Straight down type voice diaphragm punching die

A punching die, straight drop technology, applied in the field of punching die, can solve the problems of low sound film efficiency, long operation time and many processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

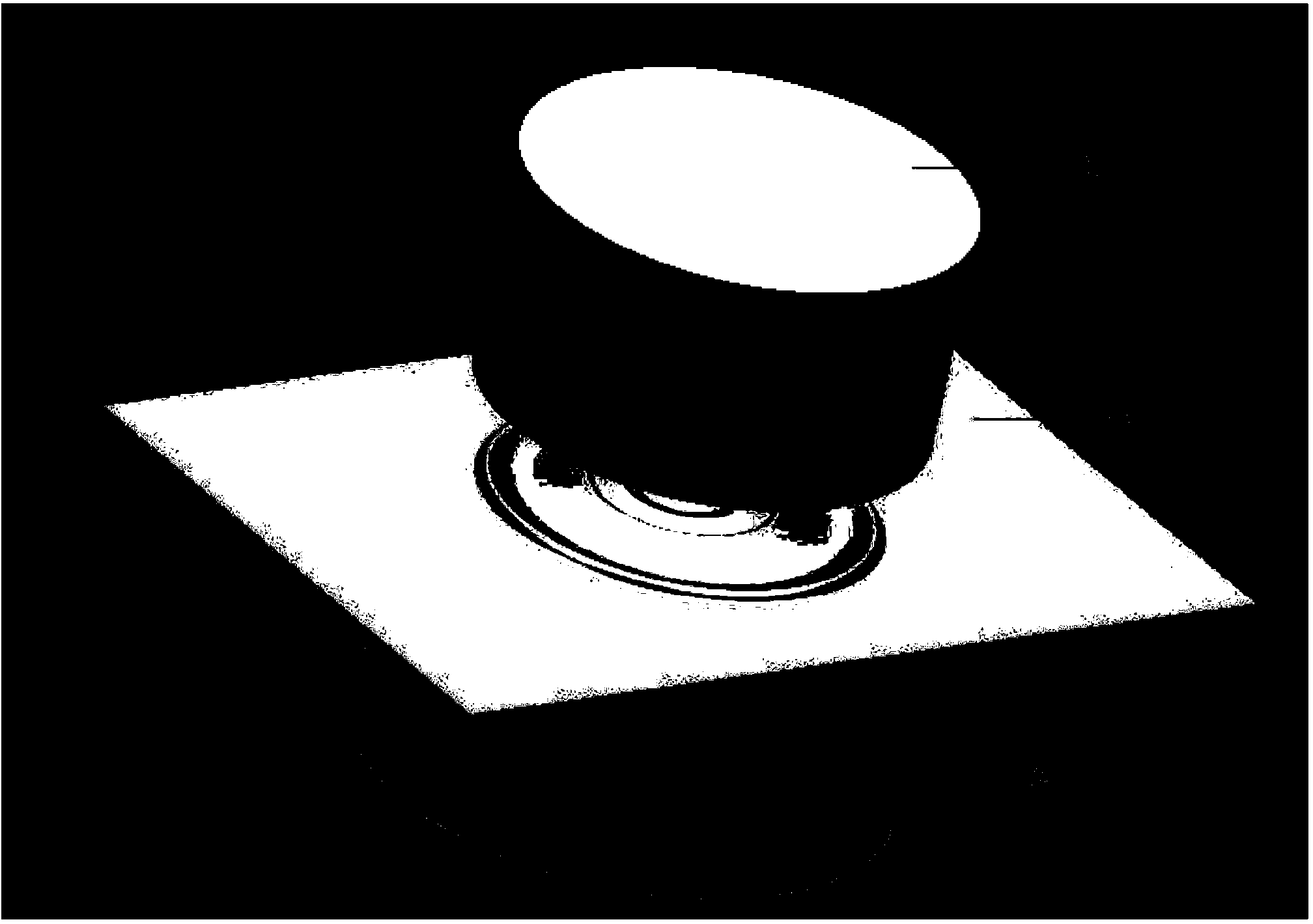

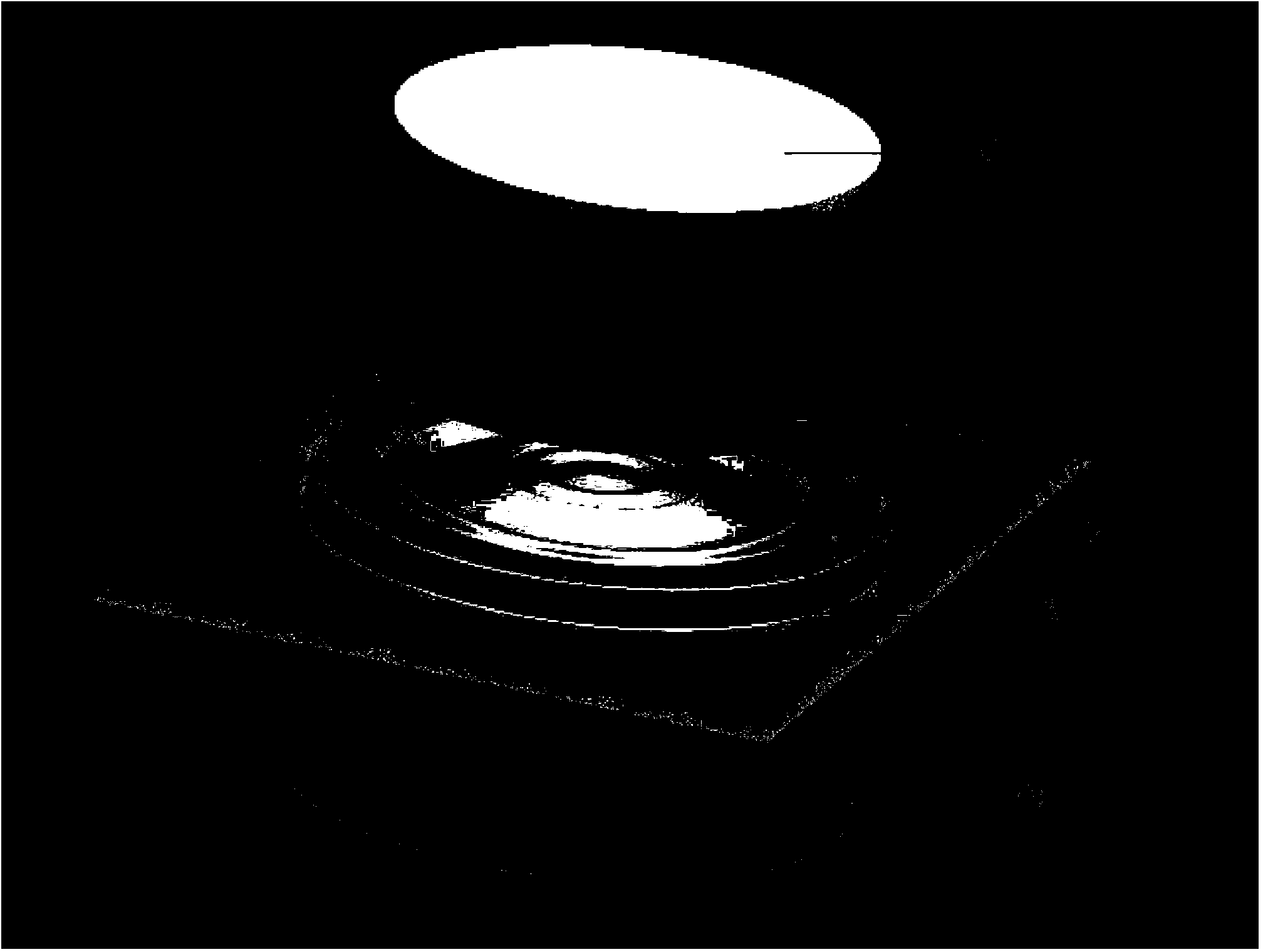

[0015] Such as image 3 and Figure 4 As shown, the straight-fall sound film punching die of the present invention includes a corresponding upper knife edge 1 and a lower knife edge 3, and the lower knife edge 3 is an annular cylinder with a hollow interior. The upper end of the lower knife edge 3 is provided with a sound film 2 to be punched, and the edge of the sound film 2 to be punched is folded inward along the vertical direction to form a positioning ring 6 that fits the outer contour of the lower knife edge. The working principle of the present invention is as follows: because the positioning ring 6 in the vertical direction of the sound film 2 to be punched fits the outer contour of the lower knife edge 3, the sound film 2 to be punched can be directly placed on the lower knife edge of the annular cylinder The upper end of 3 is fixed; start the upper knife edge 1 to punch downward, and the punched sound film can drop directly from the hollow part of the lower knife ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com