Aluminum alloy plate machining and drilling device

An aluminum alloy sheet and punching device technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing drilling time, increasing labor force, inconvenient plate processing, etc. Hole time, improve the efficiency of punching operations, and improve the effect of operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

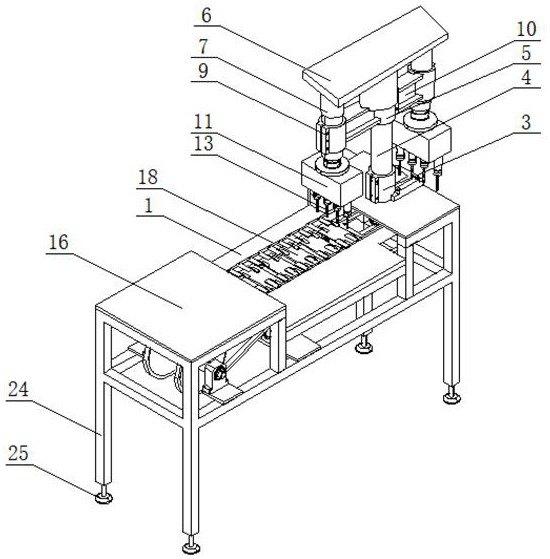

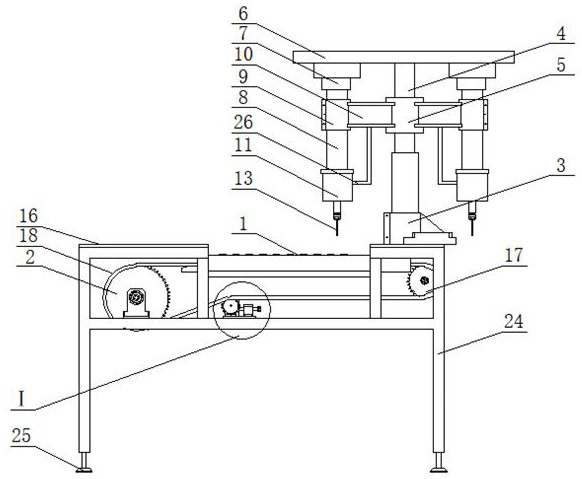

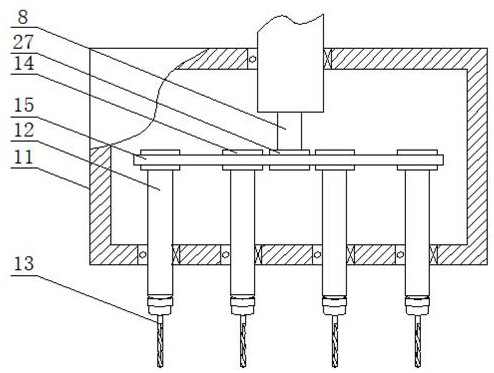

[0028] When using this device, first place the aluminum alloy plate to be punched on the workbench 1, then the transmission motor 7 located inside the workbench 1 works, the transmission motor 7 drives the connecting shaft 8 to rotate, and the rotation of the connecting shaft 8 drives the first The second sprocket 27 rotates, and the second sprocket 27 rotates through the cooperation of the chain 15 and the first sprocket 14, and simultaneously drives several connecting rods 12 to rotate, and the rotating of the connecting rods 12 drives the drill bit 13 to rotate, and then the telescopic rod 4 shrinks downwards. The telescopic rod 4 contracts to drive the horizontal plate 6 to move downward, and the movement of the horizontal plate 6 drives the drill bit 13 to move downward. The drill bit 13 contacts the top surface of the plate and performs drilling operations on the plate. The horizontal plate 6 moves upward, the movement of the horizontal plate 6 drives the drill bit 13 to ...

Embodiment 2

[0030] When it is necessary to punch holes of different sizes on the same plate, the drill bits 13 with different diameters can be installed on different connecting rods 12 .

[0031]The invention is simple in structure and easy to use. By arranging multiple drill bits, one plate can be drilled at the same time, which saves drilling time and improves the efficiency of drilling operations. When a failure occurs, another group of punching groups can be quickly replaced, which shortens the downtime, ensures the continuity of the punching operation, further improves the working efficiency, and brings convenience to the plate punching operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com