Patents

Literature

46results about How to "Improve smoothness of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

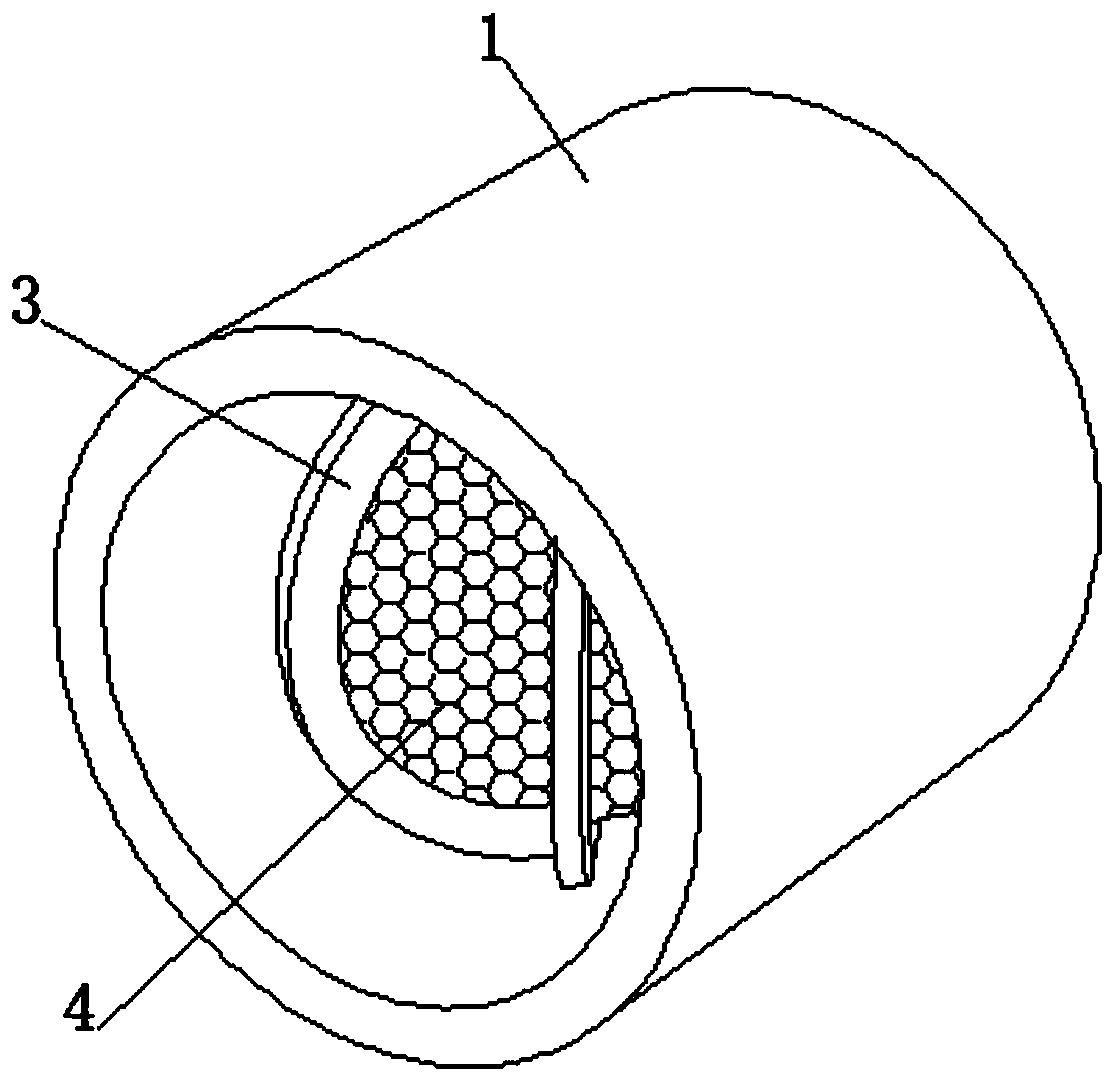

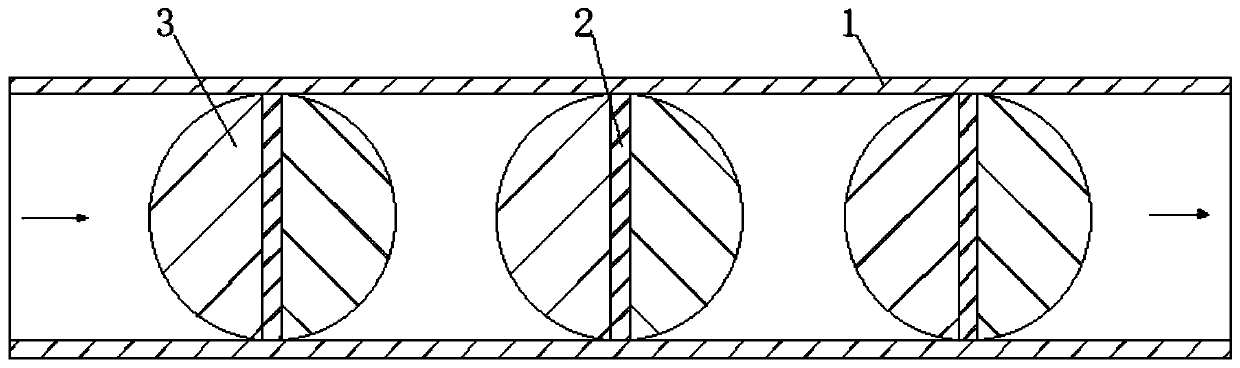

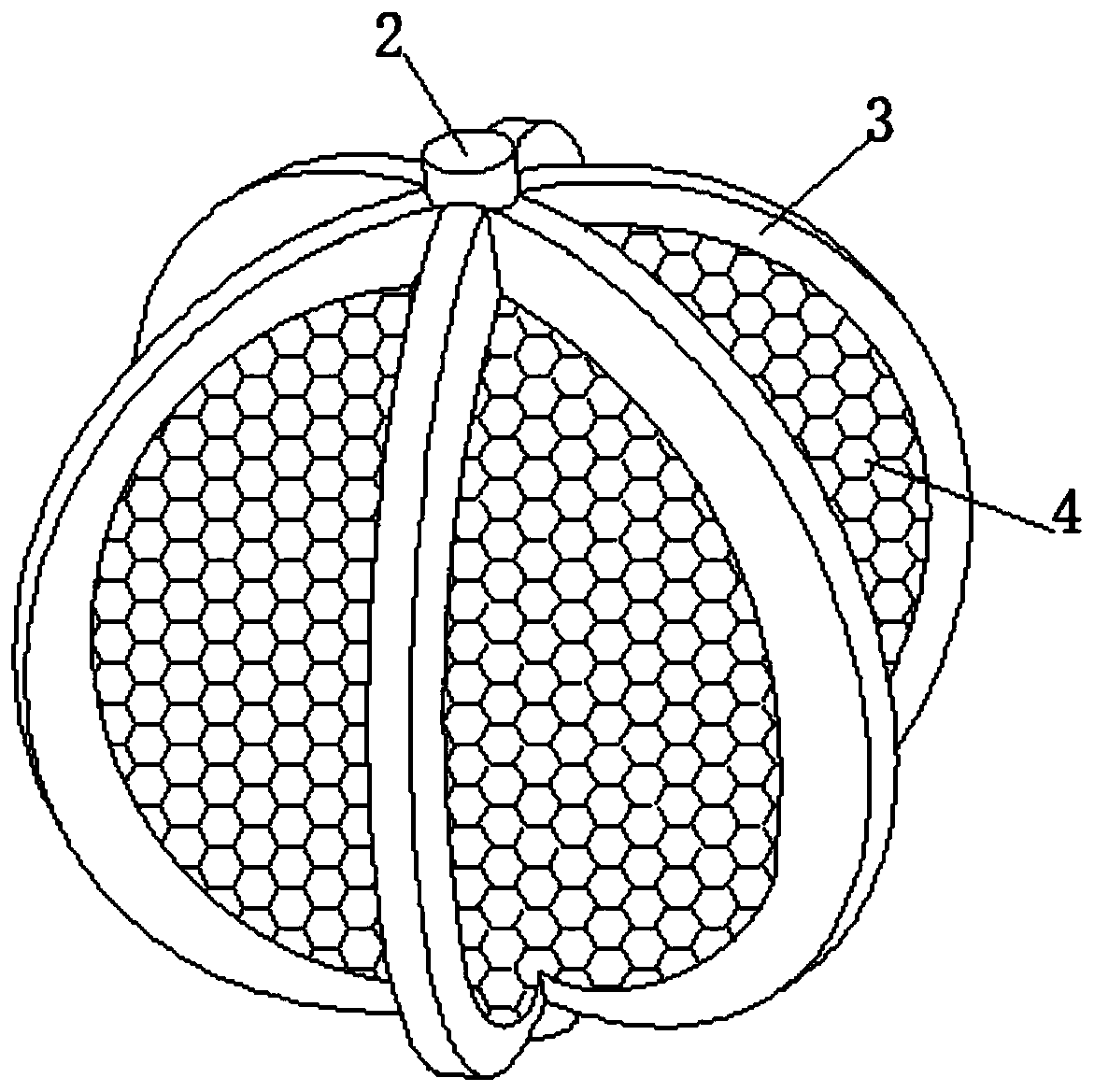

Waste gas purification equipment for medical waste incinerator and using method of waste gas purification equipment

InactiveCN110711461AImprove purification effectReduce loss rateDispersed particle separationExhaust gasProcess engineering

The invention discloses waste gas purification equipment for a medical waste incinerator and a using method of the waste gas purification equipment. The invention belongs to the field of waste gas purification equipment; in the waste gas purification equipment for a medical waste incinerator, a ball rotating adsorption body is arranged; during use, under the impact of exhaust gas, the ball rotating adsorption body can rotate; so that firstly, by means of the effect of internal mixing assisting blocks, the waste gas adsorbent is continuously stirred, so that the waste gas adsorbent is changed in position, and furthermore the waste gas adsorbent can be in full contact with the waste gas; therefore, the utilization rate of the waste gas adsorbent is effectively improved; secondly, by means ofthe rotation of the ball rotating adsorption body, the inner filter screen and the outer filter screen are arranged, so that the contact surfaces of the inner filter screen and the outer filter screen with waste gas are stressed more uniformly in the rotating process, certain wrong force can be generated when the inner filter screen and the outer filter screen are in contact with the waste gas, part of impact force is further removed, and compared with impact of straight waste gas, the damaged time of the inner filter screen and the outer filter screen can be effectively prolonged, and the service life is prolonged.

Owner:张正周

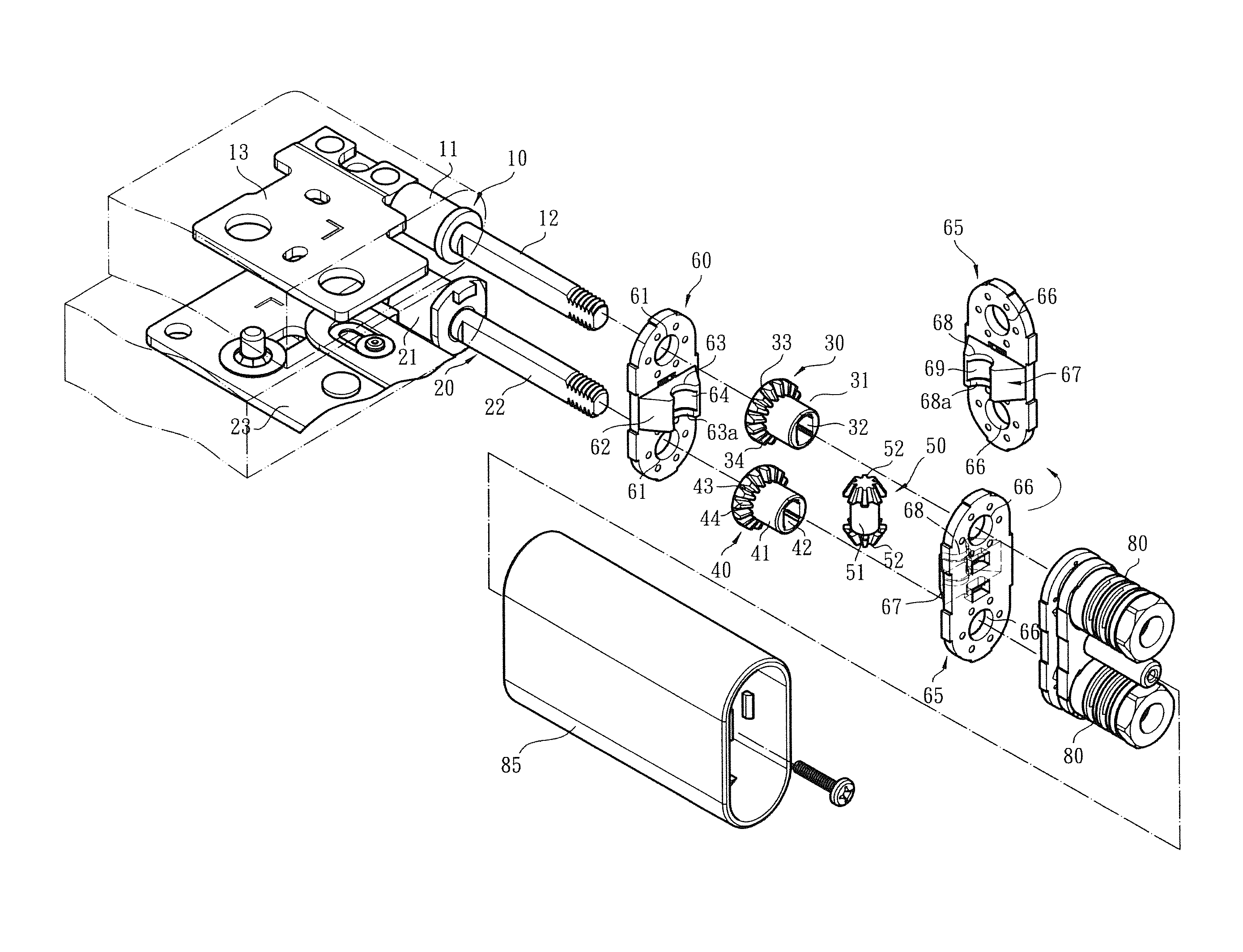

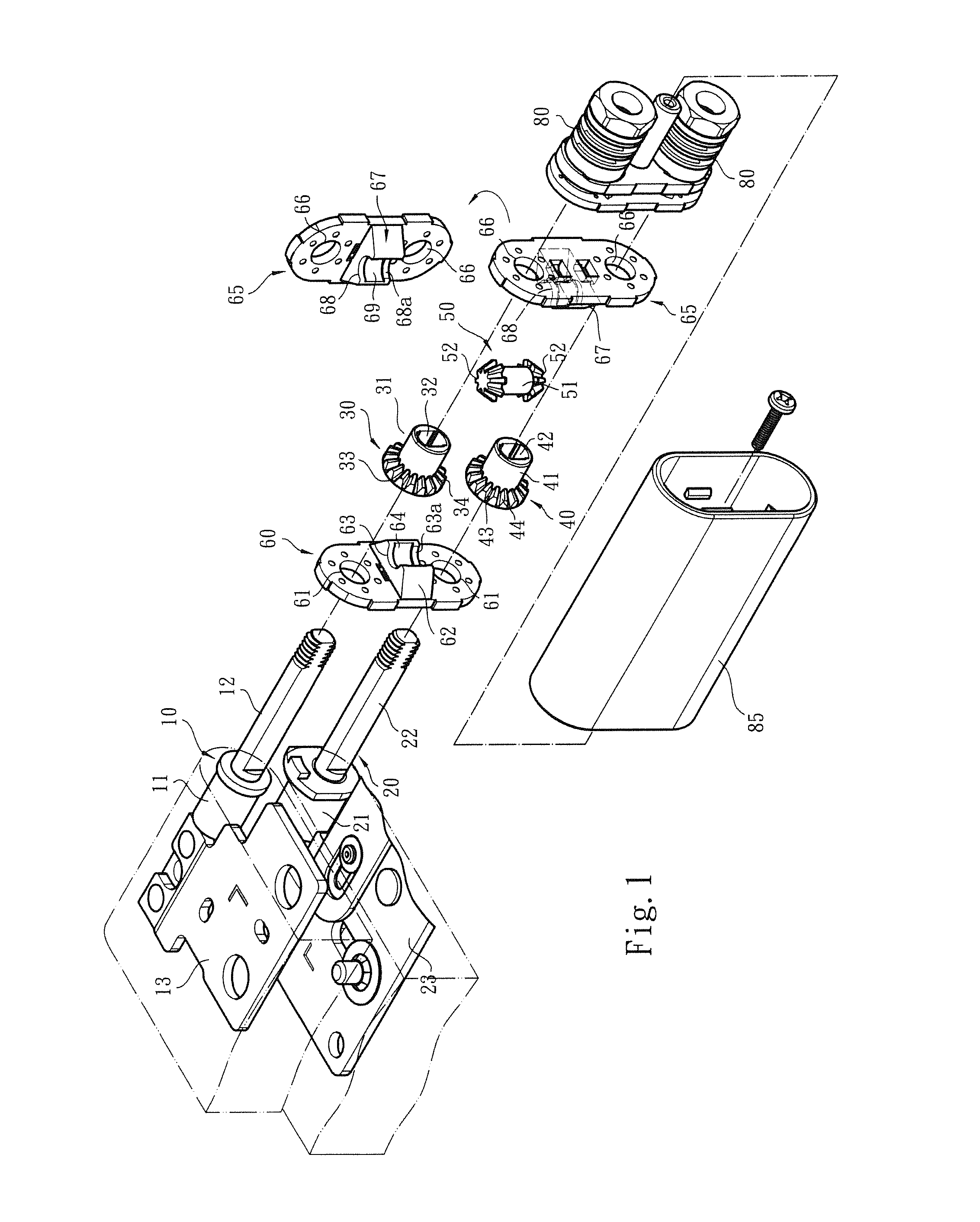

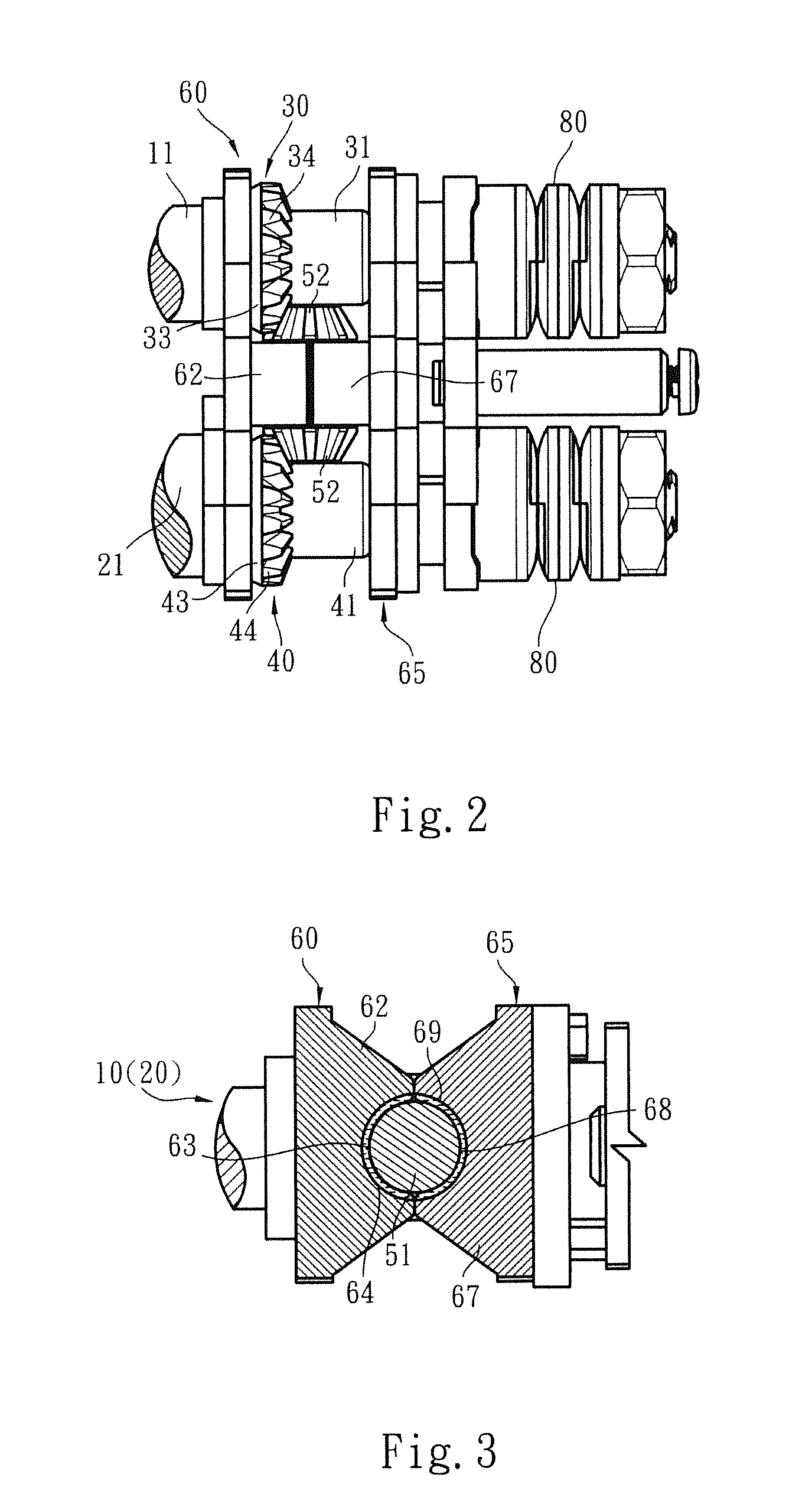

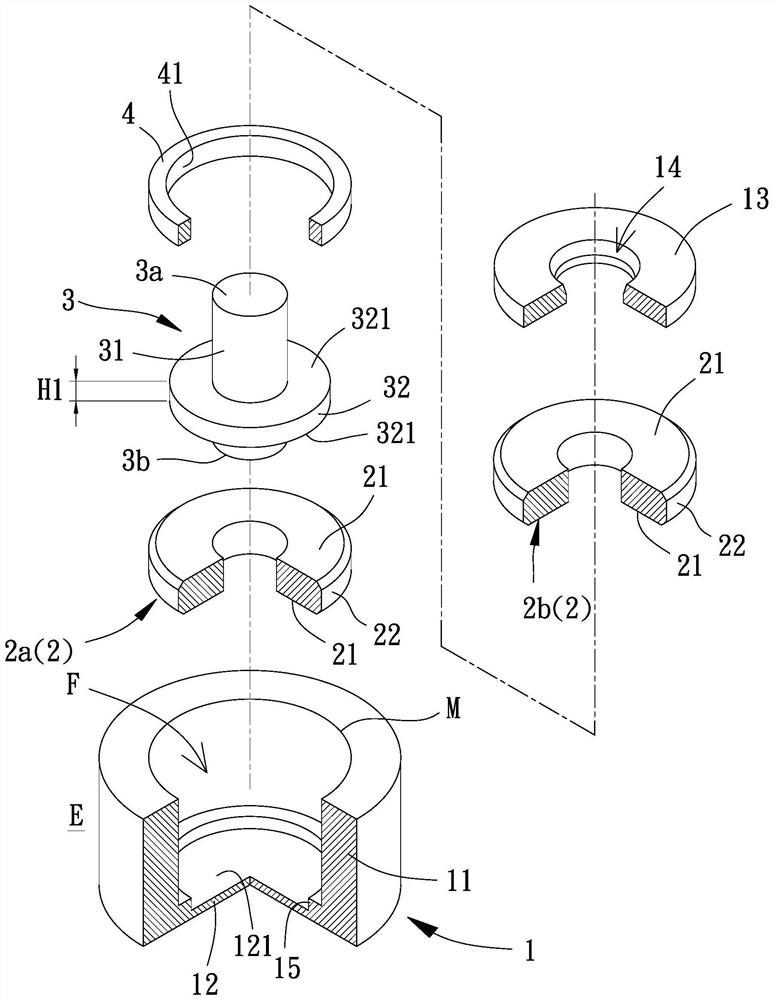

Dual-shaft synchronous transmission fixing device

ActiveUS20160032633A1Simple structureReduce volumeDigital data processing detailsPin hingesEngineeringControl theory

Owner:FIRST DOME

Dual-shaft synchronous transmission fixing device

ActiveUS9309705B2Simple structureReduce volumeDigital data processing detailsPin hingesEngineeringMechanical engineering

