Frame-coated partition batten wall and mounting method thereof

A partition wall slatted and cladding technology, which is applied in the processing of walls, buildings, and building materials, etc., can solve the problem of poor overall strength and sound insulation effect of partition wall slatted walls, reduced on-site construction efficiency, and complicated construction procedures, etc. problems, to achieve the effect of convenient assembly, high construction efficiency and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

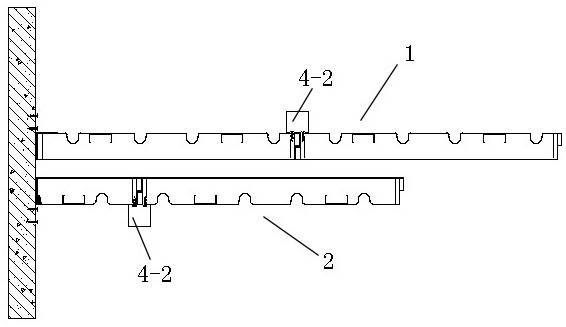

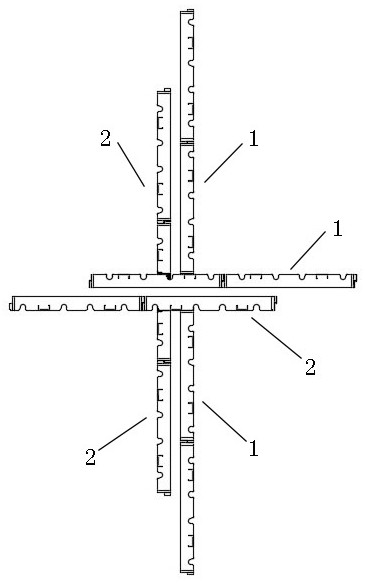

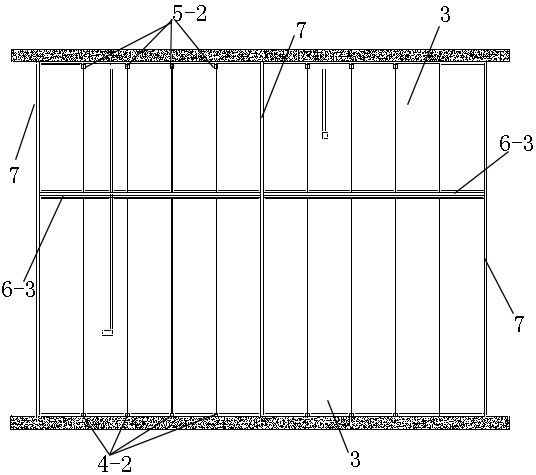

[0050] Embodiment one: if figure 1 , figure 2 As shown, a frame-wrapped partition wall slatted wall includes a first wall 1 and a second wall 2 that are arranged in parallel and are spliced by partition slats 3 .

[0051] Such as image 3 and Figure 4 As shown, the first wall body 1 is connected to the ground through the first connection structure and connected to the top surface through the second connection structure. The connection structure between the second wall body 2 and the ground is the same as the first connection structure, and the connection structure between the second wall body 2 and the top surface is the same as the second connection structure.

[0052] Such as Figure 5 and Figure 6 As shown, the first connection structure includes an L-shaped long keel-4-1 and an L-shaped point-shaped keel-4-2. The first side body of the L-shaped long keel-4-1 is connected to the ground and is used to support the bottom surface of the first wall 1, and the second si...

Embodiment 2

[0068] Embodiment 2: A method for installing a frame-wrapped partition wall slatted wall, comprising the following steps

[0069] L1 respectively splices the partition wall strips 3 to form the first wall 1 and the second wall 2 . Wherein, the specific structure of partition wall batten 3 is as follows: Figure 11 and Figure 12 As shown, it includes a peripheral frame body 3-1, a foamed cement body 3-3 that is arranged in the frame of the peripheral frame body 3-1 and has a pipeline groove 3-2 on one surface, and is embedded in the foamed cement body 3-3. The light steel keel 3-4 inside the cement body 3-3. The peripheral frame 3-1 includes a first enclosure, a second enclosure, a third enclosure and a fourth enclosure which are sequentially connected end to end, and a first splicing protrusion and a first splicing protrusion arranged on the second enclosure. The second splicing protrusions are arranged on the fourth coaming plate, and two adjacent partition wall strips ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com