A small log center punching integrated device

A technology for small logs and workbenches, which is used in transportation and packaging, conveyor objects, fixed drilling machines, etc., can solve the problems of different punching positions, inability to locate small logs, and affect processing, etc., and achieves simple operation, Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

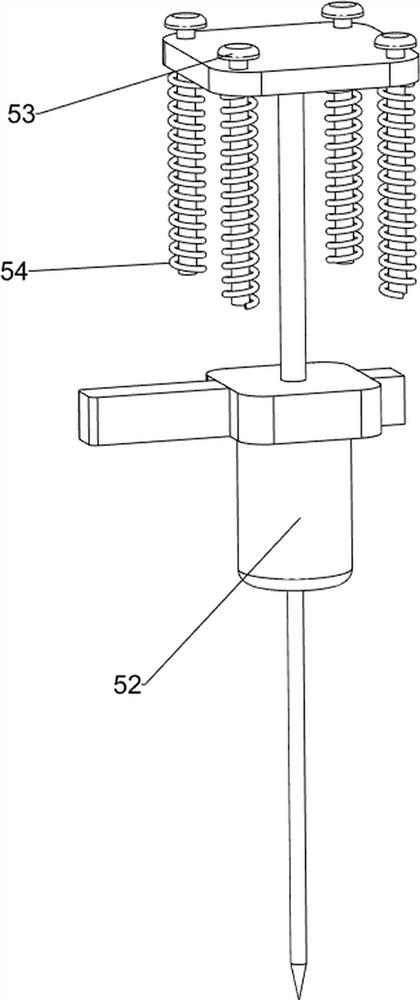

[0034] An integrated device for punching holes in the center of a small log, such as Figure 1 to Figure 4 As shown, it includes a bottom plate 1, a workbench 2 and a hydraulic cylinder 3, a workbench 2 is connected to the top of the bottom plate 1, a hydraulic cylinder 3 is installed on the right side of the top of the workbench 2, and also includes a feeding mechanism 4 and a punching mechanism 5, A feeding mechanism 4 is provided between the worktable 2 and the hydraulic cylinder 3 , and a punching mechanism 5 is provided on the worktable 2 , and the feeding mechanism 4 is connected with the punching mechanism 5 by transmission.

[0035] The feeding mechanism 4 includes a connecting block 41 , a material pushing long plate 42 , a U-shaped baffle 43 , and a discharging cylinder 44 , a connecting block 41 is connected to the telescopic rod of the hydraulic cylinder 3 , and the connecting block 41 is slidingly matched with the worktable 2 , the connecting block 41 is connected...