Owner:FIRST DOME

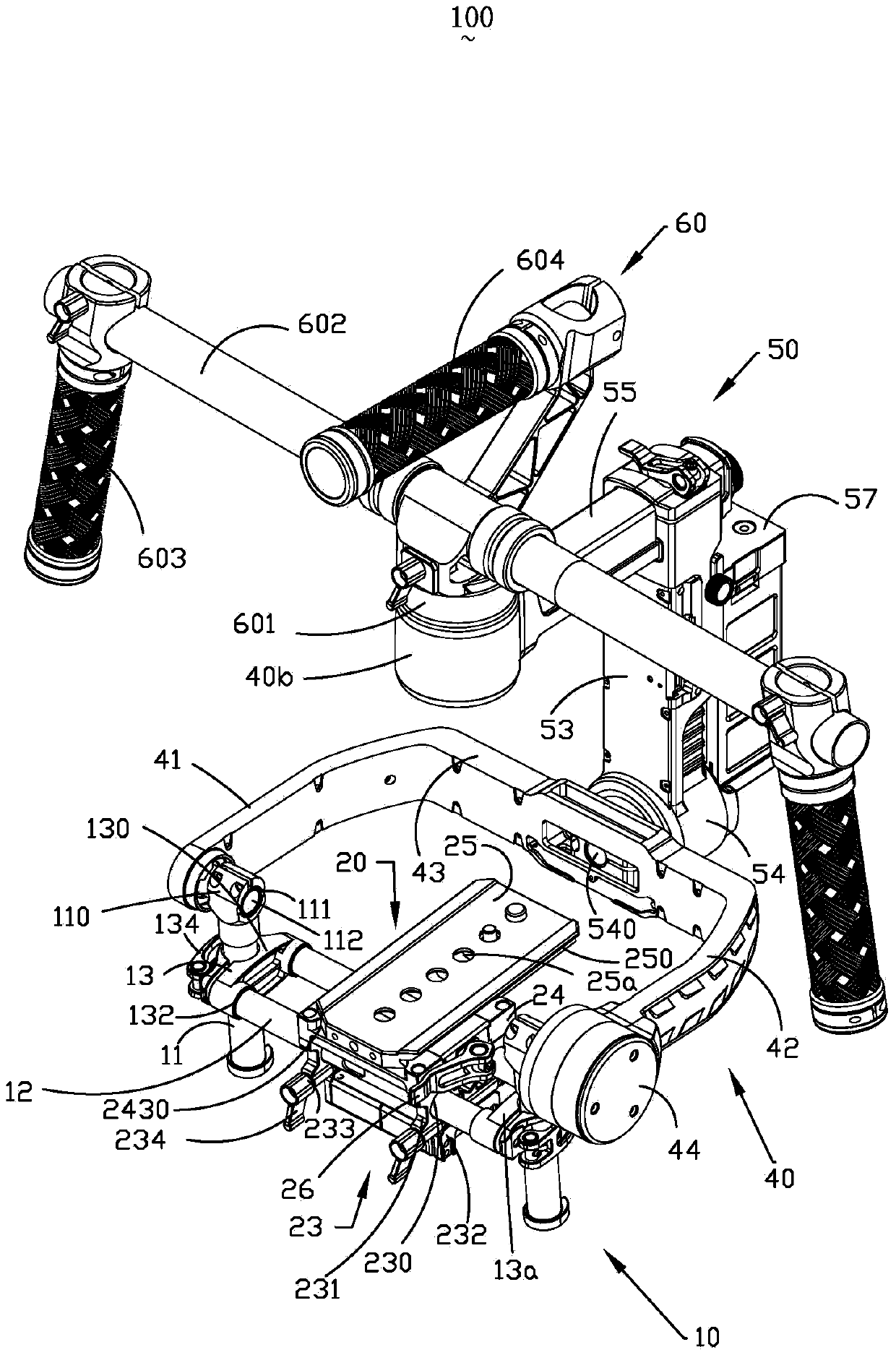

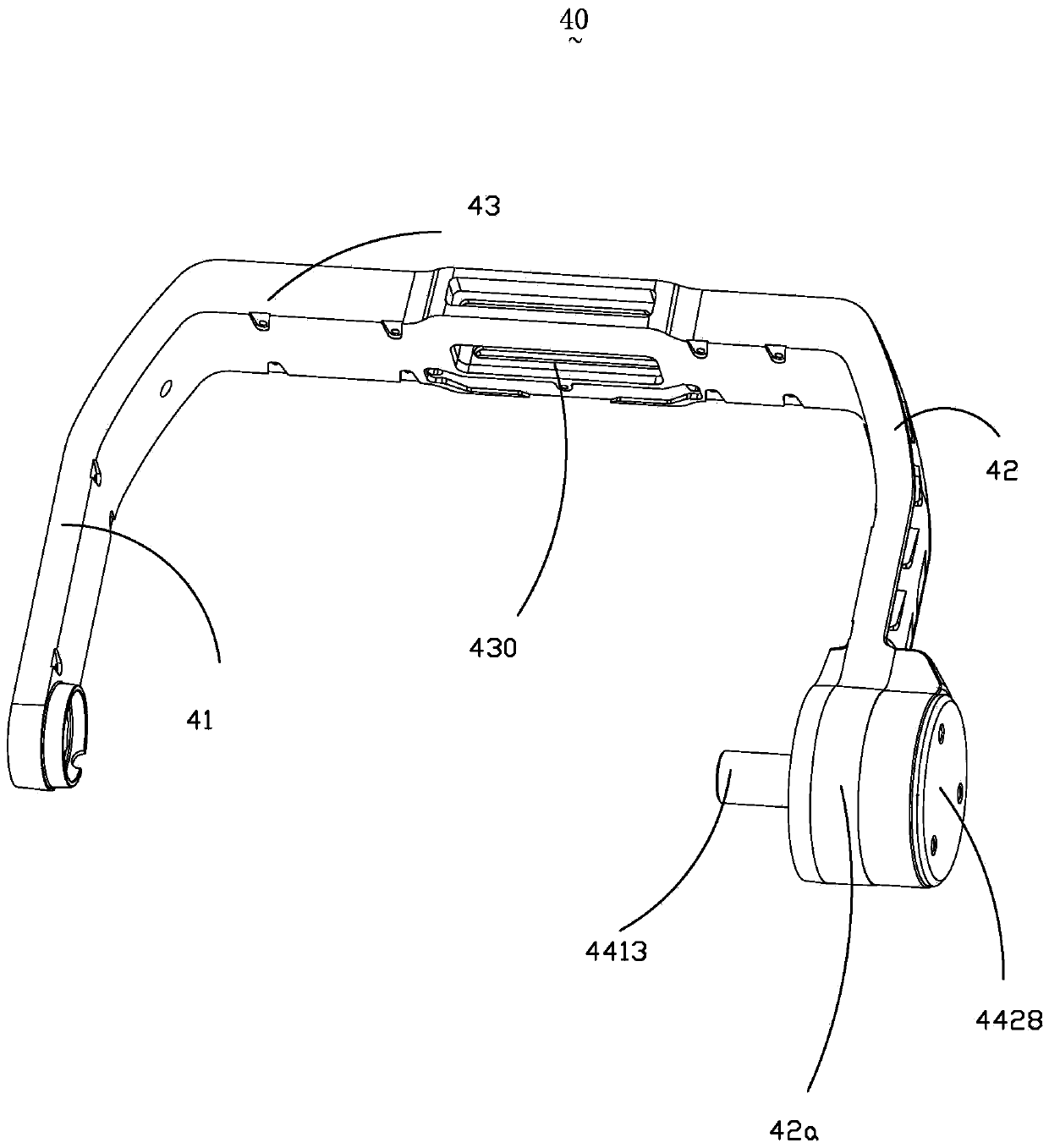

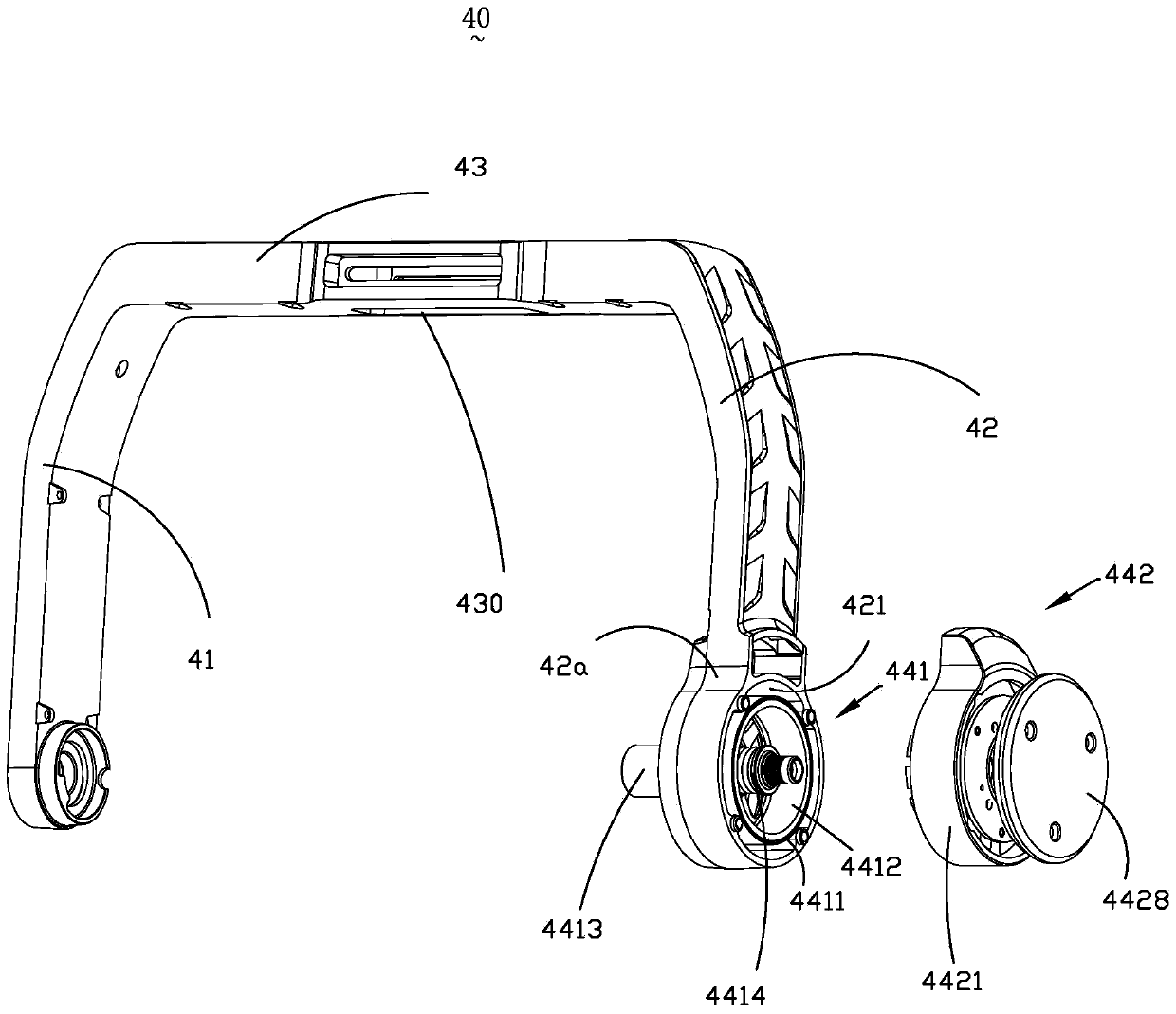

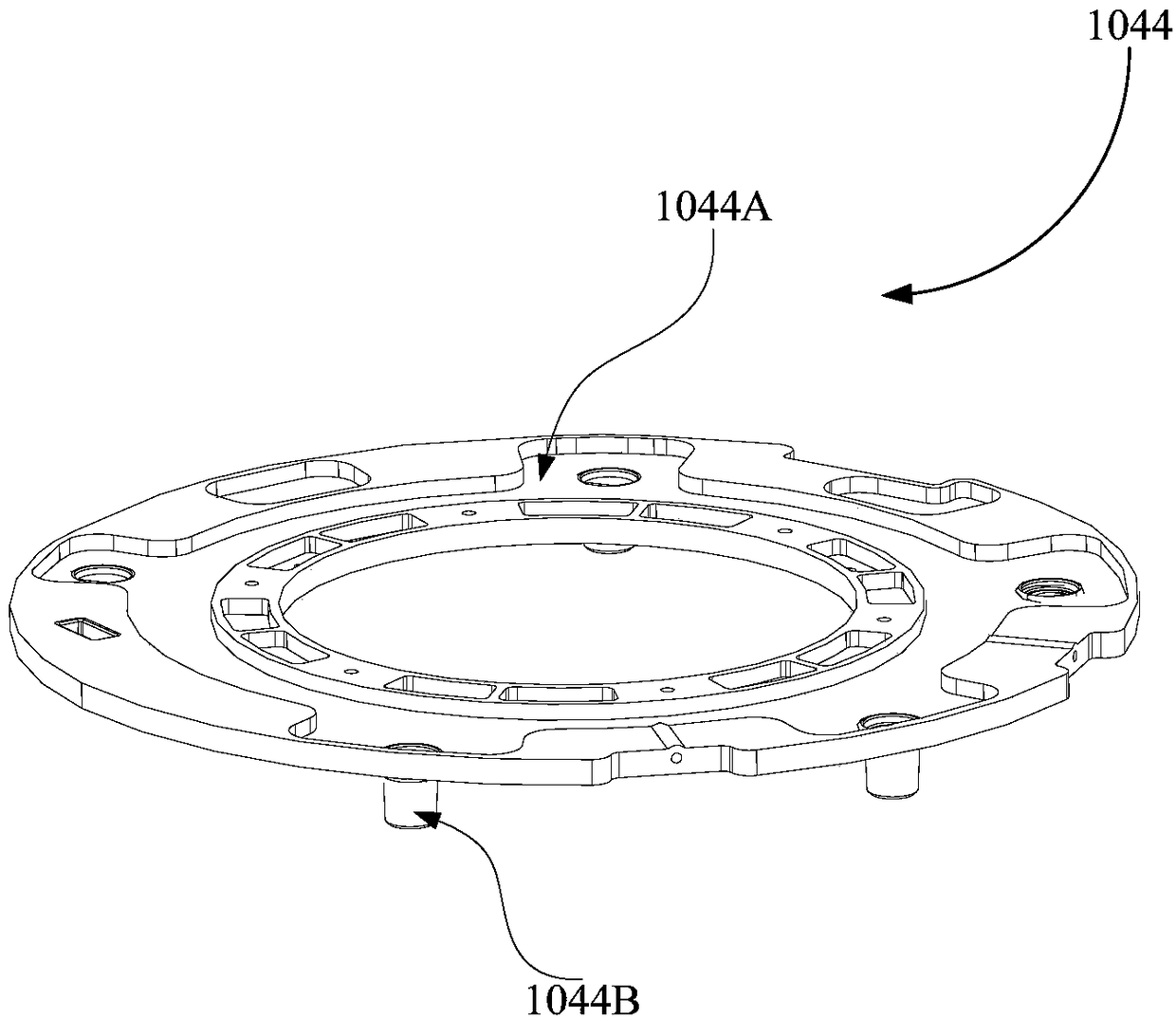

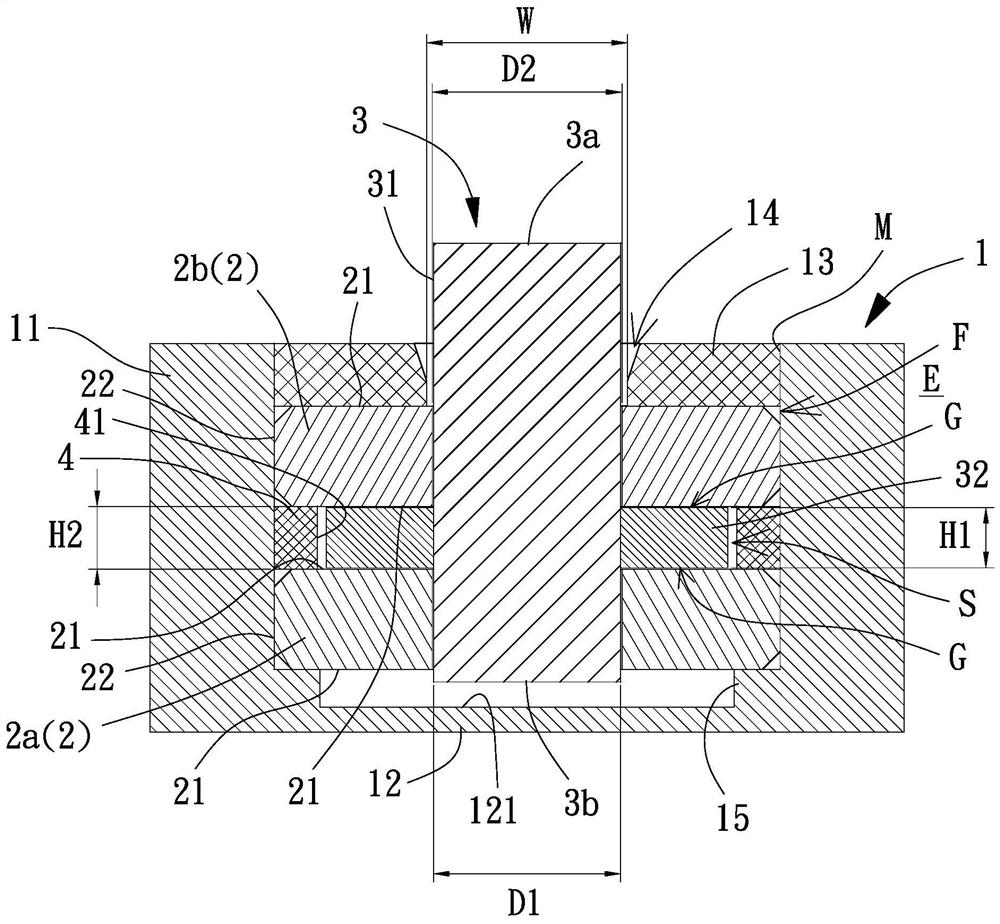

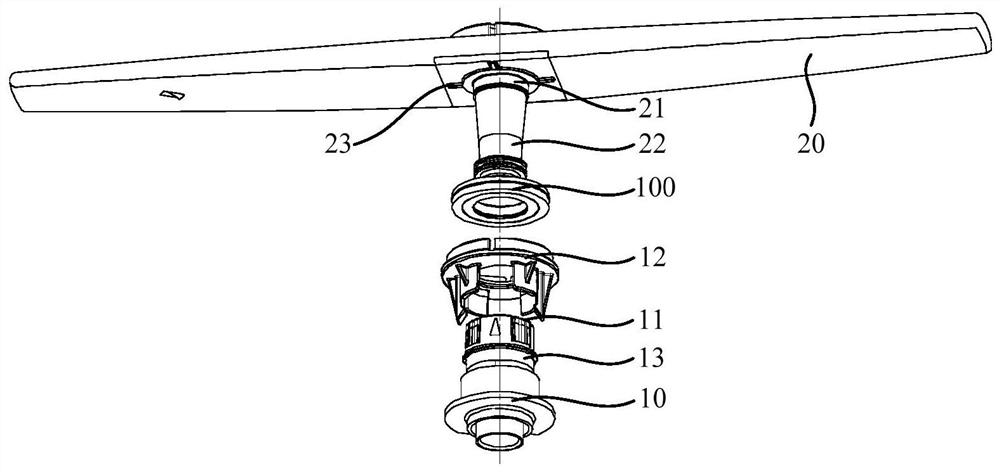

Cross rolling shaft assembly and cradle head using same

InactiveCN105518370AGuaranteed coaxiality accuracyReduce the numberStands/trestlesMechanical energy handlingMechanical engineeringStator

A rotating shaft assembly (40) and a cradle head (100) using the rotating shaft assembly (40). The rotating shaft assembly (40) comprises: a first supporting arm (41); a second supporting arm (42) disposed symmetrical to the first supporting arm (41); a connecting arm (43) connecting the first supporting arm (41) to the second supporting arm (42); and a first driving apparatus (44). A first bearing hole (410) is formed in the first supporting arm (41). A connecting seat (42a) is disposed at one end of the second supporting arm (42) away from the connecting arm (43). A second bearing hole (420) and an accommodating groove (421) are formed in the connecting seat (42a). The second bearing hole (420) is in communicated with the accommodating groove (421). The first driving apparatus (44) comprises a rotor assembly (441) and a stator assembly (442). The first supporting arm (41), the connecting arm (43) and the second supporting arm (42) are integrally formed. The rotor assembly (441) is directly accommodated in the accommodating groove (421).

