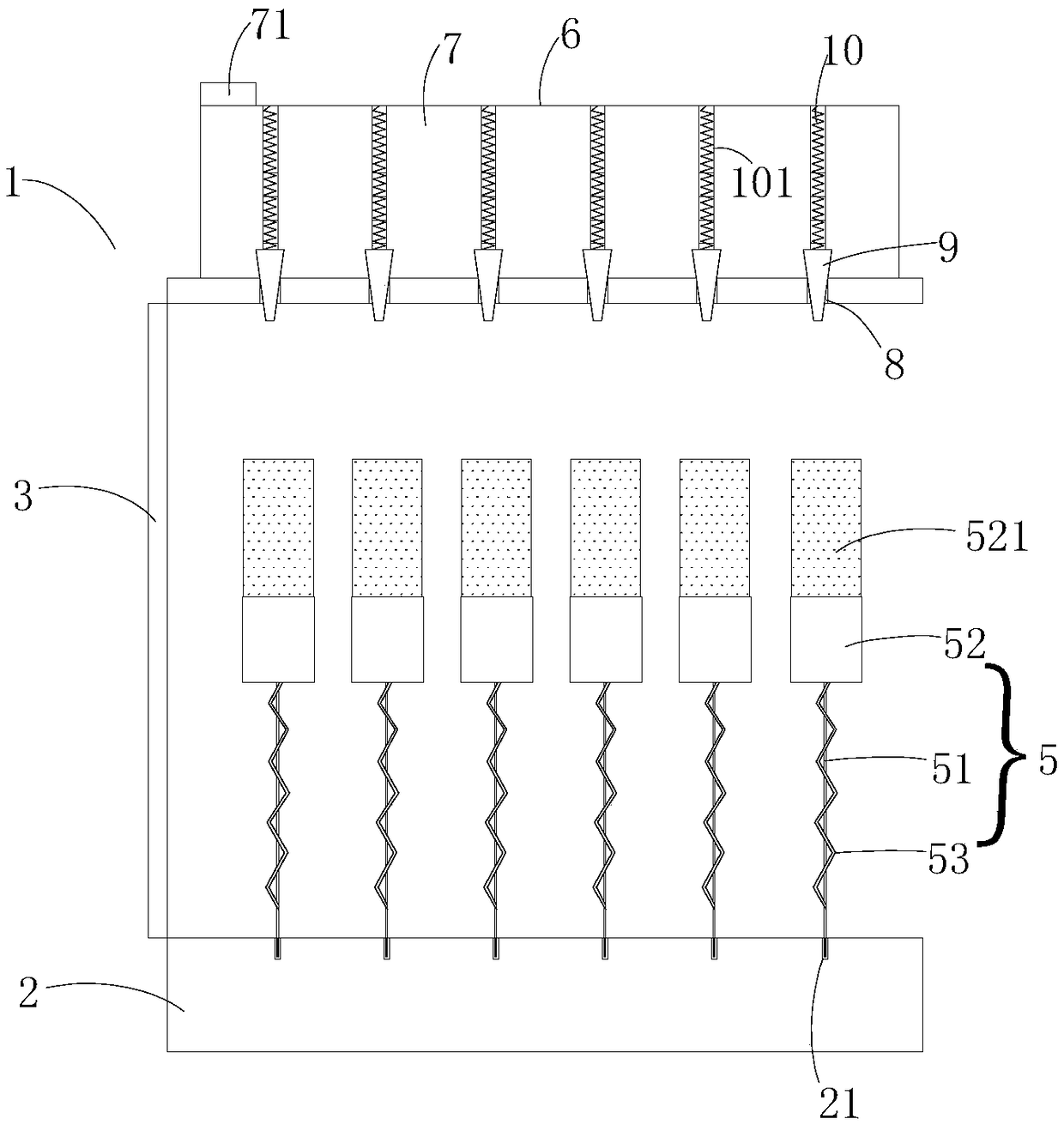

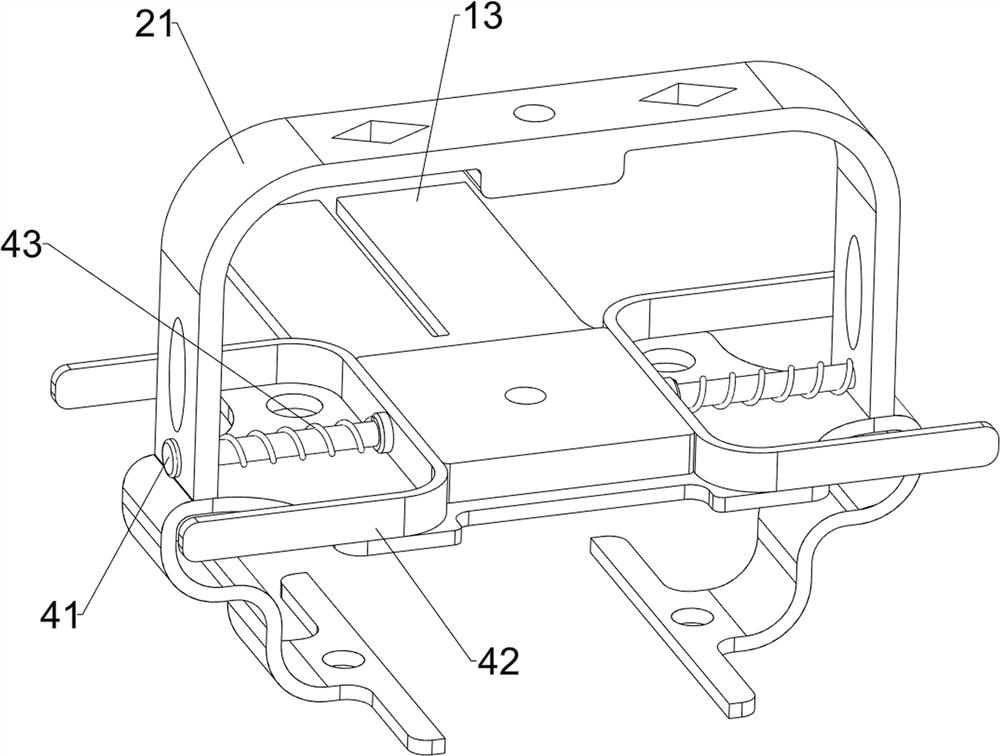

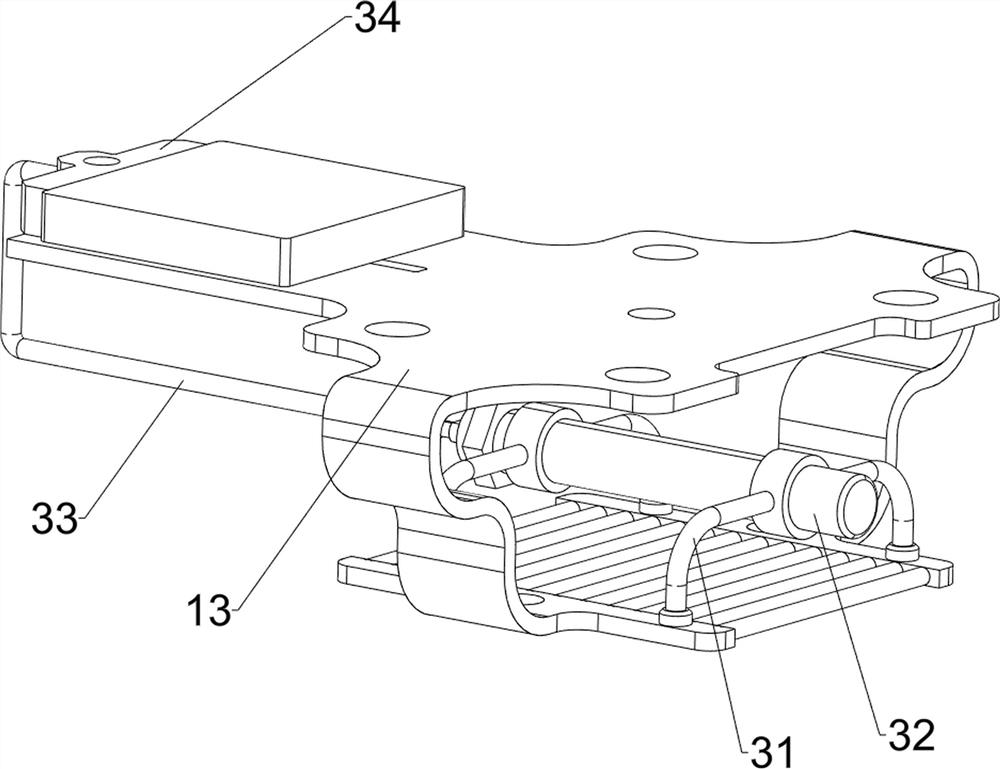

Punching equipment for metal chain wheel manufacturing

ActiveCN112620693AAchieve punching effectSave human effortLarge fixed membersDriving apparatusPunchingRolling chassis

The invention relates to punching equipment, in particular to punching equipment for metal chain wheel manufacturing. The technical problem to be solved by the invention is how to design the punching equipment for the metal chain wheel manufacturing, which can save manpower and improve the working efficiency during operation. In order to solve the technical problem, the invention provides the punching equipment for the metal chain wheel manufacturing, which comprises a chassis, and a base plate is connected to one side of the top of the chassis; a mounting frame connected to the other side of the top of the chassis; a driving device arranged in the mounting frame; a guide device arranged on the chassis; and a buffer device arranged on the driving device. Through cooperative operation of the driving device, the guide device and the buffer device, the effect of punching a chain wheel is achieved.