Embodiment 2

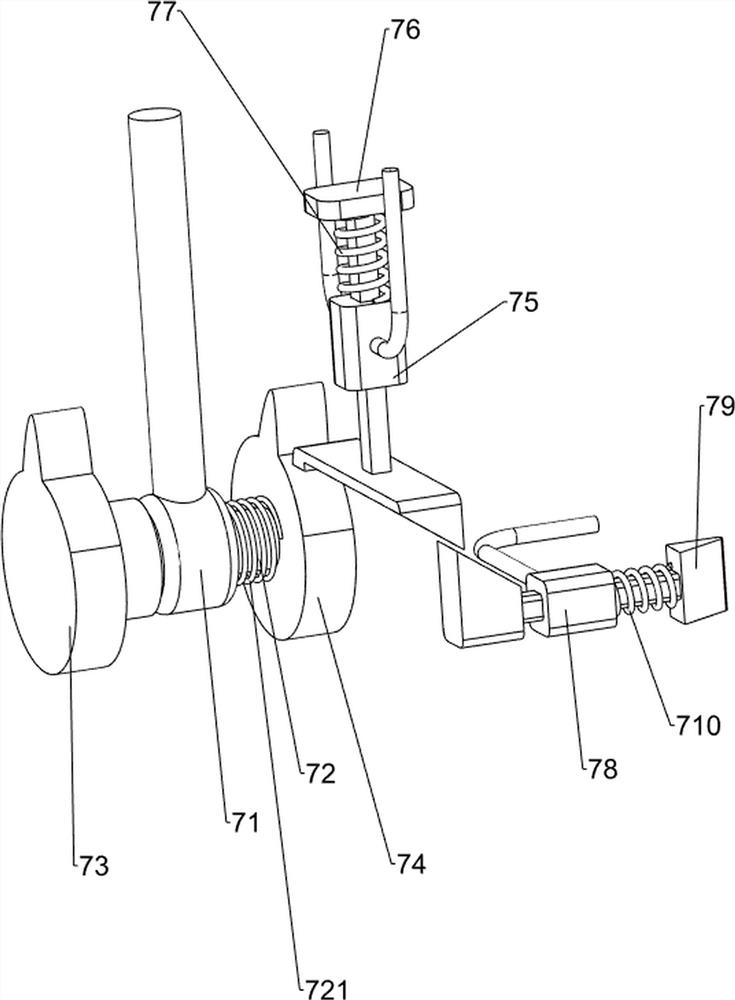

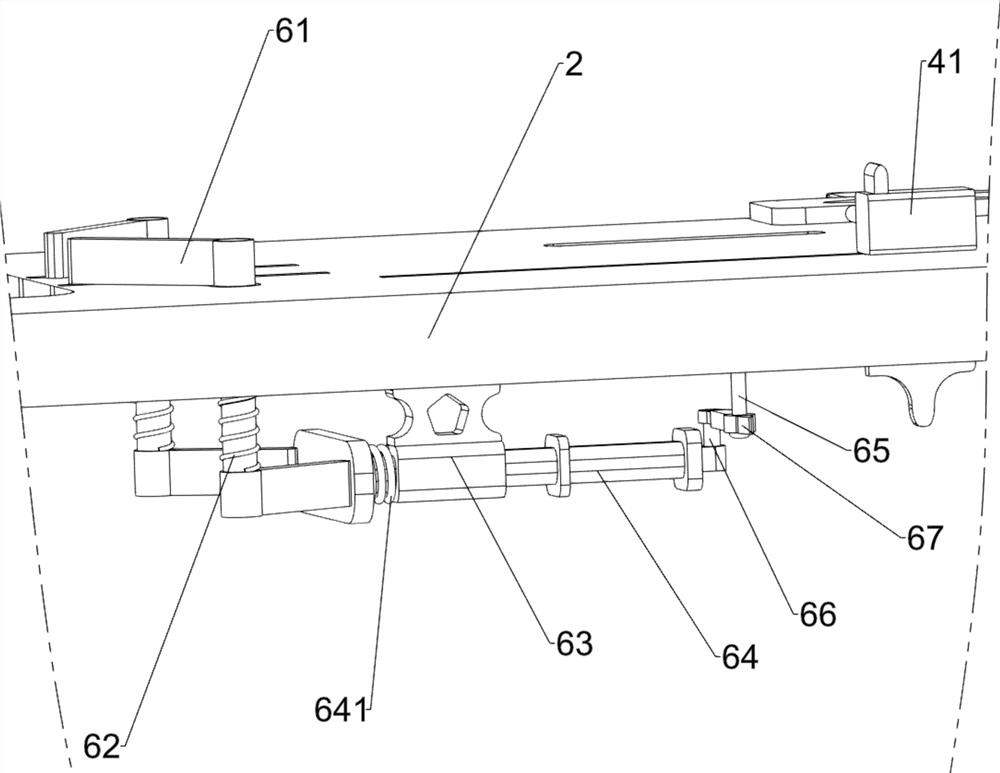

[0039] On the basis of Example 1, as Figure 5 to Figure 8 As shown, a clamping mechanism 6 and a clamping mechanism 7 are also included. The worktable 2 is provided with a clamping mechanism 6 and a clamping mechanism 7, and the clamping mechanism 6 and the clamping mechanism 7 are connected by transmission.

[0040] The clamping mechanism 6 includes a double-headed plate 61, a first torsion spring 62, a fixed guide block 63, a first push plate 64, a first rotating shaft 65, a second rotating shaft 66, a sliding link 67 and a large pressure spring 641. Both the front and rear sides of the table 2 are rotatably connected with a double-headed plate 61, a first torsion spring 62 is connected between the double-headed plate 61 and the worktable 2, a fixed guide block 63 is connected to the inner top of the worktable 2, and the inside of the fixed guide block 63 A first push plate 64 is slidably connected, the first push plate 64 cooperates with the double-headed plate 61, a large...

Embodiment 3

[0044] On the basis of Example 2, as Figures 9 to 10 As shown, it also includes a pushing mechanism 8, and the pushing mechanism 8 includes a third guide sleeve 81, a long connecting rod 82, a second push plate 83, a fourth compression spring 84, a second elastic dial 85 and a third elastic Dial block 86, a third guide sleeve 81 is connected to both the front and rear sides of the inner top of the workbench 2, a long connecting rod 82 is slidably connected to the third guide sleeve 81, and a second connecting rod 82 is connected between the right sides of the long connecting rods on both sides. Push plate 83, a fourth compression spring 84 is connected between the second push plate 83 and the third guide sleeve 81, the second push plate 83 is slidingly matched with the table 2, and the left side of the two long connecting rods 82 is connected with a second The elastic dial 85 and the second elastic dial 85 are slidably matched with the worktable 2 , and a third elastic dial 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com