Owner:SZ DJI OSMO TECH CO LTD

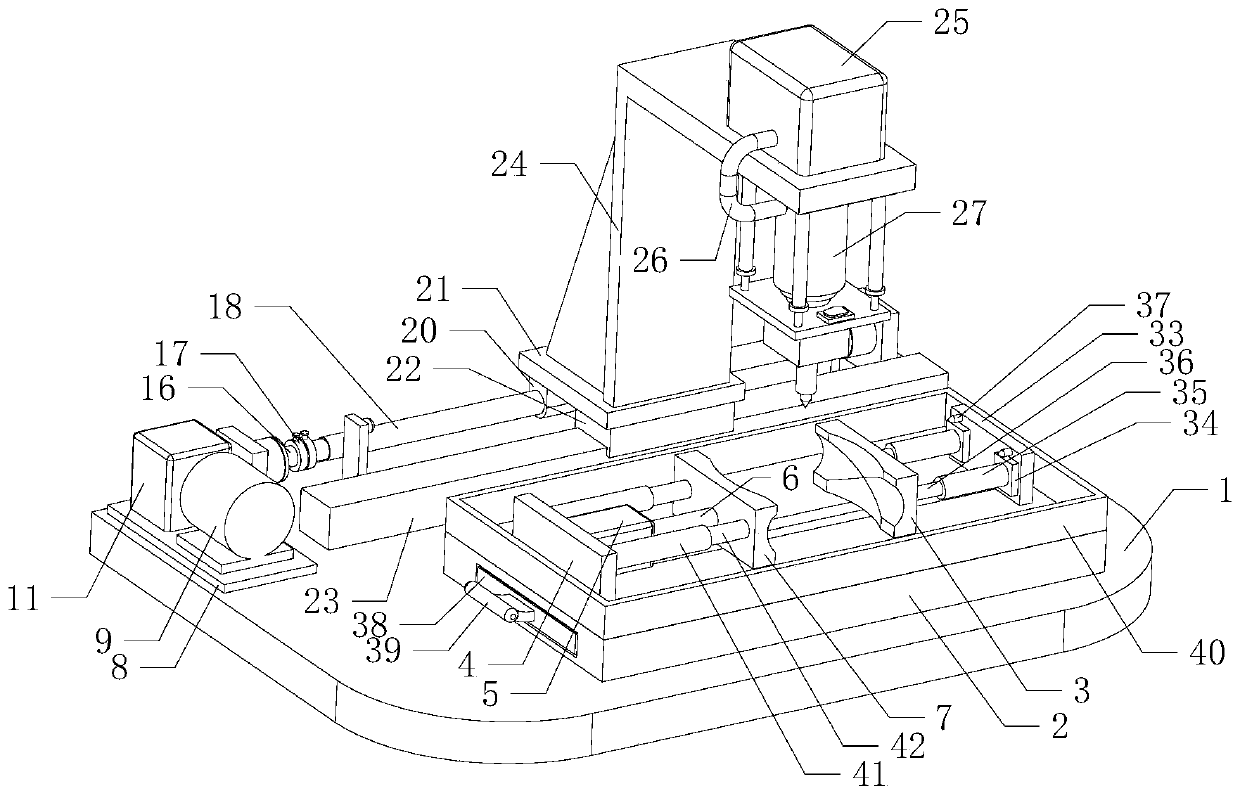

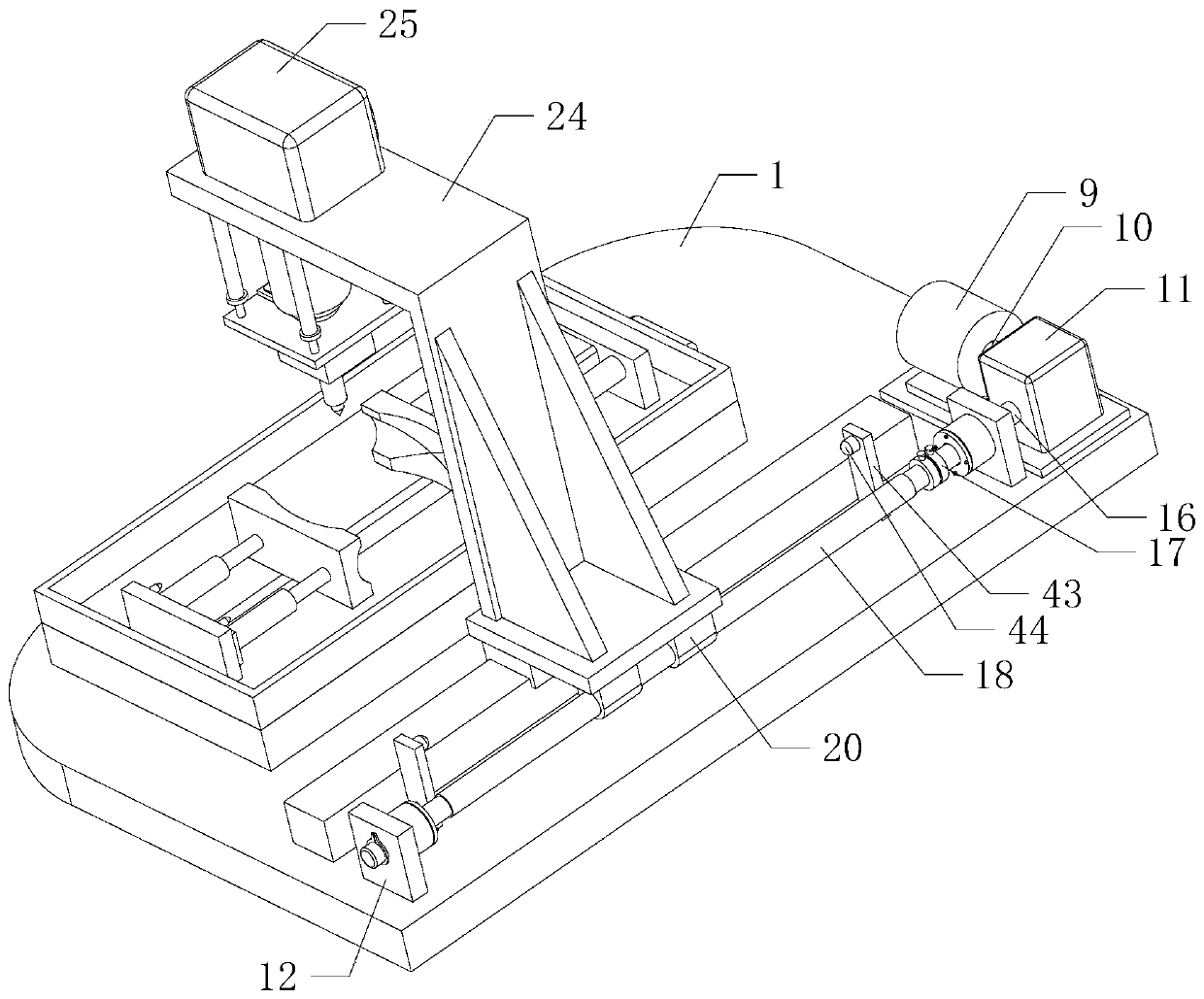

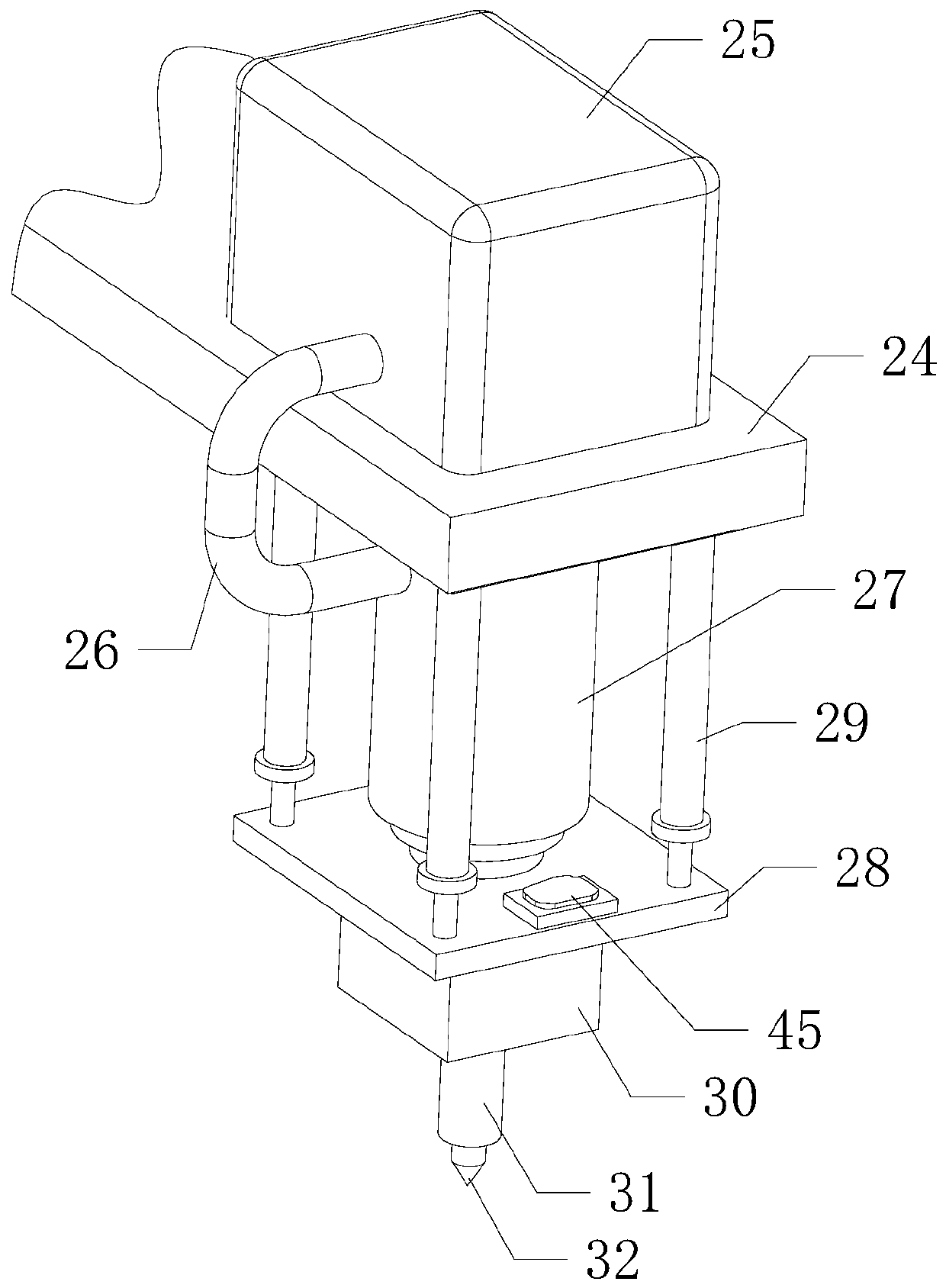

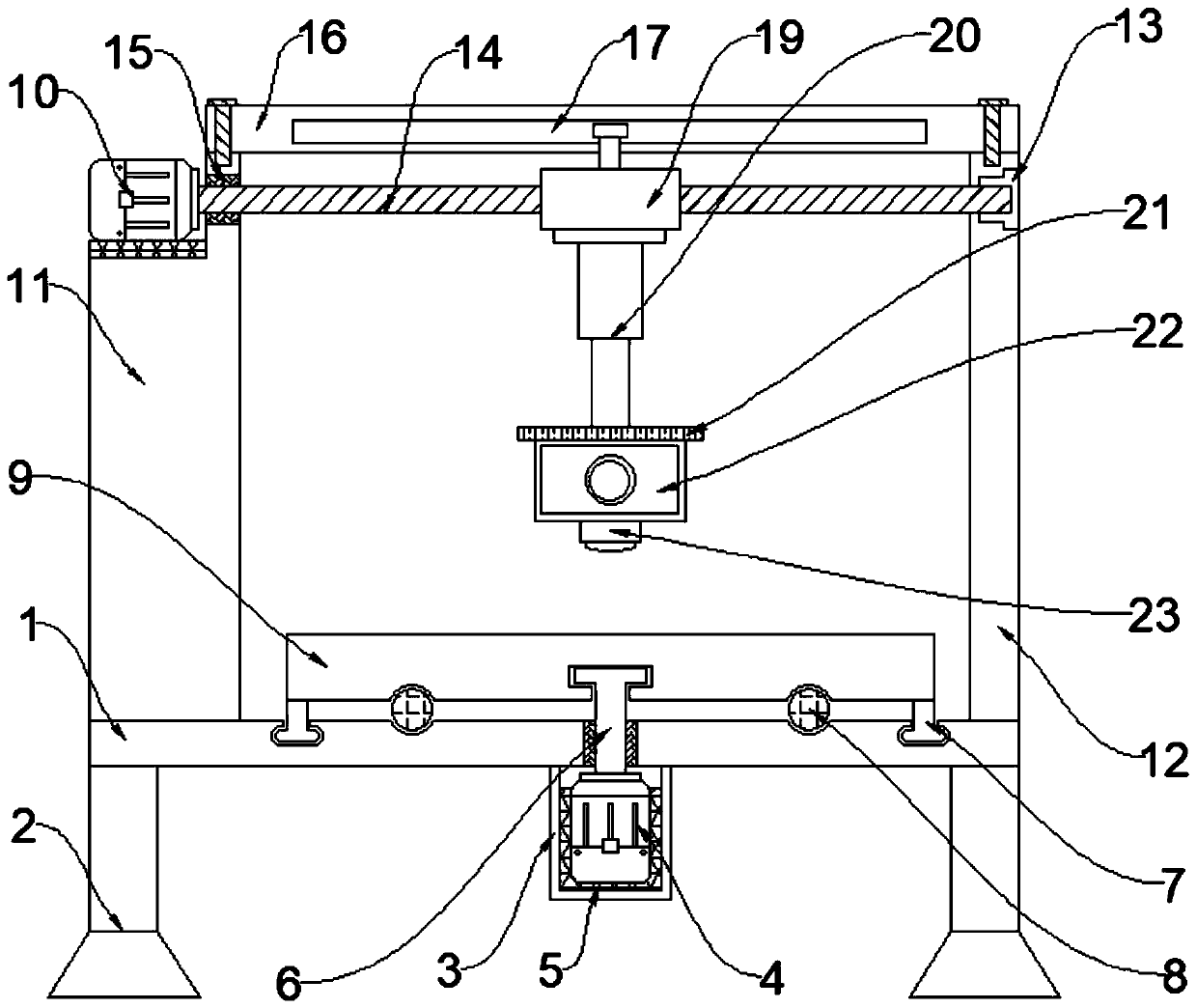

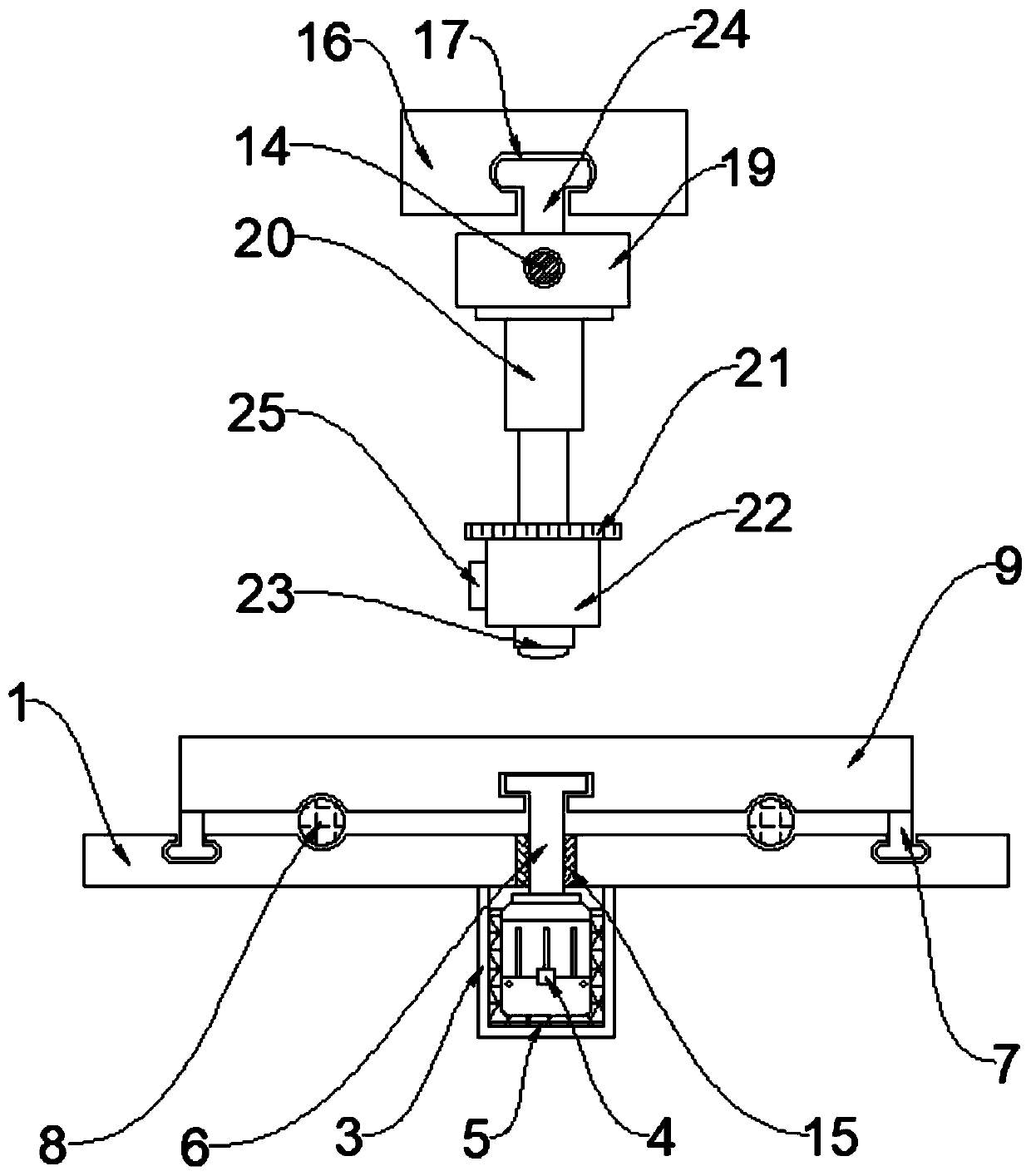

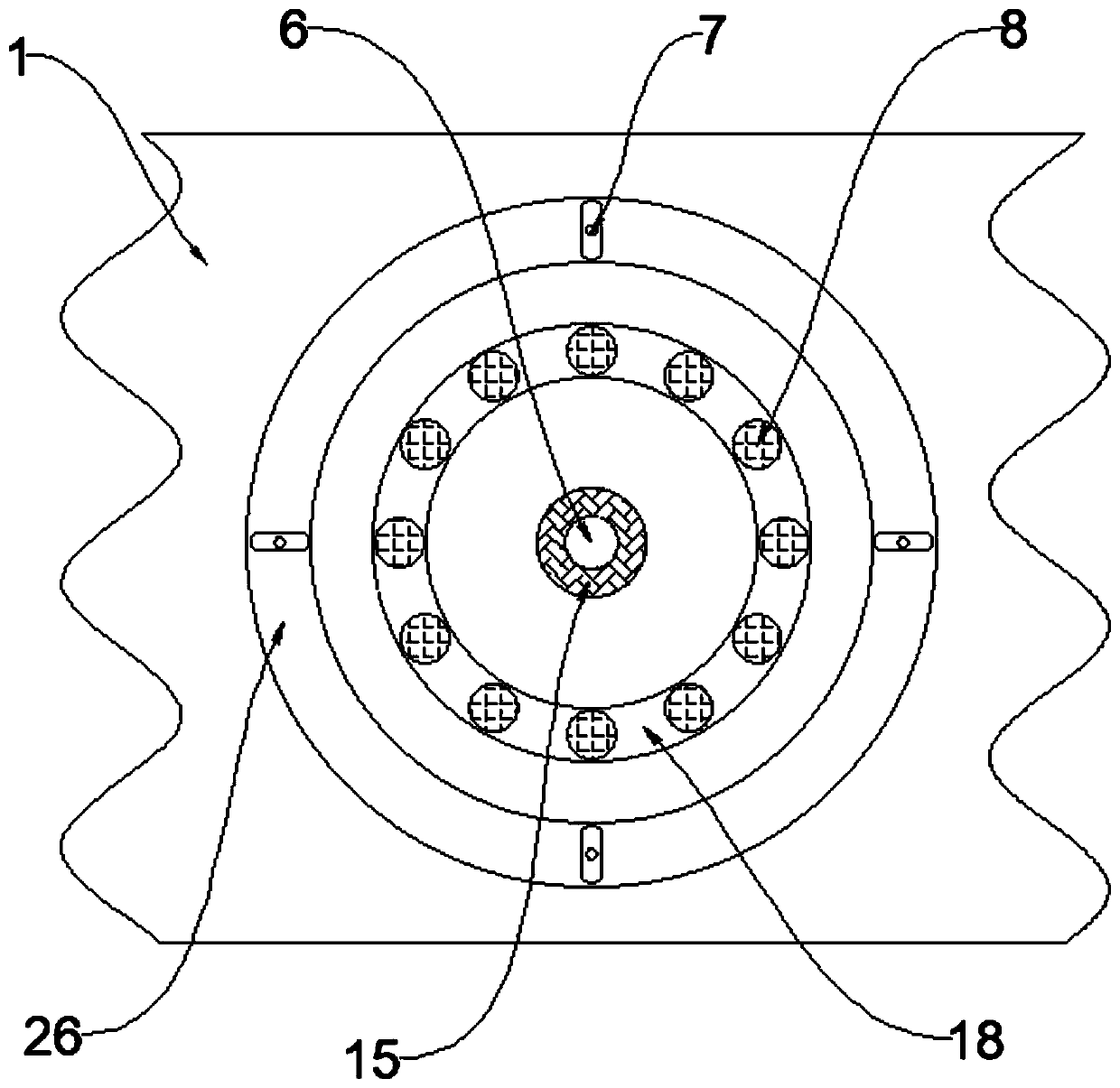

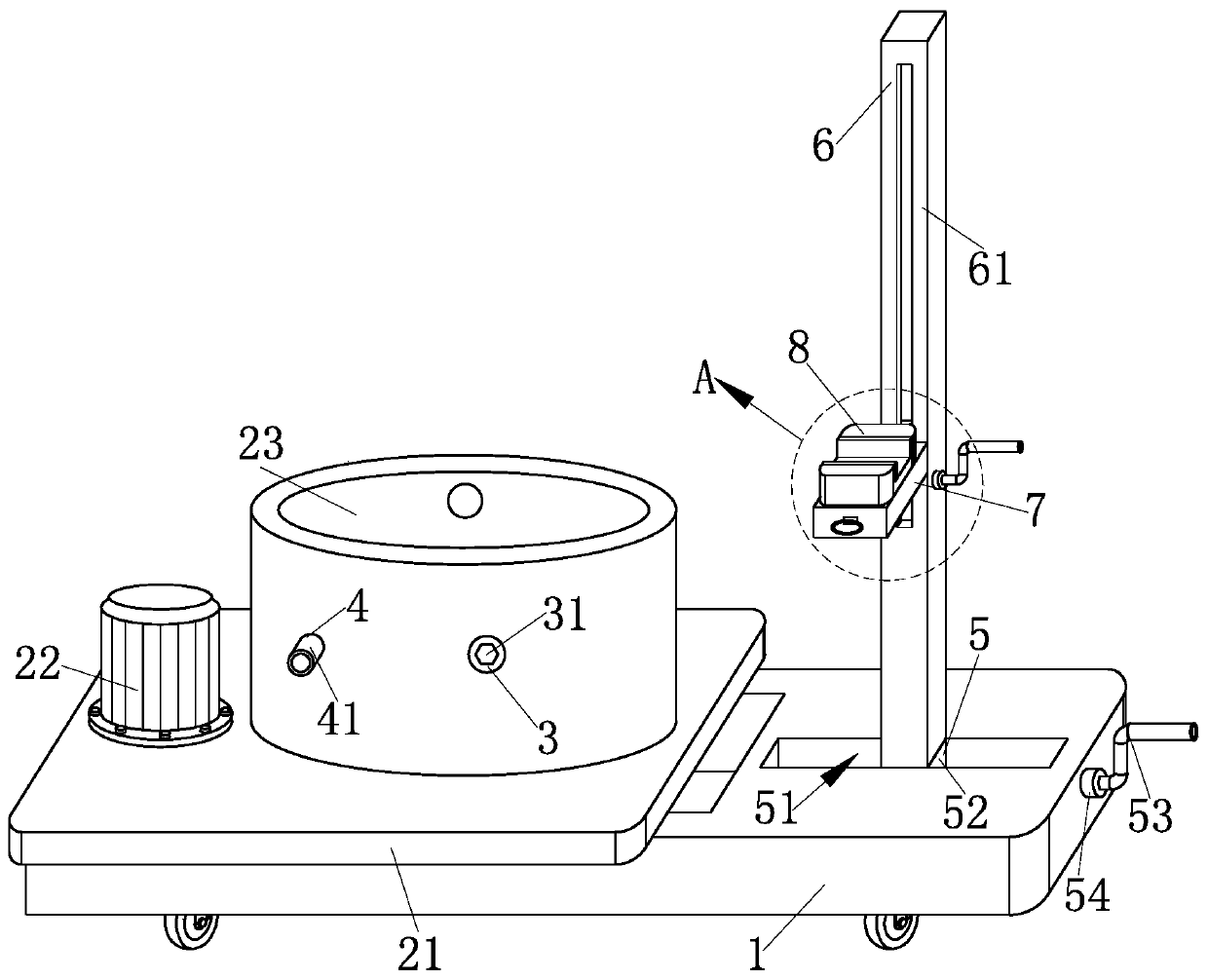

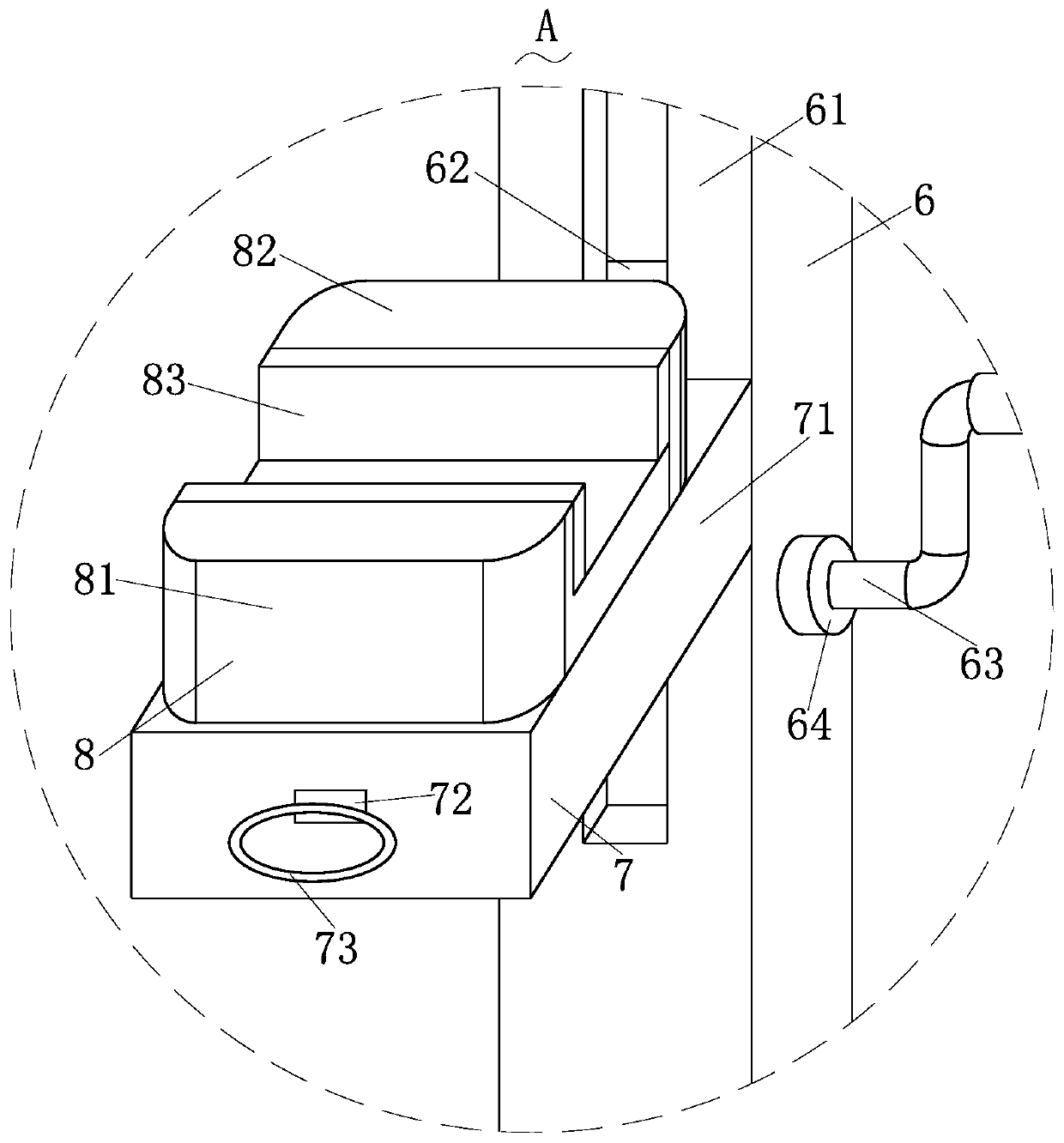

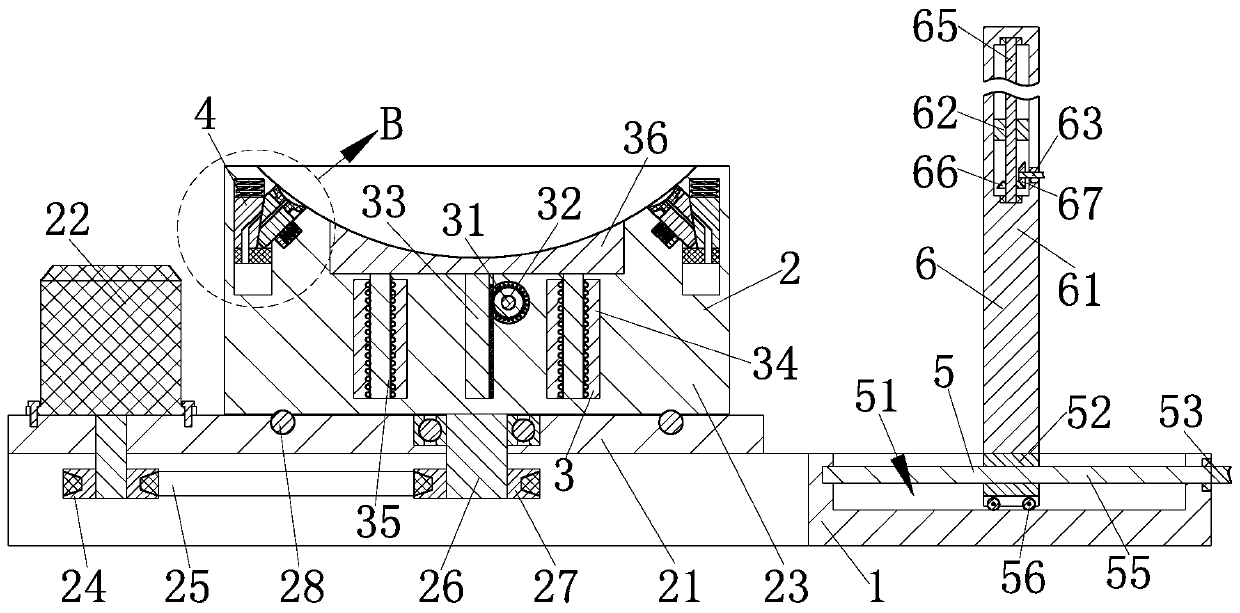

Production and machining equipment for relief butterfly valves

ActiveCN110788361AGuaranteed machining accuracyAvoid leaningPositioning apparatusBoring/drilling componentsReduction driveElectric machinery

The invention relates to the technical field of mechanical equipment, in particular to production and machining equipment for relief butterfly valves. The production and machining equipment comprisesa base, a workbench, a positioning plate, a first mounting plate, an air cylinder, a pushing rod, a clamping plate, a motor seat, a first motor, a first rotating shaft and a speed reducer, wherein thebottom end of the workbench is mounted on the front side of the top end of the base, an adjusting device is arranged on the right side of the top end of the workbench, the left end of the adjusting device is connected with the right end of the positioning plate, and the bottom end of the positioning plate is contacted with the top end of the workbench. According to the production and machining equipment for the relief butterfly valves, punching operation is carried out on the different positions on the valves, so that a punching process of the valves is effectively simplified, the punching time is shortened, the time and physical force for manually positioning the valves multiple times are saved, and the working efficiency is improved; and meanwhile, the position of a drill bit is precisely controlled, so that the position precision of a valve hole is effectively improved, the machining quality of the valves is improved, and the practicability and the reliability are improved.

Owner:SHANDONG ZHUCHENG JIANHUA VALVE MFG

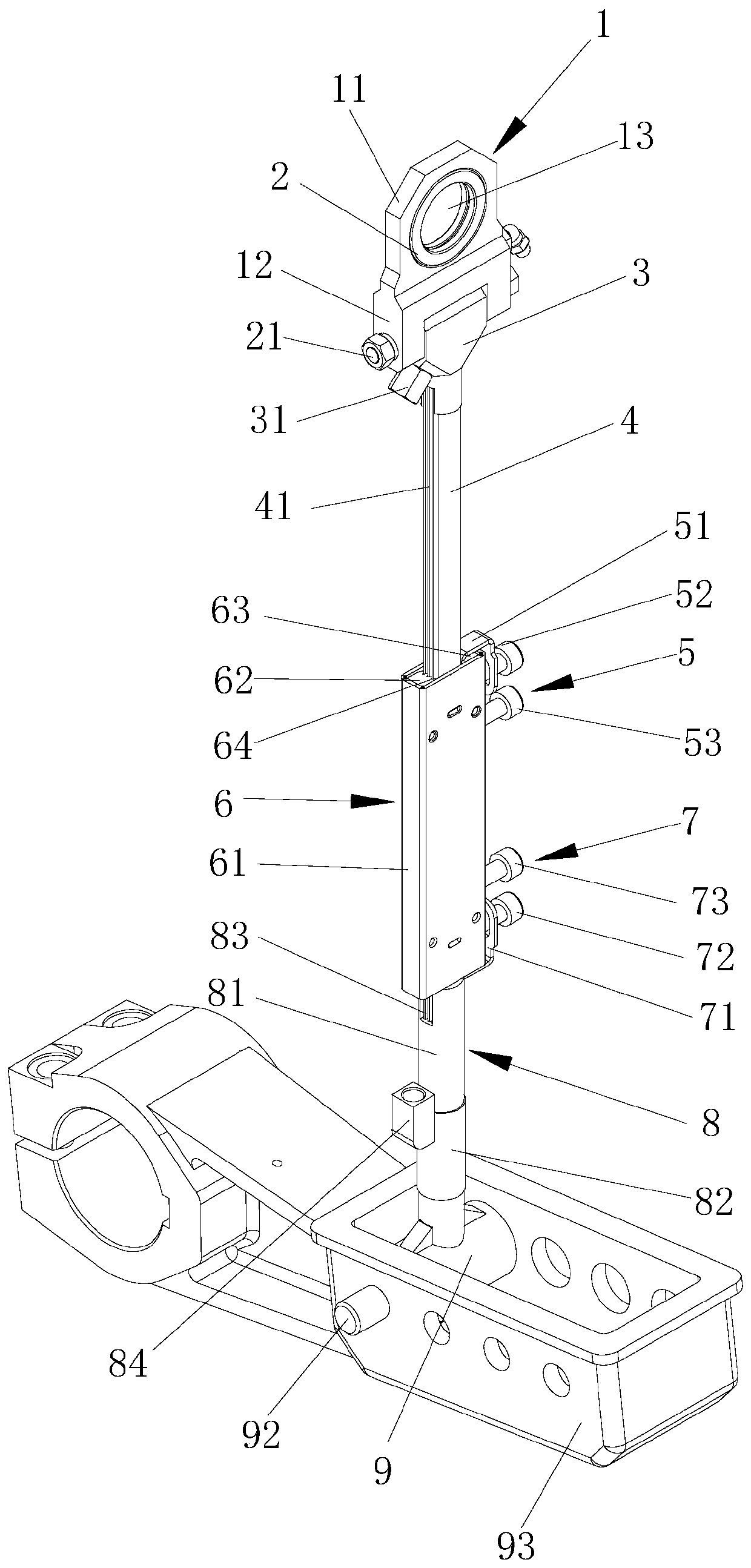

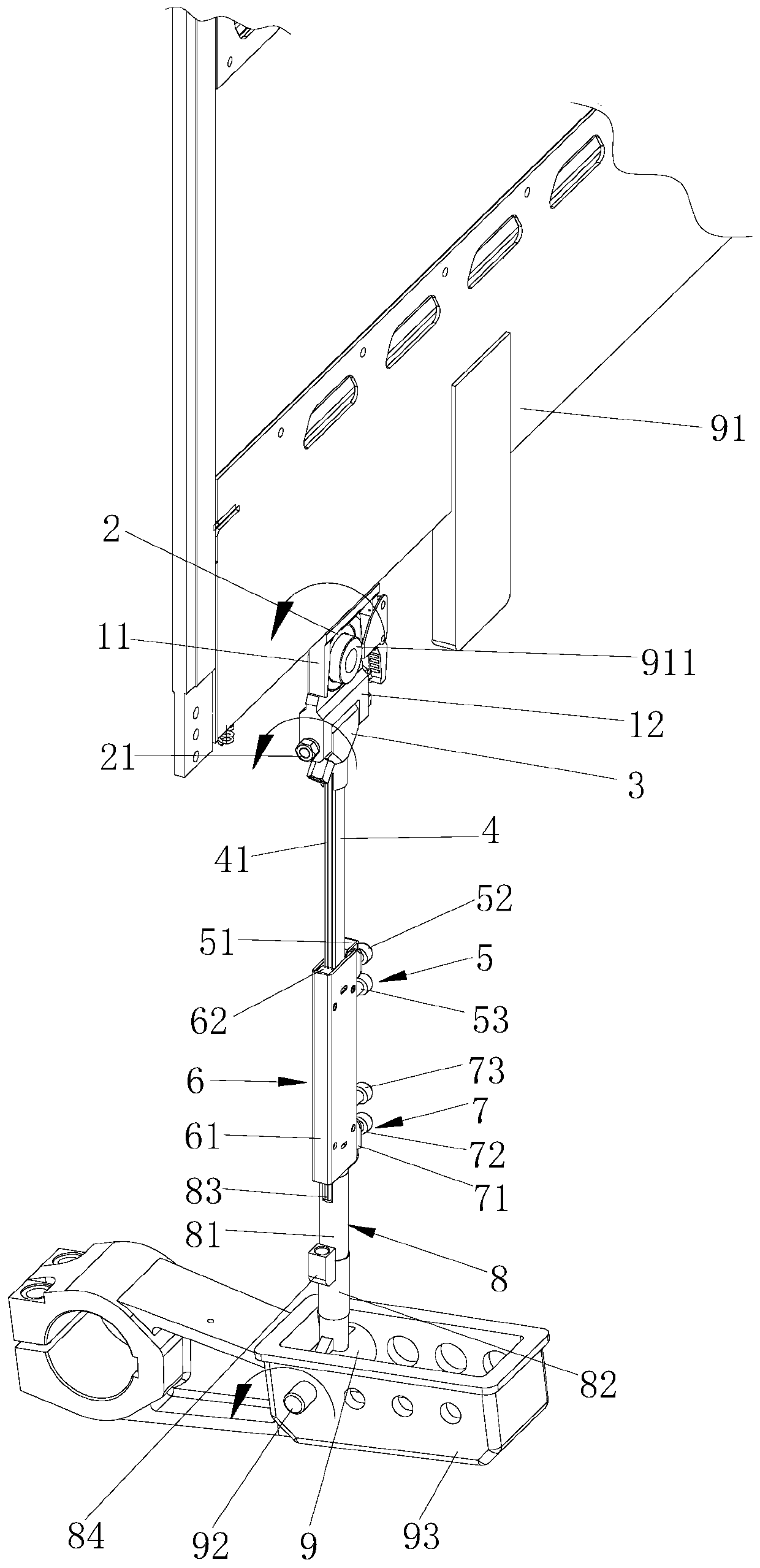

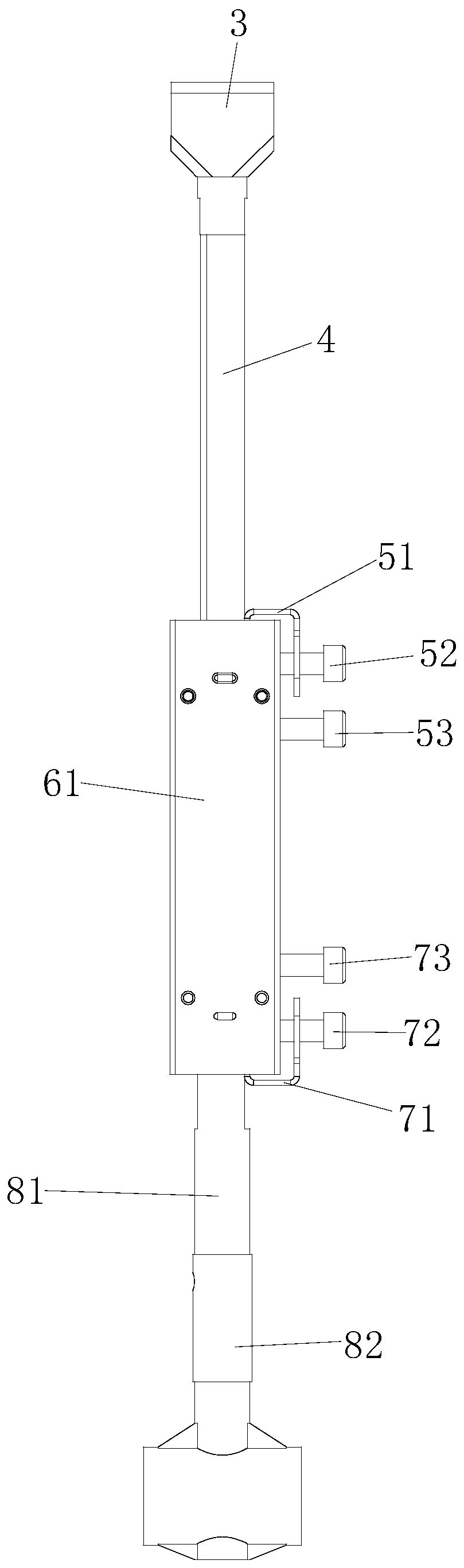

Industrial camera adjusting device

PendingCN110985823AChange space positionSolve processing problemsStands/trestlesImaging processingElectric machinery

The invention discloses an industrial camera adjusting device, relates to the technical field of industrial camera adjustment, and aims to solve the problems that since a lens and an object are not onthe same horizontal plane and the distance angle between the lens and the object is changed, the brightness of a shot image is changed, later image processing by a computer is influenced, and the analysis result is inappropriate. An object placing table is arranged above a workbench, and sliding grooves B are formed in the workbench and the object placing table; a supporting table is arranged onone side of the object placing table, and a baffle is arranged on the other side of the object placing table; a transverse plate is arranged above the baffle and the supporting table, and a sliding groove A is formed in the transverse plate; and a screw rod is arranged on one side of the output end of a motor, a connecting block is arranged outside the screw rod, an air cylinder is arranged belowthe connecting block, a camera mounting frame is arranged below the air cylinder, and a camera is arranged below the camera mounting frame.