Owner:佛山市凯泽金属制品有限公司

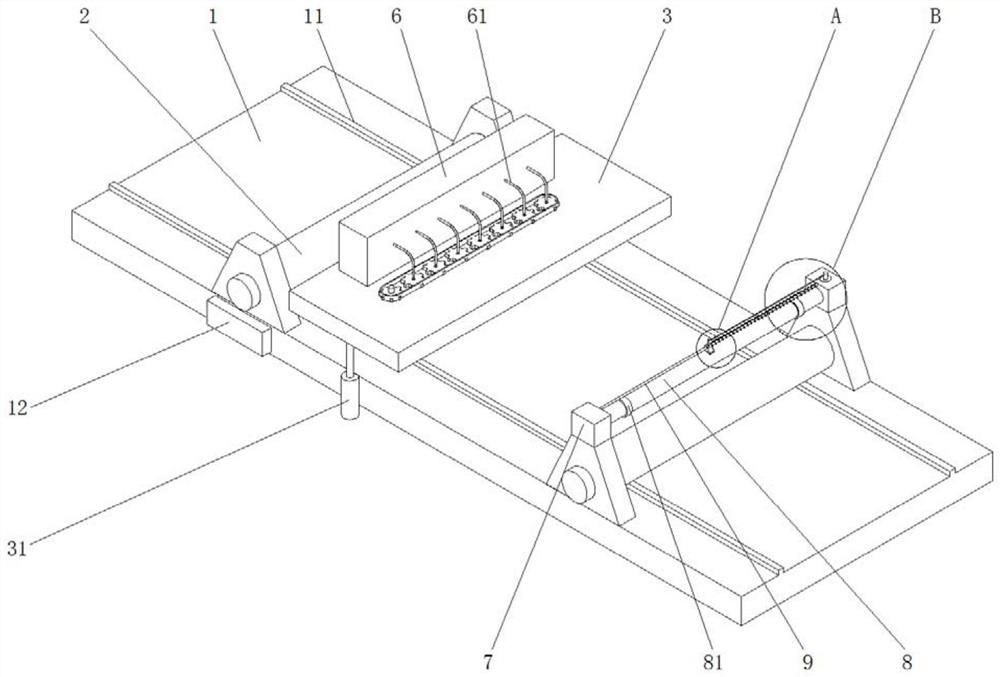

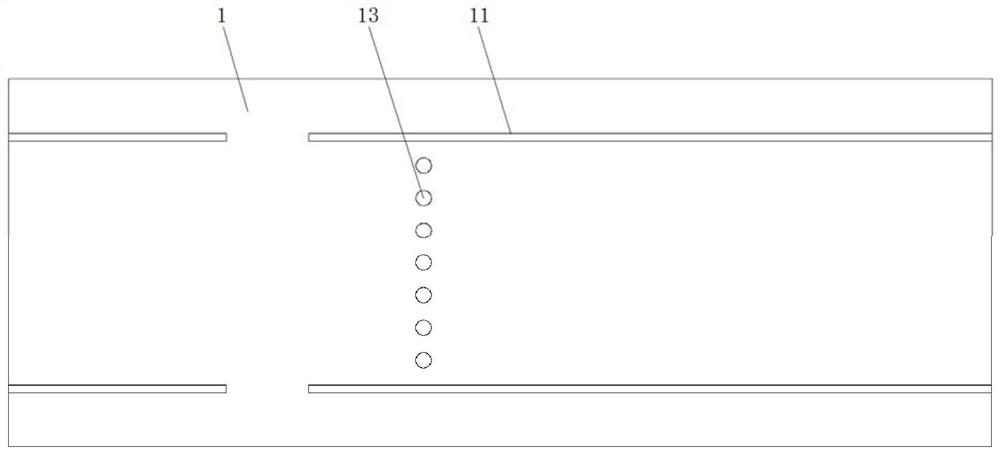

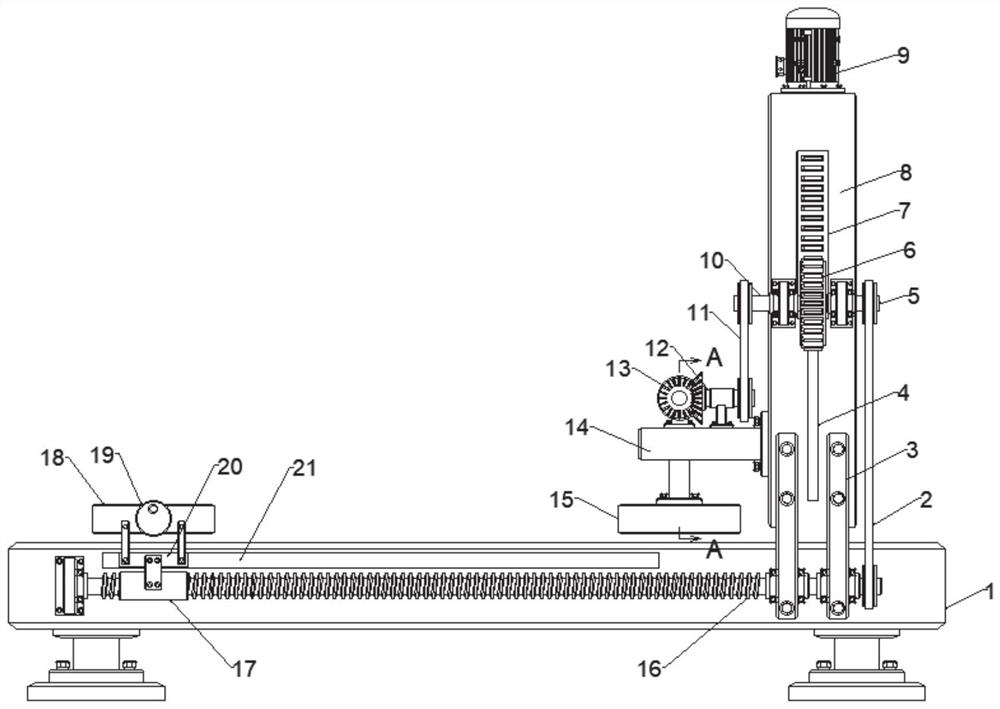

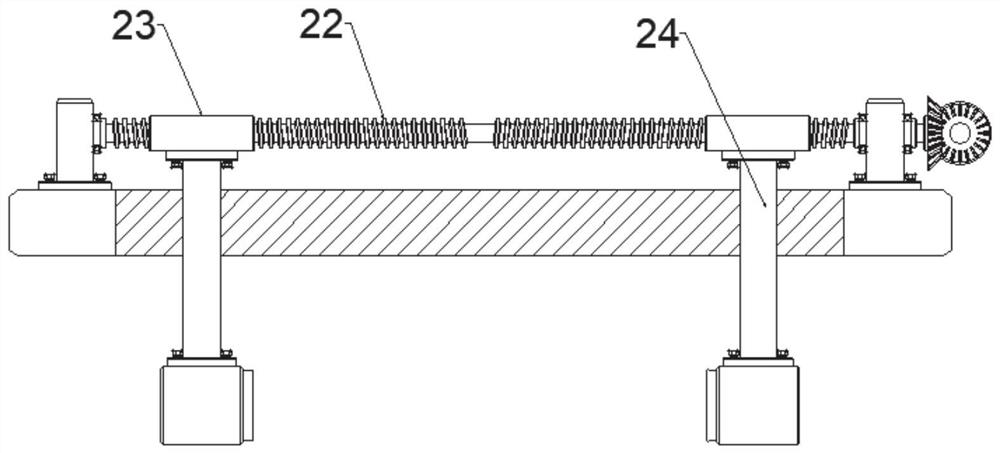

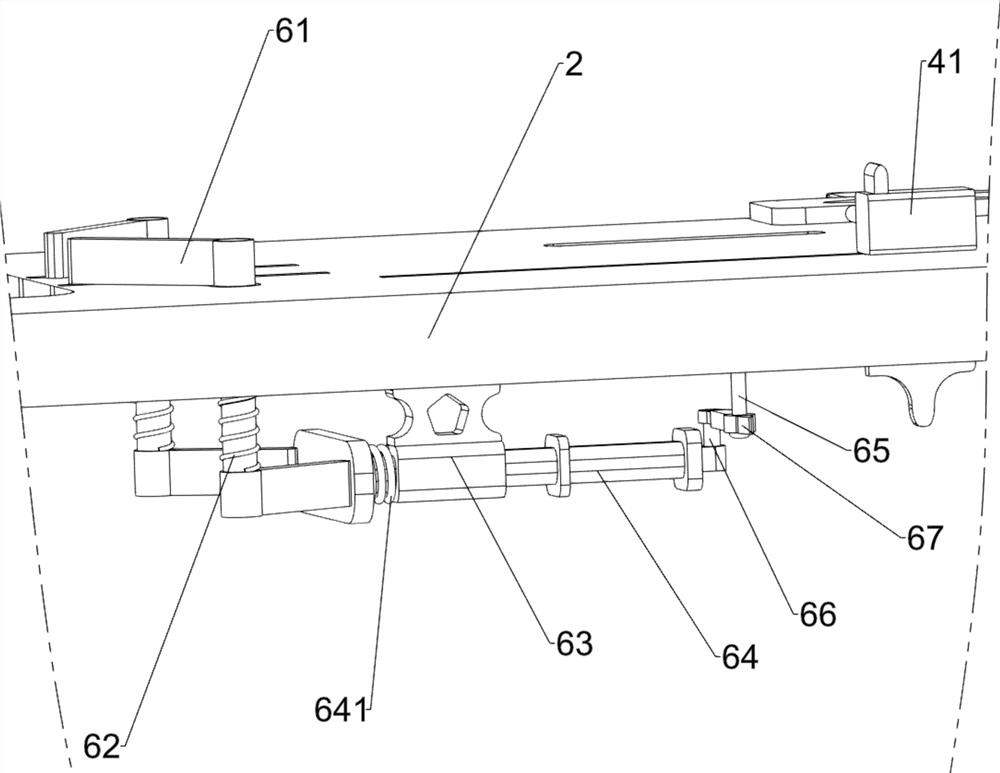

Surface fixed-distance punching device for processing of wood board

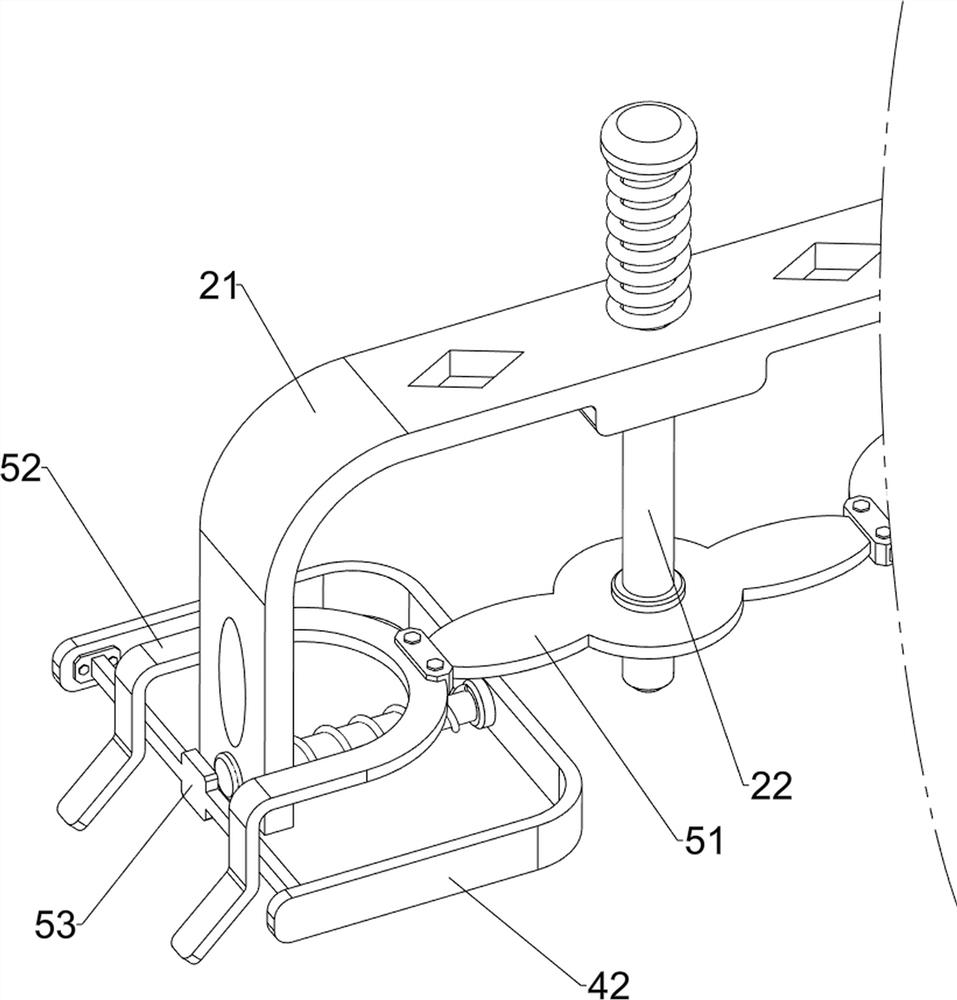

The invention relates to a surface fixed-distance punching device for processing of a wood board. The surface fixed-distance punching device for processing of the wood board comprises a workbench and a bearing frame fixed to the workbench through a mounting frame, a drill bit is arranged at one side, facing the workbench, of the bearing frame, the drill bit is connected with a driving mechanism mounted on the bearing frame, the workbench is further provided with a clamping mechanism, the clamping mechanism is connected with a horizontal conveying mechanism mounted on the workbench, the horizontal conveying mechanism is rotatably connected with a first driving rod rotatably mounted on the bearing frame through a first driving belt, the first driving rod is matched with a gear fixed to a second driving rod rotatably connected with the bearing frame through a ratchet mechanism, the gear is matched with a rack plate which slides on the bearing frame and is connected with the driving mechanism, the device further comprises an auxiliary clamping mechanism, and the auxiliary clamping mechanism is mounted on the bearing frame and connected with the second driving rod.

Owner:湖南省石城竹木制品有限公司

Die cutting and labeling unit of bottom-paper-free non-dry sticker labeling machine and labeling method of die cutting and labeling unit

InactiveCN105235965AAchieve punching effectSolve resource problemsLabelling machinesPunchingReciprocating motion

The invention discloses a die cutting and labeling unit of a bottom-paper-free non-dry sticker labeling machine. The die cutting and labeling unit comprises a die cutting linear movement pair, a labeling linear movement pair and a mechanical arm. The die cutting linear movement pair is connected with the labeling linear movement pair. The mechanical arm is connected with the labeling linear movement pair and can be driven by the labeling linear movement pair to linearly reciprocate so as to get close to or away from the die cutting linear movement pair. The invention further discloses a labeling method of the die cutting and labeling unit of the bottom-paper-free non-dry sticker labeling machine. The mechanical arm is innovatively used in the bottom-paper-free non-dry sticker labeling machine, the punching effect can be achieved in the die cutting process, and therefore only one layer of label paper is needed for a non-dry sticker label used by the bottom-paper-free non-dry sticker labeling machine, bottom paper does not need to be used, and the problem that because non-dry sticker labels used by non-dry sticker labeling machines in the prior art must be provided with bottom paper, resource waste and environment pollution are caused is effectively solved.

Owner:XIAN TIANLAI SPECIAL MACHINERY CO LTD

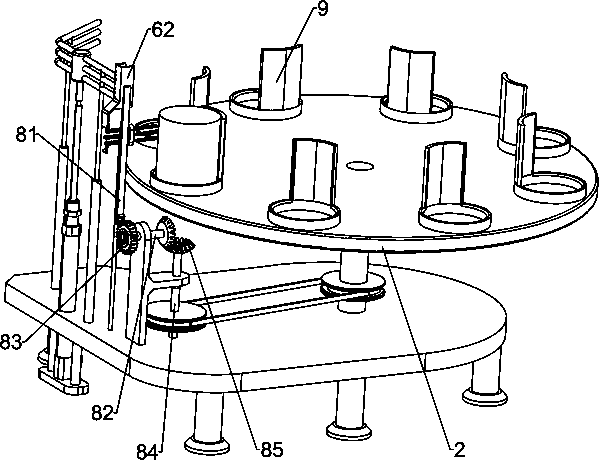

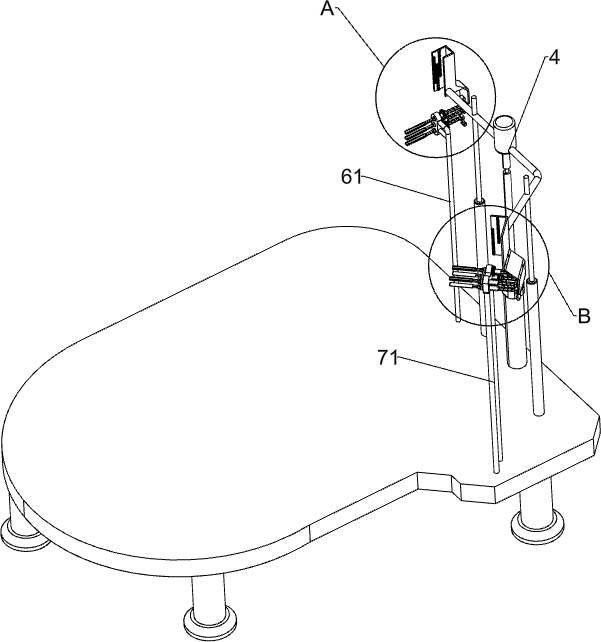

A device for punching outlet holes of purple sand teapots for pottery crafts

ActiveCN111590736BAchieve punching effectSave human effortCeramic shaping apparatusDomestic vesselsMechanical engineeringEnvironmental geology

The invention relates to a hole punching device, in particular to a hole punching device for a purple clay teapot used in pottery crafts. The technical problem to be solved by the present invention is to provide a device for punching outlet holes of purple sand teapots for pottery crafts, which can save manpower during operation and is easy to operate. In order to solve the above technical problems, the present invention provides such a device for punching water outlet holes of purple sand teapots for pottery crafts, including: a turntable, which is connected to the top side of the support base in a rotatable manner. a placement ring; a lifting frame, which is slidably connected to the other side of the top of the support base; a cylinder, which is installed on the top of the support base near the side of the lifting frame, and the telescopic rod of the cylinder is connected with the support base. The present invention perforates the purple clay pot through the cooperative operation of the first hole opening component and the second hole opening component, thereby achieving the effect of punching the purple clay pot.

Owner:柏顺娇

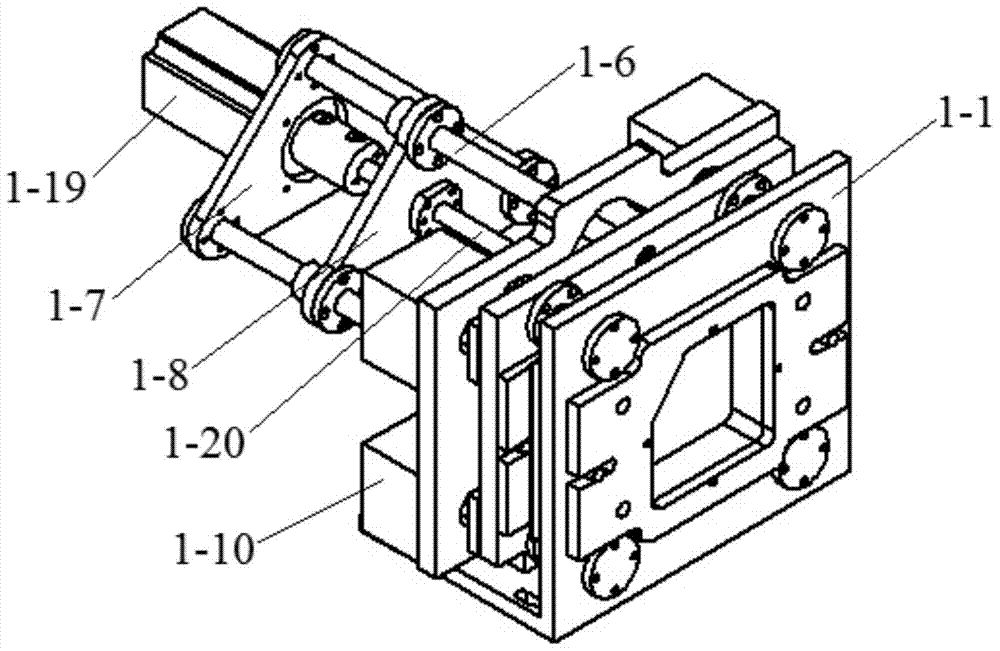

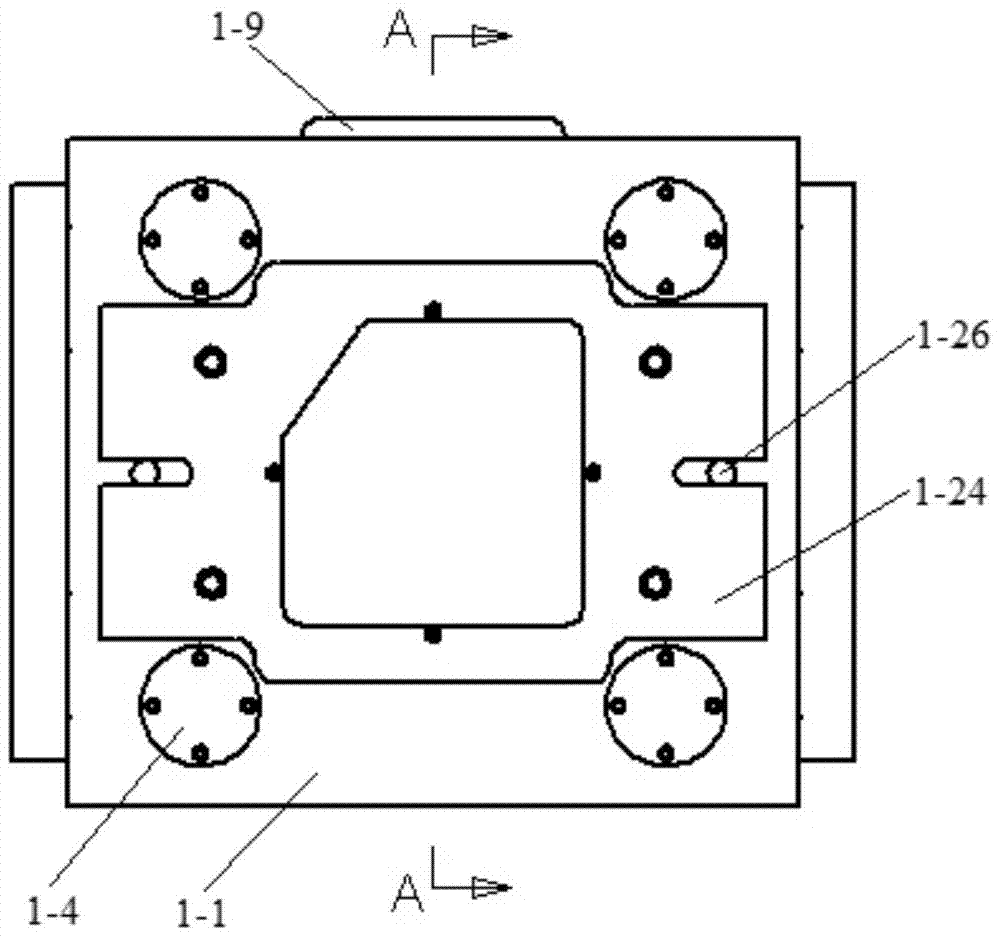

Hole punching device for precision alloy part production

InactiveCN109759616AIncrease productivityImprove production efficiencyPositioning apparatusBoring/drilling componentsPunchingAlloy

The invention relates to precision alloy production and machining equipment, and discloses a hole punching device for precision alloy part production. The hole punching device for precision alloy partproduction comprises a bottom plate, supporting legs are fixedly arranged on the bottom surface of the bottom plate and located on the left side and the right side of the bottom plate, two supportingcolumns are fixedly connected to the top surface of the bottom plate and located on the left side and the right side of the bottom plate, a fixing plate is fixedly connected to the tops of the two supporting columns and located between the two supporting columns, an air cylinder is fixedly connected to the center of the fixing plate, and a piston rod is arranged at the bottom of the air cylinder.The hole punching device for precision alloy part production can be used to increase punching quantity so as to improve production efficiency of alloy parts; the top surface of the bottom plate is fixedly provided with a fixing groove, the alloy parts are arranged in the fixing groove in a sleeved mode, the alloy parts are fixed through the rotation of screws, which make automatic positioning andpunching carried out by the hole punching device more convenient, and therefore operation personnel can operate and control the hole punching device conveniently, and production efficiency of the precision alloy parts in a factory is further improved.

