New-generation information technology photoelectric module shell punching device

A technology of photoelectric modules and information technology, applied in the direction of feeding devices, storage devices, positioning devices, etc., can solve the problems of automatic punching, automatic delivery of module shells, and automatic clamping of module shells, etc., to achieve The effect of the sliding collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

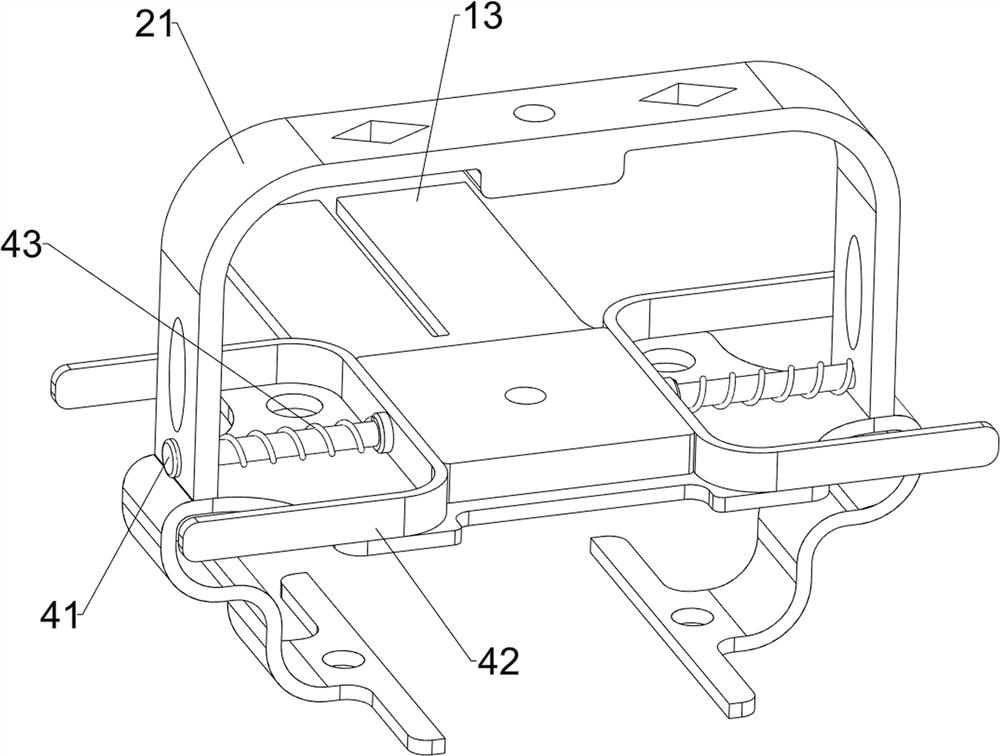

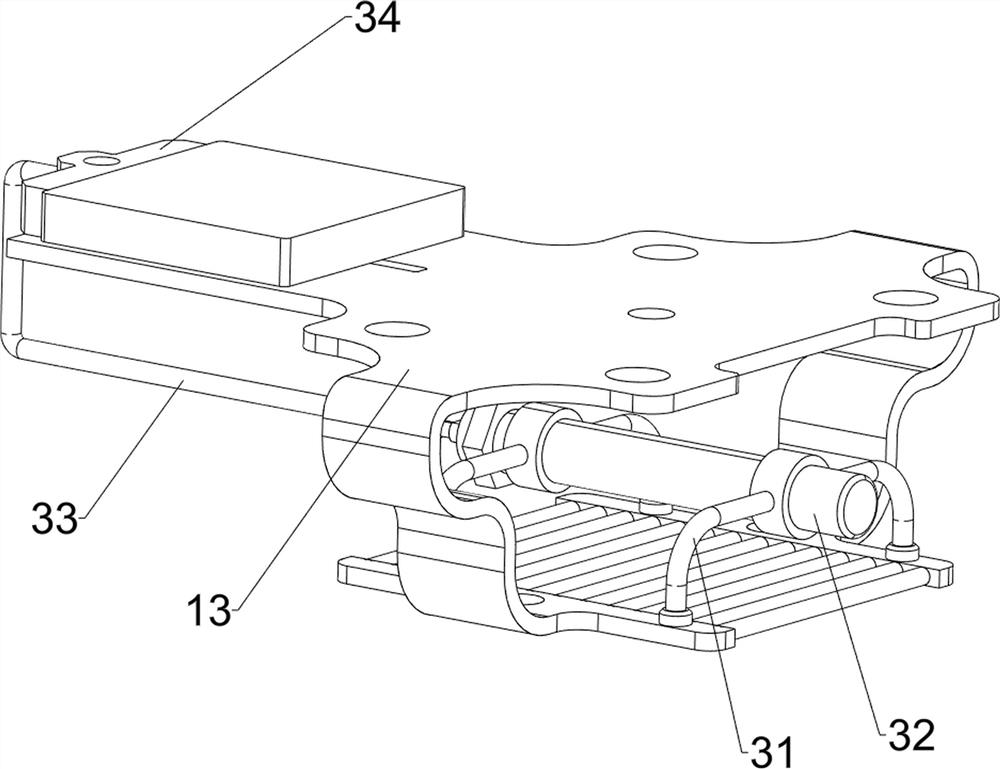

[0056] A new generation of information technology photoelectric module shell punching device, such as Figure 1-Figure 3 As shown, it includes a base 1, a pillar 11, a discharge box 12, a workbench 13, a slideway 14, a collection box 15, a punching mechanism 2 and a feeding mechanism 3, the base 1 is provided with a pillar 11, and the upper part of the pillar 11 is provided with Discharging box 12, pillar 11 front side is provided with workbench 13, and workbench 13 front side is provided with collection box 15, and collection box 15 rear side top is provided with slideway 14, and workbench 13 is provided with punching mechanism 2, and work The stage 13 is provided with a feeding mechanism 3 .