Owner:苏州贝睿尔自动化科技有限公司

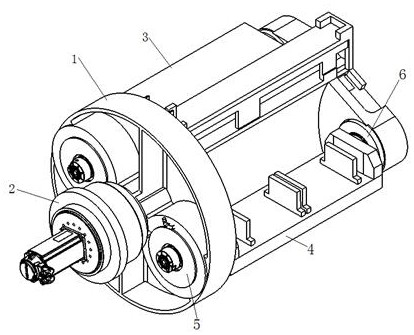

Pneumatic turbine motor air chamber

Owner:XPOLE PRECISION TOOLS

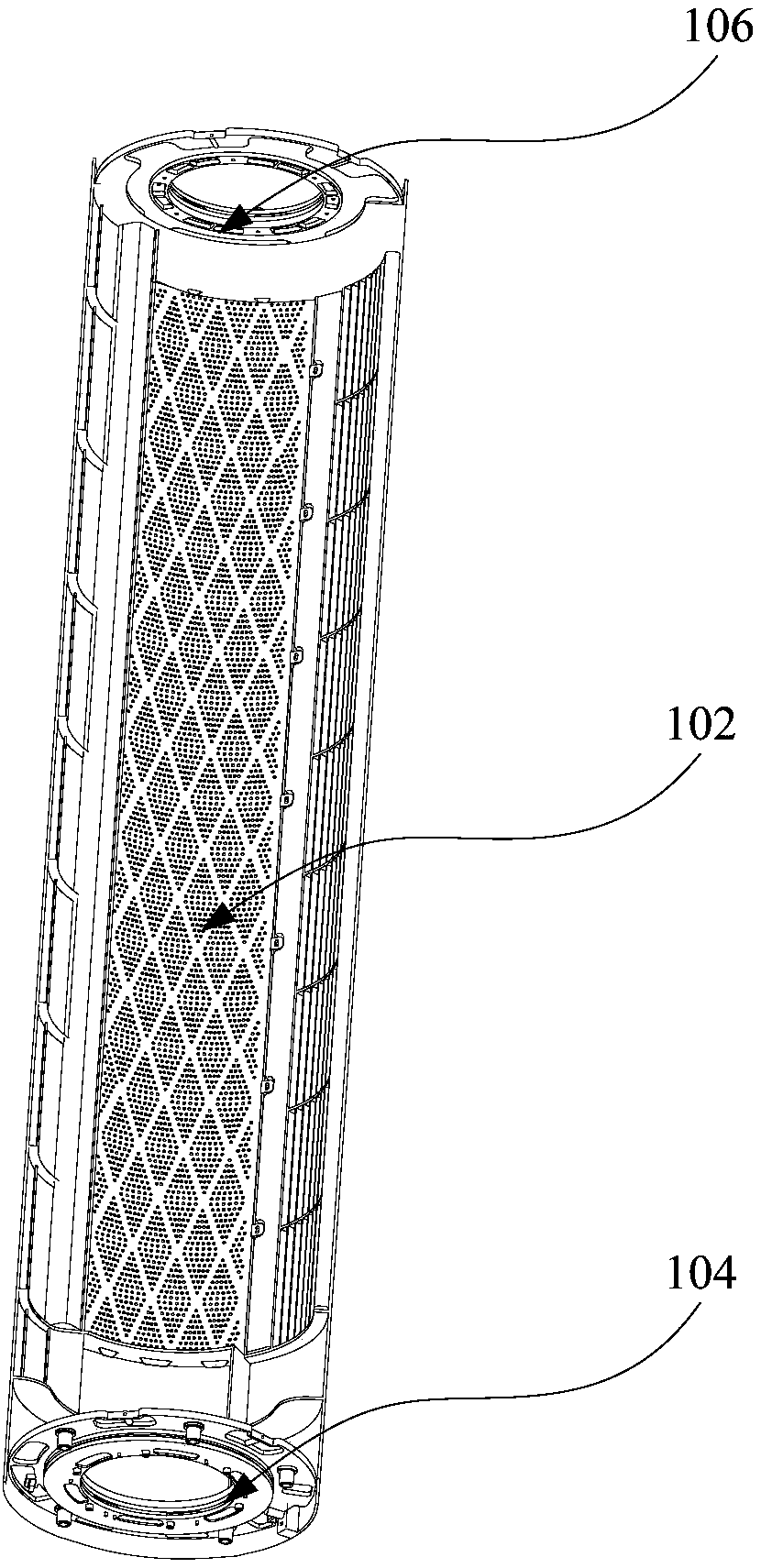

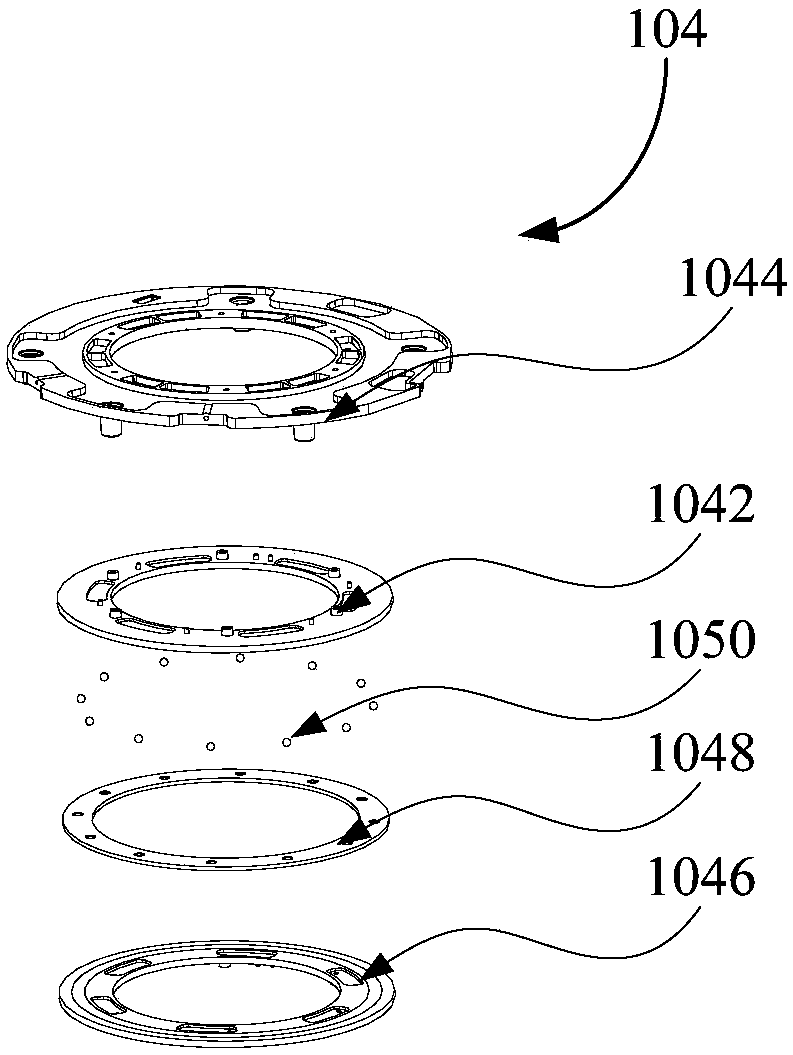

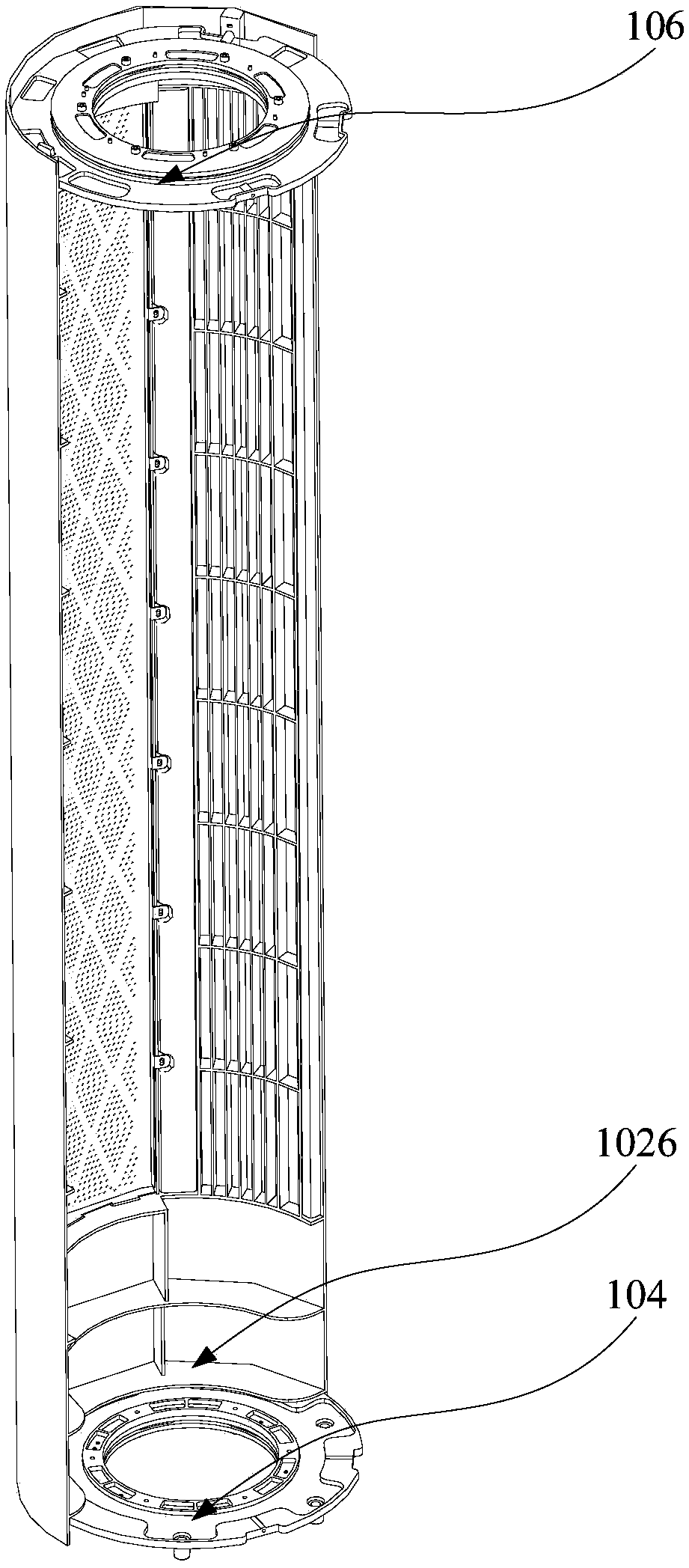

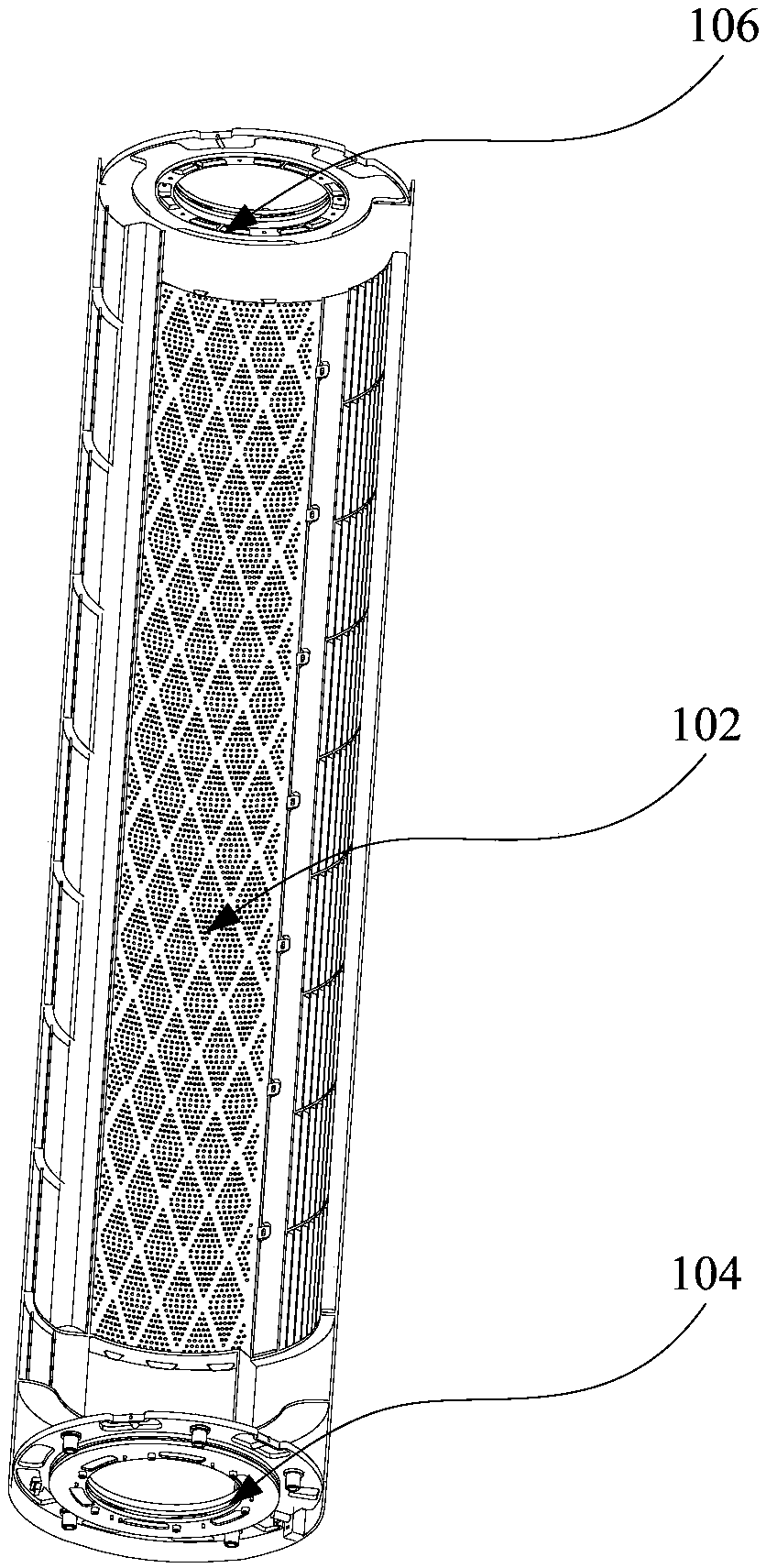

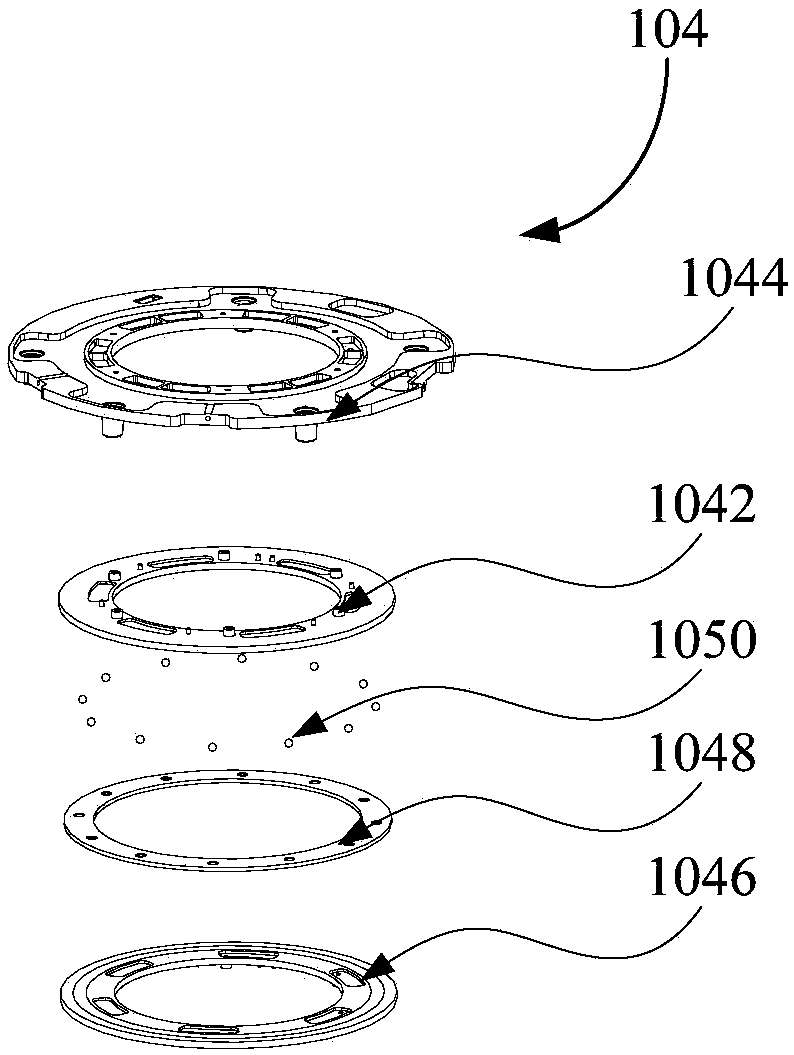

Air outlet panel assembly and vertical air conditioner

PendingCN108151155AReduce body sensationImprove comfortCondensate preventionLighting and heating apparatusWaste management

The invention provides an air outlet panel assembly and a vertical air conditioner. The air outlet panel assembly comprises an arc-shaped air outlet panel and a rotating mechanism; an air guide area and a gentle breeze area are formed in the air outlet panel in the circumferential direction of the air outlet panel in parallel; a plurality of air guide grilles are formed in the air guide areas; a plurality of micro-pores are formed in the gentle breeze area; the rotating mechanism is assembled at the bottom of the air outlet panel; and the rotating mechanism can rotate synchronously with the arc-shaped air outlet panel. According to the technical scheme disclosed by the invention, the rotating mechanism rotates synchronously with the arc-shaped air outlet panel, so that air outlets from theair guide area and the gentle breeze area; and a function of manually operating the arc-shaped air outlet panel to rotate or automatically operating the arc-shaped air outlet panel to rotate is realized, so that the gentle breeze area is rotated to an air outlet when the air is required to be supplied from the gentle breeze area.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

