A rosary punching device

A technology of punching equipment and rosary beads, which is applied in metal processing and other directions, can solve the problems of punching equipment that easily hurts hands, consumes manpower, and safety accidents, and achieves the effects of saving manpower, simple operation, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

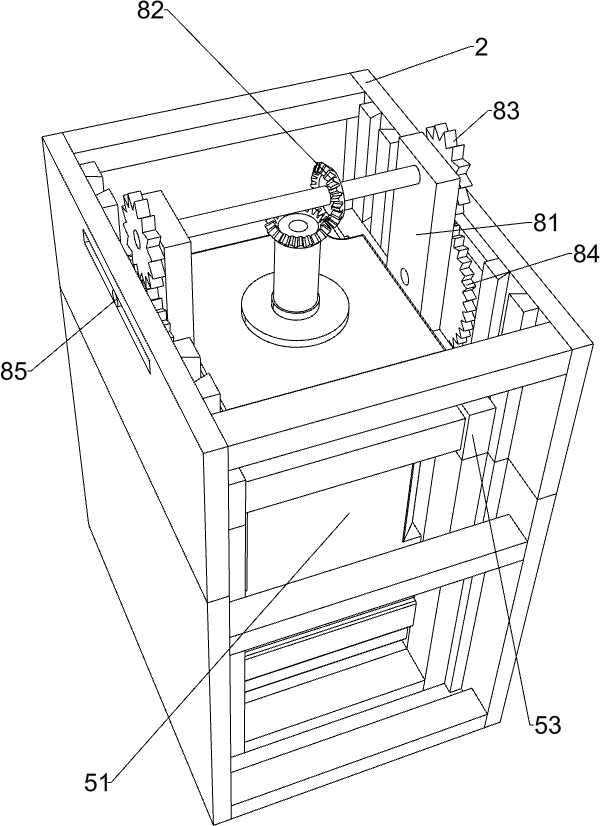

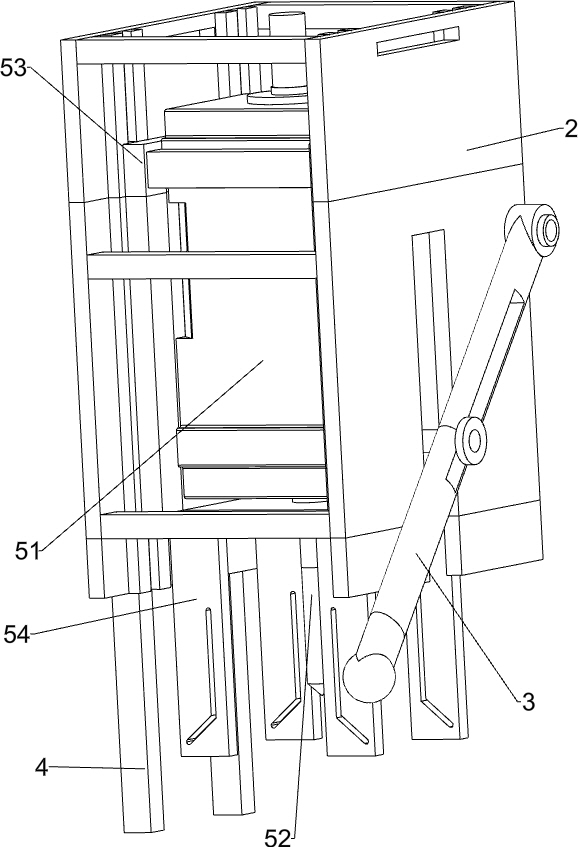

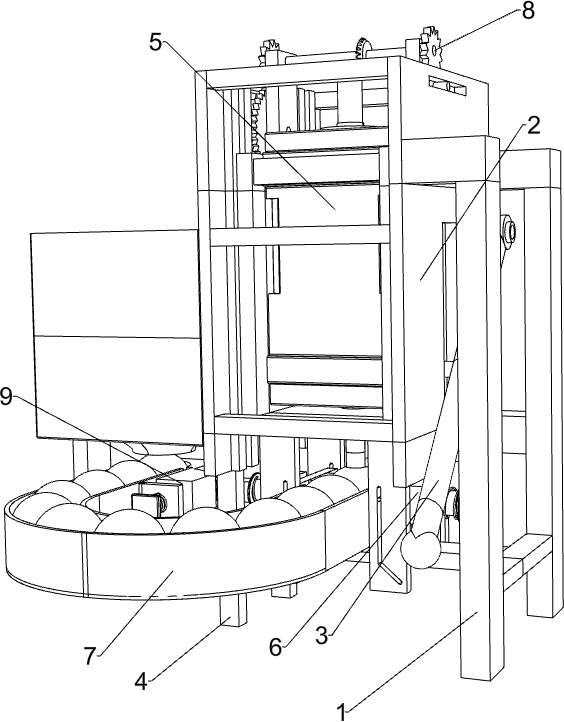

[0026] A rosary punching device such as Figure 1-5 As shown, it includes a right leg 1, a fixed frame 2, a rocker 3 and a left leg 4. The left side of the right leg 1 is connected with a fixed frame 2, and the fixed frame 2 is rotatably connected with a rocker 3, and the fixed frame 2 The left side is connected with a left leg 4, and also includes a manual drilling assembly 5, a clamping assembly 6 and a manual feeding assembly 7. A manual drilling assembly 5 is provided between the fixed frame 2 and the rocker 3, and the left leg 4 and A clamping assembly 6 and a manual feeding assembly 7 are arranged between the right legs 1 .

[0027] The manual drilling assembly 5 includes a biaxial motor 51, a drill bit 52, a motor mounting seat 53 and a guide block 54. A motor mounting seat 53 is slidably connected in the fixed frame 2, and a biaxial motor 51 is installed in the motor mounting seat 53. The motor The mounting seat 53 is slidingly matched with the rocker 3 , a drill bit ...

Embodiment 2

[0032] On the basis of Example 1, as Figure 4 As shown, it also includes an automatic drilling assembly 8. The automatic drilling assembly 8 includes a gear mounting plate 81, a bevel gear 82, a first cylindrical gear 83, a second cylindrical gear 84 and a clamping column 85. The top of the motor mounting seat 53 is left and right. The gear mounting plates 81 are connected on both sides, and the upper parts of the gear mounting plates 81 on both sides are rotatably connected with a first cylindrical gear 83. The transmission shafts of the two first cylindrical gears 83 are connected to each other. The bevel gears 82 are connected to the output shafts above the biaxial motor 51. The two bevel gears 82 mesh with each other. The lower parts of the gear mounting plates 81 on both sides are rotatably connected with a second cylindrical gear 84. The second cylindrical gear 84 is connected to the first cylindrical gear 84. The cylindrical gear 83 is meshed, and the outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com