[0057] When people want to punch the module shell, this new generation of information technology photoelectric module shell punching device can be used. At first, the user puts the module shell into the discharge box 12, and the module shell is dropped by the discharge box Fall on the...

Embodiment 2

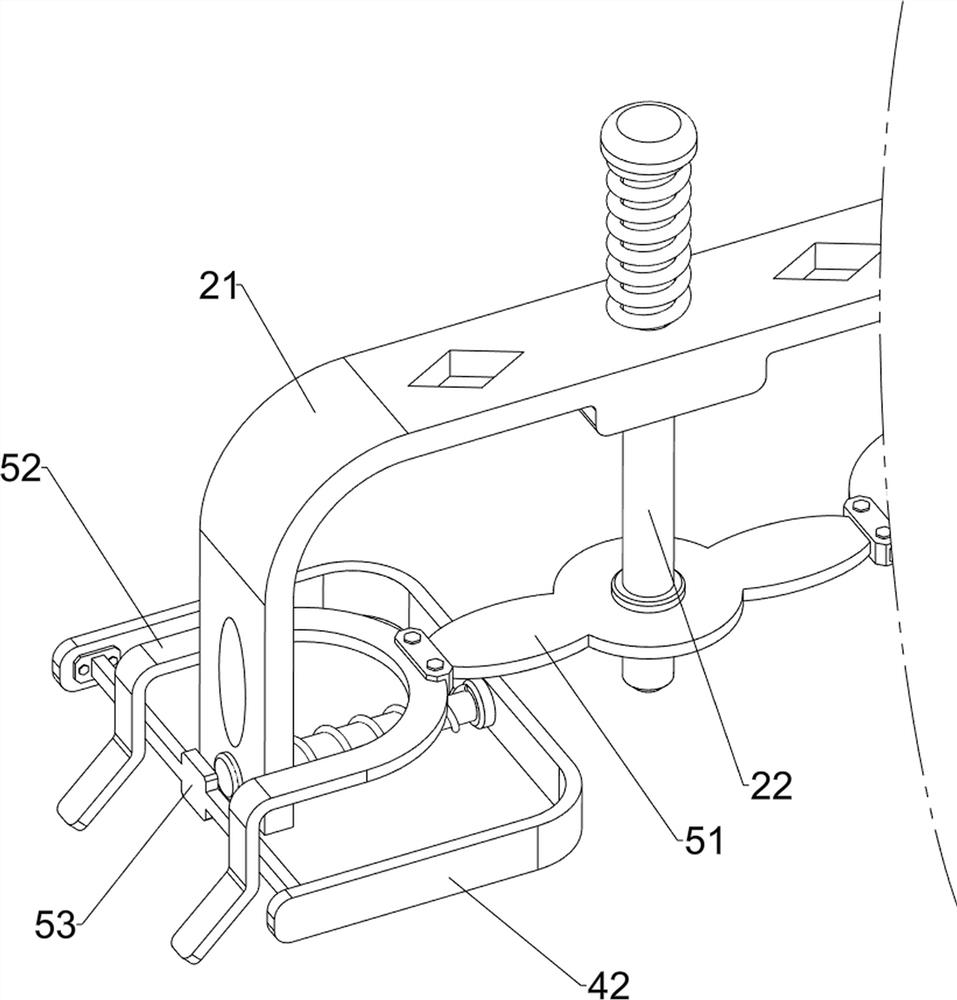

[0063] On the basis of Example 1, such as Figure 4-Figure 7 As shown, a clamping mechanism 4 is also included. The first bracket 21 is provided with a clamping mechanism 4. The clamping mechanism 4 includes a second sliding column 41, a clamp 42 and a second spring 43. The left and right sides of the first bracket 21 The even sliding type is provided with a second sliding post 41, two second sliding posts 41 are provided with clamps 42, two second sliding posts 41 are wound with a second spring 43, and the two ends of the second spring 43 are connected with the clamps respectively. 42 is connected with the first bracket 21.

[0064] When the module casing is located below the first sliding column 22, the user pushes the clamp 42 inwardly, the clamp 42 drives the second sliding column 41 to move inwardly, the second spring 43 is stretched, and after the clamp 42 contacts the module casing, the clamp 42 42 Clamp the module shell to achieve the effect of the clamp 42 clamping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com