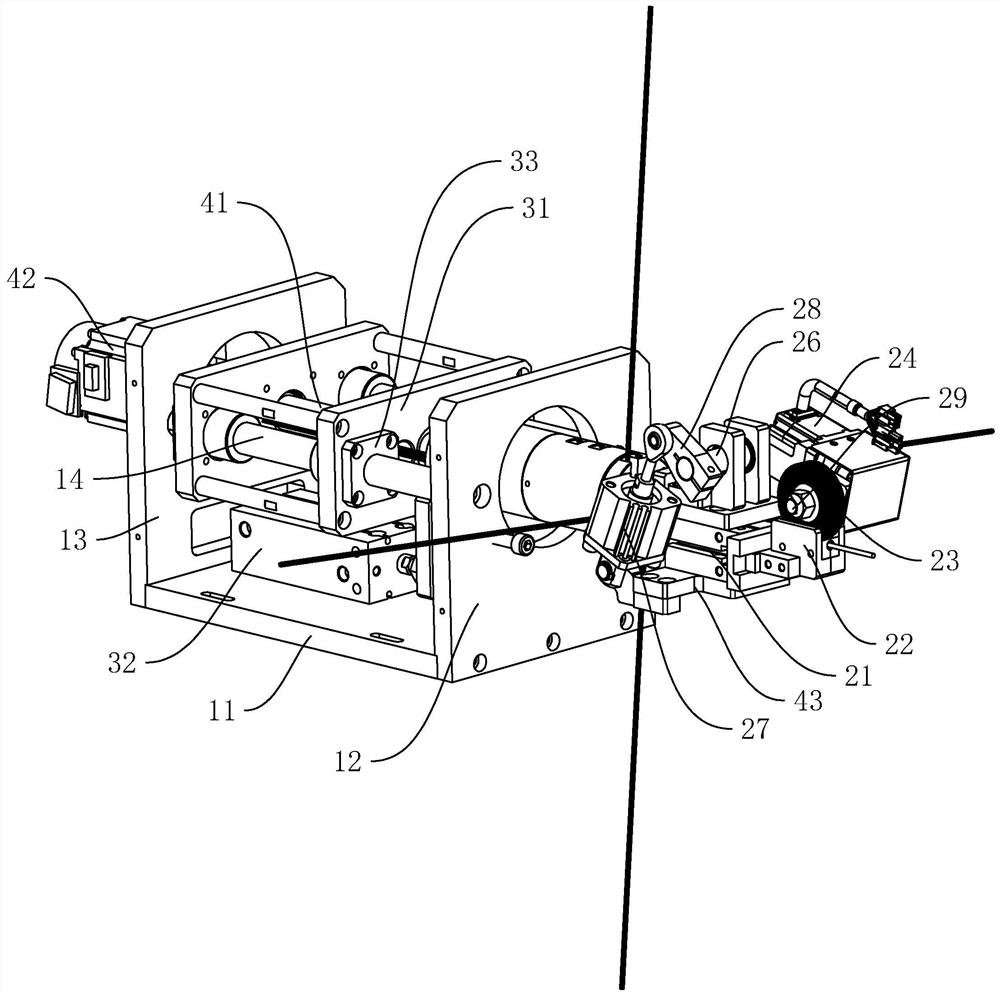

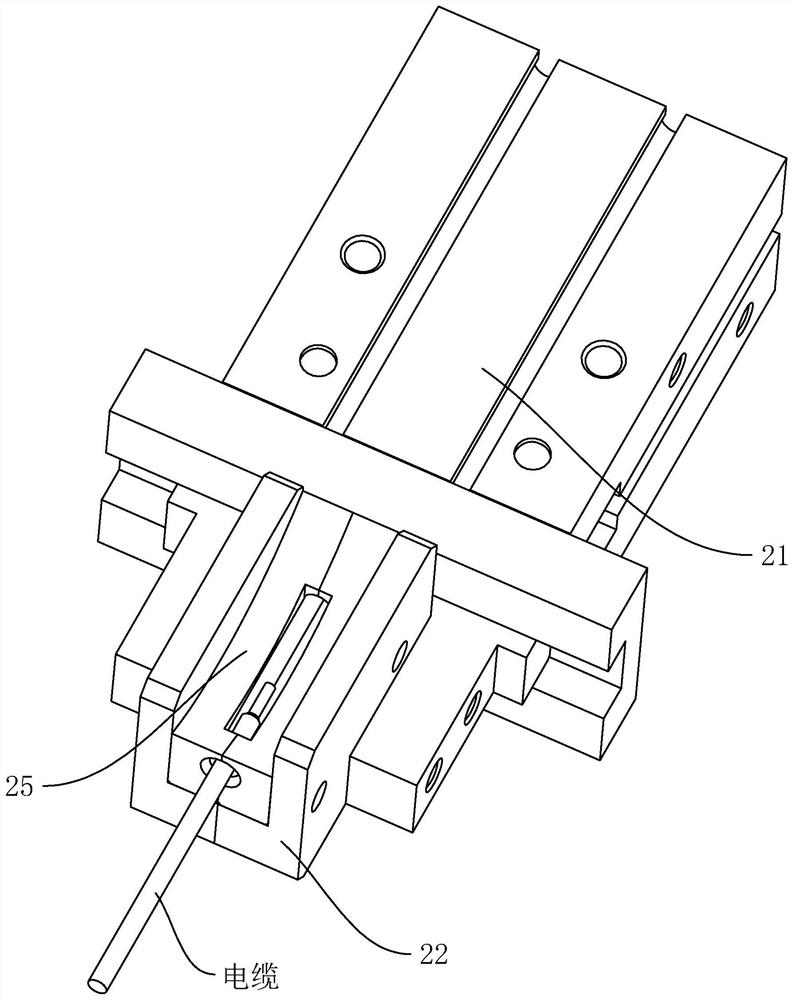

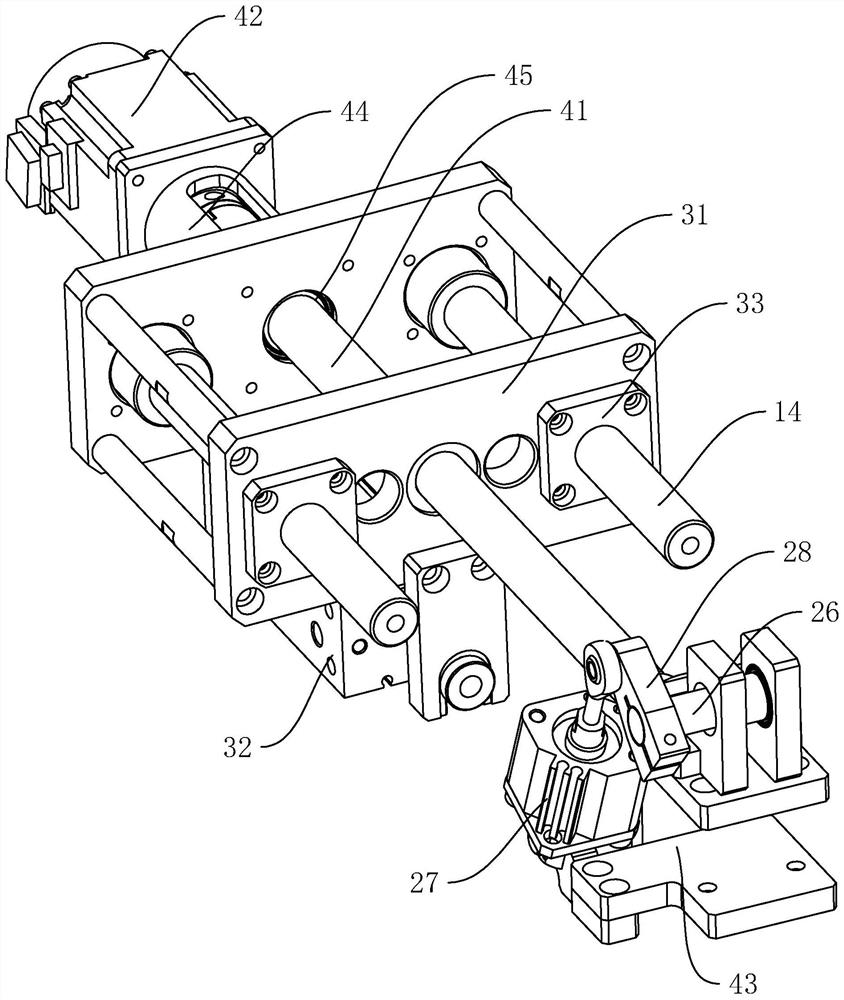

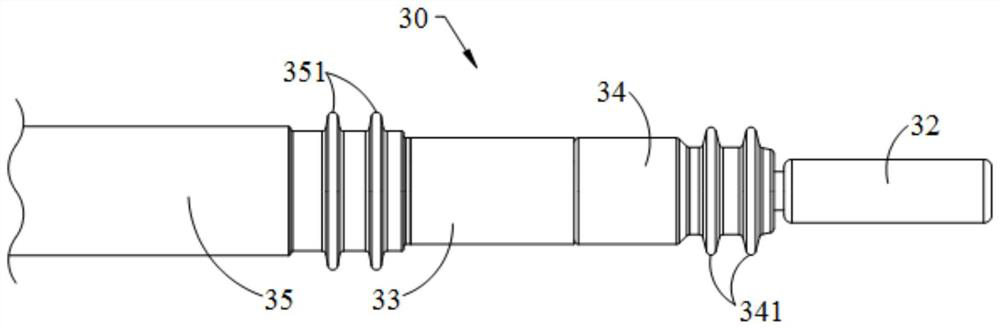

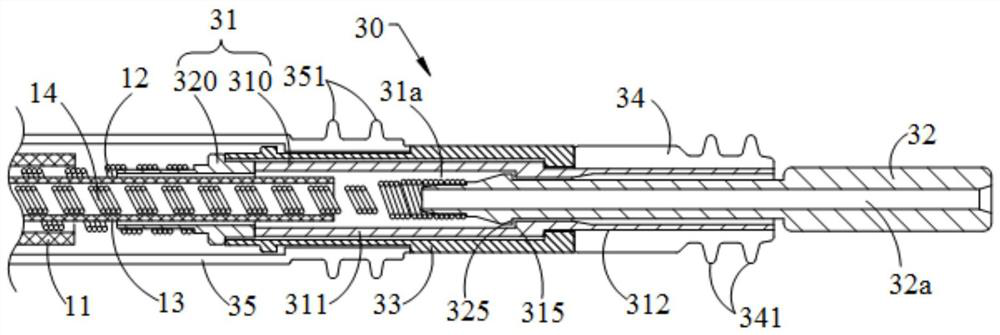

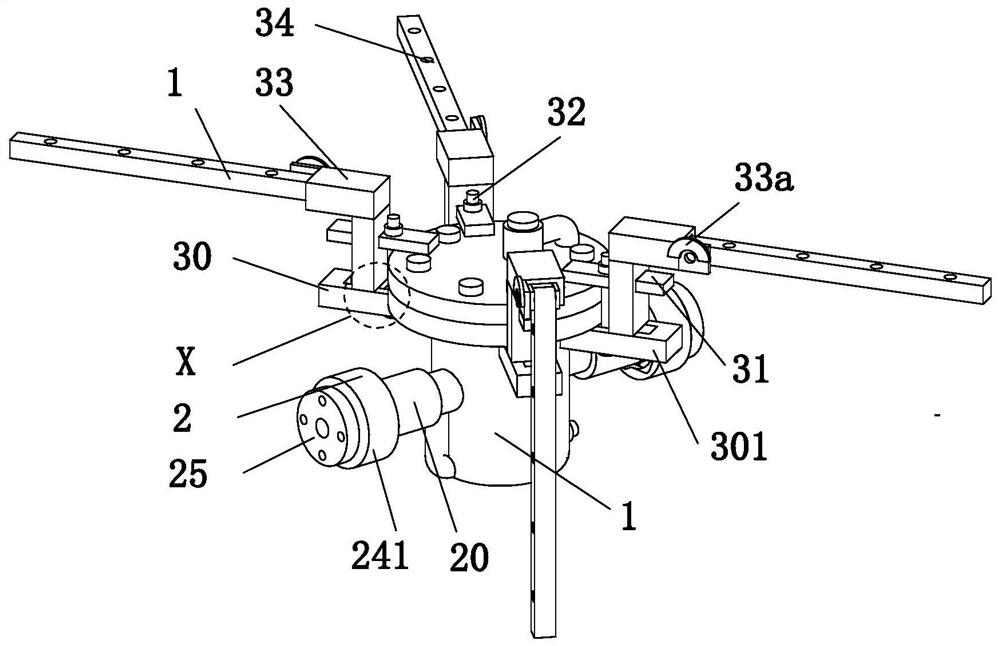

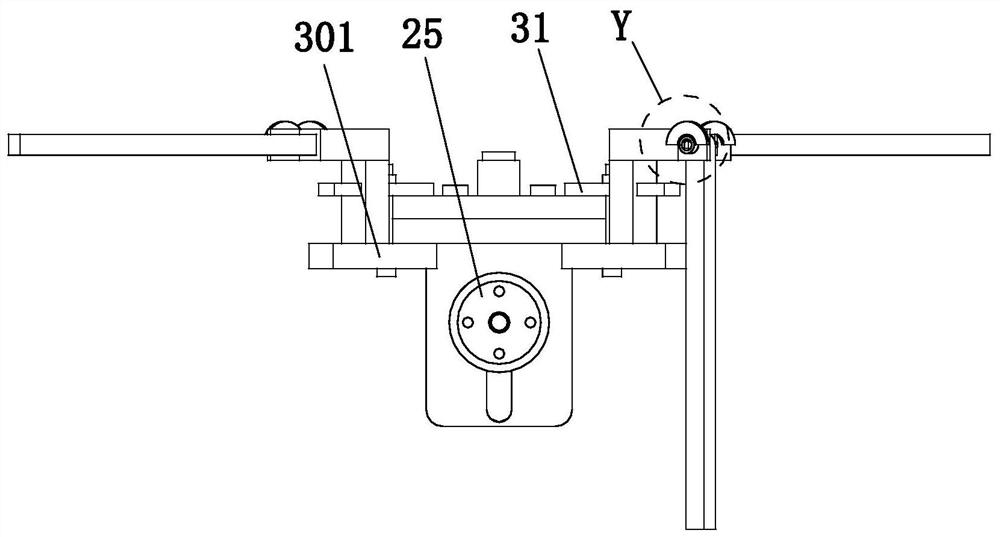

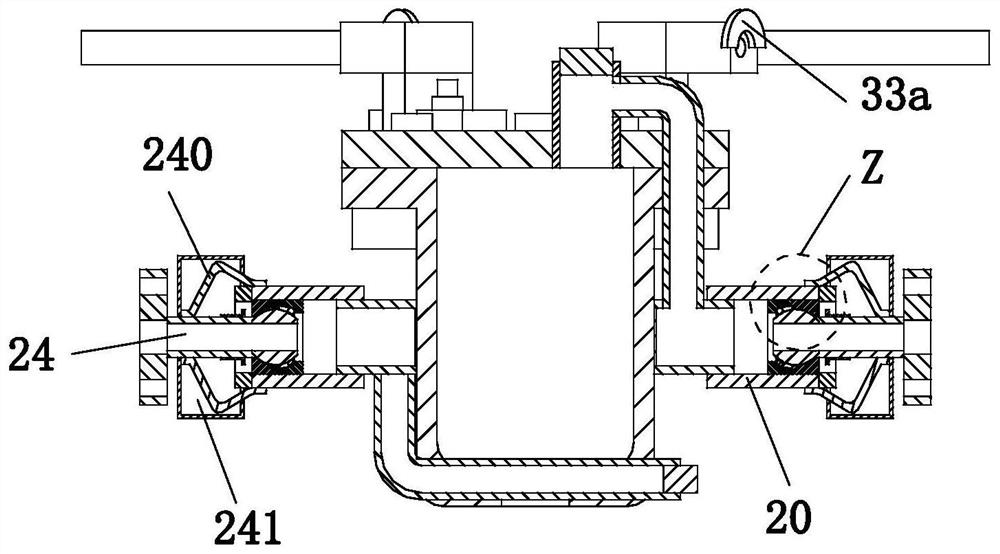

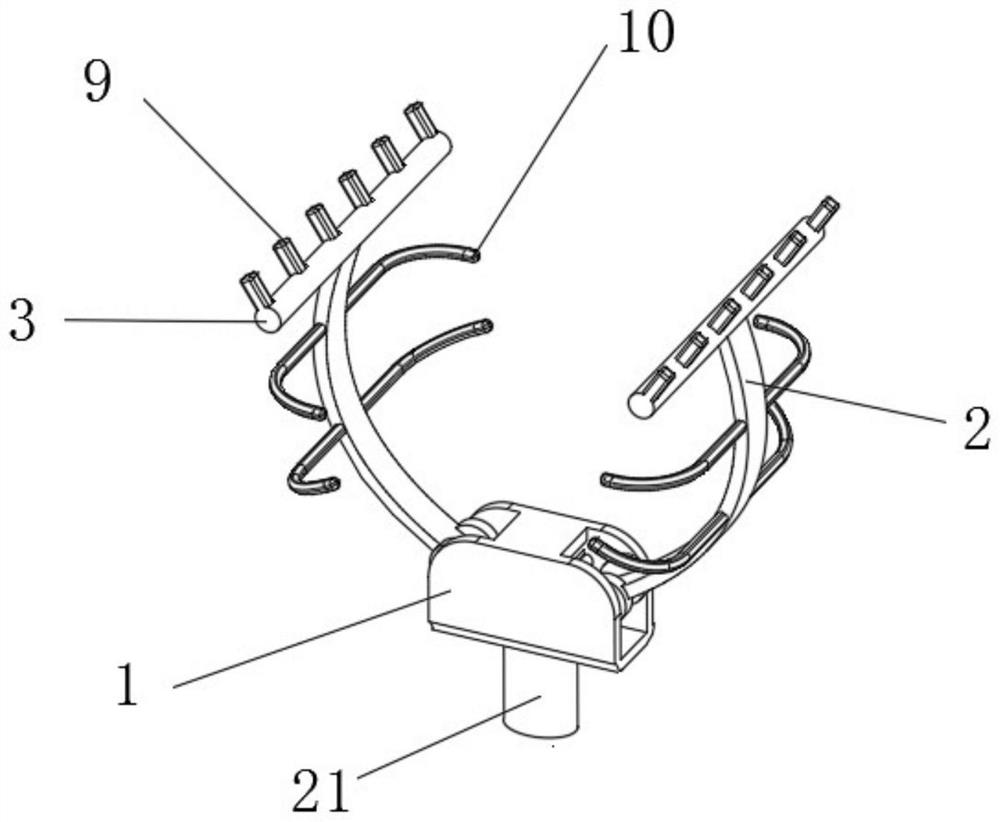

Widening mechanism of cable shielding network using rolling steel brush

ActiveCN110560613BAchieve Gap GrippingEnsure relative rotation capabilityWire networkElectric machineryStructural engineering

The invention discloses a cable shielding net expanding mechanism applying a rolling steel brush, relates to the expanding of a shielding net, and aims to solve the problem that the braided shieldingnet which is relatively tight in weaving is not easy to expand. The key points of the technical scheme are as follows that the cable shielding net expanding mechanism applying the rolling steel brushcomprises a supporting assembly, an executing assembly, a telescopic assembly and a rotating assembly; the executing assembly comprises an air claw, a gap clamping block, a steel brush wheel and a steel brush motor, the gap clamping block is provided with an arc groove, the execution assembly further comprises a swing control structure, the swing control structure comprises a rotating shaft and aswinging air cylinder, a holding block is hinged to the swinging air cylinder, and the holding block is clamped on the rotating shaft; and the rotating assembly is connected to the air claw, and the telescopic assembly is connected to the rotating assembly. According to the cable shielding net widening mechanism applying the rolling steel brush, the steel brush wheel is adopted to dial the braidedshielding net, the adaptability of the cable with different diameters is improved, and the problem that the braided shielding net which is relatively tight in weaving is not easy to expand is effectively solved.

Owner:JIAXING JUNQUAN AUTOMATION

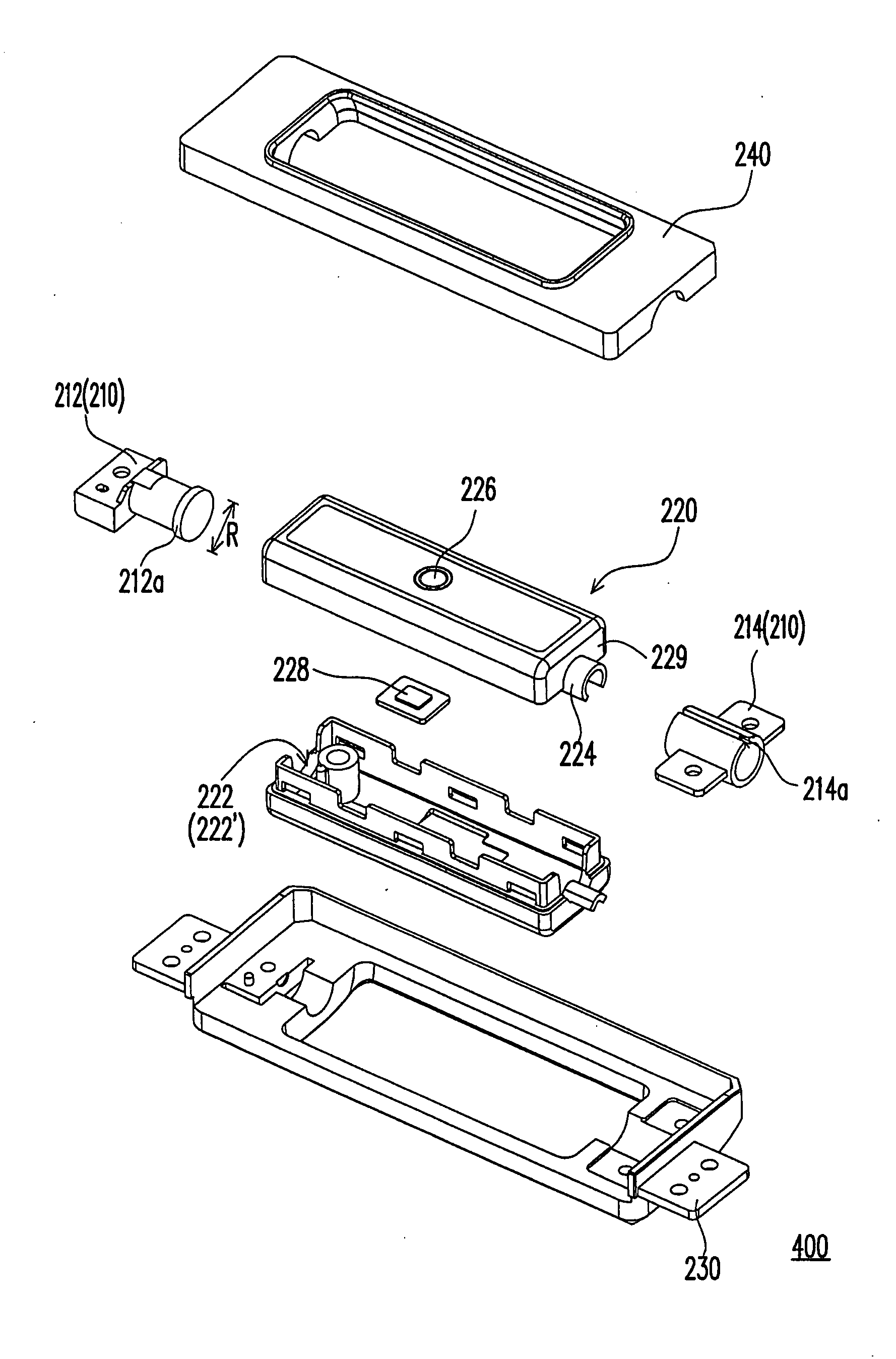

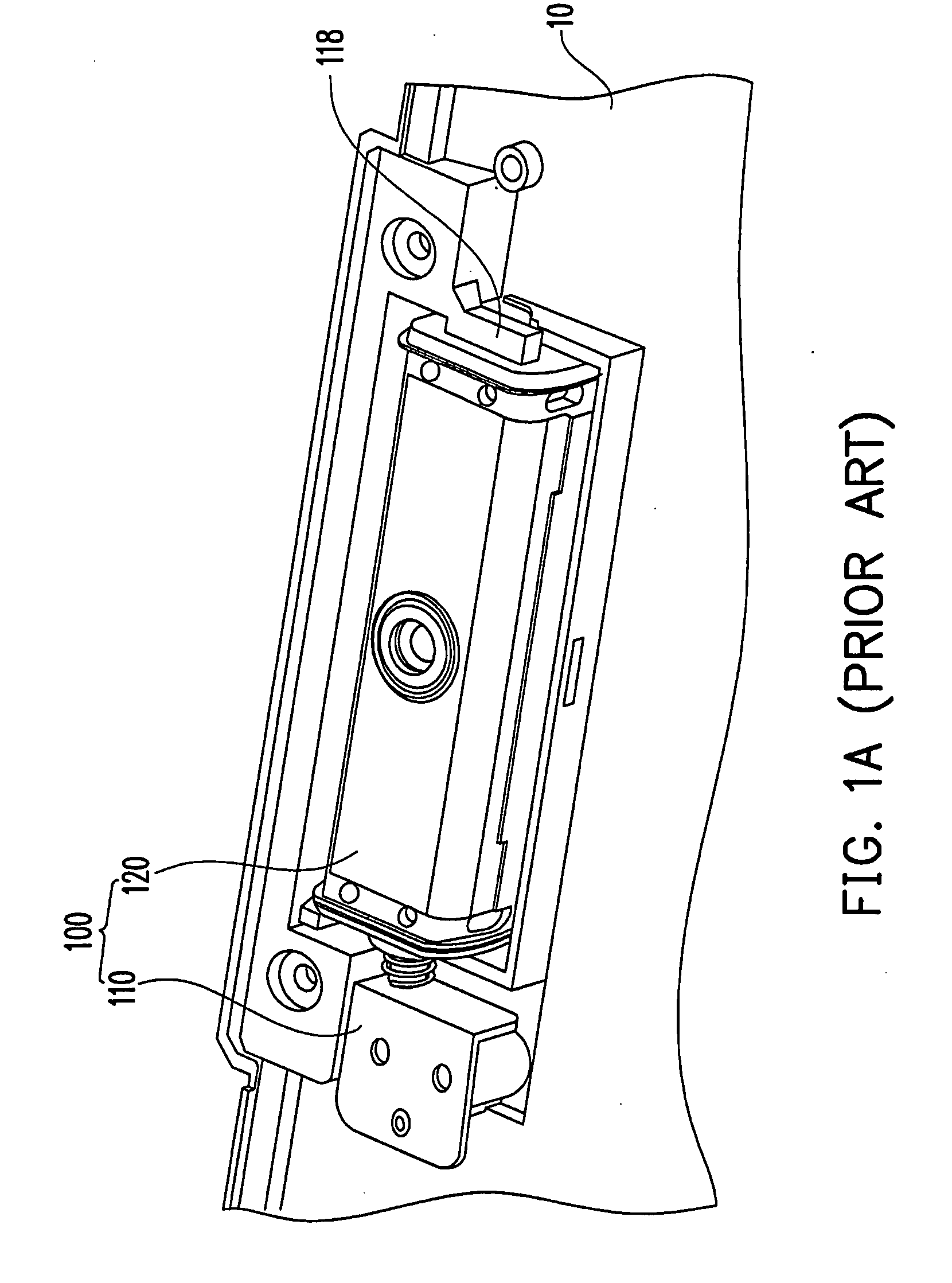

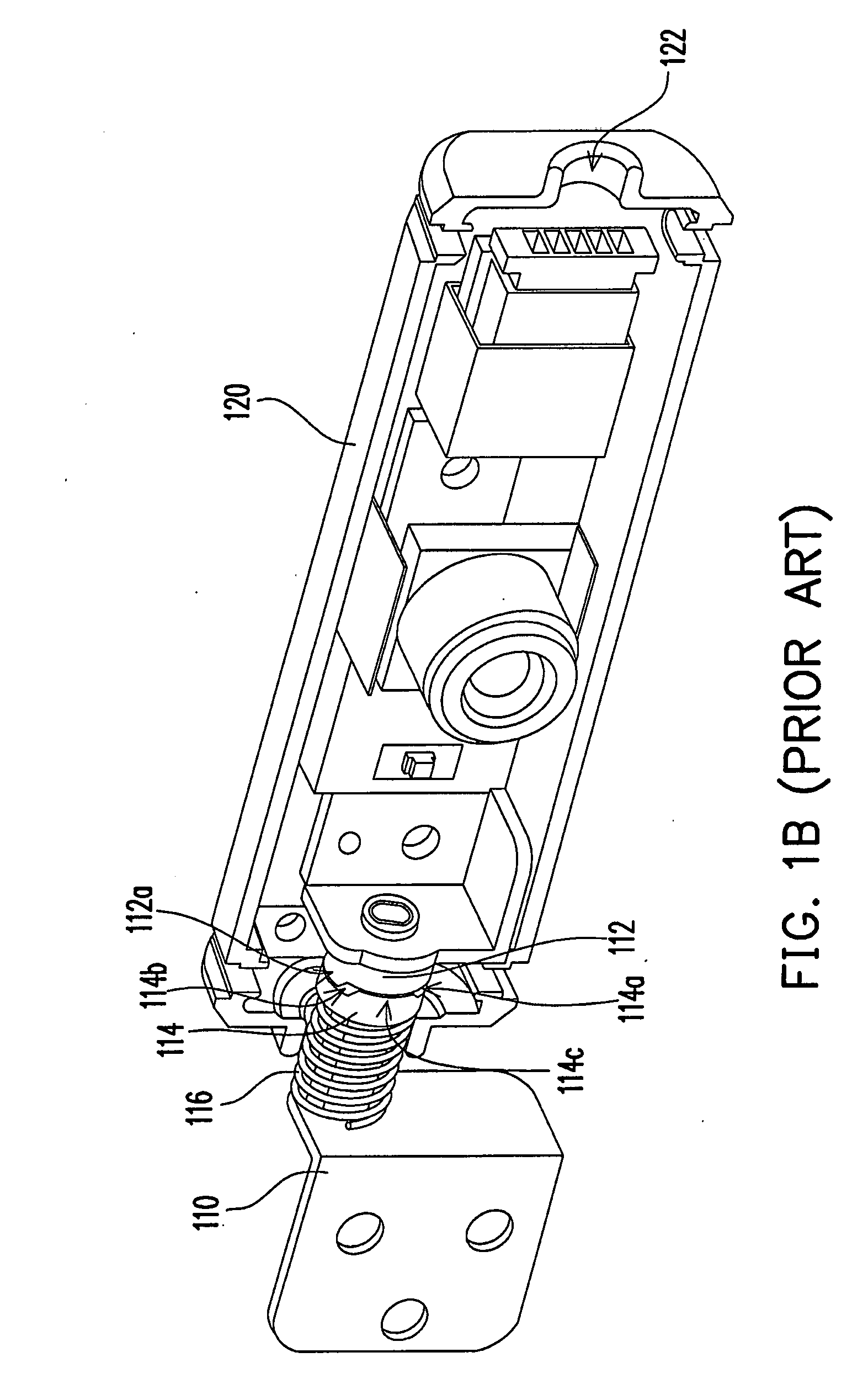

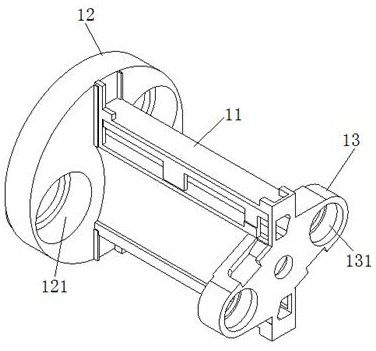

Image-capturing module and portable computer having the same

InactiveUS20080074835A1Smooth rotationImprove smoothness of rotationDetails for portable computersSupport structure mountingEngineeringMechanical engineering

A portable computer including a display module and an image-capturing module is provided, wherein the image-capturing module is provided on the display module. The image-capturing module includes a pivoting mechanism and an image-capturing device pivotally connected to the pivoting mechanism. The pivoting mechanism has a first pivot part and a second pivot part, and a slot is formed in the second pivot part. The image-capturing device has a third pivot part and a fourth pivot part. The first pivot part is pivotally connected to the third pivot part, and the second pivot part is pivotally connected to the fourth pivot part, wherein the first pivot part and the second pivot part are fixed on the display module.