Owner:江苏方略科技信息有限公司

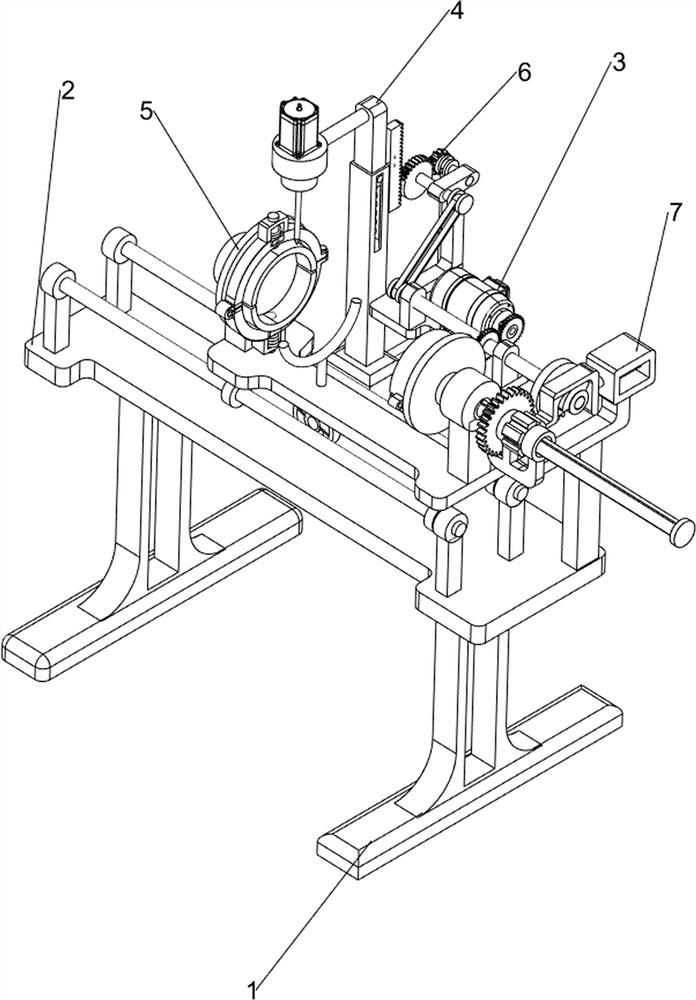

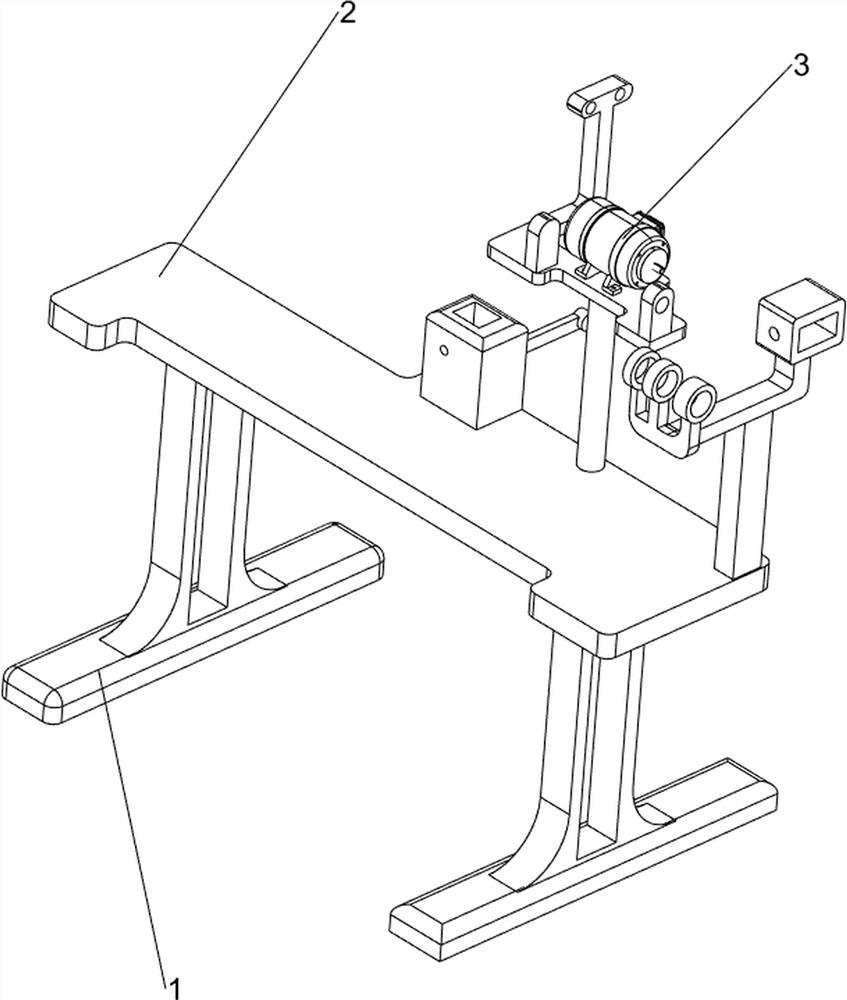

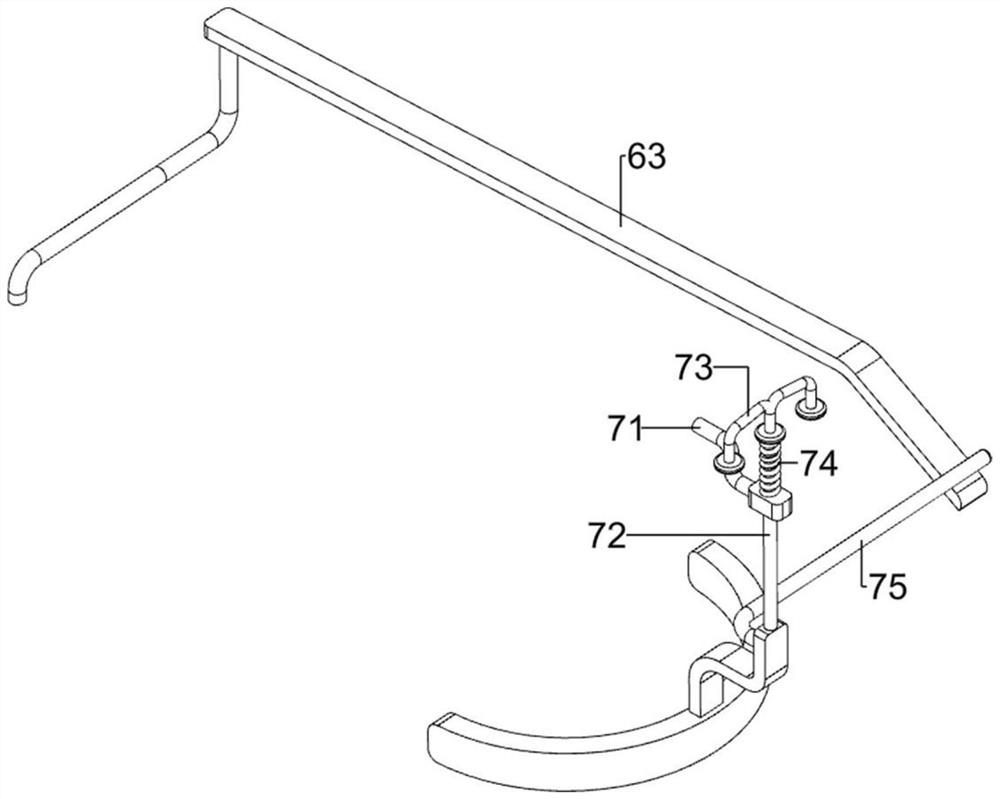

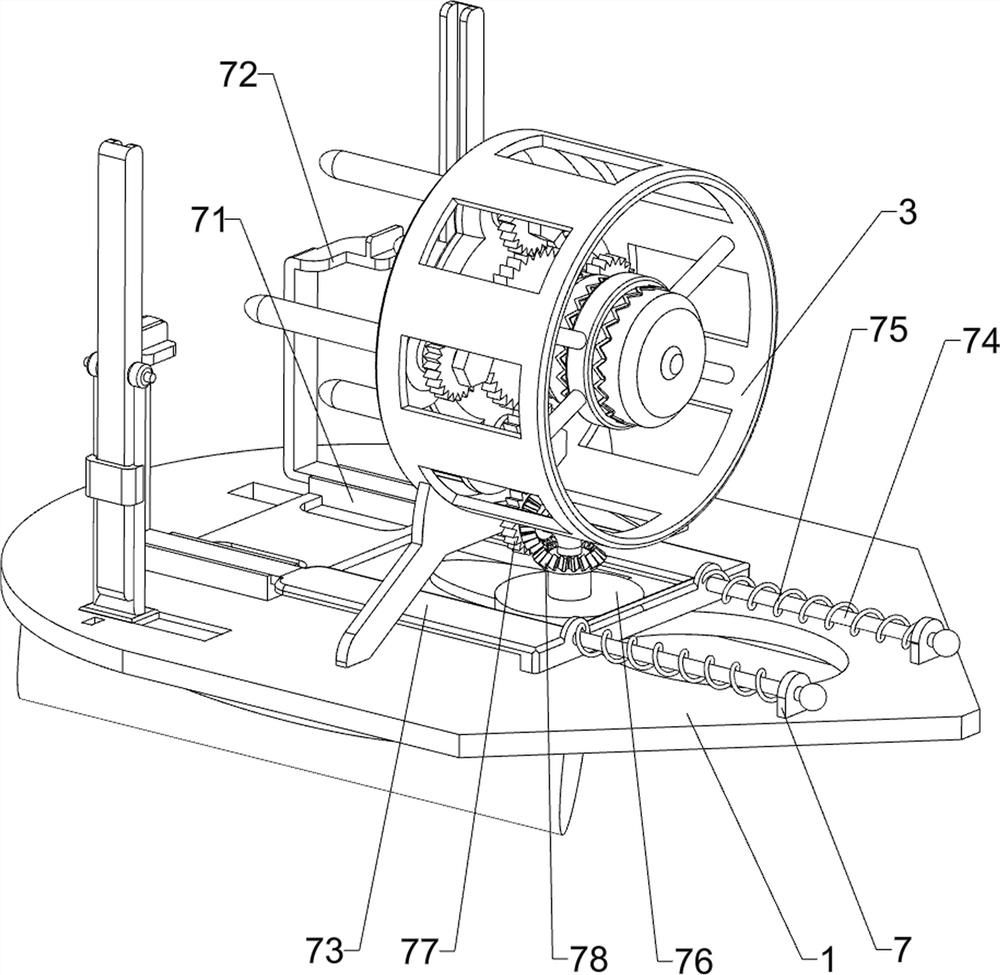

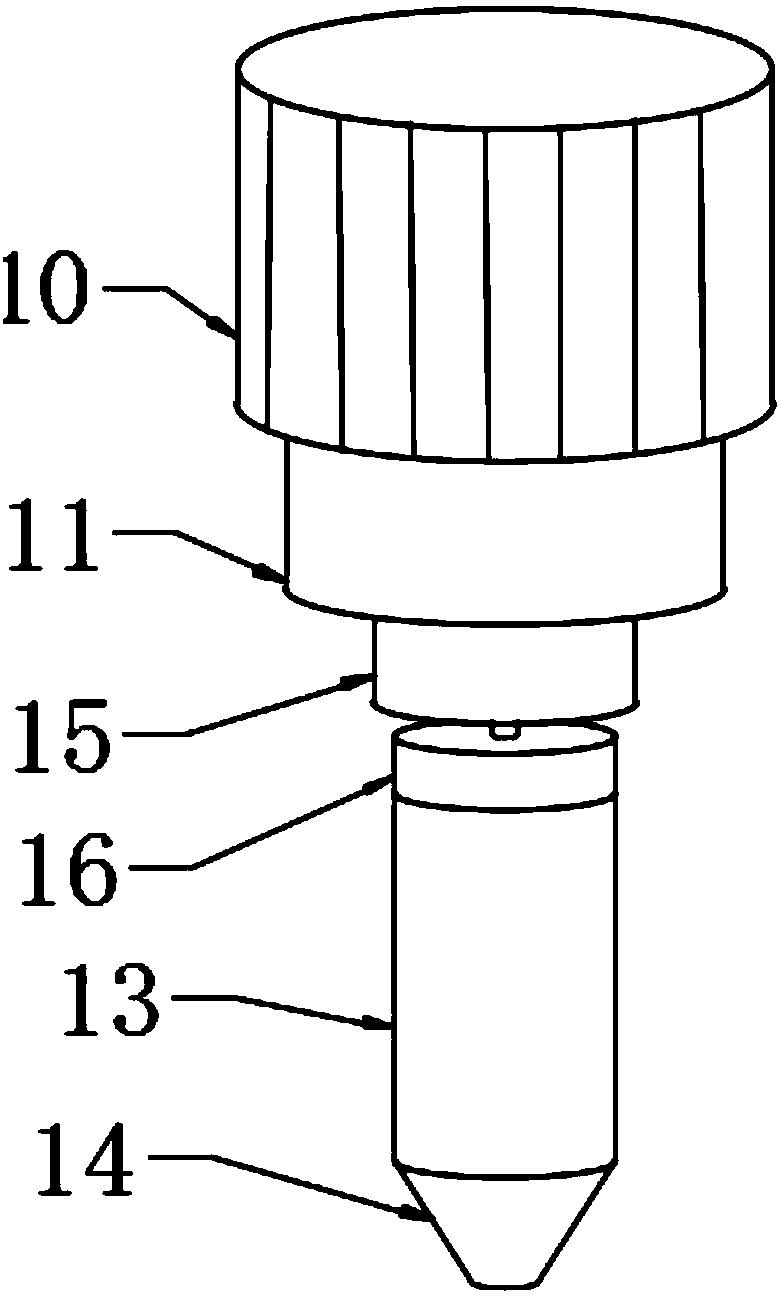

Bead punching equipment

ActiveCN111775208AAchieve punching effectEnsure safetyMetal working apparatusDrill holeStructural engineering

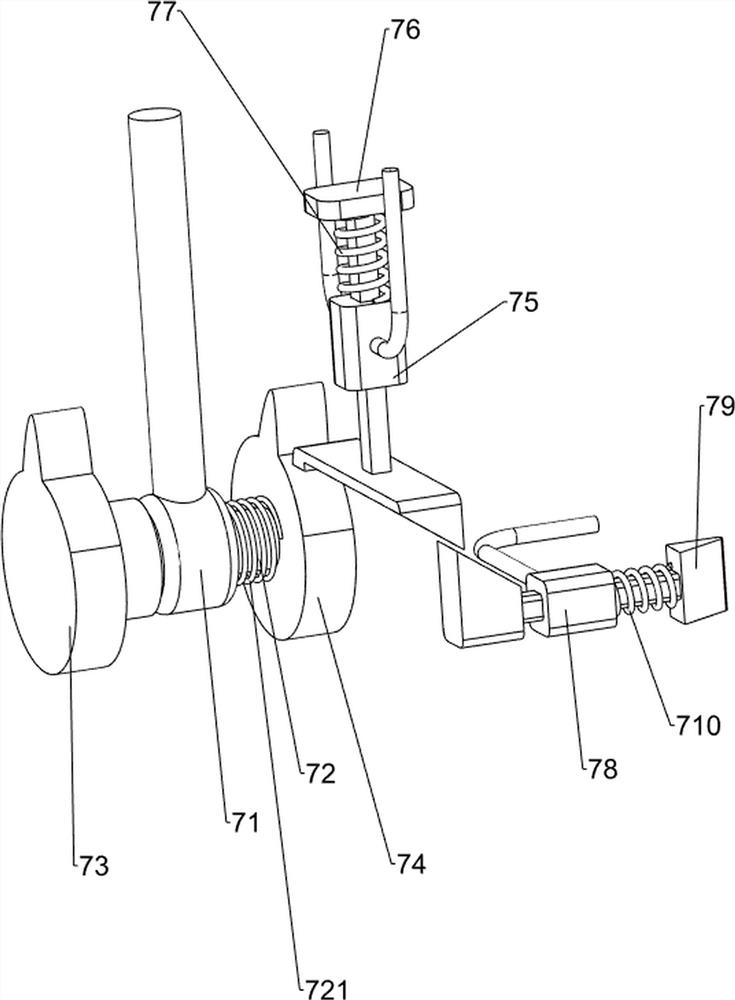

The invention relates to punching equipment, in particular to bead punching equipment. The bead punching equipment can save manpower and ensure the safety of an operator during operation. The bead punching equipment comprises a right supporting leg, a rocking bar, a left supporting leg, a manual drilling assembly, a clamping assembly and a manual feeding assembly, wherein one side of the right supporting leg is connected with a fixed frame, the rocking bar is rotationally connected to the fixed frame, the left supporting leg is connected to one side of the fixed frame, the manual drilling assembly is arranged between the fixed frame and the rocking bar, the clamping assembly is arranged between the left supporting leg and the right supporting leg, and the manual feeding assembly is arranged between the left supporting leg and the right supporting leg. Through cooperative operation of the manual drilling assembly, the clamping assembly and the manual feeding assembly, a bead is punched,and therefore the effect of punching the bead is achieved.

