Reciprocating type punching device

A punching device, reciprocating technology, applied in the direction of punching machines, presses, manufacturing tools, etc., can solve the problems of increased grinding time, reduced efficiency, reduced hydraulic oil impact force, etc., to improve punching efficiency and reduce Grinding time, effect of reducing punching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

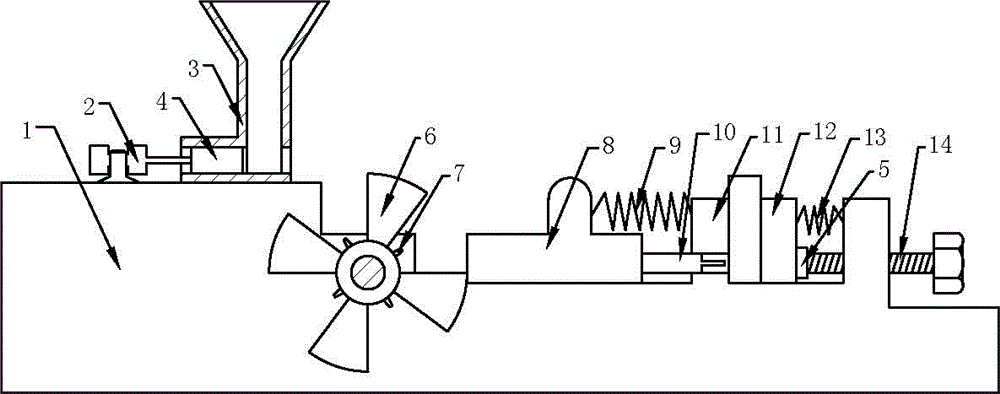

[0016] The reference signs in the drawings of the description include: frame 1, cylinder 2, hopper 3, push block 4, backing plate 5, partition plate 6, flame nozzle 7, push plate 8, compression spring 9, punch 10, fixed Clamping plate 11, punching seat 12, extension spring 13, screw rod 14.

[0017] Example basic reference figure 1 Shown: a reciprocating punching device, including a frame 1, a punch 10 and a punching seat 12 sequentially arranged on the frame 1, and a fixed frame 1 is fixed on the frame 1 between the punch 10 and the punching seat 12. The splint 11, the fixed splint 11 is integrally formed with the frame 1, the punch 10 passes through the fixed splint 11 and is slidably connected with the fixed splint 11, the compression spring 9 is connected between the punch 10 and the fixed splint 11, and the punching seat 12 is slidably connected On the frame 1, a q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com