Owner:ASUSTEK COMPUTER INC

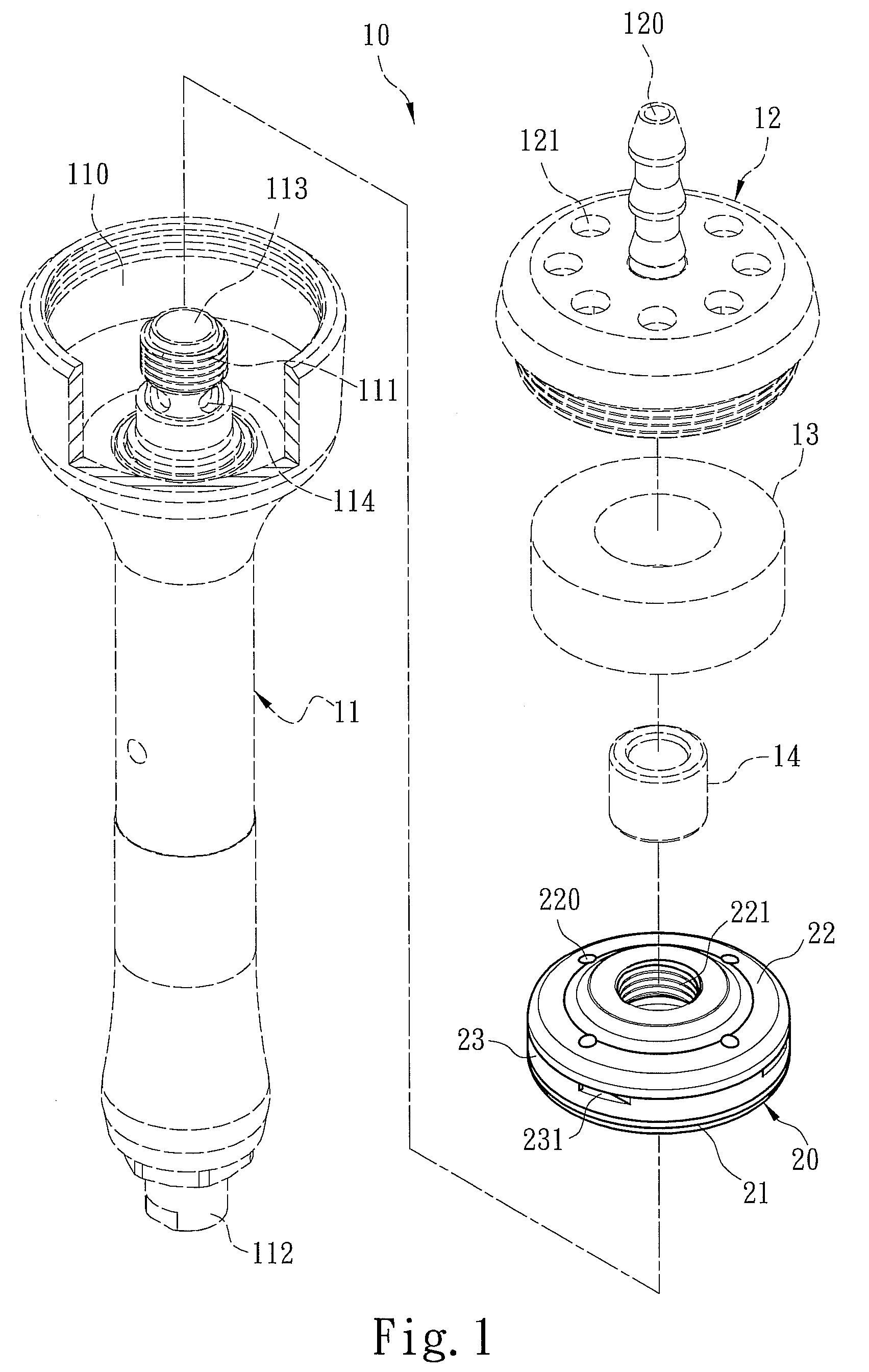

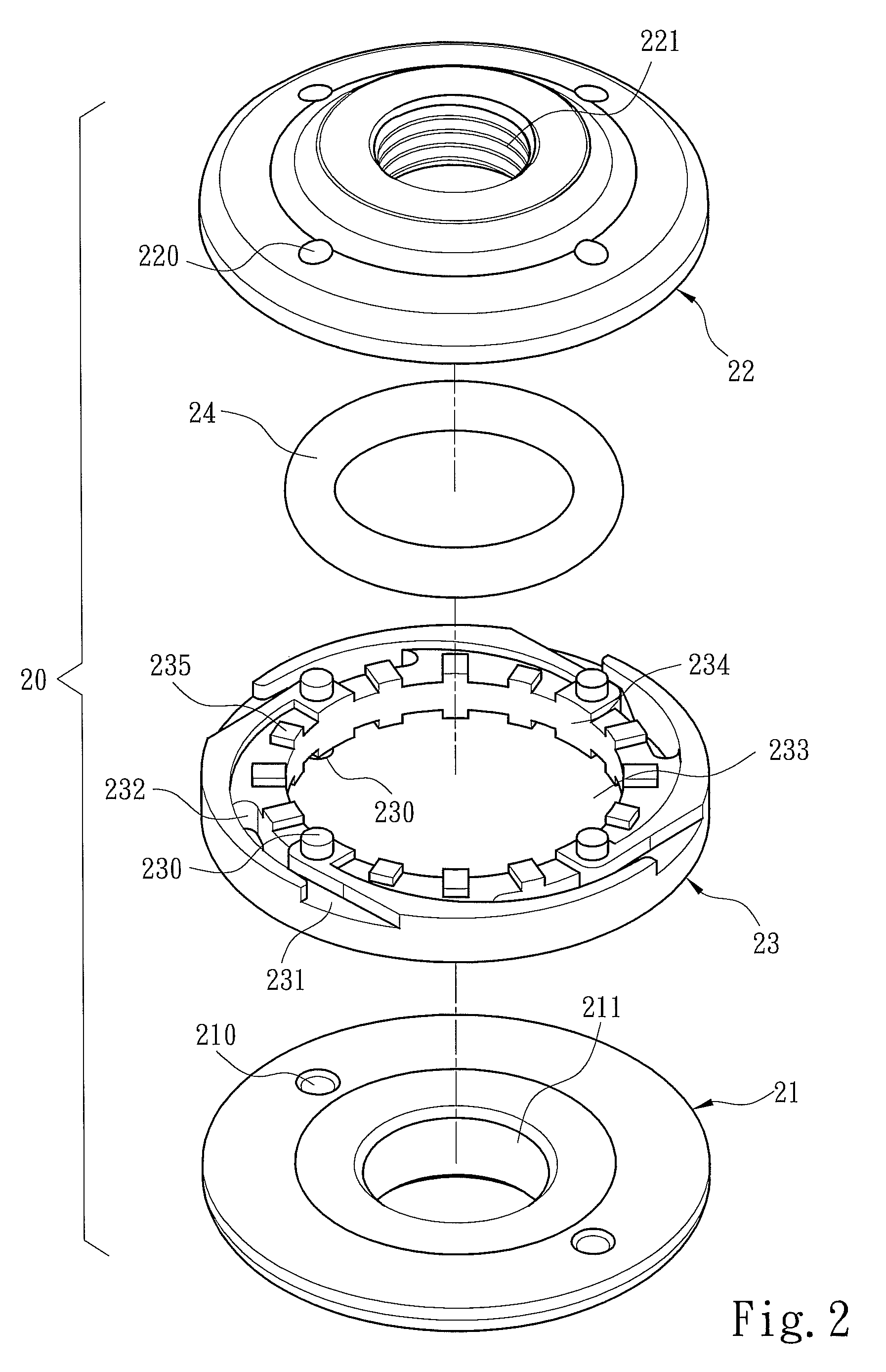

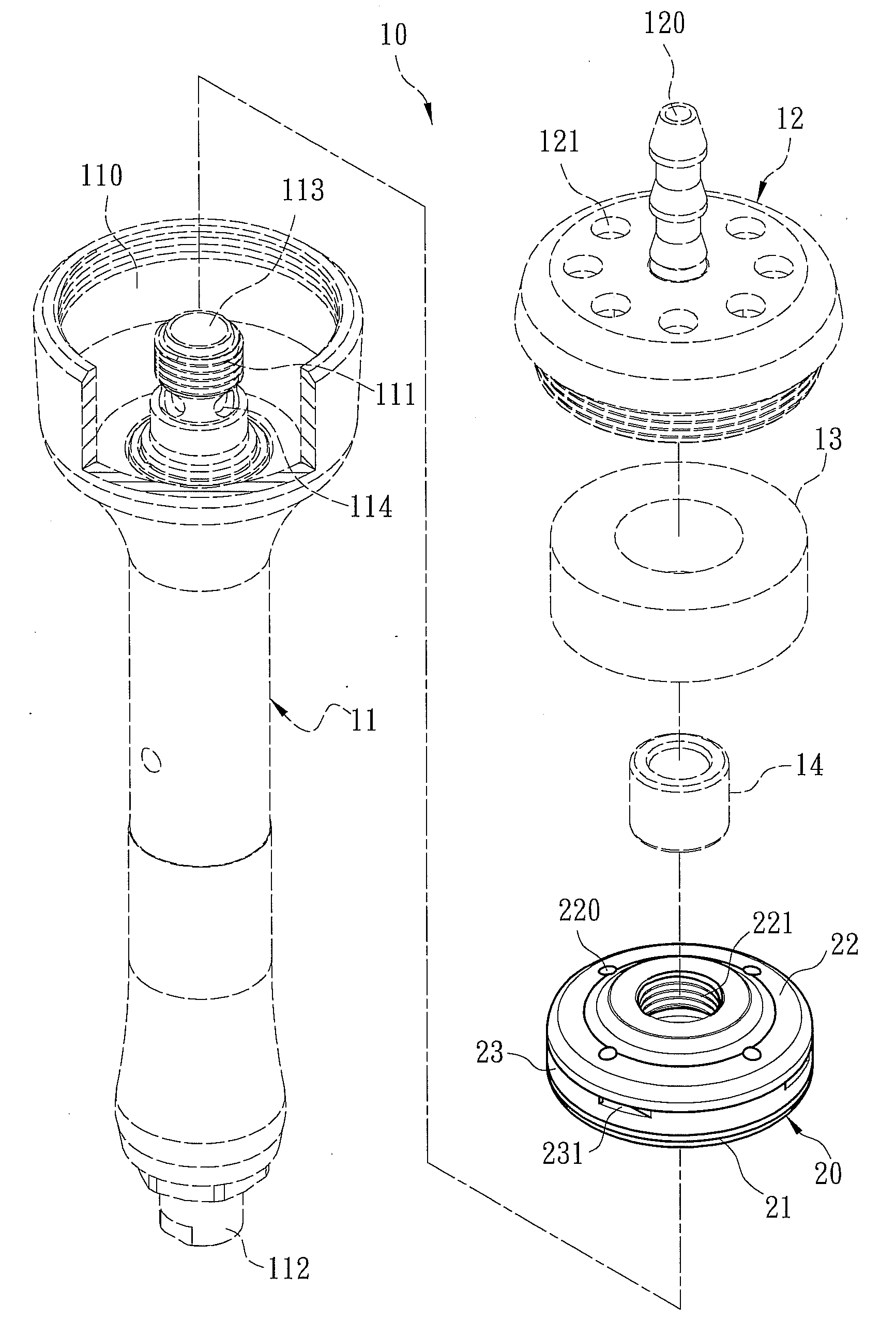

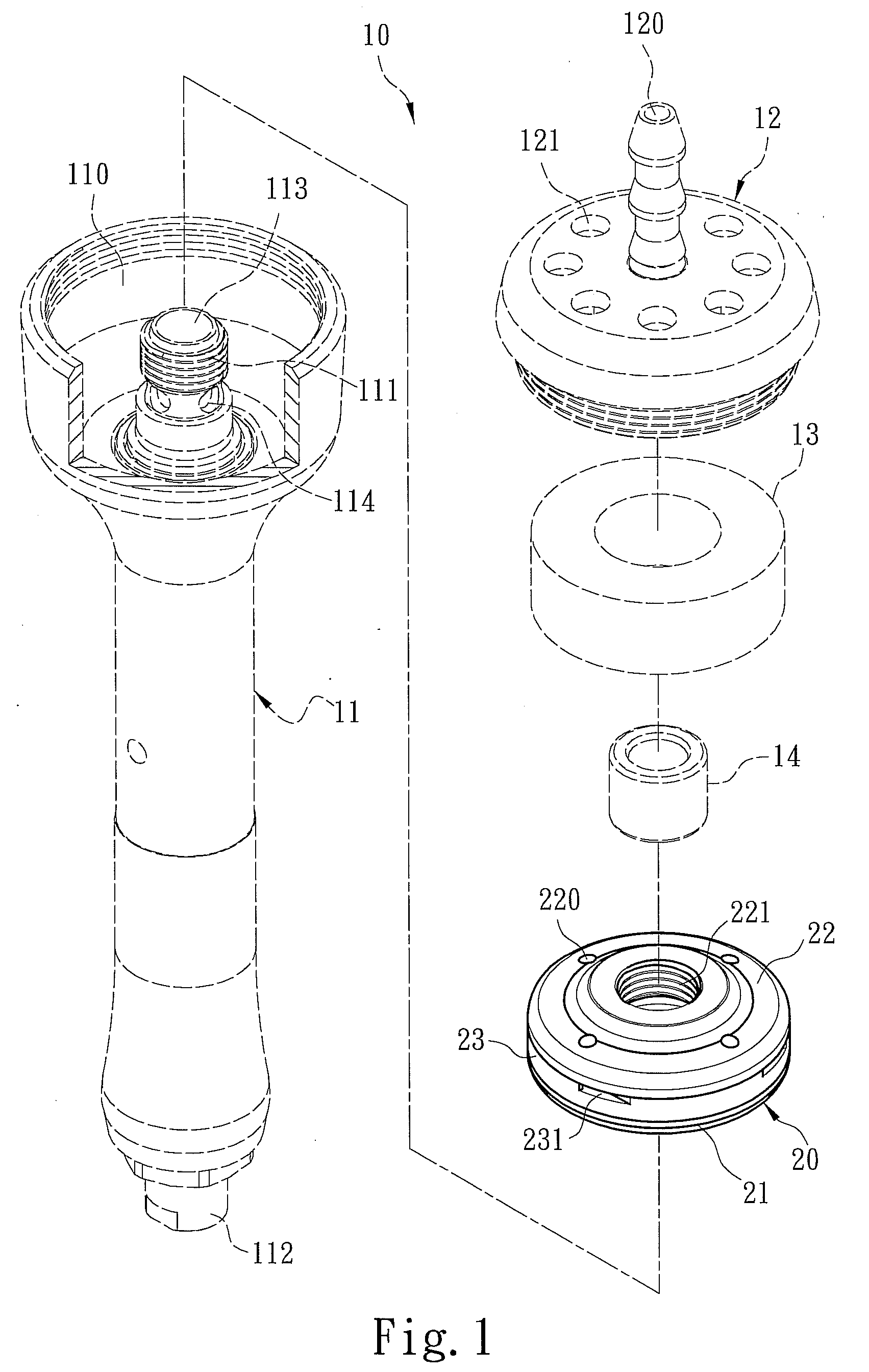

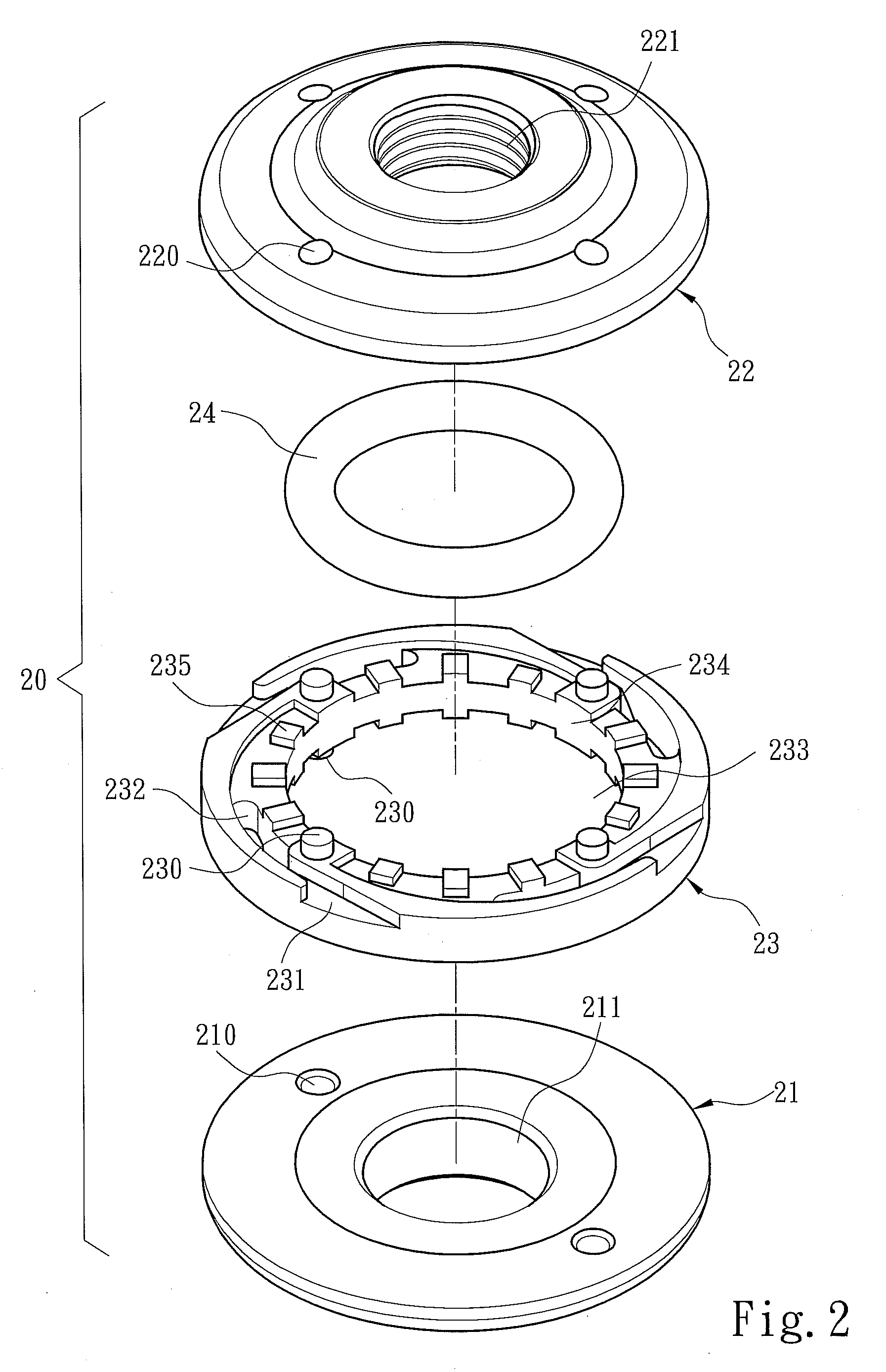

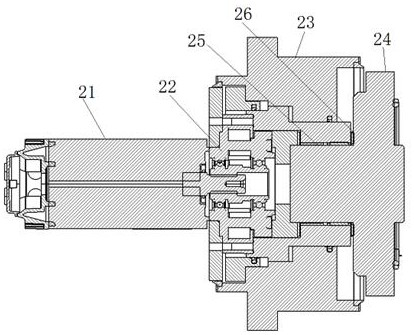

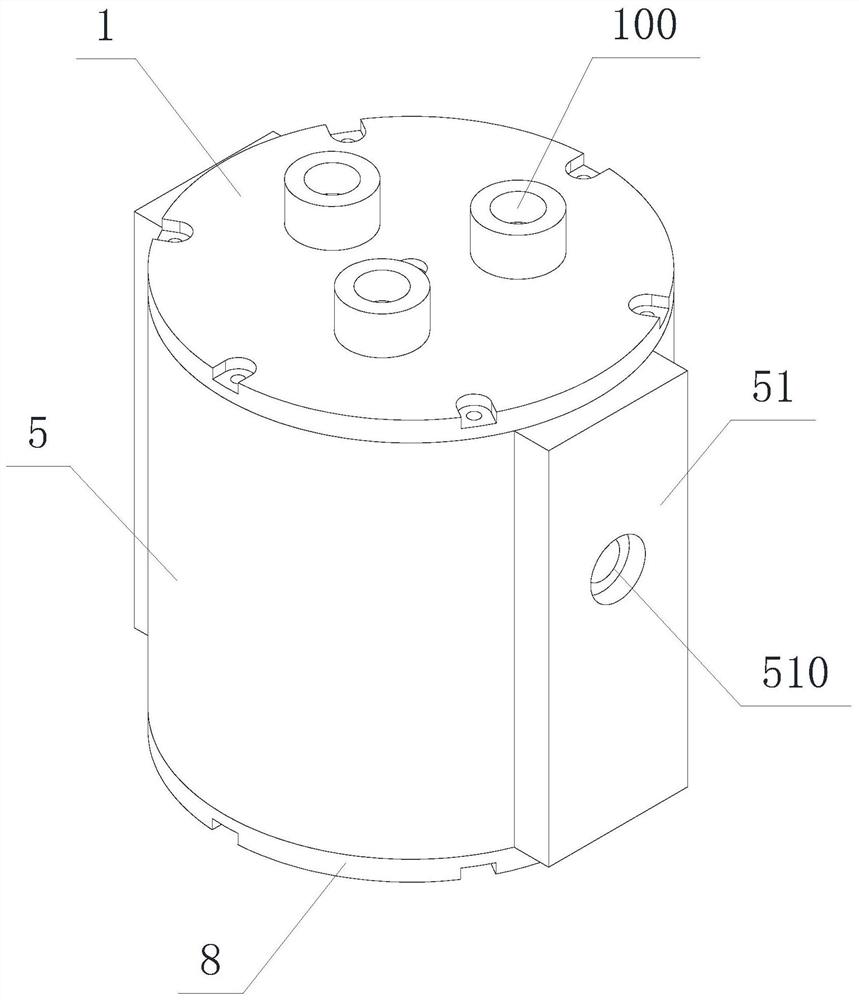

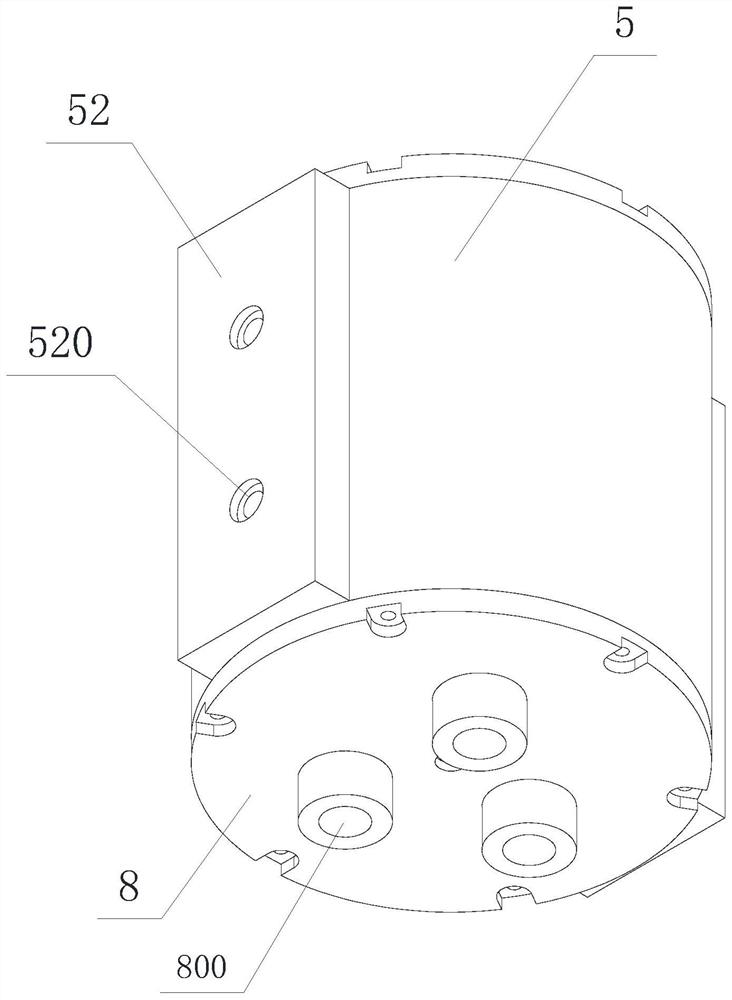

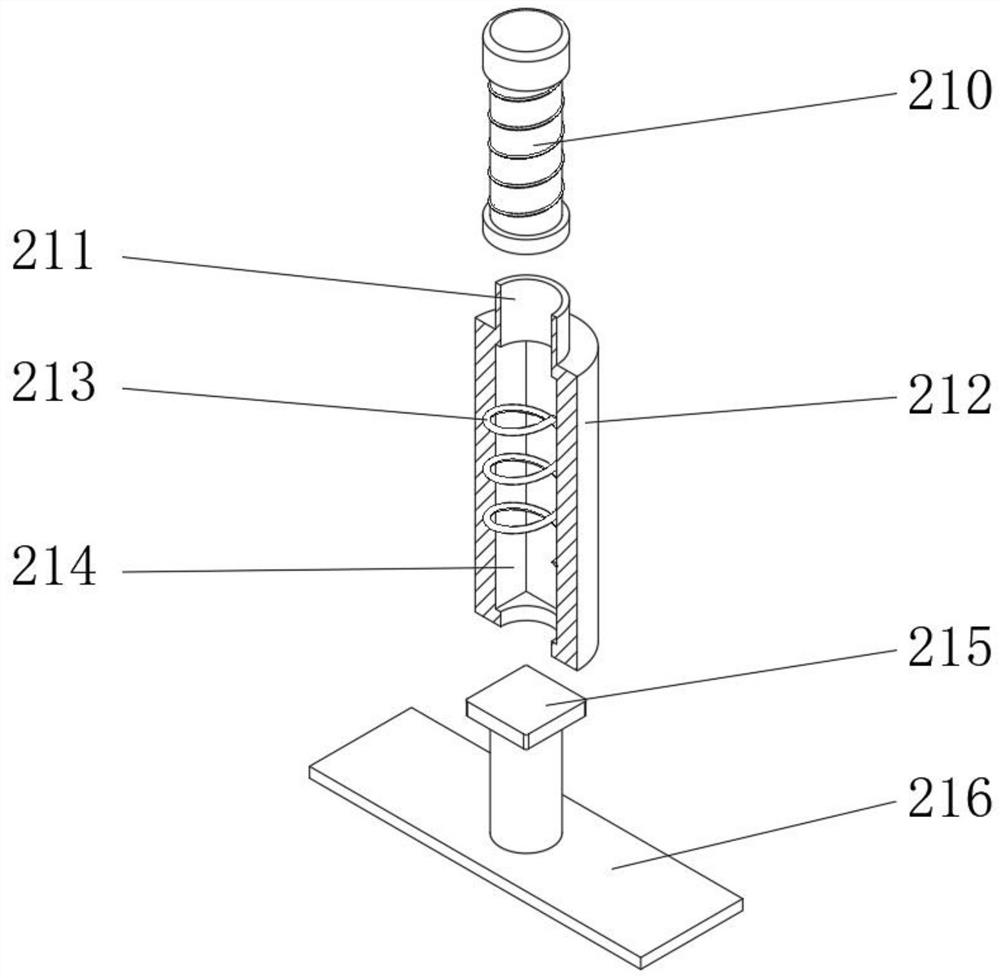

Pneumatic turbine motor air chamber

ActiveUS20090232649A1Improves smoothness of rotationSolution has disadvantagePump componentsStatorsTurbineAirbox

A pneumatic turbine motor air chamber drives a pneumatic turbine to rotate through compressed air. The pneumatic turbine has a ring extended from inside thereof that has a plurality of barriers and forms a housing space to hold a speed regulator. The pneumatic turbine also has an air intake coupling hole leading to the housing space and at least one air discharge vent communicating with an air passage to discharge the compressed air. The ring is integrally formed with the pneumatic turbine to enhance operation steadiness of the pneumatic turbine.

Owner:XPOLE PRECISION TOOLS

Cutting equipment for production and processing of elliptical head

PendingCN111545865AEasy to operateSecure cutting workWelding/cutting auxillary devicesAuxillary welding devicesCrankEngineering

The invention relates to the field of production and processing of an elliptical head, in particular to cutting equipment for the production and processing of the elliptical head. The cutting equipment comprises a base, a rotating structure, an unloading structure, a fixing structure, a transverse moving structure, a vertical moving structure, an angle adjusting structure and a clamping structure.According to the cutting equipment, the rotating structure can rotate a placed head for 360 degrees and can cooperate with flame cutting torch to complete annular cutting of the head, besides, by cooperation with the unloading structure, the head can be jacked up only by rotating a hexagonal crank externally, and unloading operation of the head can be convenient; by means of the fixing structure,the head placed on a placing sleeve can be sufficiently fixed, the fixation is firm, placement of the head and unloading work of the head cannot be affected, and the fixation is convenient and efficient; and by means of the transverse moving structure and the vertical moving structure, transverse and vertical positions of the flame cutting torch can be adjusted, so that accurate cutting can be realized when the transverse position adjustment is needed.

