GIL leg installation punching method and punching robot

A technology of robots and multi-joint robots, applied in manipulators, program-controlled manipulators, workshop equipment, etc., can solve problems such as low efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

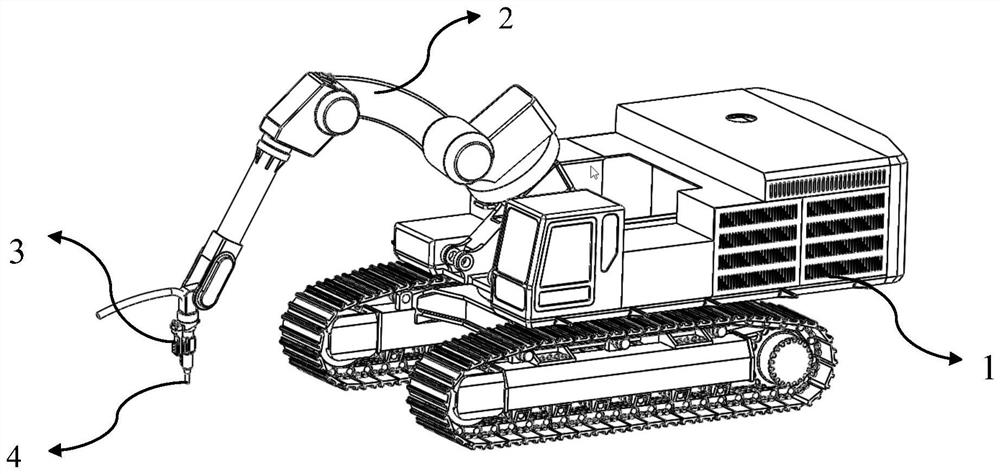

[0022] Such as figure 1 As shown, the punching robot mainly consists of a multi-mode walking chassis vehicle 1, a multi-joint robot 2 installed on the multi-mode walking chassis vehicle 1, an industrial vision system 3 fixed on the arm of the multi-joint robot 2, and a multi-joint robot fixed on the multi-joint robot. The drilling machine 4 at the end of the arm of the robot 2 is composed; the industrial vision system 3 mainly includes a camera system, a computing system and a light source system. Utilize described punching robot to be able to finish following work:

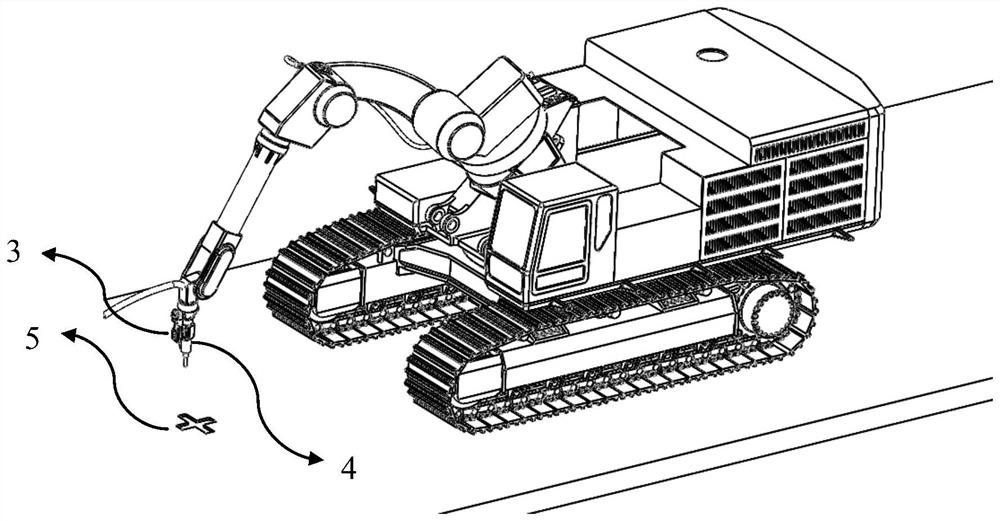

[0023] Step1 Workers draw lines on the hardened ground according to the GIL construction drawings, determine the positions of the holes and mark the hole positions 5;

[0024] Step2 The drilling robot moves to the working area driven by the multi-mode walking chassis vehicle 1;

[0025] Step3 industrial vision system 3 takes pictures of the hole site 5 (such as figure 2 shown);

[0026] Step4 The multi-joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com