Method for manufacturing flexible printed circuit board

A manufacturing method and circuit board technology, applied in the field of circuit boards, can solve the problems of high window opening precision requirements, cumbersome processing procedures, long manufacturing cycles, etc., and achieve the effects of reducing manufacturing difficulty, saving processes, and reducing production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

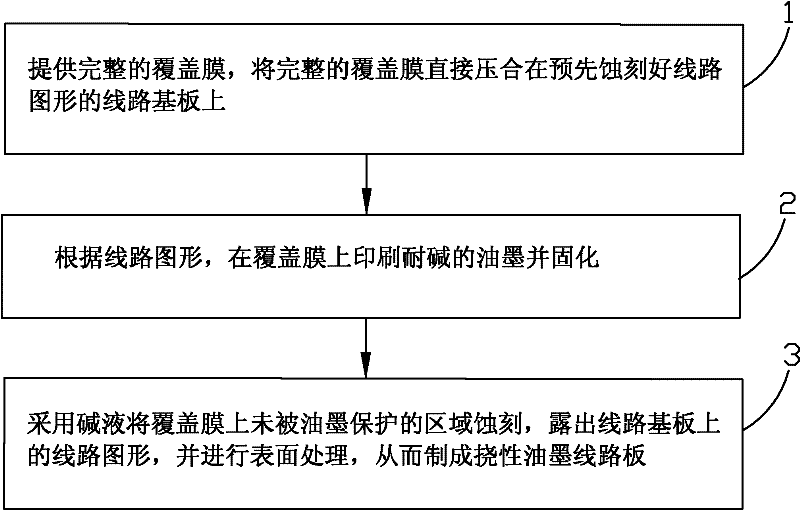

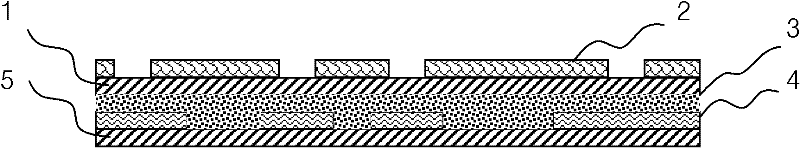

[0019] refer to figure 1 , combined with Figure 2-4 Shown, the manufacturing method of flexible ink circuit board of the present invention, it comprises the following steps:

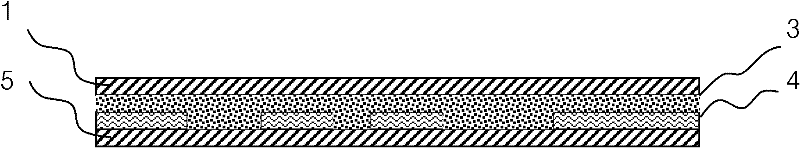

[0020] Step 1, provide a complete cover film, and directly press the complete cover film on the circuit substrate 5 with the circuit pattern etched in advance (such as figure 2 shown); wherein, the cover film includes an insulating base film 1 and an insulating adhesive layer 3 disposed on the insulating base film 1, and the insulating base film 1 includes a polyimide (PI) film, a polyester (PET) film, Polynaphthyl ester (PEN) film or liquid crystal polymer (LCP) film, etc., its thickness is 10-100 μ m, and the insulating adhesive layer 3 includes epoxy resin adhesive, acrylate adhesive, polyester adhesive, polyurethane adhesive or polyester adhesive Imide glue system, etc., the thickness is 10-50μm. In the present invention, no window is opened on the cover film, but the complete cover film is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com