Owner:肖辉

Hole puncher for leather bag production

InactiveCN107618067AGuaranteed punching qualityImprove the authenticity rateMetal working apparatusPunchingEngineering

The invention discloses a hole puncher for leather bag production. The hole puncher comprises a base, a stand column, a beam and a punching device. A fixing block is fixedly connected to the center ofthe upper surface of the base, cross wires are evenly arranged on the upper surface of the fixing block, a hole is formed in the axis of the fixing block, a control panel is fixedly connected to oneside of the upper surface of the base, a stand column is fixedly connected to one side of the base, a power source is fixedly connected to one side of the stand column, the beam is fixedly connected to the top of the stand column, a fixing plate is fixedly connected to one side of the beam, the punching device is fixedly connected with the side, away from the beam, of the fixing plate, and the punching device comprises a punching motor, an air cylinder, a motor, a coupler, a rotating shaft and a tool bit. The control panel is electrically connected with the punching motor and the motor. The hole puncher for the leather bag production is simple in structure, through adding of the fixing block, the leather bag punching quality can be ensured, and through adding of the air cylinder, the holepuncher can automatically carry out hole punching.

Owner:响水金瑞皮件有限公司

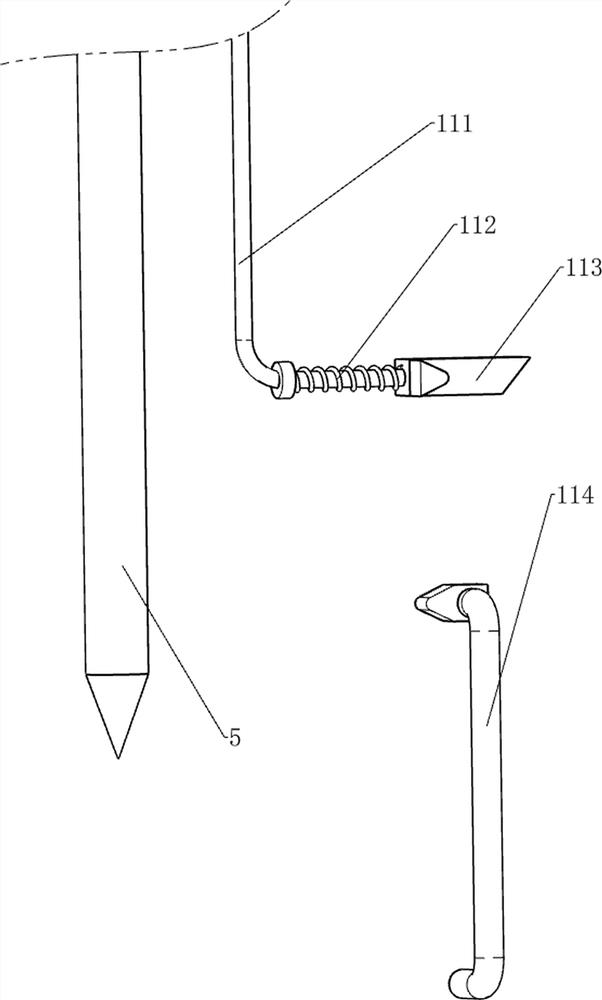

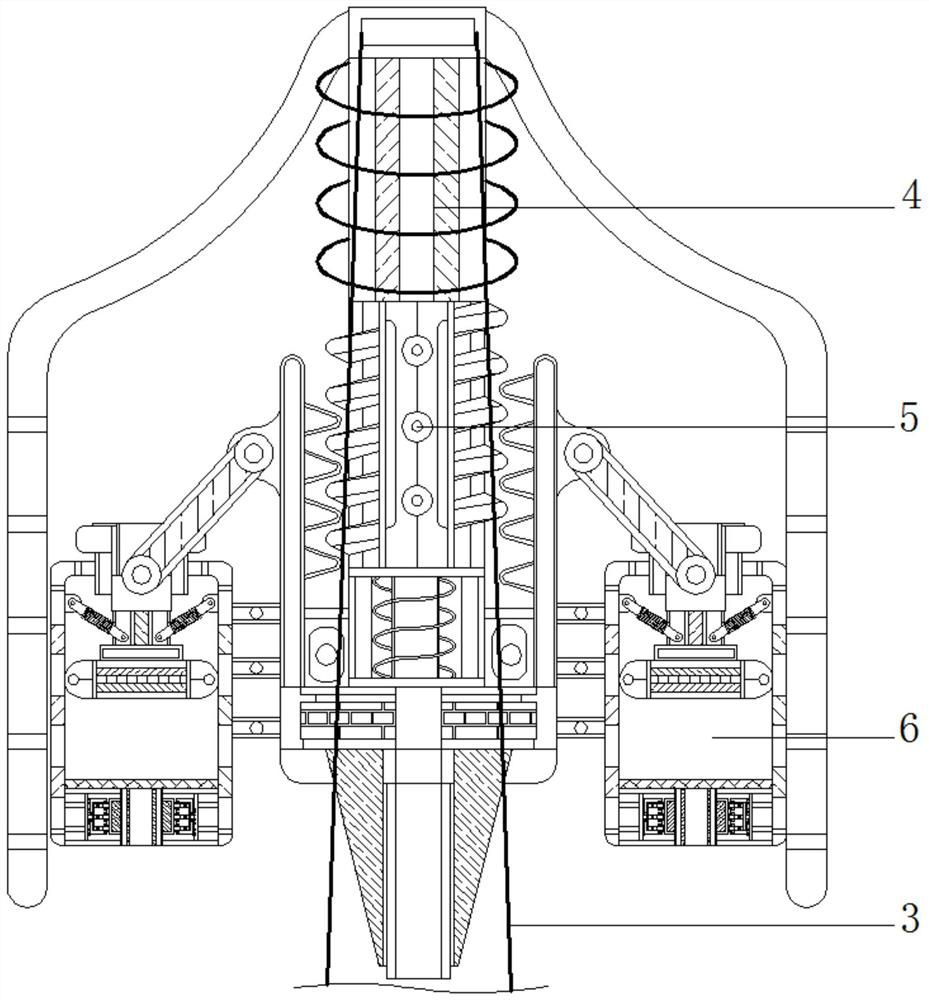

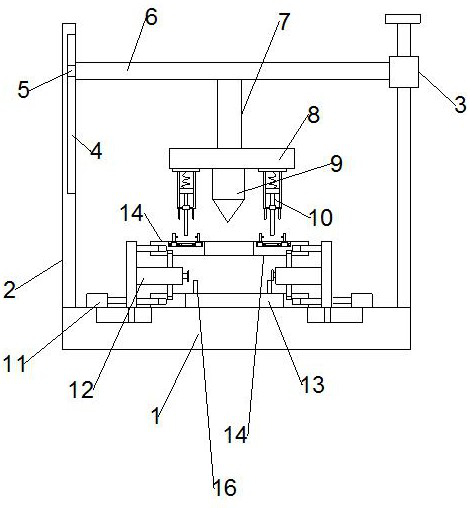

Automatic sowing and fertilizing agricultural robot

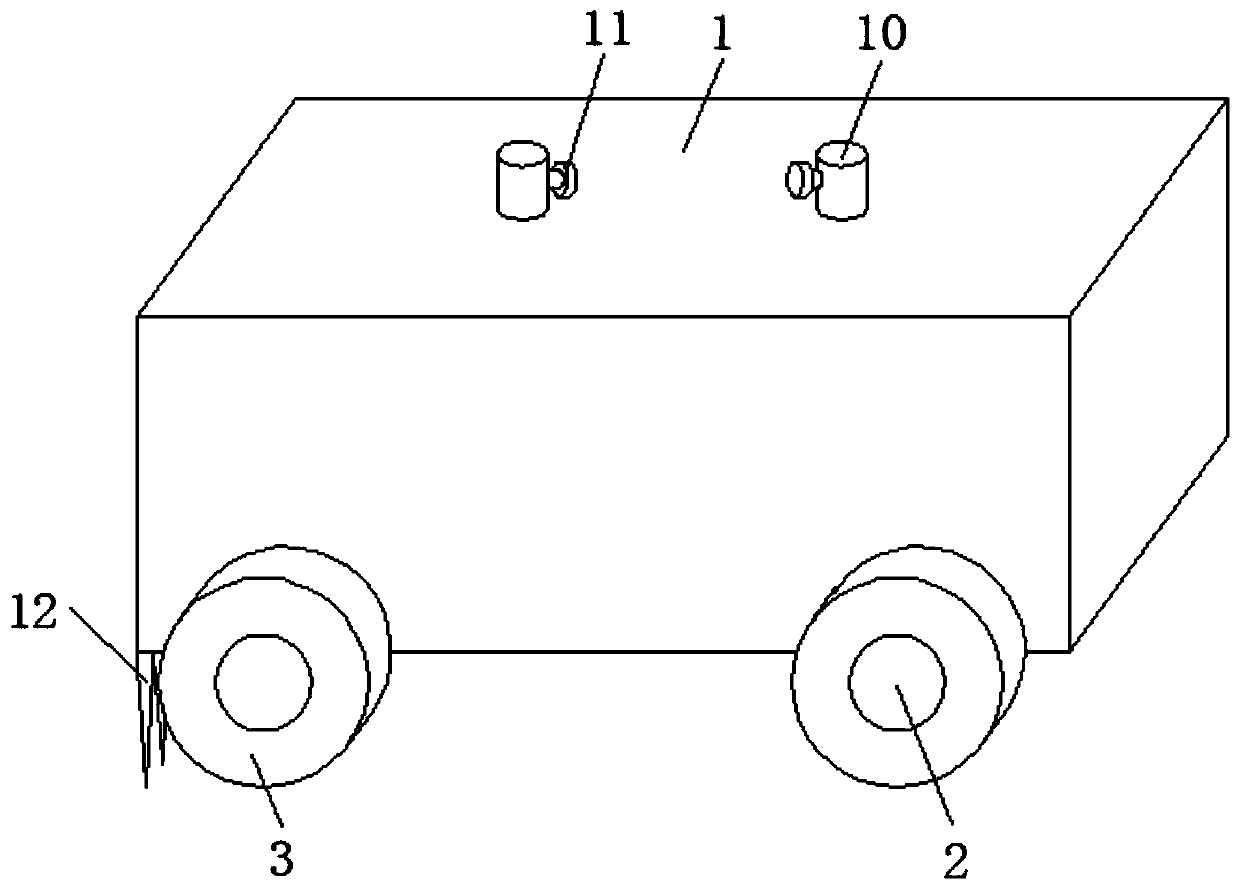

ActiveCN111165128AAchieve punching effectAchieve the effect of automatic drillingPlantingFurrow making/coveringAgricultural scienceAgricultural engineering

The invention discloses an automatic sowing and fertilizing agricultural robot. The automatic sowing and fertilizing agricultural robot comprises a robot body, wherein rotating shafts are arranged atthe bottom of the robot body; one end of one rotating shaft is fixedly connected with a driving power device of the robot body; and moving wheels are fixedly connected to the two ends of the two rotating shafts. According to the automatic sowing and fertilizing agricultural robot, an automatic opening device is arranged in a drilling cavity, the automatic opening device comprises a first motor mounting plate, and the surface of the first motor mounting plate is fixedly connected with the inner top wall of the drilling cavity, so that the automatic sowing and fertilizing agricultural robot hasthe advantages that during sowing and fertilizing, the driving power mechanism in the robot body is controlled to work to drive the moving wheels to move forwards, meanwhile, a first motor is controlled to work to drive a spiral drill bit to move downwards, move upwards and reset after drilling is finished, and therefore the automatic drilling effect is achieved, and the situation that a hoe is adopted manually to dig holes in the prior art is avoided, the labor intensity is reduced, and the working efficiency is improved.

Owner:IANGSU COLLEGE OF ENG & TECH

Directional perforating machine for industrial production

PendingCN114290428ARealize the effect of pressing and resettingAvoid jitterMetal-working feeding devicesMetal working apparatusManufacturing engineeringIndustrial engineering

The invention relates to a perforating machine, in particular to a directional perforating machine for industrial production. The invention provides an industrial production directional punching machine which is suitable for small factories, low in manufacturing cost and easy to operate. A directional punching machine for industrial production comprises a material, a base, a punching mechanism and a punching mechanism, the rear baffle is arranged on the base; the two first fixing rods are arranged at the top of the rear baffle; the firing pin is arranged between the two first fixing rods in a sliding mode; the pressing reset mechanism is arranged on the base; the clamping mechanism is arranged on the rear baffle; the clamping mechanism is arranged on the base; and the punching mechanism is arranged among the base, the rear baffle and the two first fixing rods. The pressing reset mechanism is arranged, the pressing reset mechanism is matched with the clamping mechanism, the pressing reset mechanism operates to drive the clamping mechanism to operate, and therefore the pressing reset effect can be achieved.

