Quick footwear upper punching device for shoe production

A technology for punching equipment and shoe uppers, which is applied to footwear, applications, heel pads, etc., and can solve the problems of low punching efficiency and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

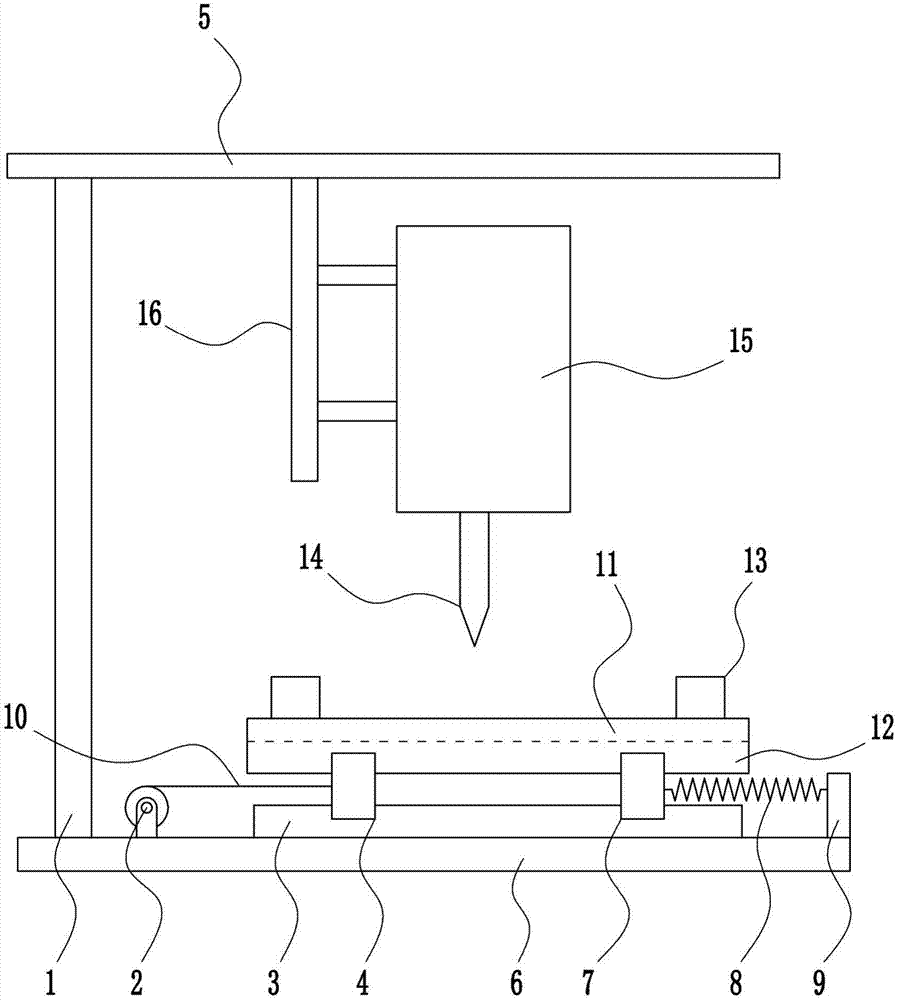

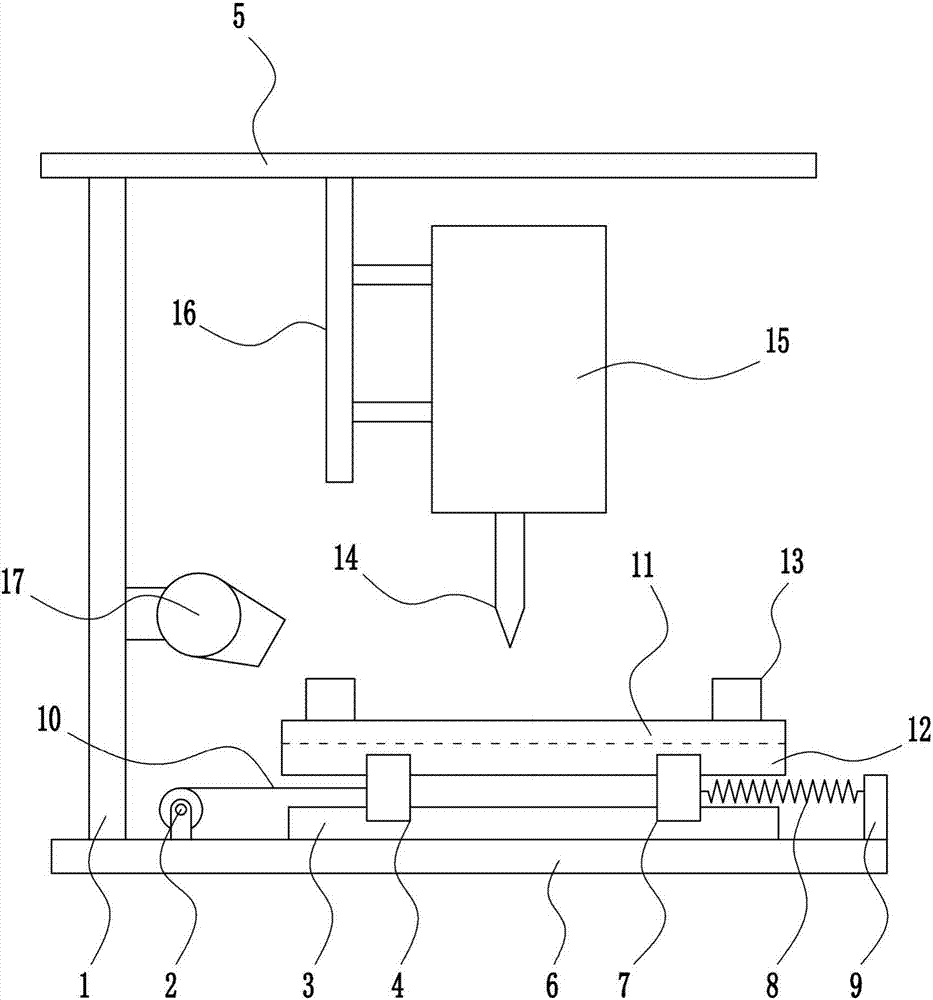

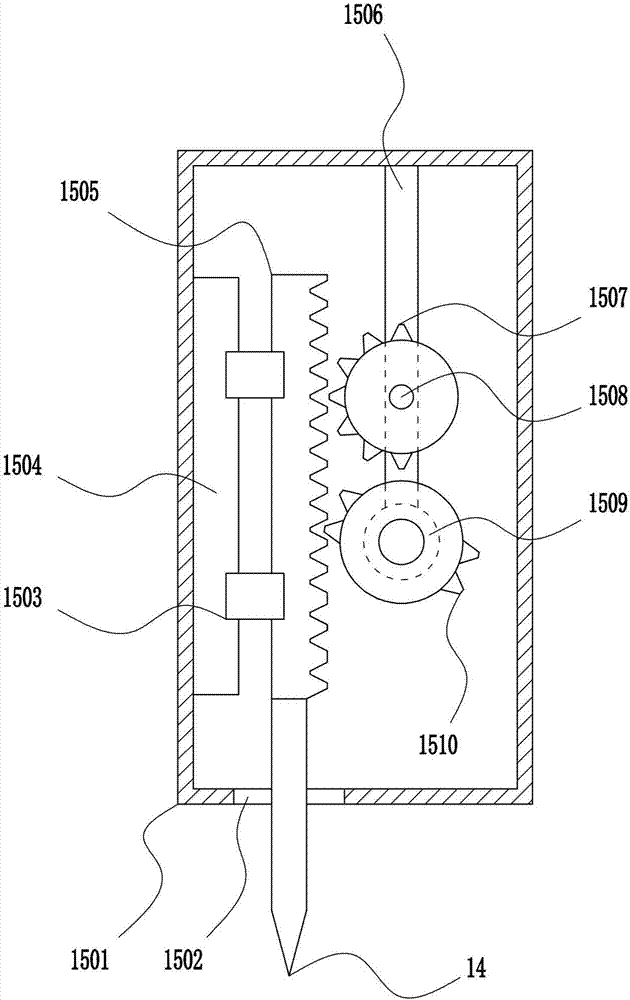

[0029] A kind of shoe upper fast punching equipment for making shoes, such as Figure 1-4 As shown, it includes a left frame 1, an electric reel 2, a first slide rail 3, a first slide block 4, a top plate 5, a bottom plate 6, a second slide block 7, a first spring 8, a baffle plate 9, and a pull wire 10 , console 12, fixing device 13, drill bit 14, lifting device 15 and fixed frame 16, the left frame 1 is welded on the left side of the bottom plate 6 top, the first slide rail 3 is connected with the mode of bolt connection in the middle of the bottom plate 6 top, the first The upper end of the slide rail 3 is slidingly connected with the first slider 4 and the second slider 7, the first slider 4 is located on the left side of the second slider 7, and the left side of the top of the bottom plate 6 is connected with an electric reel by means of screw connection 2. The electric reel 2 is located between the left frame 1 and the first slide rail 3. The electric reel 2 is wound wit...

Embodiment 2

[0031] A kind of shoe upper fast punching equipment for making shoes, such as Figure 1-4As shown, it includes a left frame 1, an electric reel 2, a first slide rail 3, a first slide block 4, a top plate 5, a bottom plate 6, a second slide block 7, a first spring 8, a baffle plate 9, and a pull wire 10 , console 