Pot cover manufacturing method

A manufacturing method and technology of pot lids, which are applied to cooking utensil lids and other directions, can solve the problems of many production processes, low material utilization rate, and easy dripping of water vapor in the lids into the dishes, and achieve the effect of saving punching processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

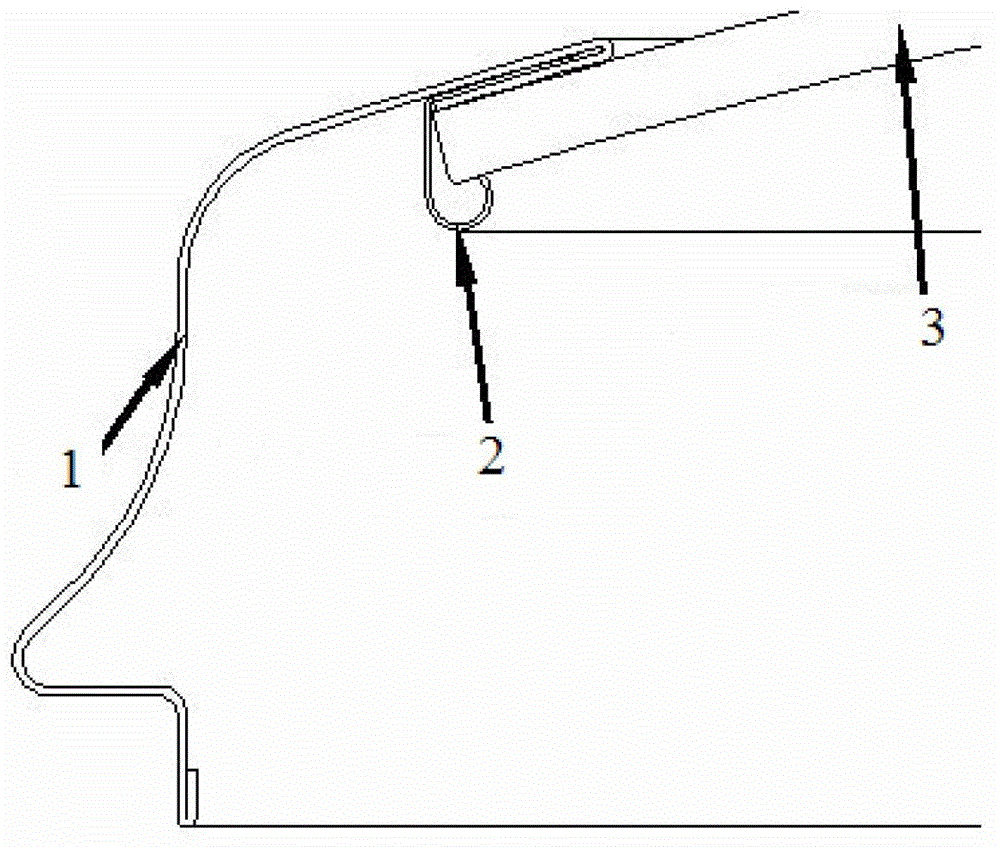

[0017] refer to figure 1 , the manufacture method of pot cover, described method comprises the steps:

[0018] a. Strip butt welding;

[0019] b. Piping;

[0020] c. Steel body 1 is formed after roll forming;

[0021] d, the wrapping ring 2 is rolled with the steel body 1;

[0022] E, glass 3 is put into described hemming ring 2;

[0023] f. Roll glass 3.

[0024] Further, the hemming ring 2 is formed by butt-welding strips and rolling.

[0025] Further, the glass 3 is sintered from the lower wafer.

[0026] Said pot cover in the present invention comprises steel body 1, wrapping circle 2 and glass 3, described glass 3 is inlaid in described steel body 1, and described glass 3 is arranged on the top of described steel body 1, and described glass 3 is pressed in the steel body 1 by the hemming ring 2 fixed in the steel body 1 .

[0027] The content described in the embodiments of this specification is only an enumeration of the implementation forms of the inventive conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com