Owner:杨茂超

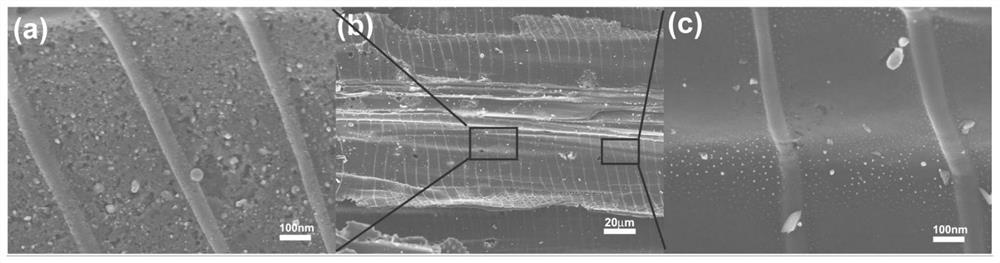

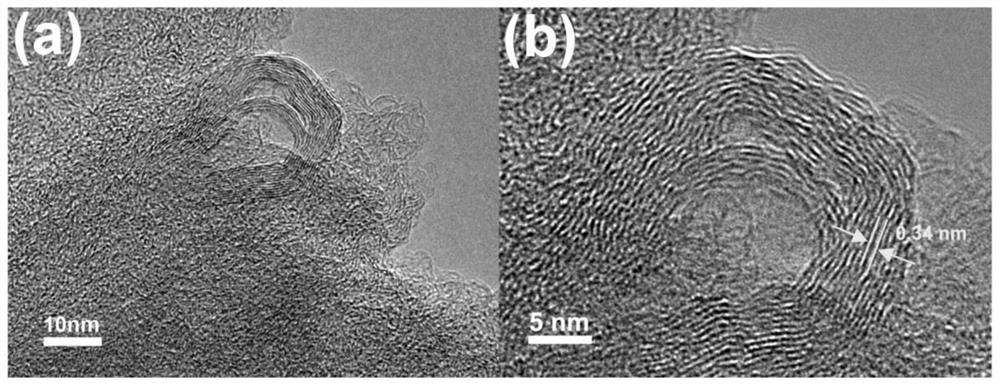

Thick-layer three-dimensional vertical hierarchical multi-channel graphitized activated wood-source carbon electrode and its preparation method

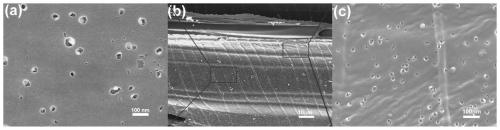

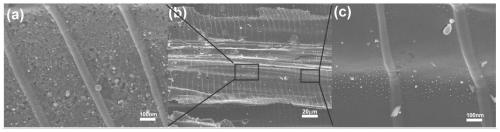

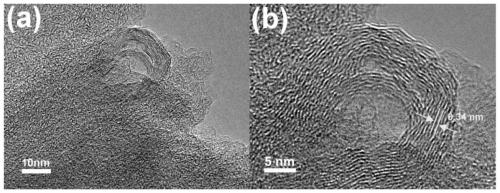

InactiveCN111392709BRich sourcesEasily biodegradableHybrid capacitor electrodesCarbon preparation/purificationPtru catalystSupercapacitor

The invention discloses a preparation method of a thick-layer three-dimensional vertical hierarchical multi-channel graphitized active wood-source carbon electrode, which belongs to the technical field of supercapacitors. The present invention prepares a thick-layer three-dimensional vertically graded multi-channel graphitized active wood-source carbon electrode for the first time through a simple vacuum-assisted catalytic method, and for the first time realizes uniform vertical perforation on the wall of a thick-layer wood-source carbon material graded multi-channel pipe wall Effect. At the same time, the synergistic treatment of graphitization and activation of wood-sourced carbon electrodes is completed. This method makes the catalyst solution evenly adhere to the inner wall of the wood source carbon channel, effectively overcomes the influence of the internal pressure of the pipe in the wood pipeline on the effect of substrate pretreatment and activated graphitization, and improves the pore structure and specific surface area of the wood source carbon electrode material. Next, the degree of graphitization of the electrode material can be improved, so that it can become a thick layer electric double layer electrode material with excellent electrochemical performance. The method has a short production cycle and is easy to control, and can realize the macro-preparation of deep-channel thick-layer carbon material pore wall drilling and graphitization.