Owner:浙江豪特金属封头制造有限公司

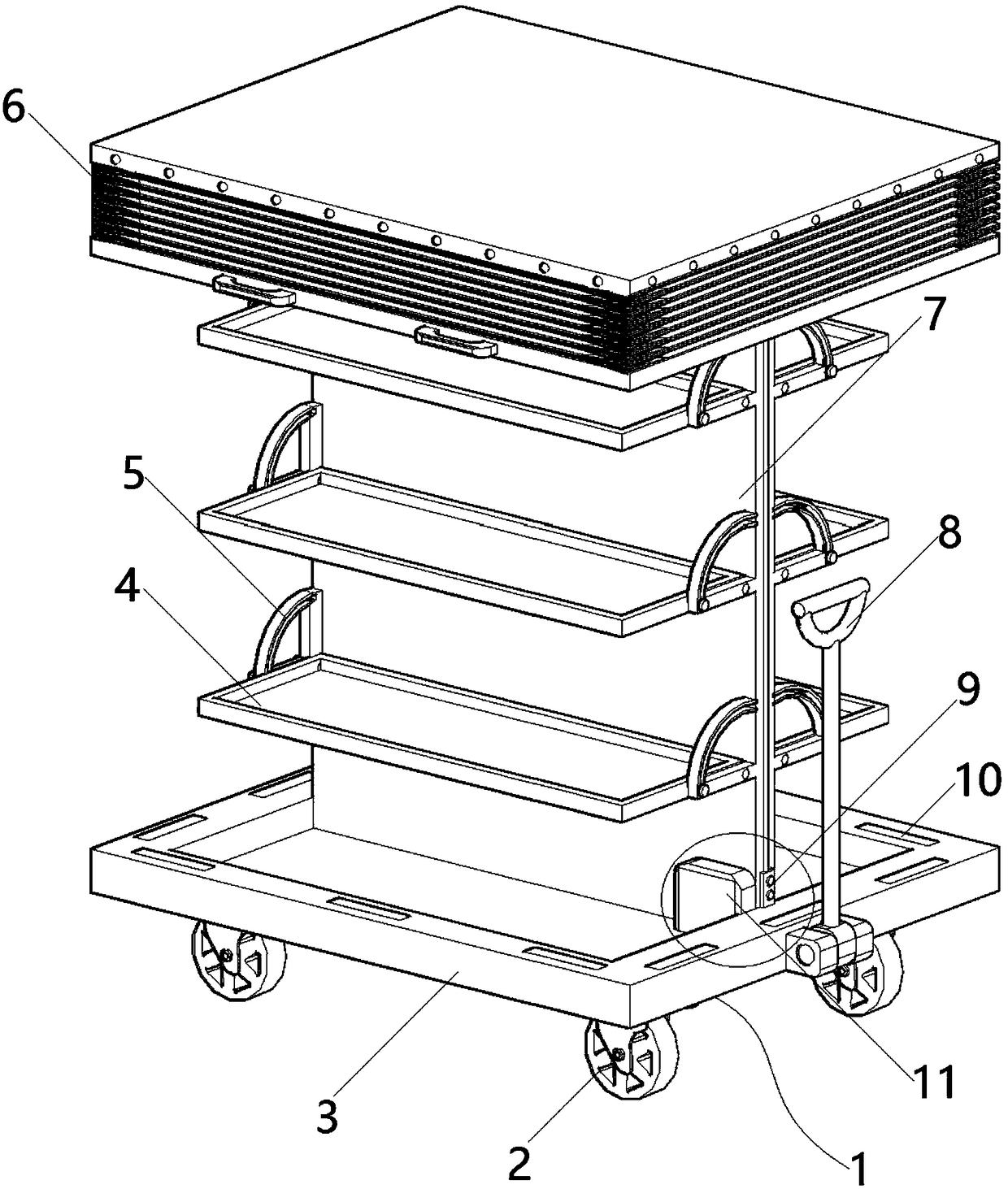

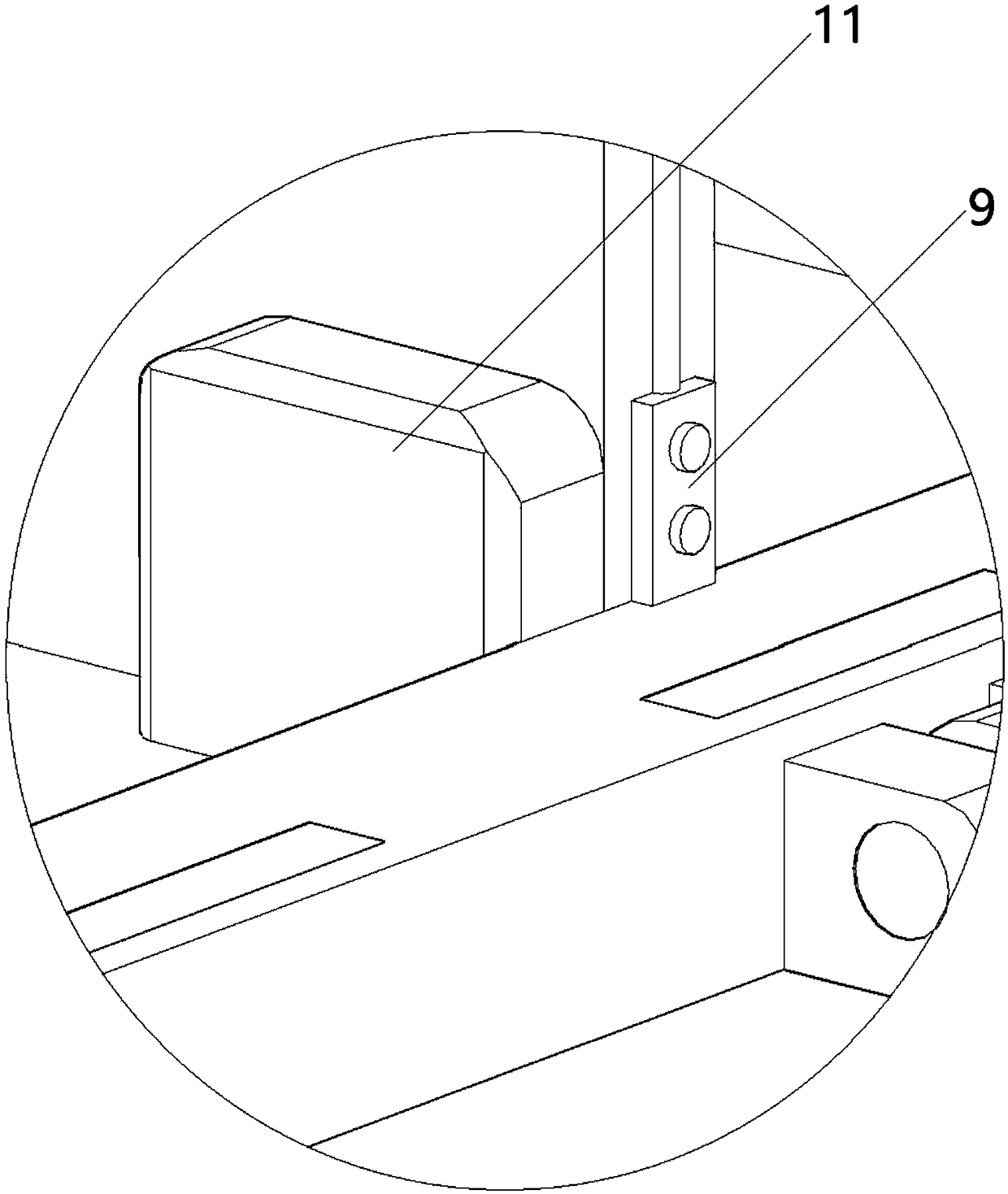

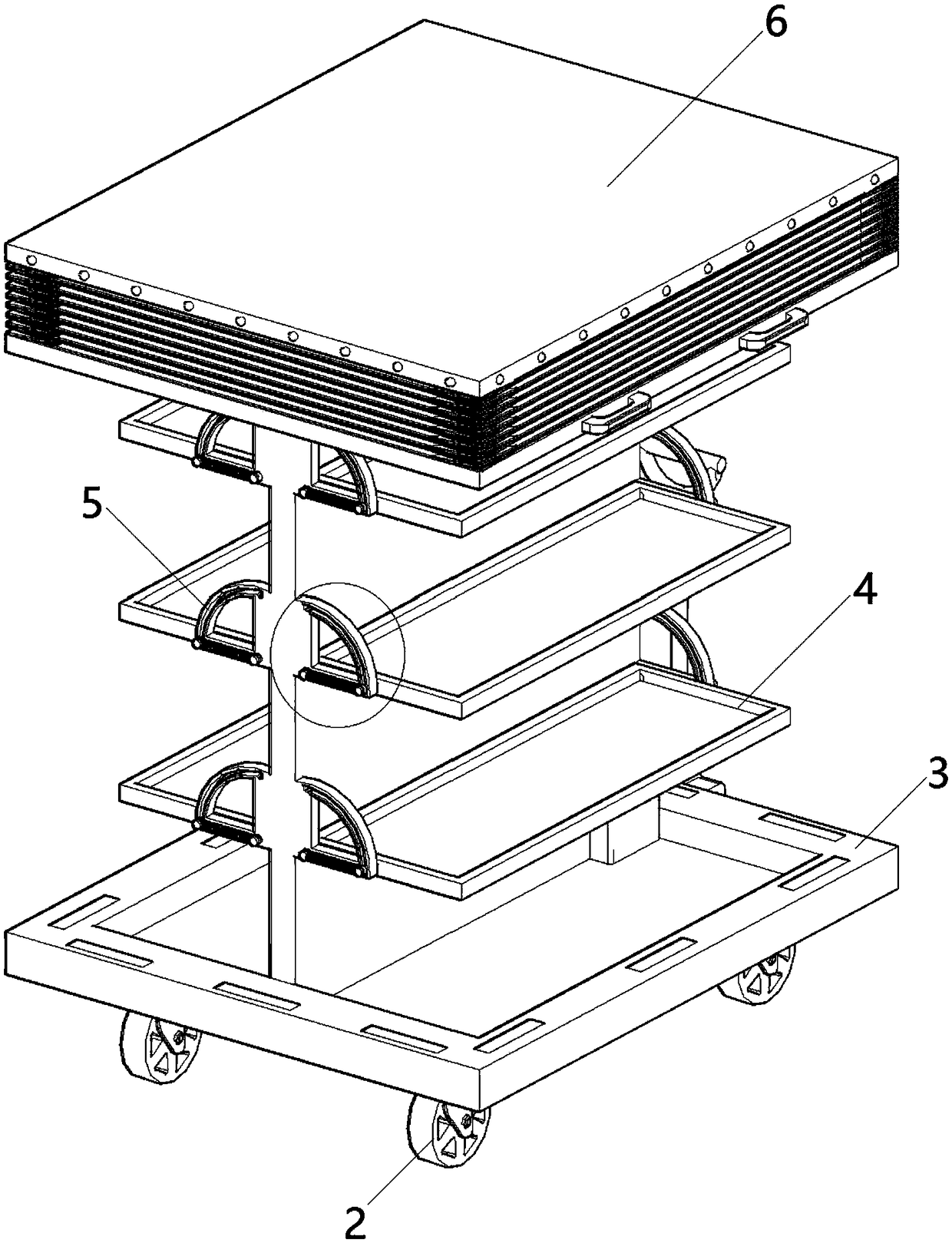

Short-distance material transfer device with dust-proof protection structure

InactiveCN108284861ASmooth rotationImprove the fixing strengthHand carts with multiple axesHand cart accessoriesShortest distanceEngineering

The invention discloses a short-distance material transfer device with a dust-proof protection structure. The short-distance material transfer device with the dust-proof protection structure comprisesplacing plates, rotating supporting frames and a dust-proof cover. Moving wheels are symmetrically arranged on the bottom side of a supporting chassis. Locking magnetic disks are symmetrically embedded in the upper side of the top side edge of the supporting chassis. A traction handle is arranged on the side wall of one side of the supporting chassis. A middle partition board is fixedly arrangedon the middle position of the upper side of the supporting chassis. The rotating supporting frames are symmetrically arranged on two sides of the middle partition board in a welded mode. The placing plates are arranged on movable fixing shafts on the rotating supporting frames. The dust-proof cover is arranged at the top end of the middle partition board. A top cover is arranged at the top end ofa curtain cover. The rotating supporting frames are arranged on the short-distance material transfer device with the dust-proof protection structure, and each of the rotating supporting frames is designed as a one forth circular-arc-shaped track; and guiding grooves are formed in the rotating supporting frames, the placing plates can carry out rotating movement by taking structures of the rotatingsupporting frames as a track, the placing plates rotate more stably, and the fixing strength is higher.

Owner:沈向红

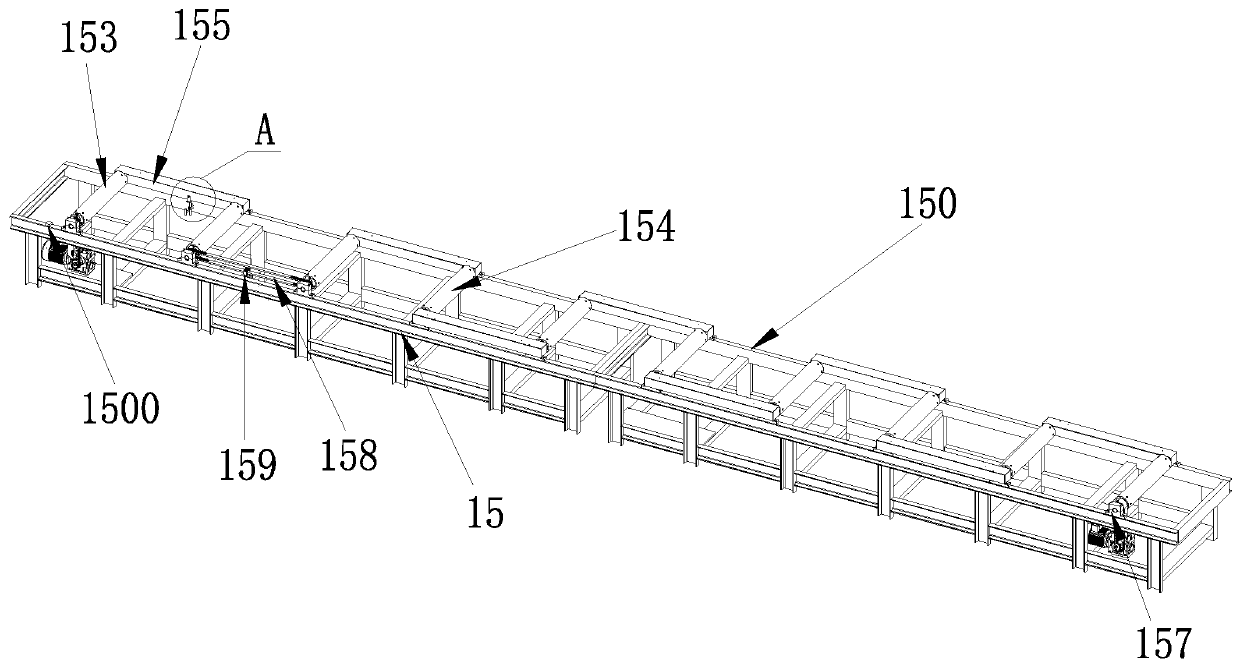

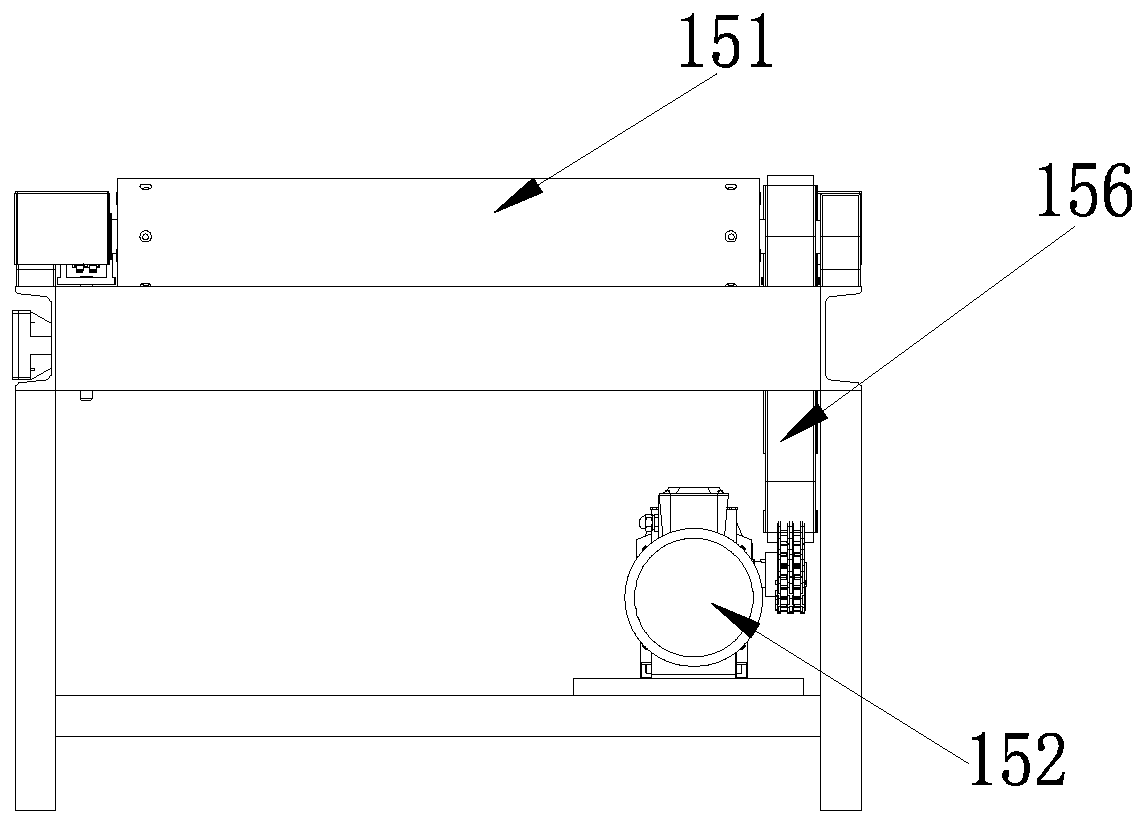

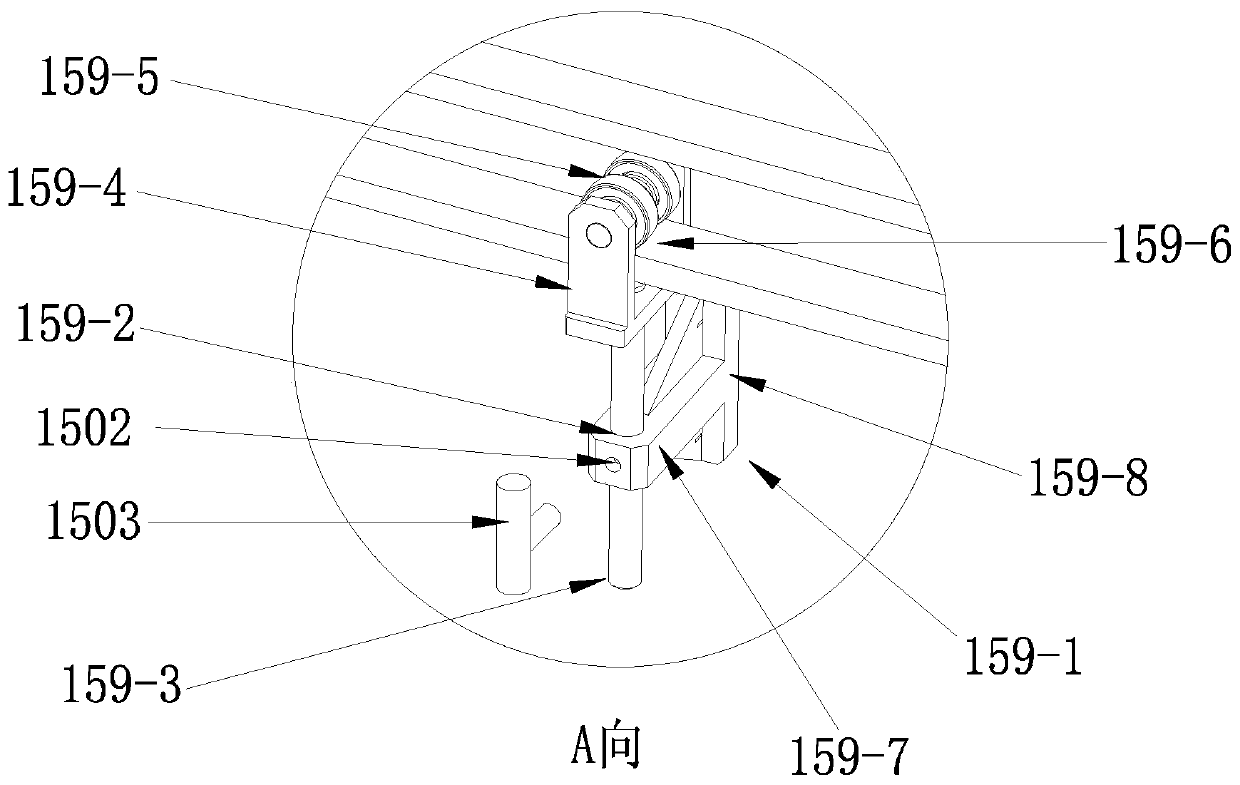

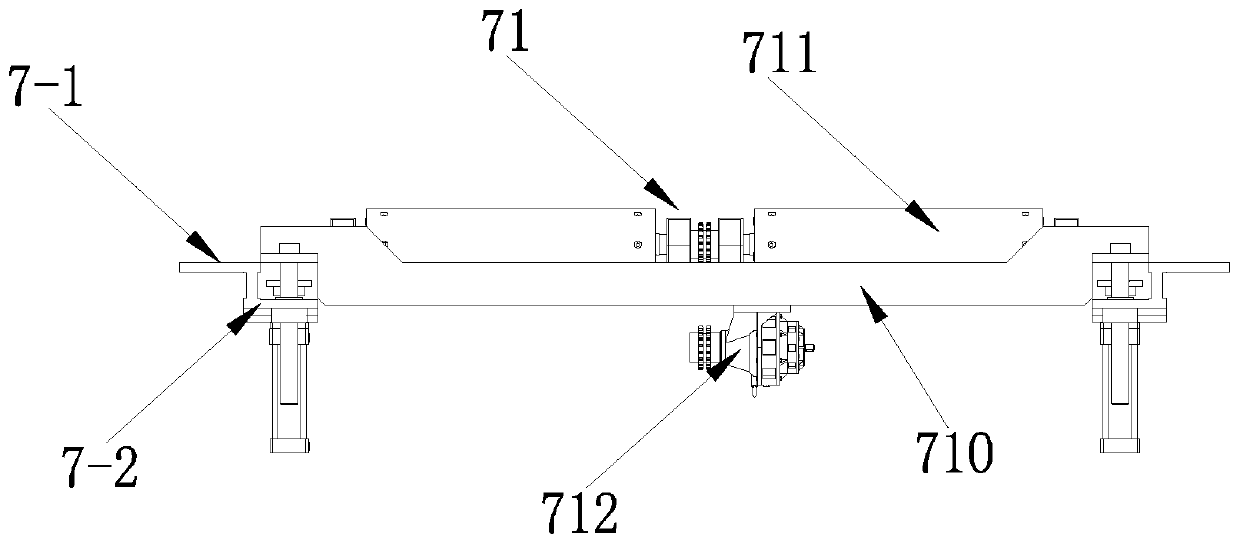

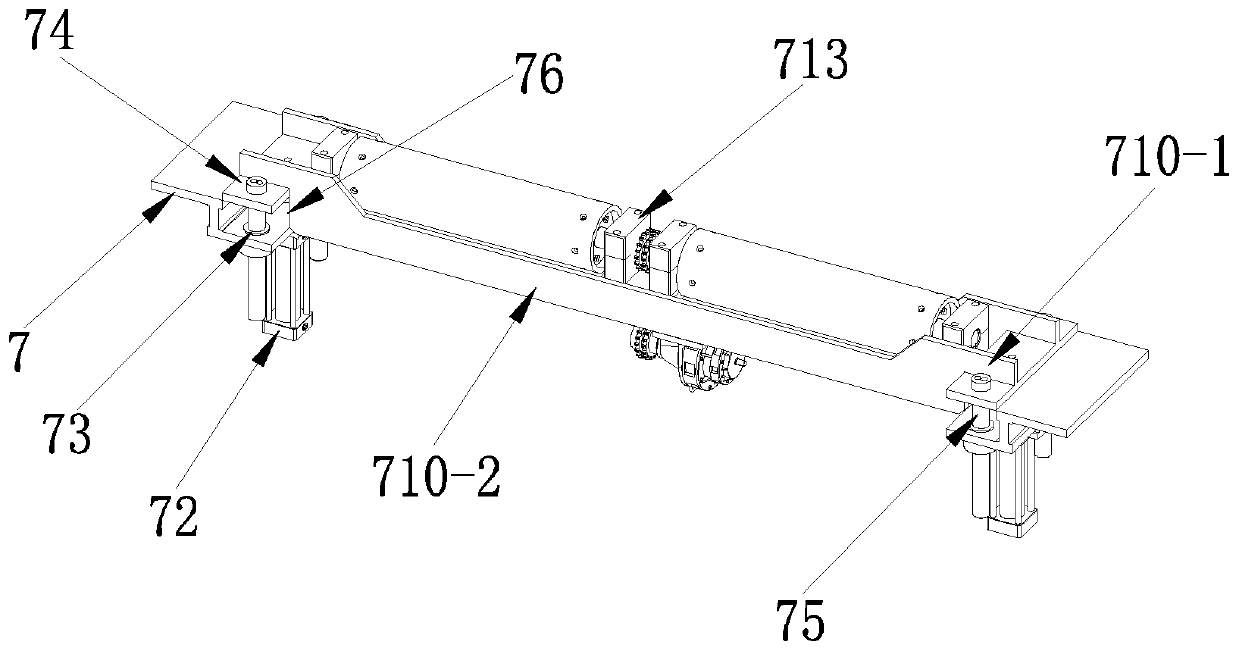

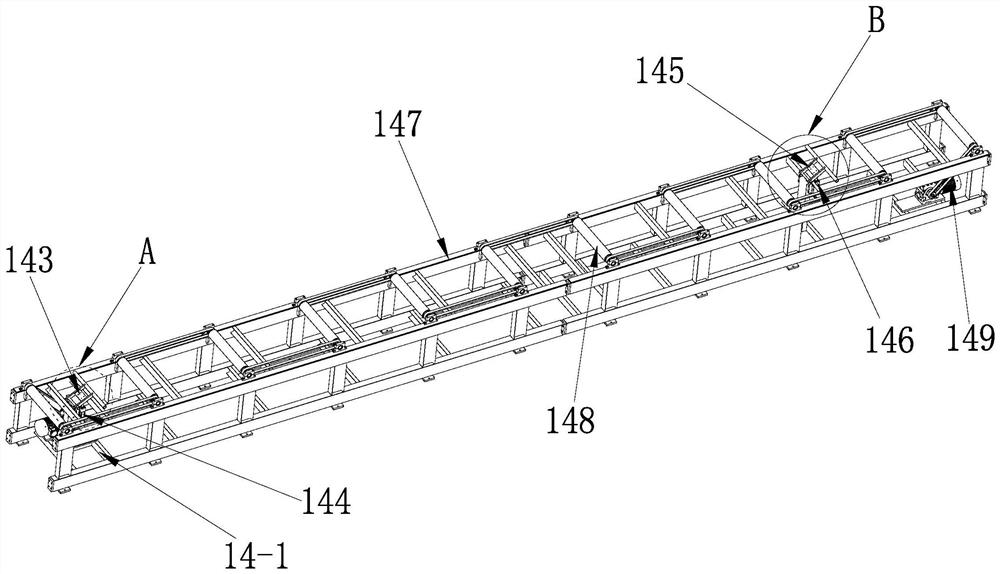

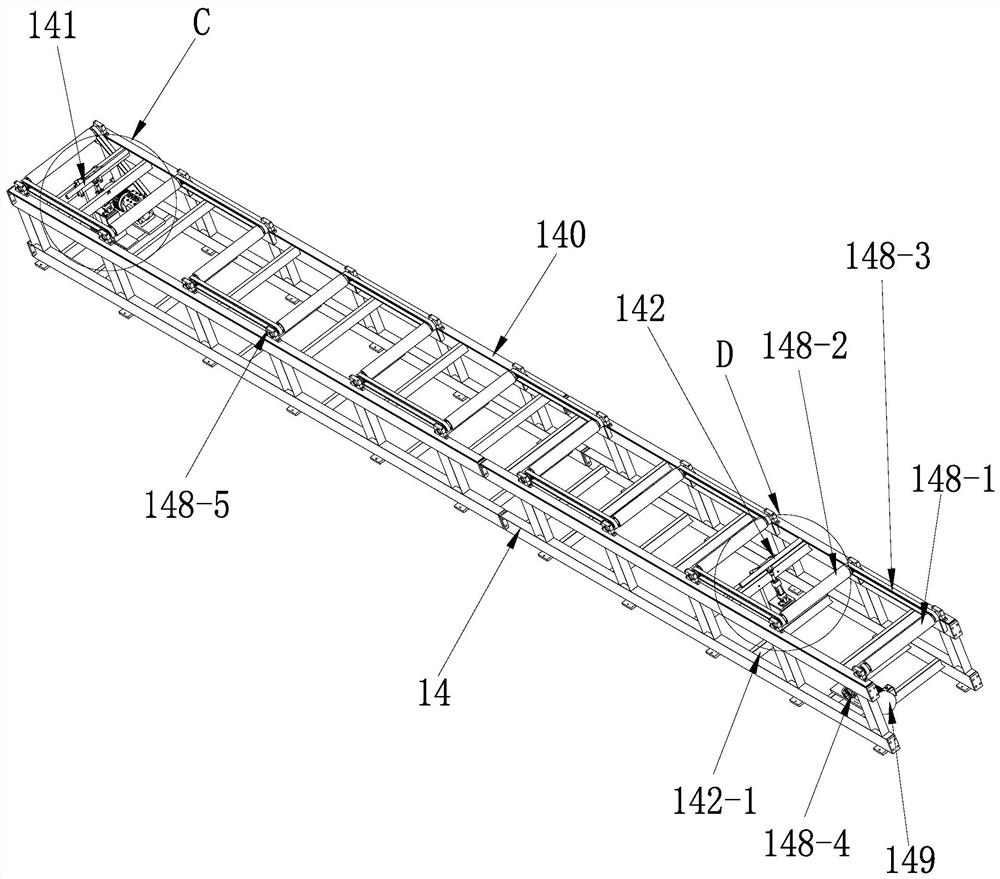

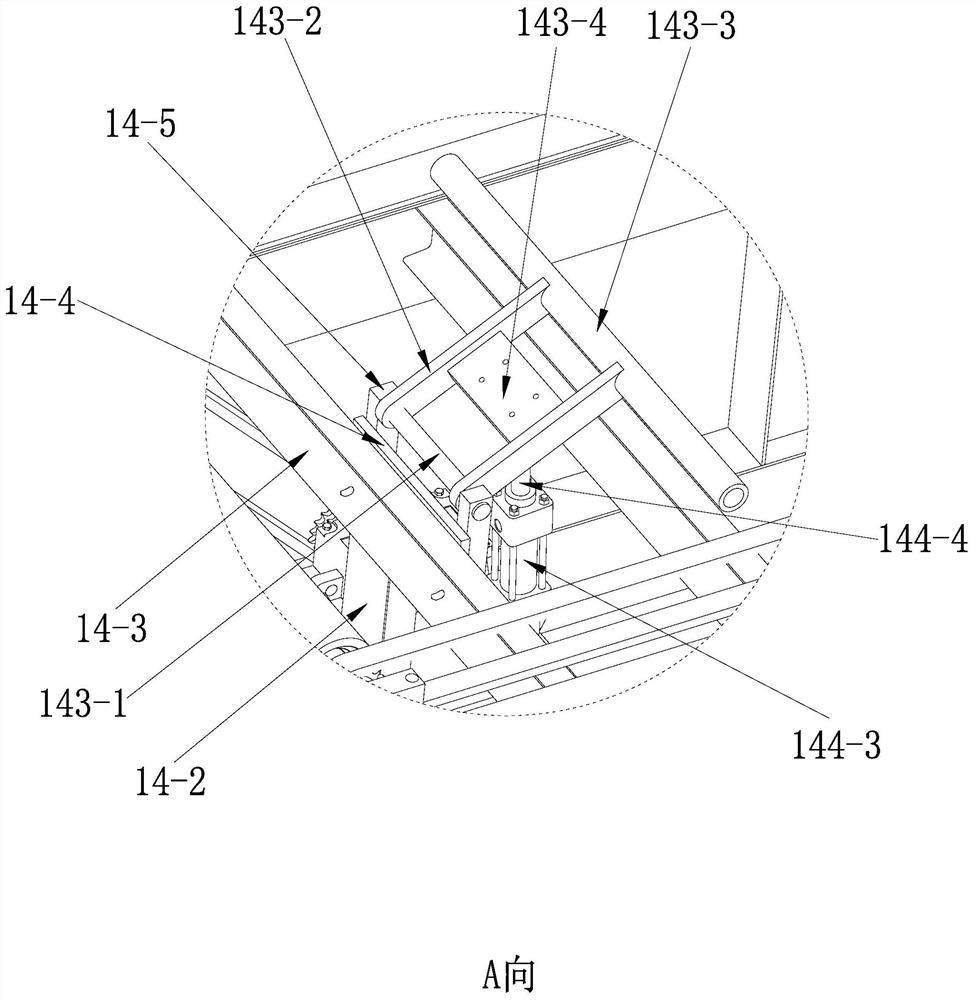

Feeding roller bed of chamfering machine

InactiveCN110817243AReal online cacheReality deliveryEdge grinding machinesGearingElectric machineryDrive motor

