Drilling, punching, screening and transporting integrated gas treatment method

A gas, drill-flushing technology, which is applied in the gas control field of the integration of finger drilling, flushing, and screening, can solve the problems of defective anti-reflection technology and process methods, unsatisfactory effects, and large impact on working face production, and achieves the reduction of links, The effect of increasing input cost and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

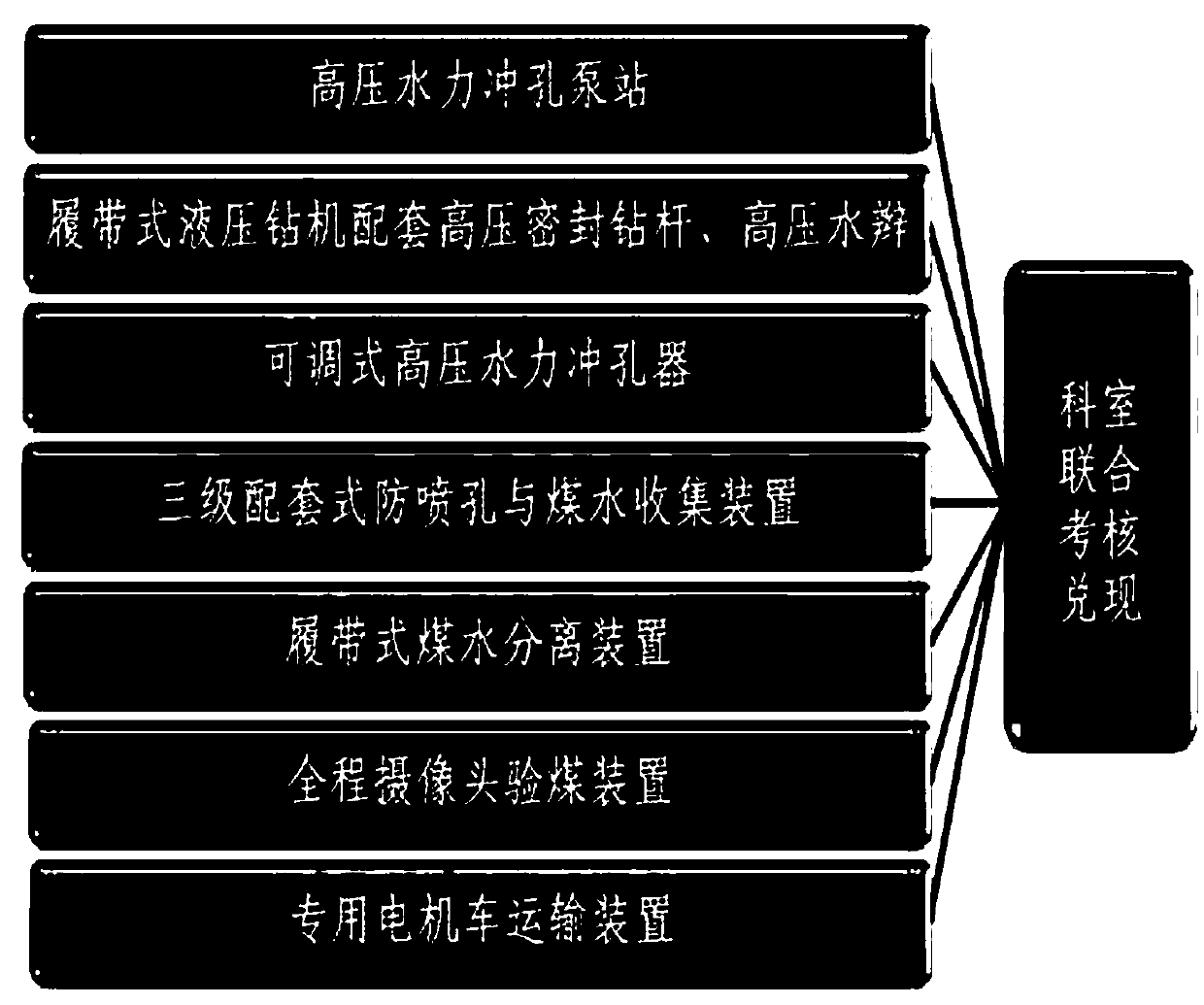

[0033] According to its own conditions, through the continuous practice and summary of the bottom pumping roadway, a set of high-pressure hydraulic drilling, flushing, screening and transportation integration (7+1 mode) process for the bottom pumping roadway is explored, such as figure 1 Shown:

[0034] 1. High-pressure hydraulic punching pump station: Two sets of high-pressure hydraulic punching pumps are installed at the hydraulic punching site of 3205 bottom pumping alley, one for use and one for standby, which can provide water source with a pressure of 31.5MPa and a flow rate of 200L / min for high-pressure hydraulic punching. The water supply pipeline is φ32mm; and a water meter is installed at the water outlet of the pump station, which can record the amount of water required for flushing coal in each borehole. After the coal is seen in the drilling construction, the hydraulic punching pump is turned on, and the hydraulic punching is kept between 8-10Mpa. The punching pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com