Owner:SHAANXI TECHN INST OF DEFENSE IND

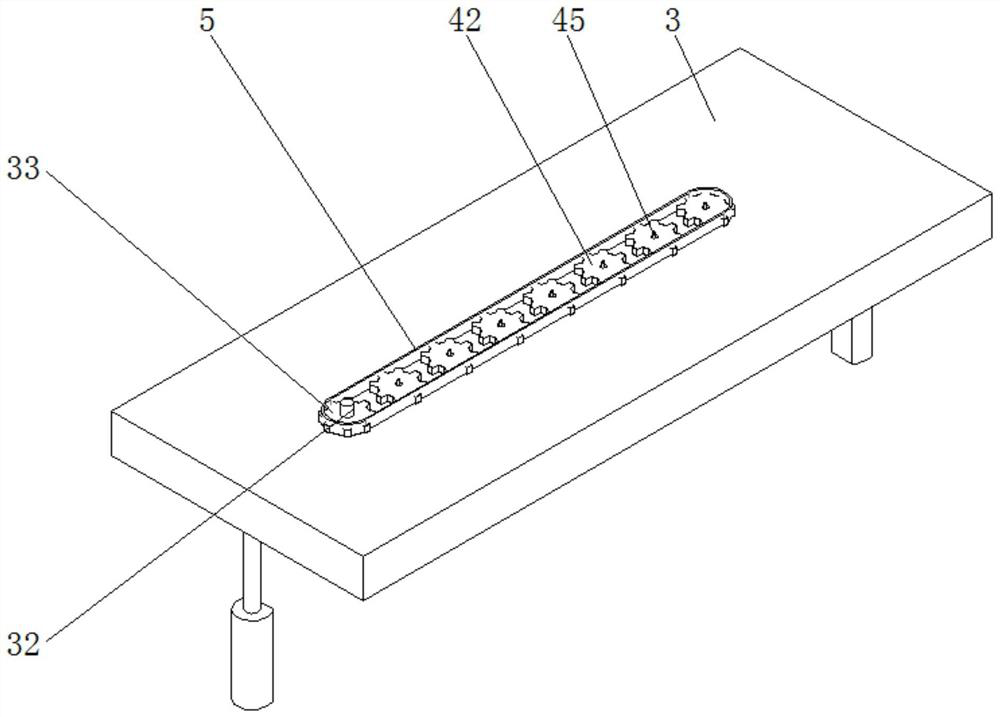

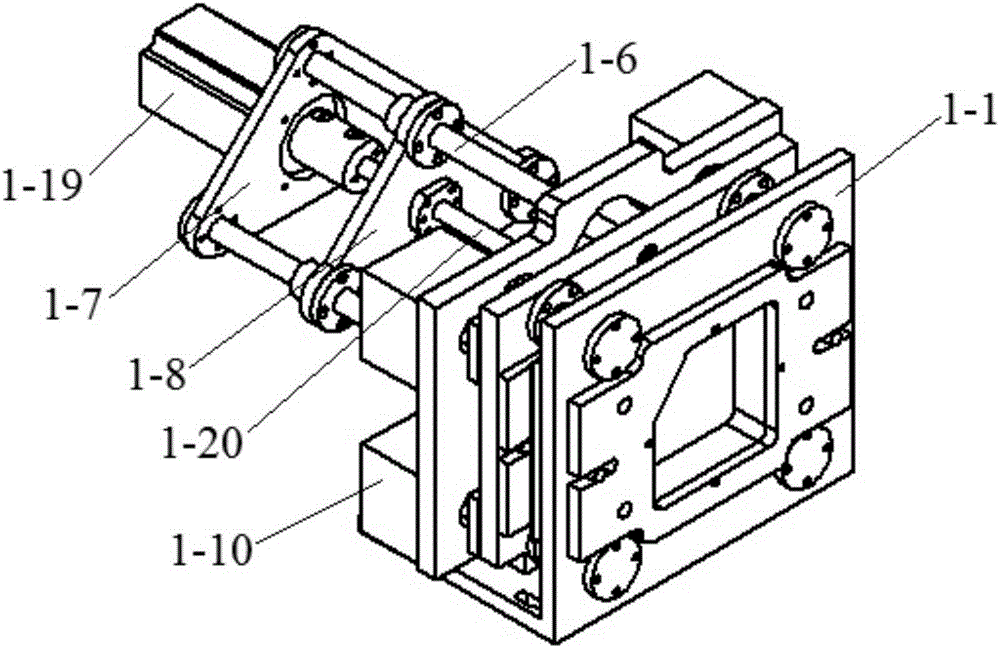

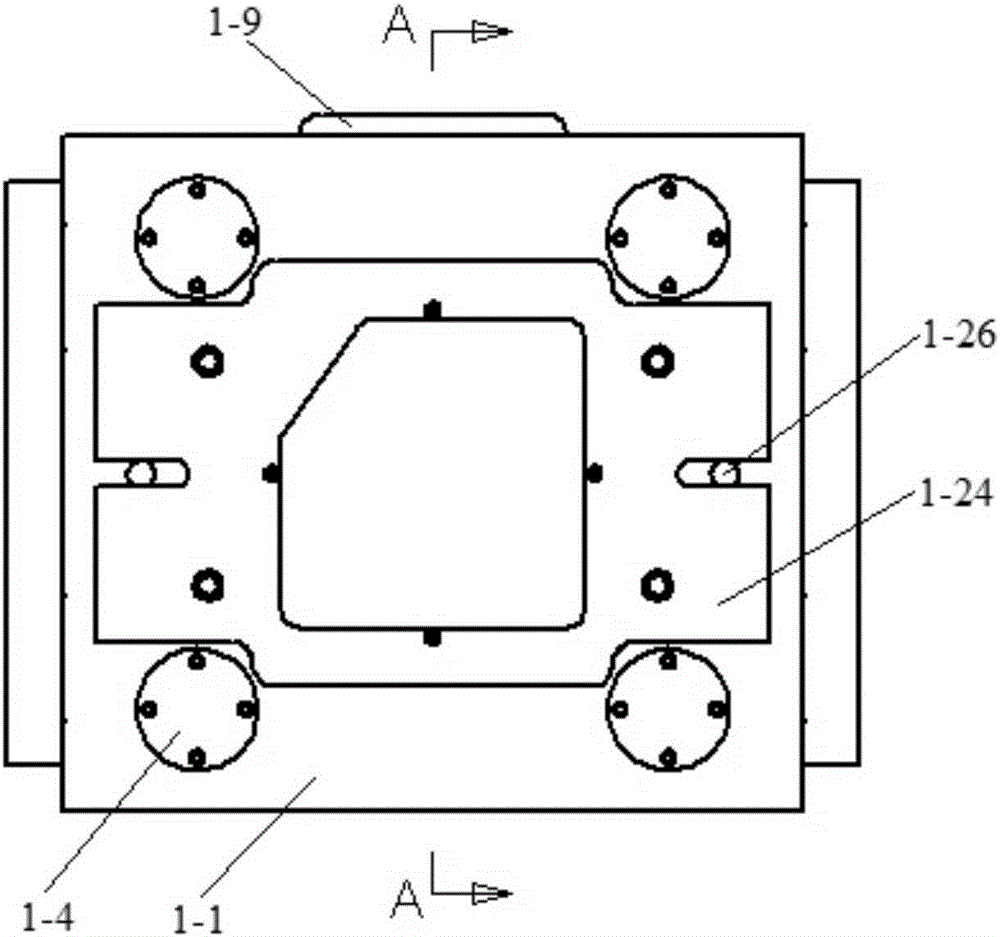

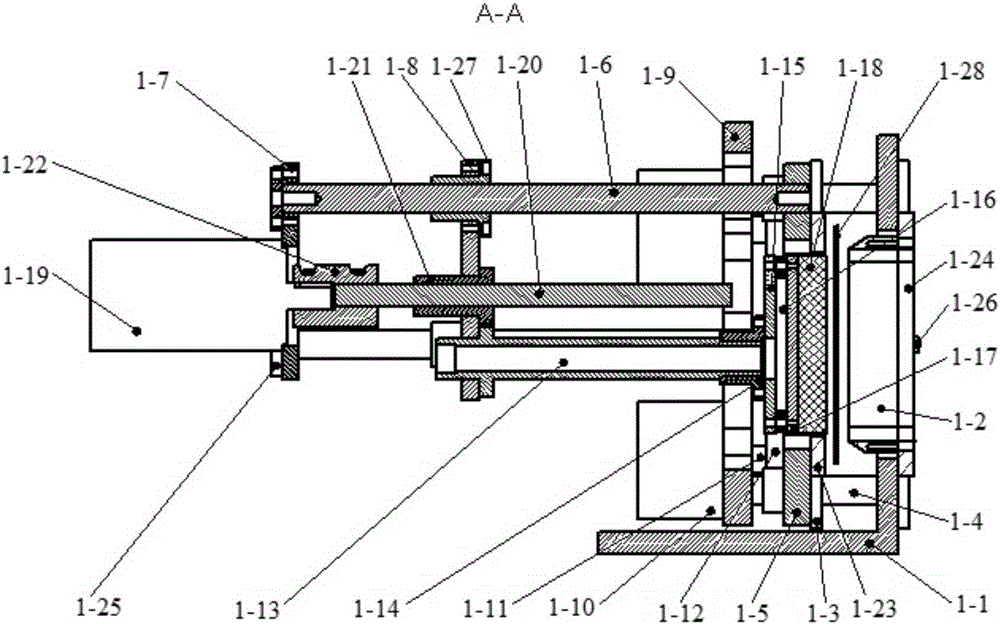

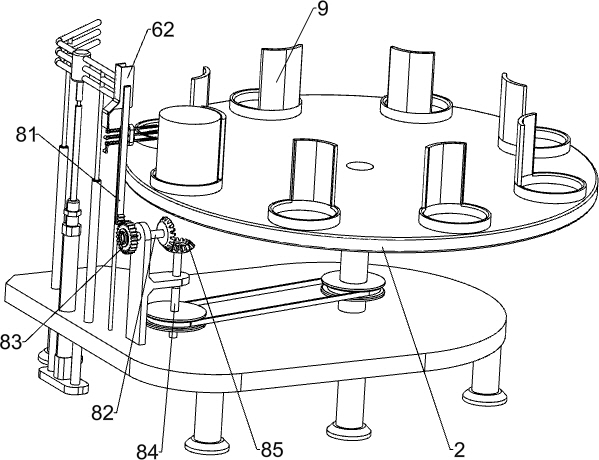

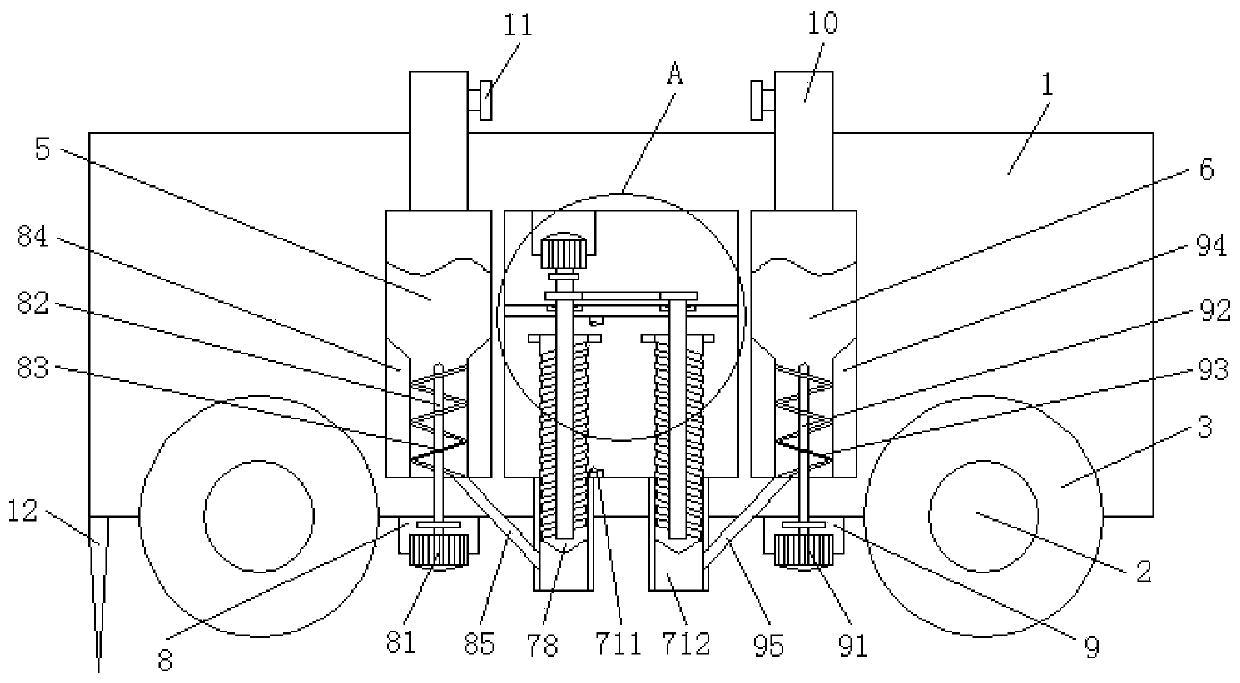

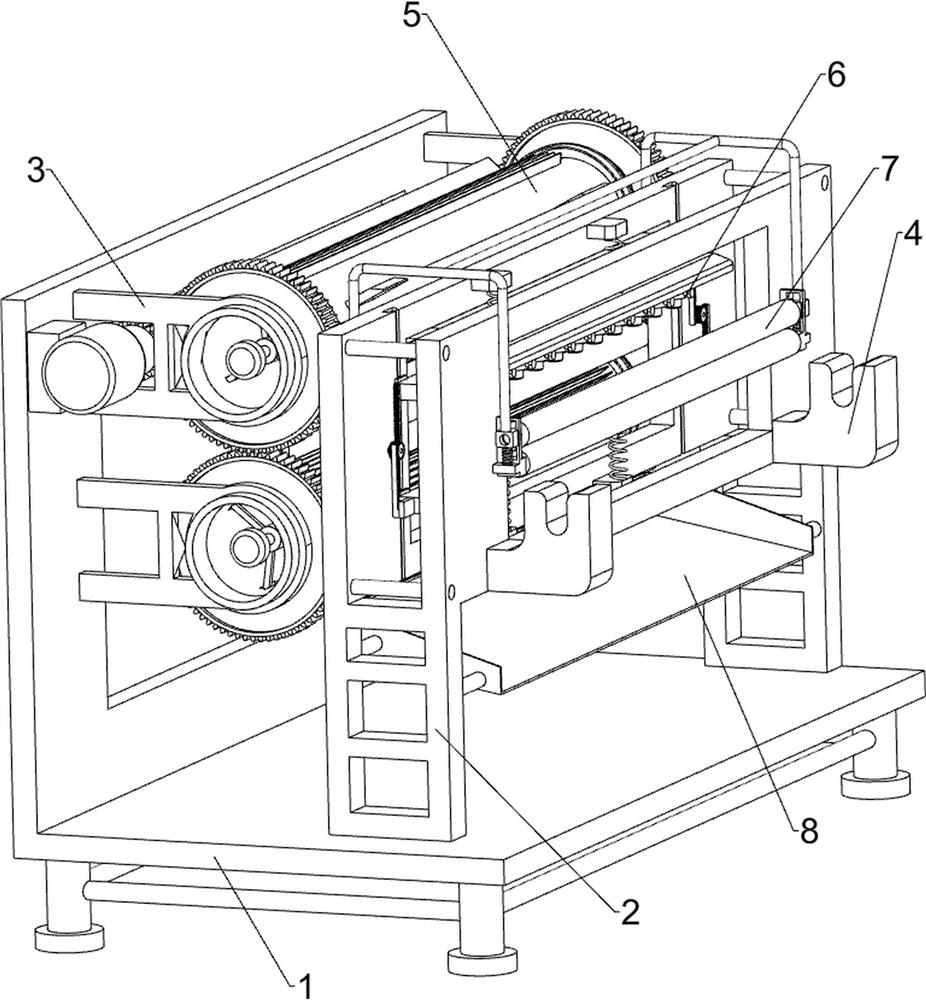

A small log center punching integrated device

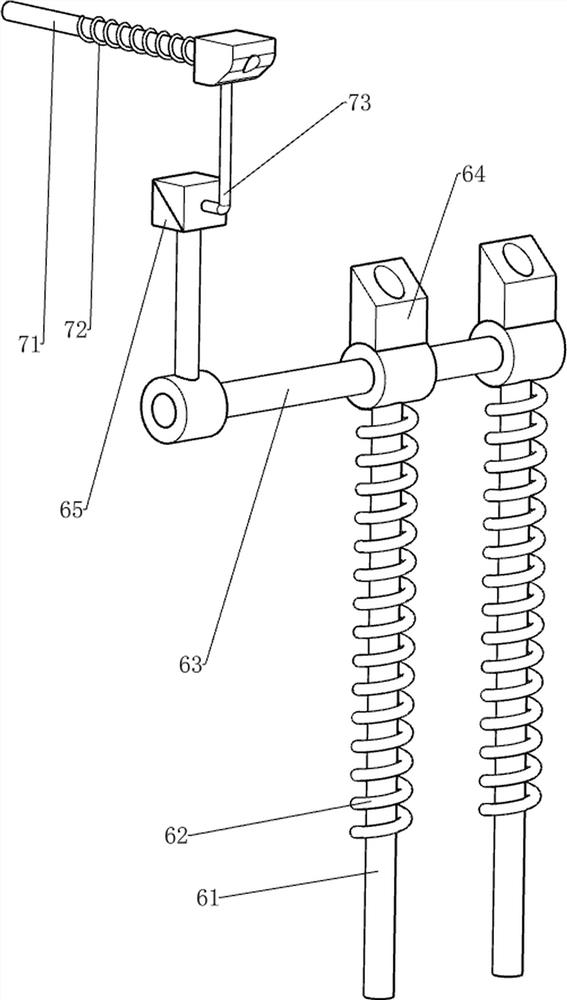

ActiveCN112356159BAchieve punching effectAchieve positioning effectStationary drilling machinesConveyorsHydraulic cylinderPunching

The invention relates to a punching device, in particular to an integrated device for central punching of a small log. The technical problem to be solved by the present invention is how to design a small log center punching integrated device that is easy to operate, can save manpower, and can position the small log. In order to solve the above-mentioned technical problems, the present invention provides such an integrated device for center punching of small round logs, which includes: a bottom plate, the top of which is connected with a workbench, and a hydraulic cylinder is installed on one side of the top of the workbench; a feeding mechanism, which The punching mechanism is arranged between the workbench and the hydraulic cylinder; the punching mechanism is arranged on the workbench, and the feeding mechanism is connected with the punching mechanism by transmission. According to the invention, the small log is punched through the cooperative operation of the feeding mechanism and the punching mechanism, so as to achieve the effect of punching the small log.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

Auxiliary equipment for automatically punching holes at equal intervals and recycling waste materials for leather clothing

InactiveCN113502358AAchieve punching effectLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusPunchingStructural engineering

The invention relates to the technical field of garment manufacturing, and discloses an auxiliary equipment for automatically punching holes at equal intervals and recycling waste materials for leather clothing. The auxiliary equipment comprises a processing wall; a winding mechanism is movably connected to the interior of the processing wall; a transmission rope is movably connected to the exterior of the winding mechanism; a winding shaft is movably connected to the top of the transmission rope; the bottom of the winding shaft is movably connected with a punching mechanism; the left side and the right side of the punching mechanism are both movably connected with impurity removing mechanisms; a winding roller is driven by a driving source to wind leather products; and in the process, the winding roller can synchronously drive a winding wheel to rotate so as to wind the transmission rope wound around the winding wheel to drive a rotating screw to rotate, at the moment, a lifting seat can move after stretching a reset spring, the lifting seat moves to drive a punching seat to move, the punching seat moves to drive a drill bit to move until the drill bit is in contact with leather, then the leather is punched, and therefore the effect that the leather can be automatically punched at equal intervals is achieved.

Owner:杭州和乐广告有限公司

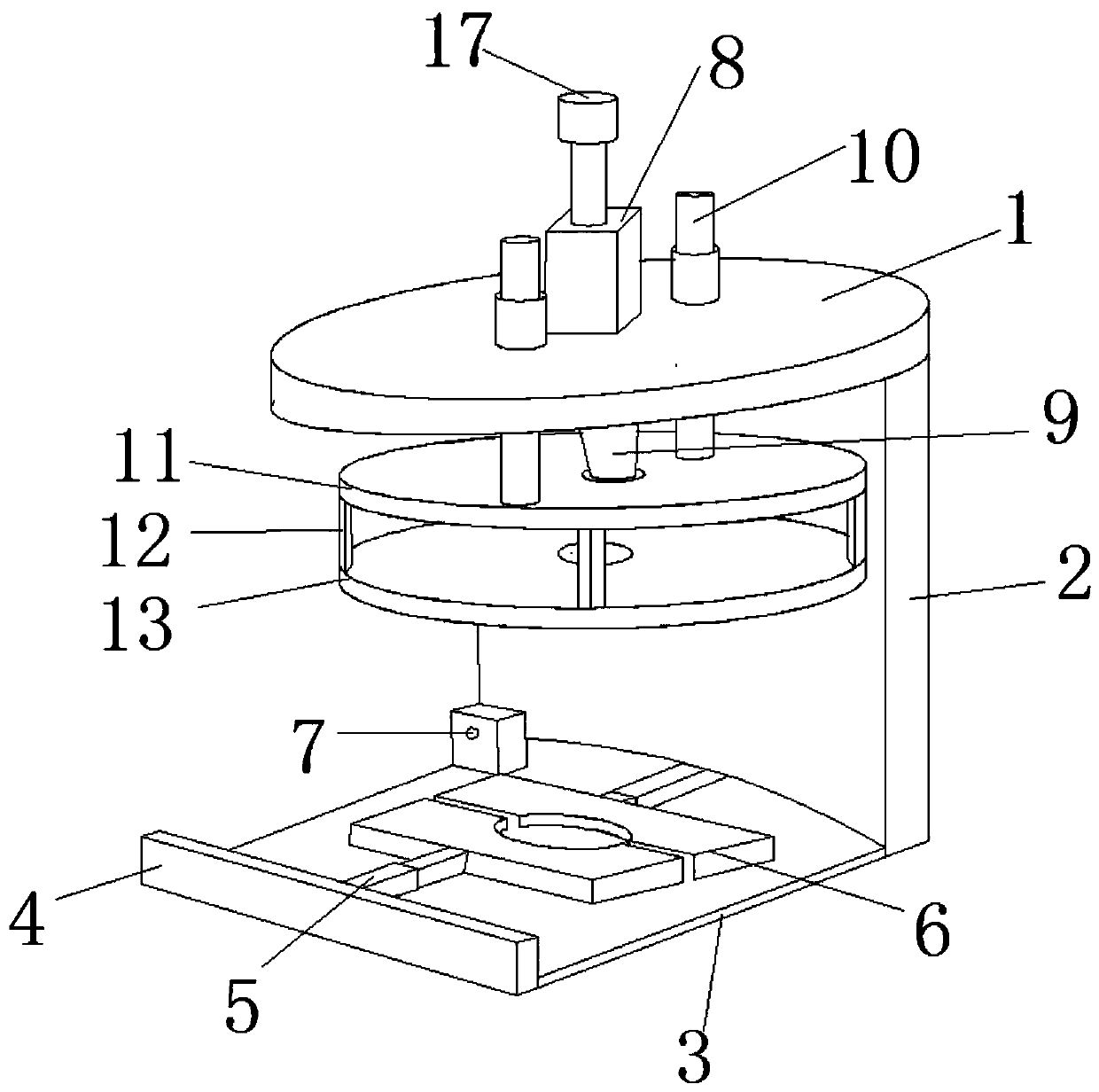

A rosary punching device

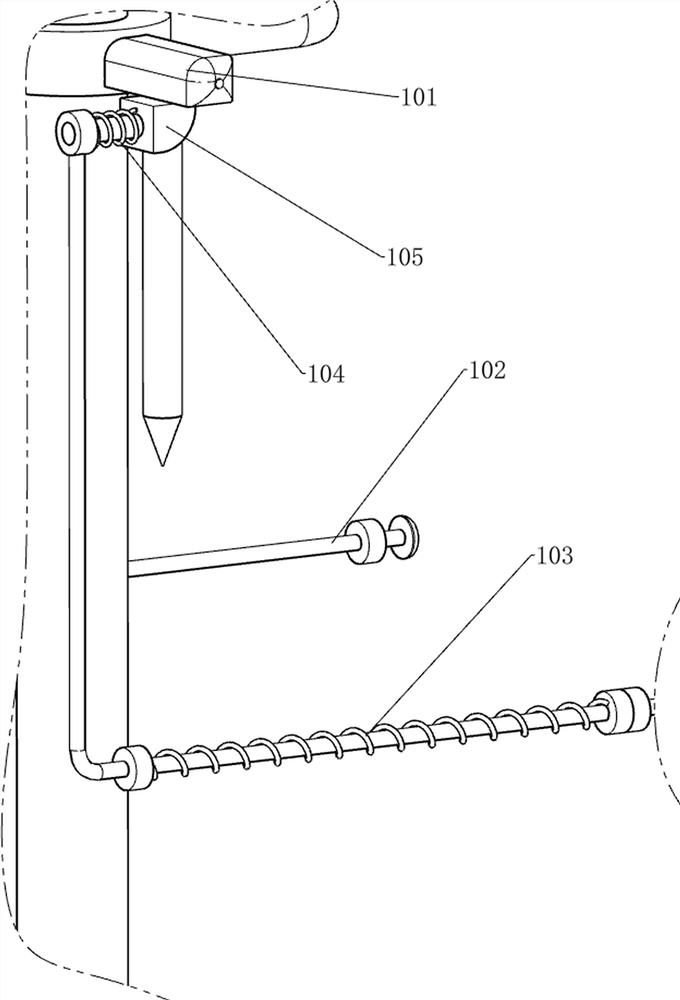

ActiveCN111775208BAchieve punching effectSave human effortMetal working apparatusPunchingStructural engineering

The invention relates to a punching device, in particular to a rosary punching device. The technical problem to be solved by the present invention is how to design a rosary punching device that can save manpower and ensure the safety of operators during operation. The invention provides such a rosary punching device, which includes: a right leg, one side of which is connected with a fixed frame; a rocker, which is rotatably connected to the fixed frame; and a left leg, which is connected to one side of the fixed frame ; Manual drilling assembly, which is set between the fixed frame and the rocker; clamping assembly, which is set between the left and right legs; Manual feeding assembly, which is set between the left and right legs . In the present invention, the manual drilling component, the clamping component and the manual feeding component cooperate to drill the rosary, so as to achieve the effect of drilling the rosary.

Owner:肖辉

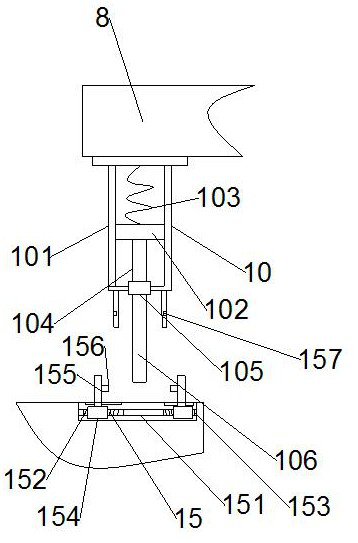

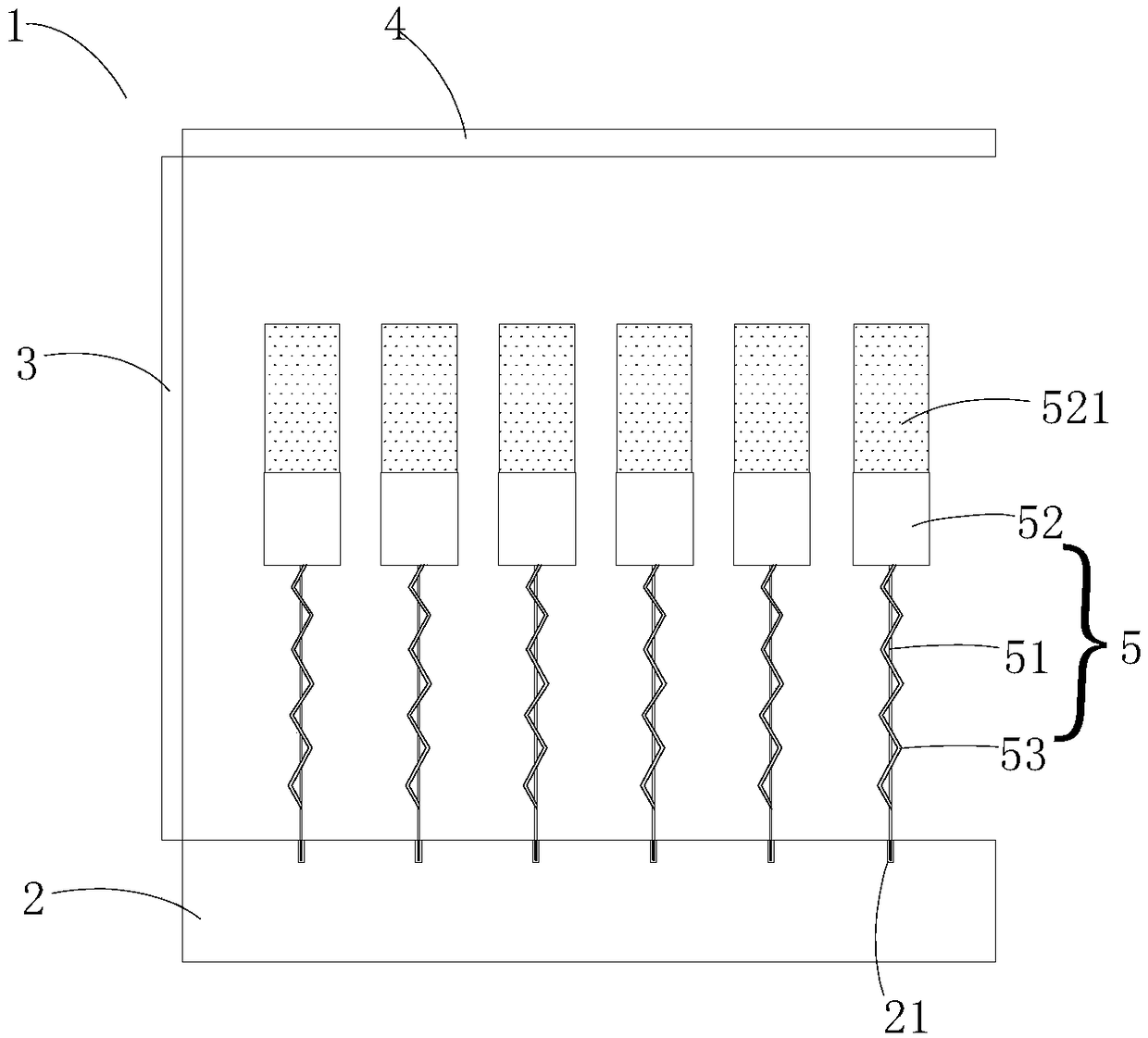

Device for edible fungi stock seed culture and injection

InactiveCN110447468AControl movementAchieve punching effectCultivating equipmentsMushroom cultivationPunchingEngineering

The invention relates to the technical field of edible fungi stock seed culture, and discloses a device for edible fungi stock seed culture and injection. The device comprises a processor and an electric extension rod, the lower portion of the processor penetrates through a top plate to be movably connected with the upper portion of an injector, the lower portion of the electric extension rod penetrates through the top plate to be movably connected with the upper portion of an upper pressure plate, the lower portion of the upper pressure plate is fixed with the upper portion of a lower pressure plate through a supporting rod, and the lower portion of the top plate is fixed with the upper portion of a bottom plate through a supporting plate. The left side of the bottom plate is fixedly provided with a baffle, the right side of the baffle is movably connected with an electric telescoping rod, and the right side of the electric telescoping rod is movably connected with a mould. Accordingto the device for edible fungi stock seed culture and injection, a signal is transmitted to the processor through a sensor to control the electric extension rod, the injector and the electric telescoping rod, so that movement of a punch needle, movement of the injector and movement of the mould are controlled, and the effects of punching, injection and fixation of a culture medium are achieved.

