Positioning and punching device for nixie tube shell processing and production

A punching device and digital tube technology, applied in the field of digital tube shells, can solve the problems of affecting the punching efficiency, poor positioning efficiency, affecting the life of the punching structure, etc., and achieve the effect of adjusting the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

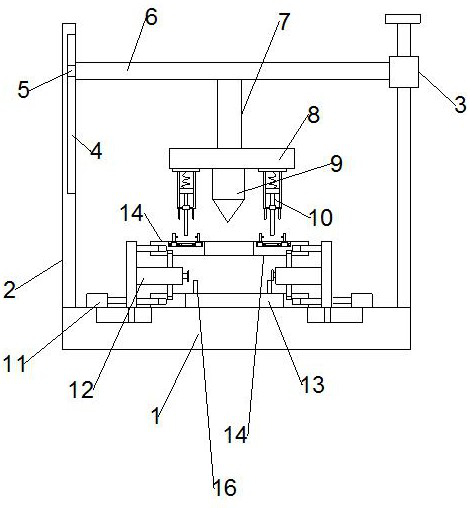

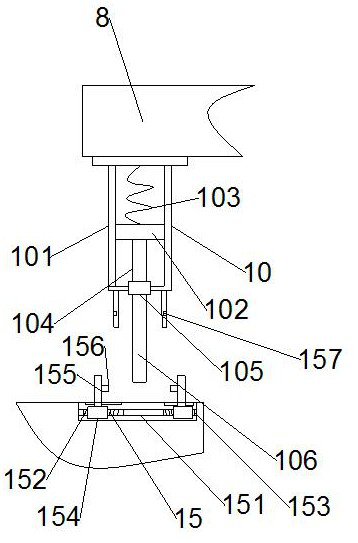

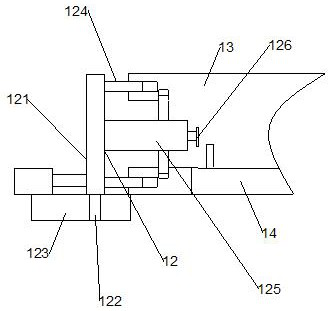

[0027] see Figure 1-6 , in the present invention, a kind of positioning punching device that the nixie tube shell is processed and produced comprises positioning punching seat 1, and the upper part of positioning punching seat 1 is provided with positioning vertical column 2 and positioning sleeve column 3, and positioning vertical column 2 side walls An electric slide rail 4 is provided, and an electric slide block 5 is provided for sliding inside the electric slide rail 4, and an elevating seat 6 is provided for sliding on the electric slide block 5; A punching seat 8 is provided, and a punching head 9 is provided at the bottom of the punching seat 8;

[0028] Start the electric slide rail 4, which can realize the movement of the electric slider 5, and then realize the movement of the lifting seat 6, and at the same time move through the punching head 9, and then realize the punching effect;

[0029] Both sides of the punching head 9 are provided with protective components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com