Bamboo joint pipe processing device with adjustable bamboo joint processing density

A processing device and bamboo tube technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of bamboo tube adjusting density and bamboo tube not having aesthetic feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

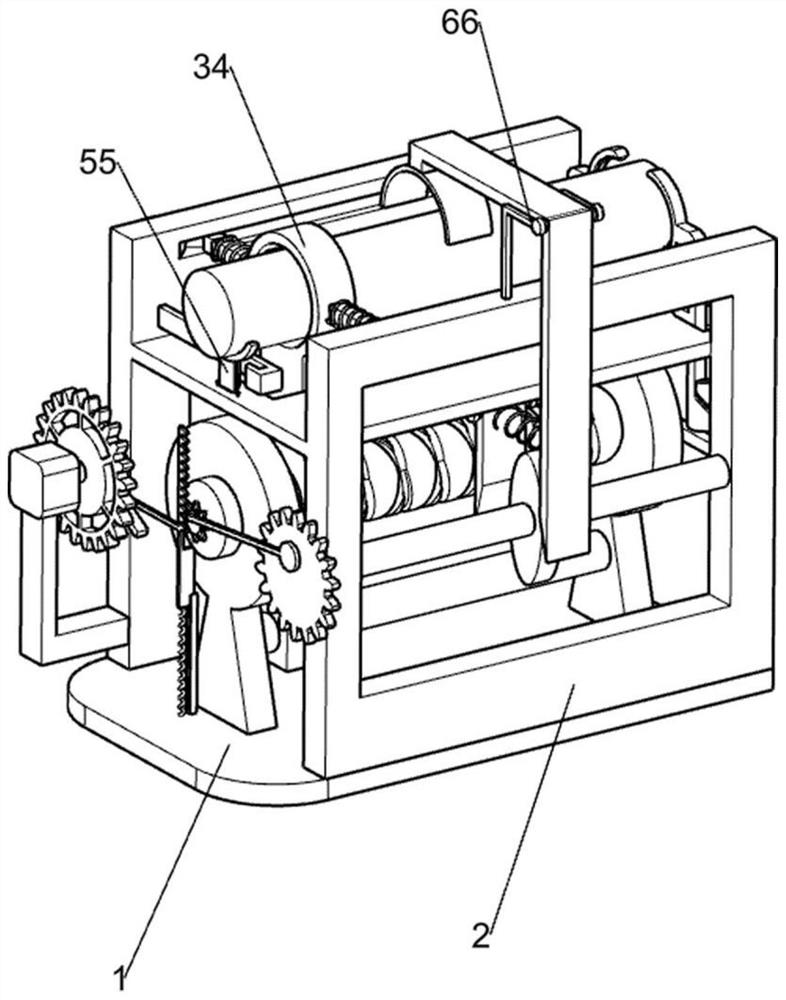

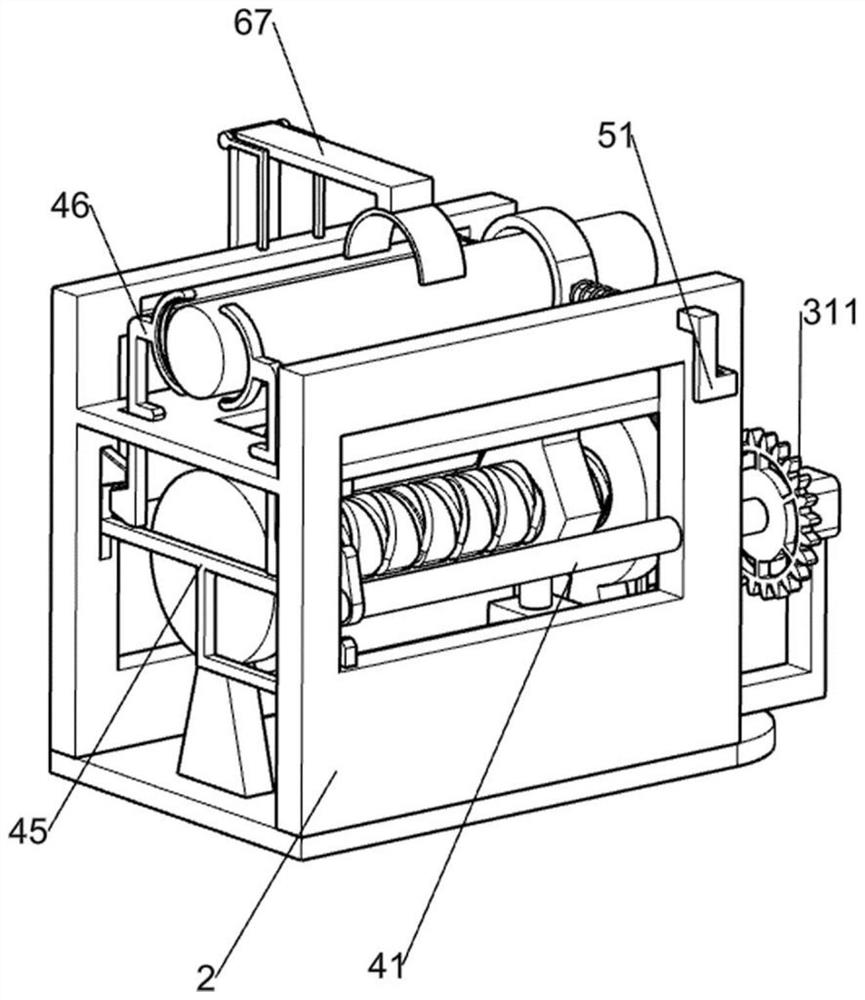

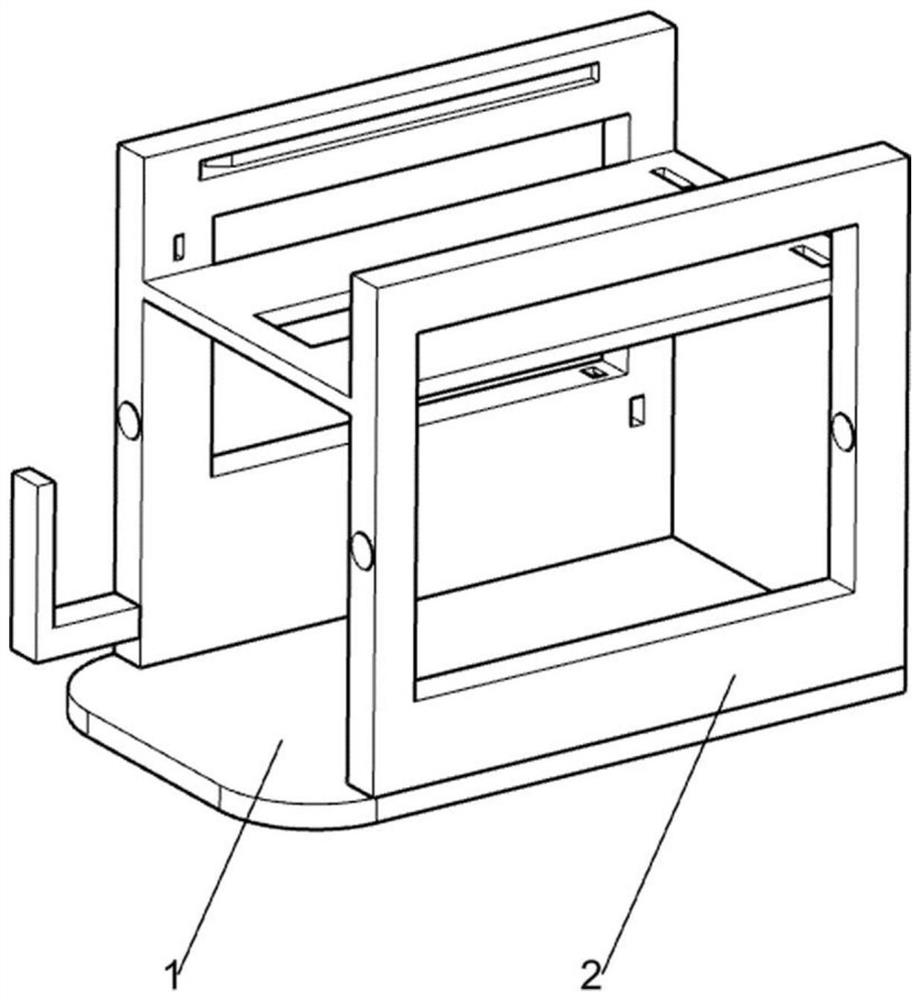

[0028] Embodiment: a bamboo tube processing device with adjustable bamboo processing density, such as Figure 1-13 As shown, it includes a support base plate 1, an H-shaped slotted guide support frame 2, a clamping reciprocating mechanism 3, a bamboo tube stamping mechanism 4, and a bamboo tube node position adjustment mechanism 5. The bracket base plate 1 is equipped with an H-shaped slotted guide The support frame 2, the clamping reciprocating mechanism 3 is installed on the support bottom plate 1, the clamping reciprocating mechanism 3 is used to clamp the bamboo tube and move it, the bamboo tube stamping mechanism 4 is set on the H-shaped slotted guide support frame 2 , The bamboo pipe joint position adjustment mechanism 5 is installed above the clamping reciprocating mechanism 3, and the bamboo joint pipe joint position adjustment mechanism 5 is used to adjust the position of the bamboo joint pipe.

[0029] Including a clamping reciprocating mechanism 3, the clamping reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com