Owner:湖南永爱生物科技有限公司

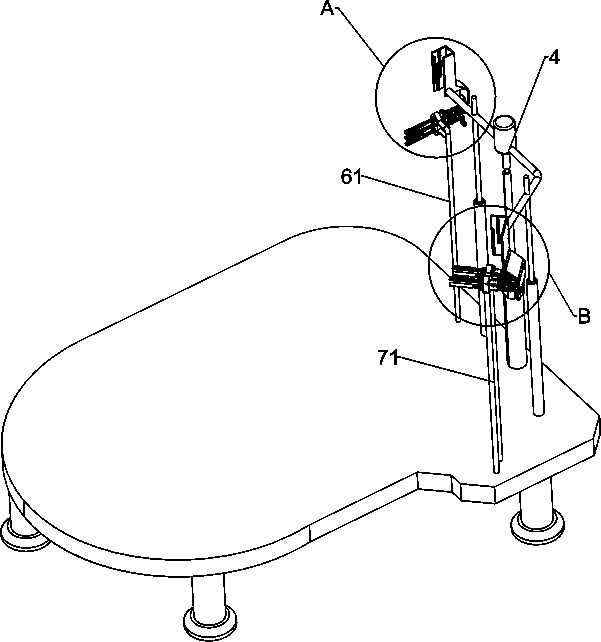

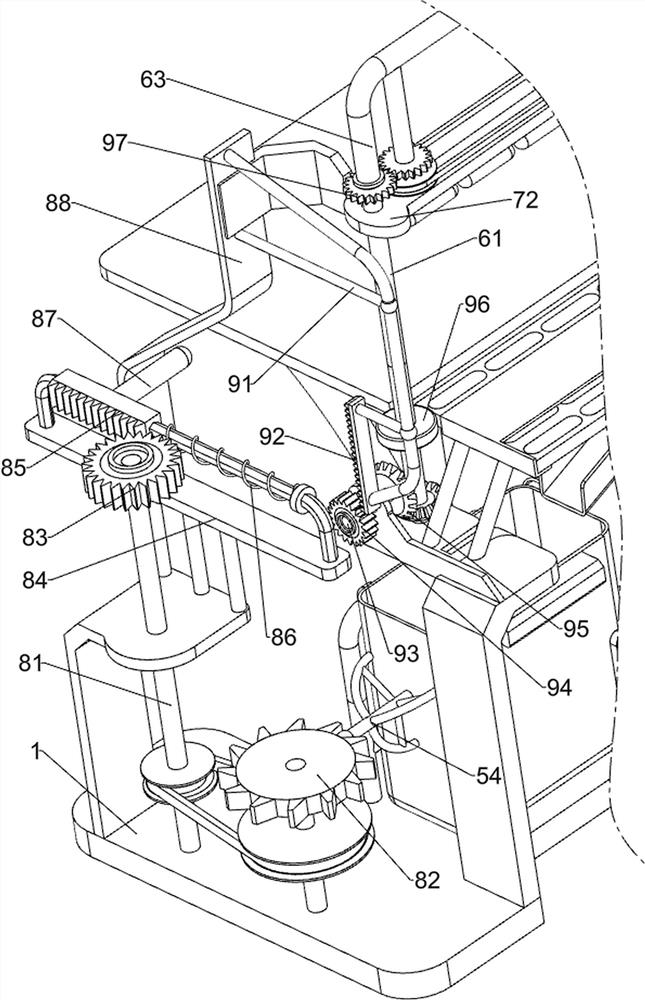

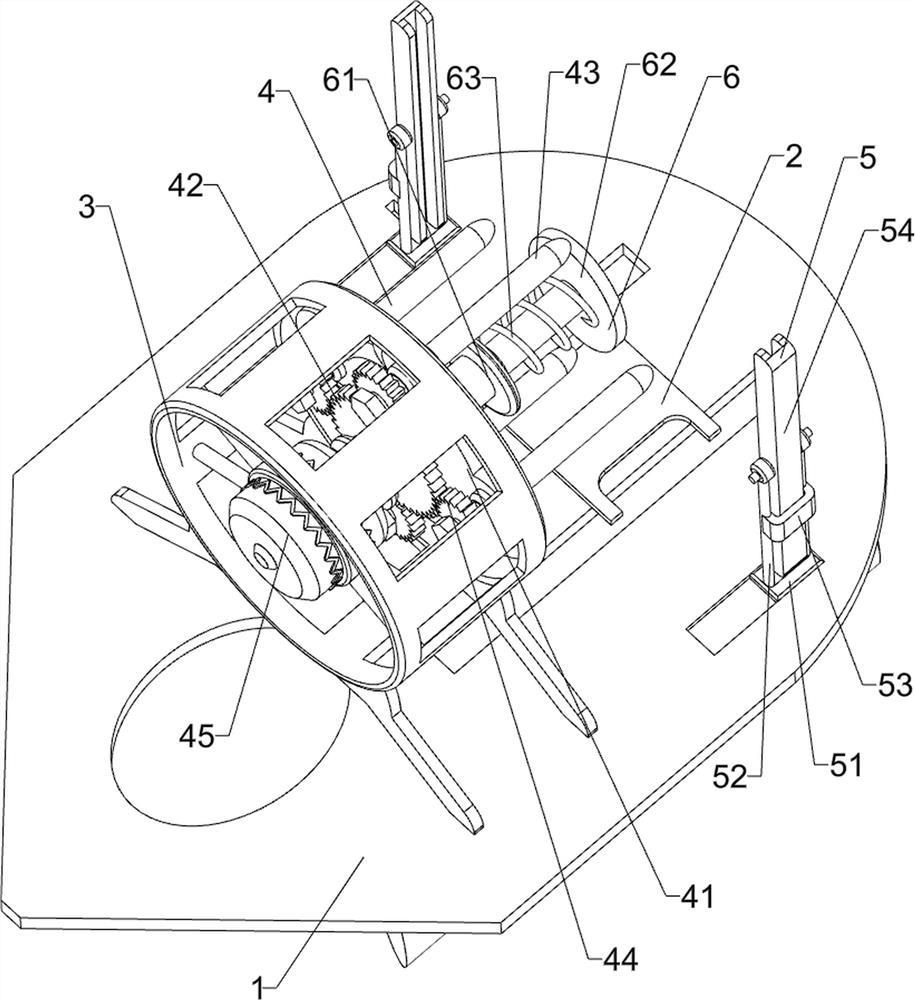

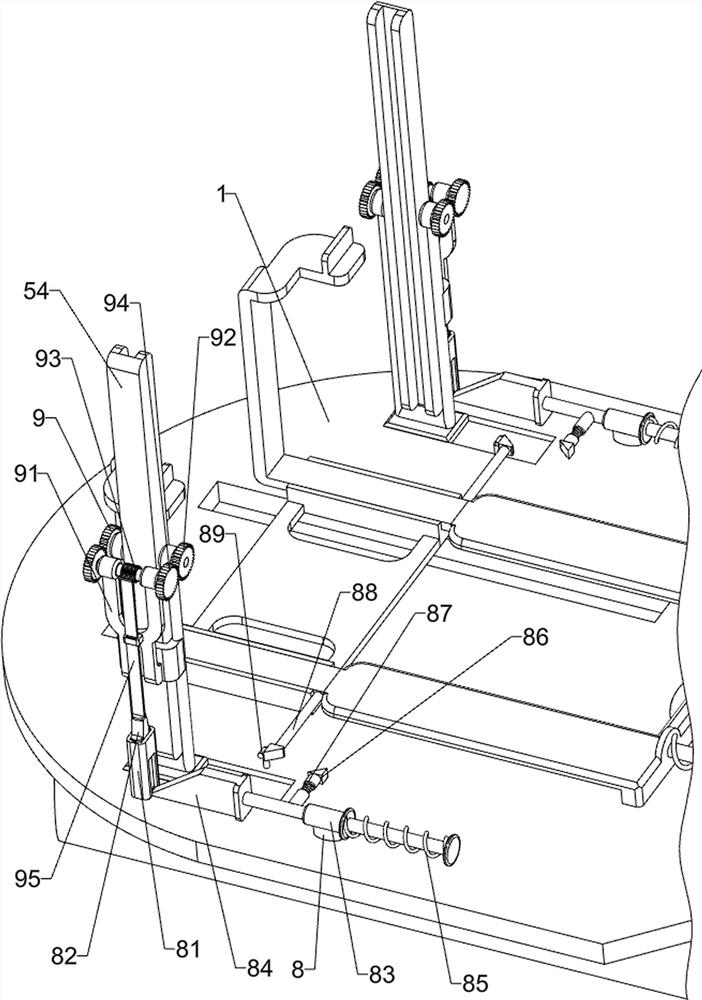

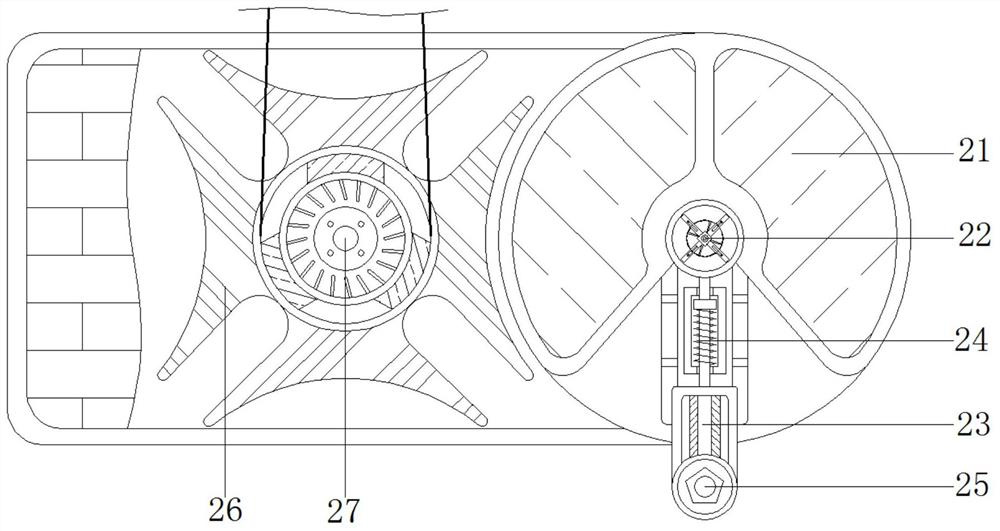

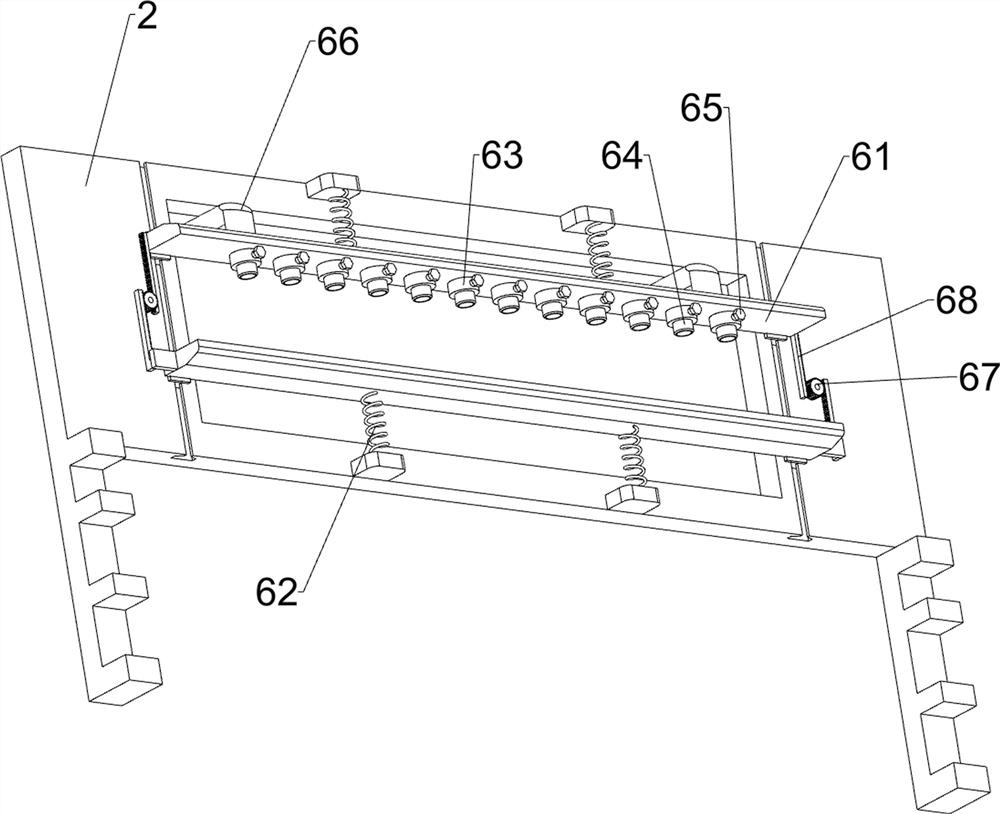

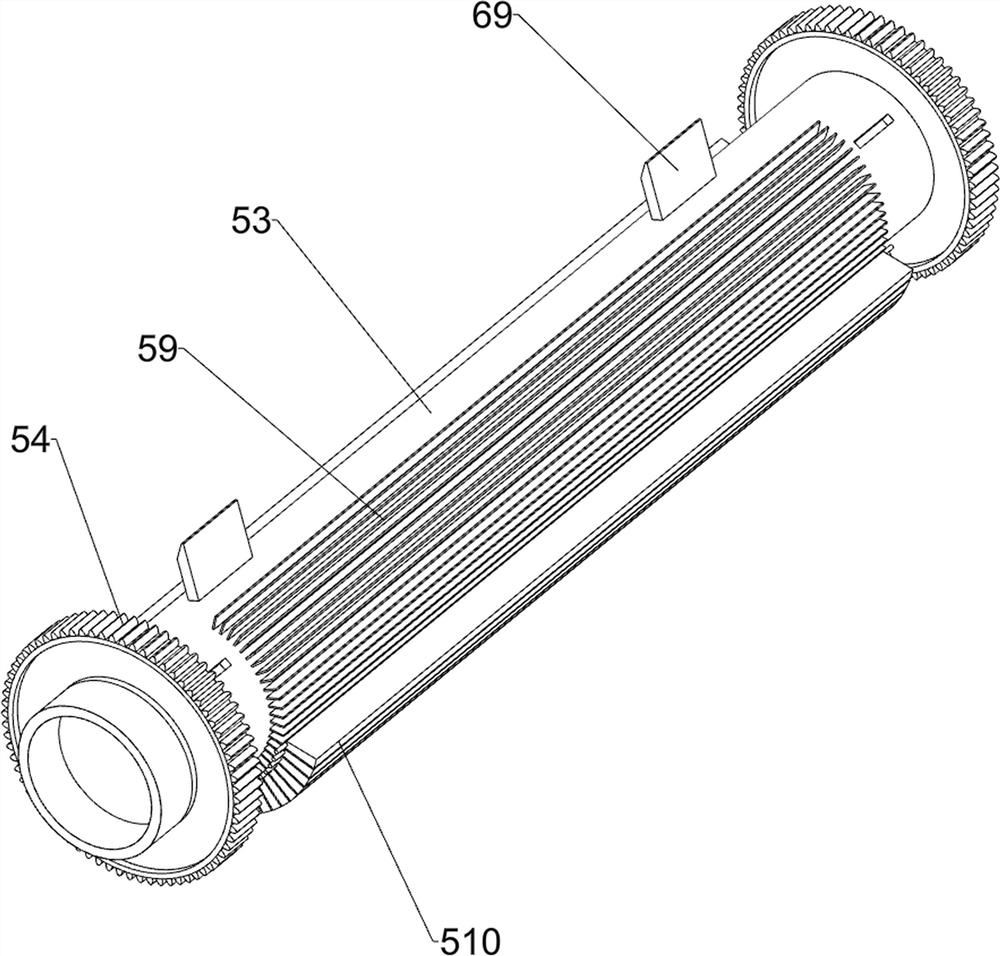

Bamboo joint pipe processing device with adjustable bamboo joint processing density

