Cutting device with moving head

A technology of moving head and workbench, which is applied in metal processing and other directions, can solve the problems of low production efficiency and high energy consumption, and achieve the effects of improving production efficiency, saving punching time, and safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

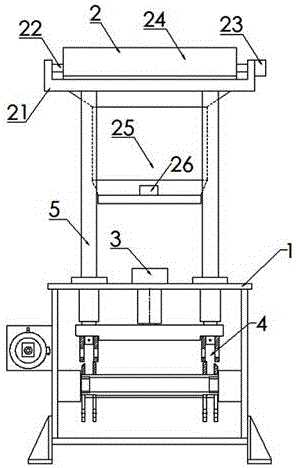

[0010] As shown in Fig. 1, a cutting device with a moving head is composed of a workbench 1 and a moving indenter part 2. The workbench 1 is provided with an oil cylinder device 3 and a balance shaft connected to the oil cylinder device 3. The rod part 4, the column 5 connected with the balance shaft connecting rod part 4, the moving pressure head part 2 is connected on the workbench 1 through the column 5; the oil cylinder device 3 drives the moving pressure head part 2 to press down against the The material is punched; the moving head part 2 consists of an upper platen 21, a lead screw 22 set on the top of the upper platen 21, a servo motor II23 connected to the lead screw 22, and a moving part set on the lead screw 22. The head slide rail 24, the moving head 25 connected on the moving head slide rail 24 and the sensor 26 arranged on the moving head 25 are composed; the moving head 25 is controlled by the servo motor II 23 to move left and right, and is sensed by the sensor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com