12, fixing device 13, drill bit 14, lifting device 15 and fixed frame 16, the left frame 1 is welded on the left side of the bottom plate 6 top, the first slide rail 3 is connected with the mode of bolt connection in the middle of the bottom plate 6 top, the first The upper end of the slide rail 3 is slidingly connected with the first slider 4 and the second slider 7, the first slider 4 is located on the left side of the second slider 7, and the left side of the top of the bottom plate 6 is connected with an electric reel by means of screw connection 2. The electric reel 2 is located between the left frame 1 and the first slide rail 3. The electric reel 2 is wound with...

Embodiment 3

[0034] A kind of shoe upper fast punching equipment for making shoes, such as Figure 1-4 As shown, it includes a left frame 1, an electric reel 2, a first slide rail 3, a first slide block 4, a top plate 5, a bottom plate 6, a second slide block 7, a first spring 8, a baffle plate 9, and a pull wire 10 , console 12, fixing device 13, drill bit 14, lifting device 15 and fixed frame 16, the left frame 1 is welded on the left side of the bottom plate 6 top, the first slide rail 3 is connected with the mode of bolt connection in the middle of the bottom plate 6 top, the first The upper end of the slide rail 3 is slidingly connected with the first slider 4 and the second slider 7, the first slider 4 is located on the left side of the second slider 7, and the left side of the top of the bottom plate 6 is connected with an electric reel by means of screw connection 2. The electric reel 2 is located between the left frame 1 and the first slide rail 3. The electric reel 2 is wound wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com