ActiveCN112974648AAchieve punching effectTo achieve the effect of intermittent heatingShaping toolsBio-packagingGear wheelCam

The invention relates to the field of bamboo joint pipe processing, in particular to a bamboo joint pipe processing device with the adjustable bamboo joint processing density. The bamboo joint pipe processing device comprises a support bottom plate, an H-shaped slotting guide supporting frame, a clamping reciprocating mechanism and the like. The H-shaped slotting guide supporting frame is installed on the support bottom plate, the clamping reciprocating mechanism is installed on the support bottom plate, a bamboo joint pipe punching mechanism is arranged on the H-shaped slotting guide supporting frame, and a bamboo joint pipe joint position adjusting mechanism is installed above the clamping reciprocating mechanism. Through mutual cooperation of a one-way cam, a gear with a shifting rod, a first special-shaped wedge-shaped rod and a wedge-shaped stamping ring, a bamboo joint pipe can be punched.

Owner:湖南宝顶竹木科技有限公司

Die-cut labeling unit and labeling method of linerless self-adhesive labeling machine

InactiveCN105235965BAchieve punching effectSolve resource problemsLabelling machinesLinear motionPunching

The invention discloses a die-cutting and labeling unit of a bottomless paper self-adhesive labeling machine, which comprises a die-cutting linear motion pair, a labeling linear motion pair and a manipulator; the die-cutting linear motion pair is connected with the labeling linear motion pair , the manipulator is connected with the labeling linear motion pair and can be driven by the labeling linear motion pair to perform linear reciprocating motion to approach or stay away from the die-cutting linear motion pair. The invention also discloses a labeling method of the die-cut labeling unit of the bottomless paper self-adhesive labeling machine. The present invention creatively uses a manipulator in the self-adhesive labeling machine to make the die-cutting process achieve the punching effect, so that the self-adhesive label used only needs one layer of label paper without using a backing paper, effectively It solves the problem that the self-adhesive labels used in the self-adhesive labeling machine in the prior art must have a backing paper, thereby causing resource waste and environmental pollution.

Owner:XIAN TIANLAI SPECIAL MACHINERY CO LTD

Positioning and punching device for nixie tube shell processing and production

InactiveCN114055638AEasy to moveAchieve rotationWorking accessoriesStone-like material working toolsStructural engineeringNixie tube

The invention discloses a positioning and punching device for nixie tube shell processing and production. The positioning and punching device comprises a positioning and punching base, a positioning vertical column and a positioning sleeve column are arranged on the upper portion of the positioning and punching base, an electric sliding rail is arranged on the side wall of the positioning vertical column, an electric sliding block is arranged in the electric sliding rail in a sliding mode, and a lifting base is arranged on the electric sliding block in a sliding mode; and a punching column is arranged on the lifting base. The electric sliding rail is started, the electric sliding block can move, then the lifting base moves, meanwhile, a punching head moves, and the punching effect is achieved; and protection assemblies are arranged on the two sides of the punching head. An air cylinder is arranged on the bottom wall of the positioning and punching base, the free end of the air cylinder is connected with a clamping assembly, a clamping base is arranged on the upper portion of the positioning punching base, the clamping base is matched with a buffering base through the clamping assembly to start the air cylinder and the clamping sliding base to move, and then clamping clamping blocks are clamped with clamping clamping blocks on the clamping base and the buffering base in a matched mode. Therefore, the clamping base and the buffering base are positioned and fixed.

Owner:YLIN ELECTRONICS CO LTD

A device for punching holes in fixed-cut fabrics in a garment factory

ActiveCN112157716BAchieve punching effectAvoid punching effectsMetal working apparatusPunchingIndustrial engineering

The invention relates to a punching device, in particular to a punching device for fixedly cut cloth in a garment factory. The technical problem to be solved by the present invention is a garment factory fixed cutting cloth punching device which is easy to operate, can save manpower and improve work efficiency. In order to solve the above-mentioned technical problems, the present invention provides such a device for punching holes in fixedly cut fabrics in a garment factory, which includes: a frame with a support base connected to one side of its top; The racks are connected to the other side of the rack, and each set of mounting racks has two settings, and the two mounting racks of each group are respectively connected to both sides of the rack; Both sides of the support seat. The invention punches the cloth through the cooperative operation of the adjustable feeding mechanism and the punching device, thereby achieving the effect of punching the cloth.

Owner:山东靓华制衣有限公司

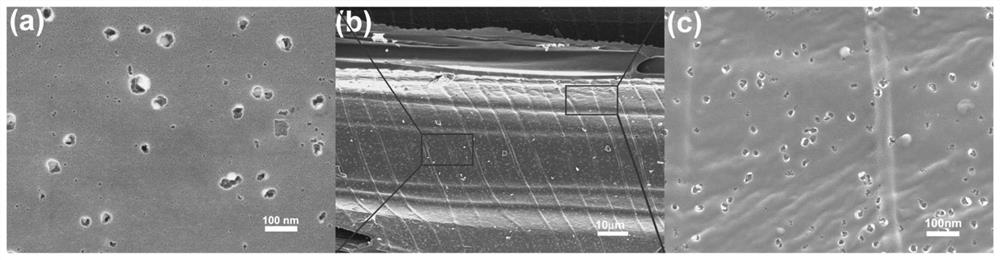

Thick-layer three-dimensional vertical graded multi-channel graphitized active wood source carbon electrode and preparation method thereof

InactiveCN111392709ARich sourcesEasily biodegradableHybrid capacitor electrodesCarbon preparation/purificationGraphiteElectrode material

The invention discloses a preparation method of a thick-layer three-dimensional vertical graded multi-channel graphitized active wood source carbon electrode, which belongs to the technical field of supercapacitors. According to the method, the thick-layer three-dimensional vertical graded multi-channel graphitized active wood source carbon electrode is prepared for the first time through a simplevacuum assisted catalysis method, and the effect of uniformly and vertically punching holes in the graded multi-channel pipe wall of the thick-layer wood source carbon material is achieved for the first time. Meanwhile, the graphitization and activation synergistic treatment on the wood source carbon electrode is completed. According to the method, a catalyst solution is uniformly attached to theinner wall of a wood source carbon pore channel; the influence of pipeline internal pressure in a wood pipeline on substrate pretreatment and activated graphite effect is effectively overcome, and the graphitization degree of the electrode material is improved on the premise of improving the pore structure and specific surface area of the wood source carbon electrode material, so that the electrode material becomes a thick-layer electric double-layer electrode material with excellent electrochemical performance. The method is short in production period and easy to control, and macro preparation of hole wall punching and graphitization of the thick-layer carbon material of the deep hole channel can be achieved.

Owner:SHAANXI TECHN INST OF DEFENSE IND

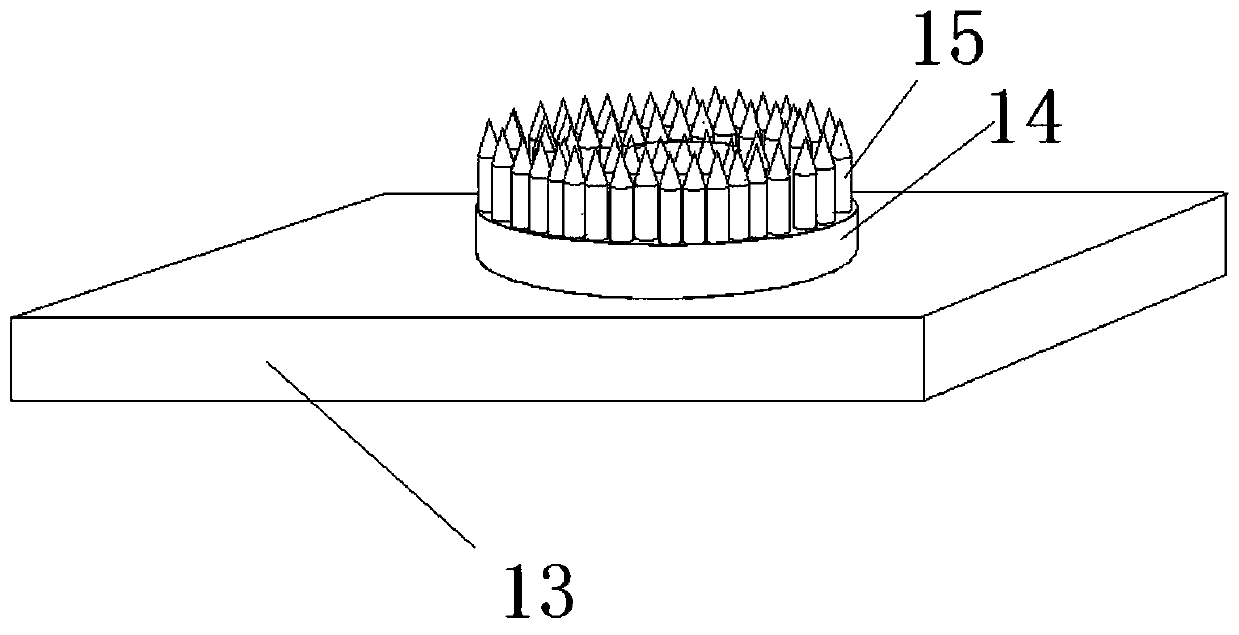

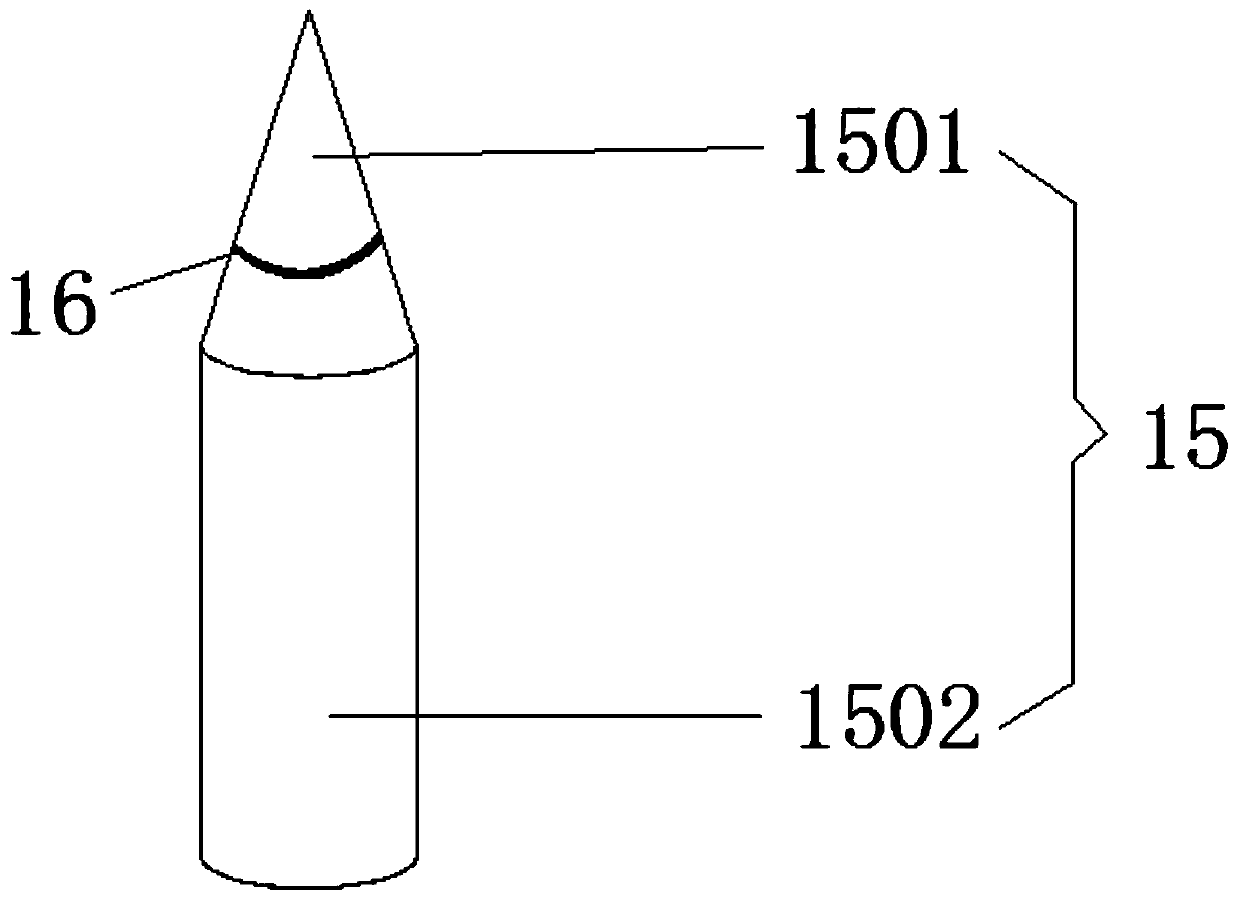

An aizhu punching device based on warm needling therapy

InactiveCN108890754AAchieve punching effectSave punching timeDevices for heating/cooling reflex pointsMetal working apparatusMedical equipmentPunching

The invention relates to the field of medical equipment, in particular to a moxa post punching device based on warm needle therapy, which comprises a base, a connecting piece, a pressing plate and a punching assembly, wherein the base is slidably connected with the pressing plate through the connecting piece; An upper surface of that base is provide with a plurality of perforation assemblies, theperforation assembly comprise a puncture rod, a moxa column placement groove and a first spring, one end of the puncture rod is connected with the base, the other end of the puncture rod is slidably connected with the moxa column placement groove, and the moxa column placement groove slot is toward the side where the pressure plate is located; One end of the first spring is connected with the outer side of the moxa column placing groove, the other end of the first spring is connected with the puncture rod, and the elastic force direction of the first spring is parallel to the puncture rod; When the first spring has no pressure plate action and the force balance is stationary, the piercing rod and the socket post face but do not abut. The punching device can simultaneously punch a pluralityof moxa posts, thereby saving the punching time of the operator and improving the working efficiency.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

New-generation information technology photoelectric module shell punching device

PendingCN113843342AAchieve punching effectRealize the effect of clamping the module shellPerforating toolsMetal-working feeding devicesPunchingWorkbench

The invention relates to a shell punching device, in particular to a new-generation information technology photoelectric module shell punching device. The invention provides the new-generation information technology photoelectric module shell punching device which realizes automatic conveying of module shells, automatically punching and automatically clamping the module shells. The new-generation information technology photoelectric module shell punching device comprises a base, a material placement box, a workbench, a collecting box, a sliding way, a punching mechanism and a feeding mechanism; a supporting column is arranged on the base; the material placement box is arranged at the upper part of the supporting column; the workbench is arranged on the supporting column; the collecting box is arranged on the workbench; the sliding way is arranged at the upper part of the collecting box; the punching mechanism is arranged on the workbench; and the feeding mechanism is arranged on the workbench. According to the device, a first sliding column is pressed downwards, and a first spring is compressed, so that the first sliding column punches the module shells, and the effect that the first sliding column punches the module shells is achieved.

Owner:张治周

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com