Thick-layer three-dimensional vertical graded multi-channel graphitized active wood source carbon electrode and preparation method thereof

A carbon electrode and porous channel technology, which is applied in the field of thick-layer three-dimensional vertical hierarchical porous channel graphitized active wood-source carbon electrode and its preparation field, can solve the problems of high degree of non-graphitization, damage to base structure, poor rate performance, etc. Achieve the effect of graphitization degree and specific surface area improvement, specific surface area improvement and pore structure rationalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

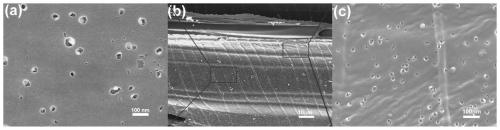

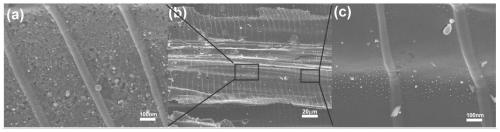

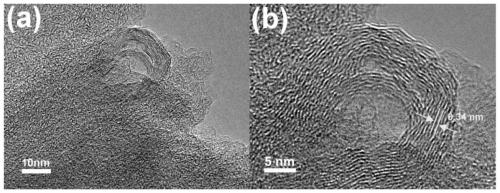

[0036] 1. Preparation of thick-layer wood-derived carbon electrodes

[0037]Clean the wood with a size of 0.8cm×0.8cm×2.0cm with ethanol and deionized water, dry it, raise the temperature to 900℃ at 5℃ / min in a nitrogen atmosphere, carbonize at a constant temperature for 3 hours, and then cool down to room temperature naturally. Ultrasonic cleaning with ethanol and deionized water and drying in an oven at 100 °C for 1 hour yielded a thick-layer wood-derived carbon electrode (TWC).

[0038] 2. Vacuum-assisted modification

[0039] Place the TWC obtained in step 1 in 50mL mixed acid solution, the mixed acid solution is composed of nitric acid, sulfuric acid and deionized water, wherein the mass fraction of nitric acid is 10%, the mass fraction of sulfuric acid is 50%, in a vacuum environment at 60°C After soaking for 30 minutes, the product was sequentially washed with ethanol and deionized water until the pH was neutral, and then dried in an oven at 100°C for 1 hour to obtain ...

Embodiment 2

[0047] 1. Preparation of thick-layer wood-derived carbon electrodes

[0048] This step is the same as in Example 1.

[0049] 2. Vacuum-assisted modification

[0050] Place the TWC obtained in step 1 in 50mL mixed acid solution, the mixed acid solution is composed of nitric acid, sulfuric acid and deionized water, wherein the mass fraction of nitric acid is 5%, the mass fraction of sulfuric acid is 25%, in a vacuum environment at 60°C After soaking for 10 minutes, the product was sequentially washed with ethanol and deionized water until the pH was neutral, and dried in an oven at 100°C for 1 hour to obtain the modified TWC.

[0051] 3. Impregnated catalytic activator

[0052] The modified TWC obtained in step 2 was impregnated in 50mL 0.05mol / L Fe(NO 3 ) 3 In aqueous solution, reflux at 80°C for 6 hours to obtain impregnated Fe(NO 3 ) 3 Modified TWC.

[0053] 4. One-step preparation of thick-layer three-dimensional vertically hierarchical porous graphitized active wood-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com