The invention relates to a feeding roller bed of a chamfering machine. The feeding roller bed comprises a platform arranged horizontally; linear guiding rails, a cache component for containing steel plates and driving motors are mounted on the platform; the cache component comprises at least one receiving roller and conveying rollers; the at least one receiving roller and the conveying rollers aremounted on the linear guiding rails in an end-to-end connected manner and are connected through receiving chains; the ends of the at least one receiving roller are connected with the driving motors through connecting chains; and the driving motors are fixedly arranged at the bottom of the platform. The feeding roller bed is simple in structure and convenient to operate; the receiving rollers anda plurality of transmission rollers are arranged, and then active transmission among the conveying rollers is realized through the chains, so that the conveying efficiency is greatly improved; and online caching and conveying of workpieces are realized.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

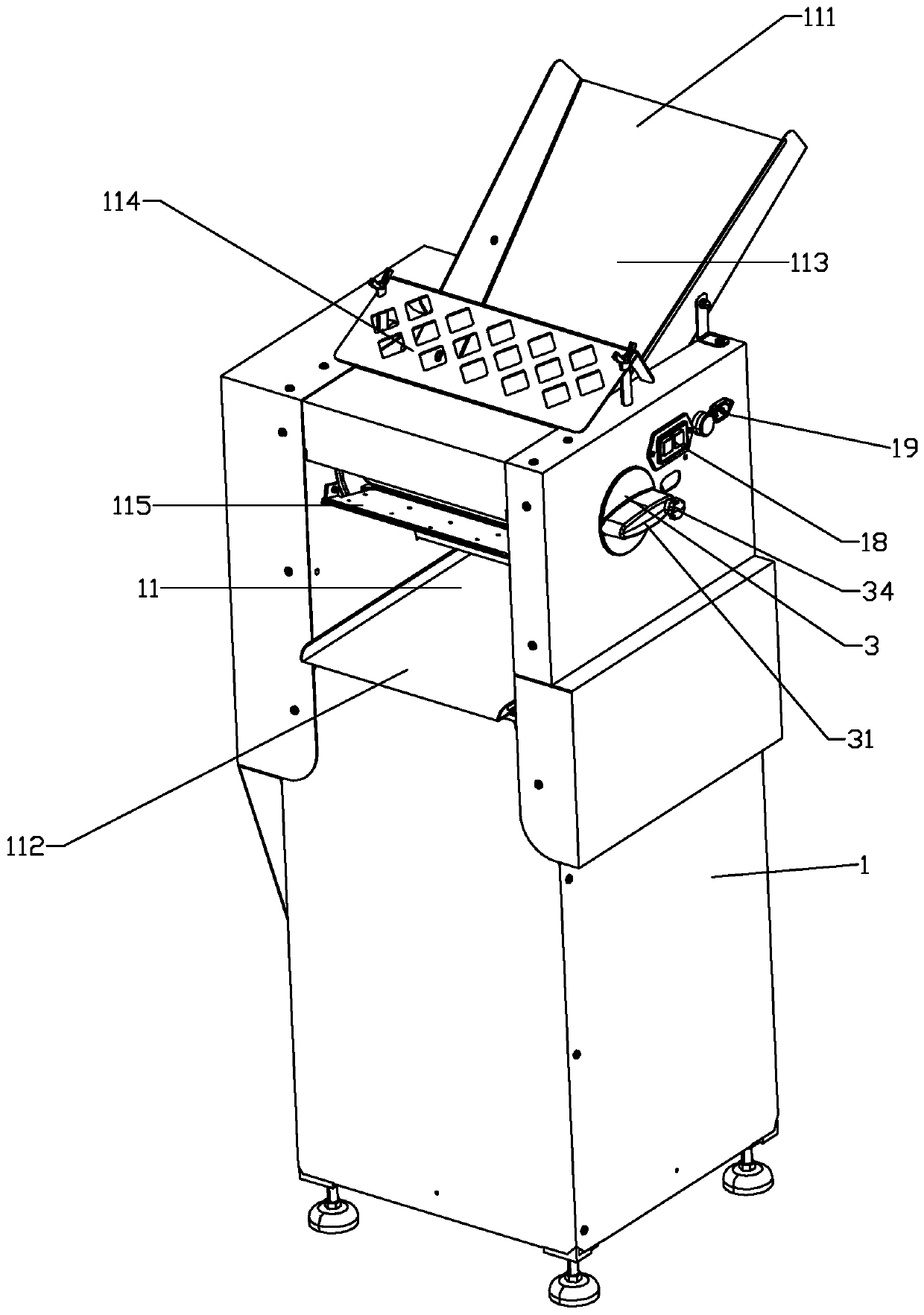

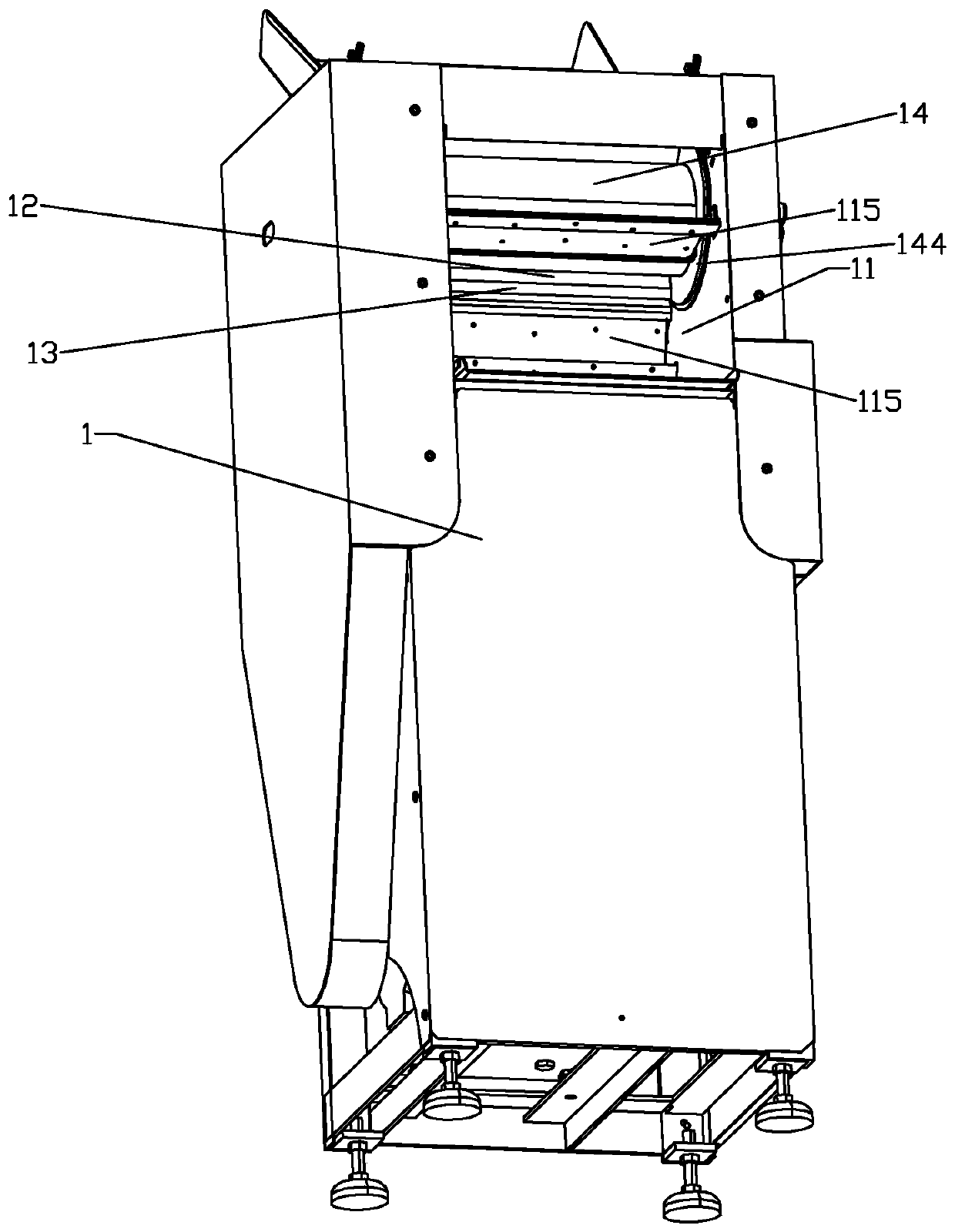

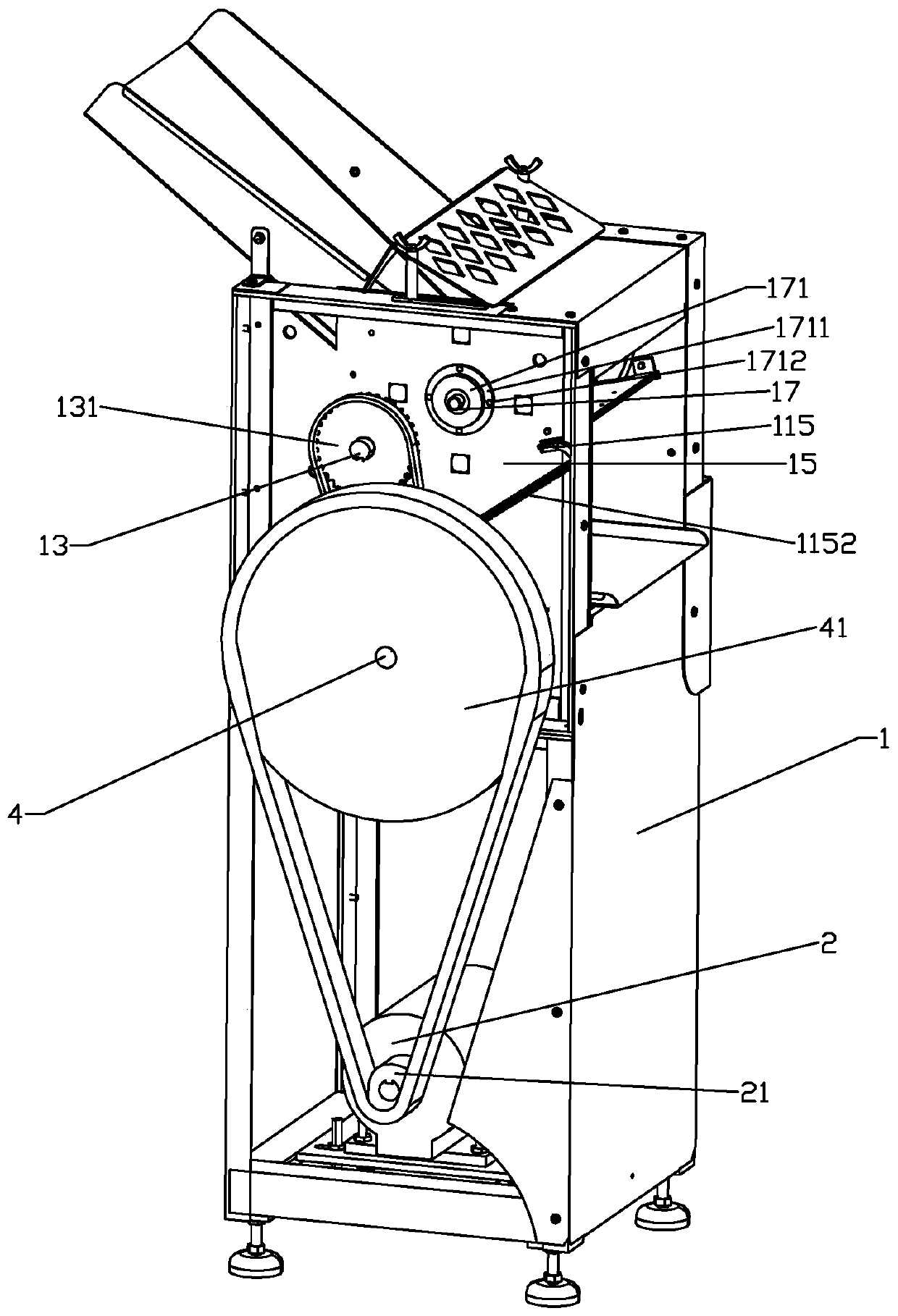

Dough kneading machine

PendingCN110402977AEasy to replaceEasy maintenanceMixing/kneading structural elementsMixing/kneading with rollersEngineeringMechanical engineering

The invention relates to a dough kneading machine, which comprises a rack, a motor and two dough kneading rollers and further comprises a spacing adjusting device. The rack is provided with a dough kneading channel, one end of the dough kneading channel is a storing end for storing dough, and the other end of the dough kneading channel is a discharging end for sending the dough out; the two doughkneading rollers are parallelly and rotationally arranged on the rack and located on the two vertical sides of the dough kneading channel correspondingly; a gap between the two dough kneading rollersserves as a rolling gap for rolling the dough; the motor is fixed to the rack and drives the two dough kneading rollers to rotate; and the two dough kneading rollers include the fixed roller keeping the only position relative to the rack and the adjusting roller capable of moving relative to the rack correspondingly, and the spacing adjusting device is arranged between the adjusting roller and therack and adjusts the spacing of the rolling gap by moving the adjusting roller. By adopting the dough kneading machine, the spacing of the rolling gap can be adjusted, and thus different processing demands are met.

Owner:管玲敏

Rotating assembly and floor air conditioner

PendingCN108167946AReduce body sensationImprove comfortCondensate preventionLighting and heating apparatusElectrical and Electronics engineeringMicro holes

The invention provides a rotating assembly and a floor air conditioner. The rotating assembly includes an arc air-out panel, an arc air-in panel and a driving mechanism, wherein, the arc panels are provided with micro-holes areas; the arc air-in panel and the arc air-out panel can be detachably contacted and assembled; and the driving mechanism is assembled at the bottom and / or the top of the arcair-in panel, and the driving mechanism is used for driving the arc air-in panel and the arc-out panel to rotate. According to the technical scheme, the arc air-in panel and a driving device are cooperatively assembled, thereby achieving corresponding autorotation of an air-out assembly to achieve air-out of various modes.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Steel plate lifting and conveying mechanism

InactiveCN110921191AImprove stabilityImprove securityConveyor partsRoller-waysDrive shaftClassical mechanics

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

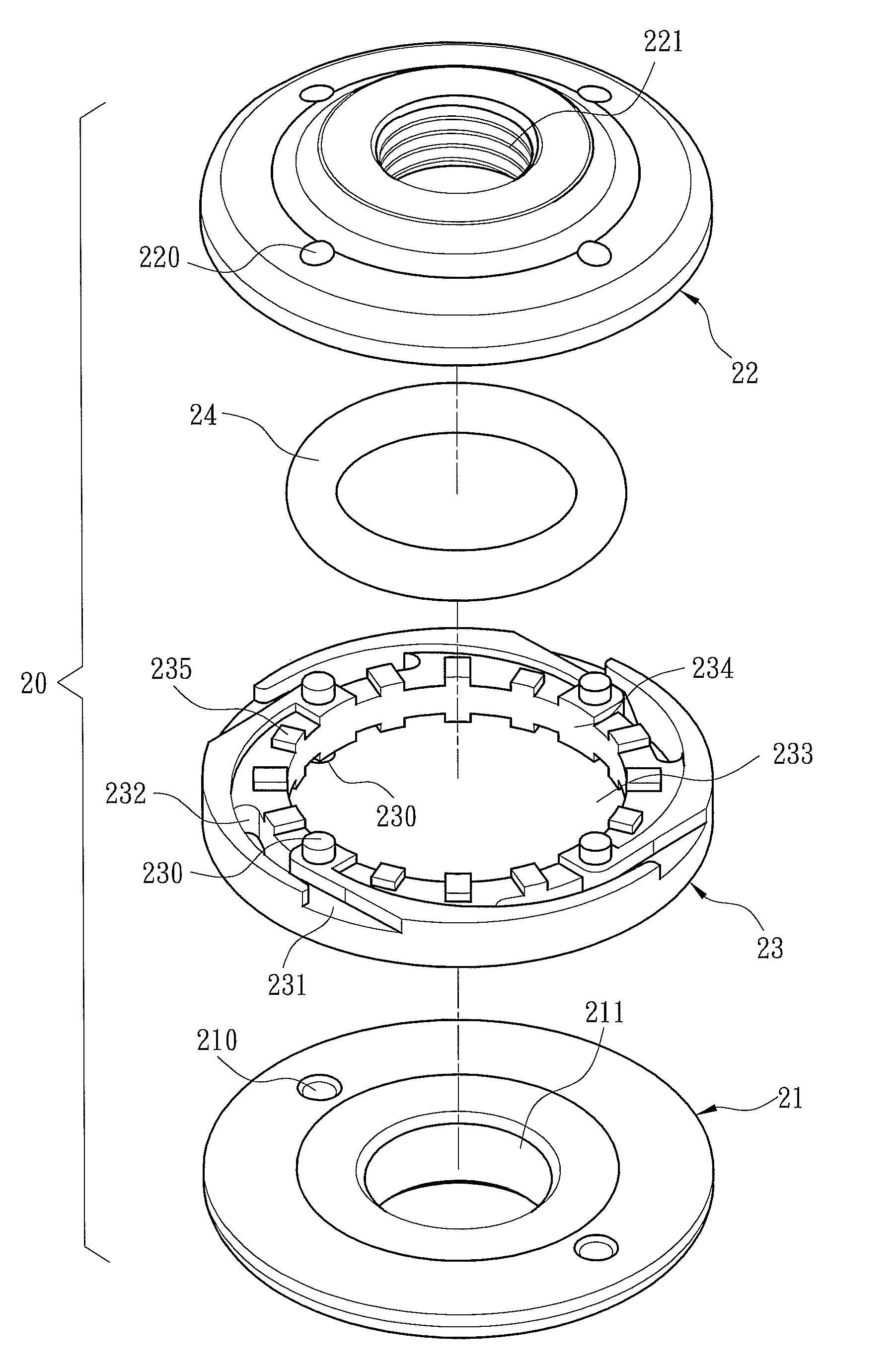

Rotary cross beam workbench

ActiveCN114734272AImprove space utilizationAvoid repeated clampingLarge fixed membersMaintainance and safety accessoriesRotational freedomControl system

The rotary cross beam workbench comprises a cross beam rotary table and a rotary power assembly for driving the cross beam rotary table to rotate, and is characterized in that a plurality of rotary workbenches capable of rotating are arranged on the cross beam rotary table, are parallel to the cross beam rotary table and are uniformly distributed in the circumferential direction of the cross beam rotary table; a workpiece is clamped on the rotary workbench, and the rotary power assembly and the rotary workbench are both controlled by the control system. Alternate rotation of the stations and automatic change of the directions of the workpieces are achieved, the rotary workbench has two rotational freedom degrees of revolution and rotation, the workbench high in space utilization rate and compact in structure is formed, multi-station and multi-direction machining can be achieved by clamping the workpieces at a time, the automation level of workpiece machining is improved, labor intensity is reduced, and production efficiency is improved. The space utilization rate of the rotary cross beam workbench is increased, multi-station and multi-direction high-efficiency and high-precision machining is achieved, and the precision and reliability of workpiece machining are improved.

Owner:SHENZHEN XIANGJU IND CO LTD

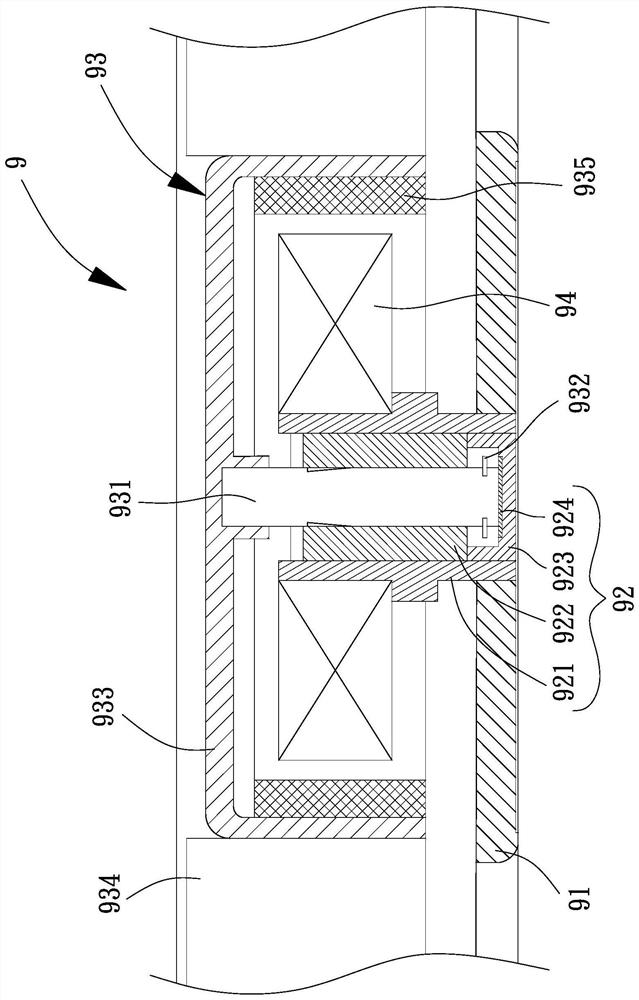

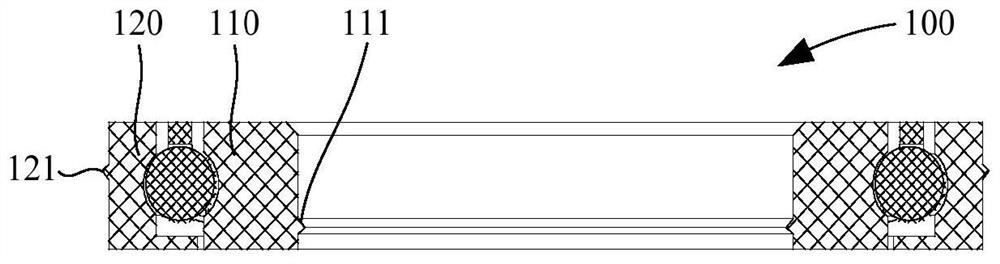

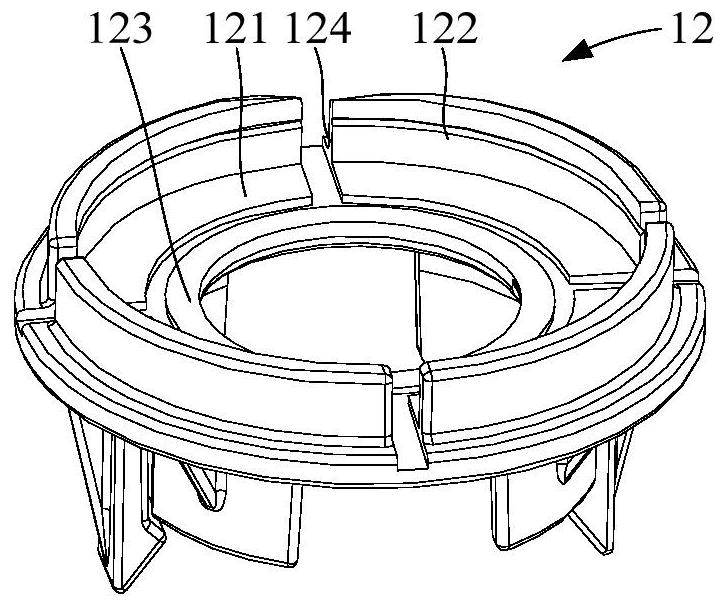

Bearing system

InactiveCN112443584AAvoid collisionImprove qualityBearing unit rigid supportMechanical engineeringDynamic pressure

A bearing system is used for solving the problem that an existing motor or fan is prone to generating vibration and noise due to collision of rotating components. The system comprises a lining which is communicated with the inside and the outside of the lining through a shaft hole; two bearings which are axially and oppositely located in the lining, and an interval space is formed between the twobearings; a rotating shaft which penetrates through the two bearings, the first end of the rotating shaft penetrates out of the shaft hole, the circumferential face of the rotating shaft is connectedwith an outwards-protruding part, the outwards-protruding part is located in the interval space, and a dynamic pressure gap can be formed between the outwards-protruding part and the axial end faces of the bearings when the rotating shaft rotates.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

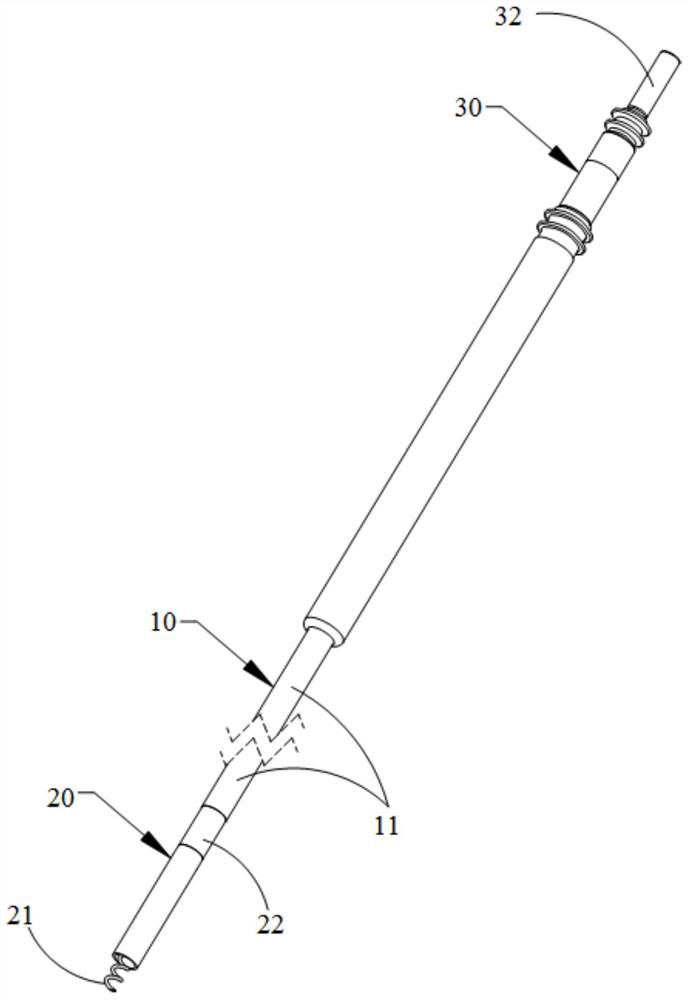

Rear hanging type rotary tillage device of agricultural tractor

ActiveCN113348800AReduce volumeEasy to installSpadesTilling equipmentsAgricultural engineeringStructural engineering

The invention provides a rear hanging type rotary tillage device of an agricultural tractor. The rear hanging type rotary tillage device comprises a rotary tillage mechanism, the rotary tillage mechanism comprises a rotating shaft and at least two paddles arranged on the rotating shaft, cavities are formed in the paddles, and exhaust holes communicating with the cavities are formed in the side walls of the paddles; a plurality of air passages are arranged in the rotating shaft, and each air passage communicates with the cavity of the paddle on the same side; when the paddles rotate into the soil, the cavities of the paddles communicate with an air source; and when the paddles rotate to the outside of the soil, the cavities of the paddles do not communicate with the air source. The rear hanging type rotary tillage device of the agricultural tractor is compact in structure, small in size, convenient to assemble, capable of greatly improving the soil loosening effect and improving the soil quality, wide in application range and suitable for popularization.

Owner:XINCHANG BENYE AGRI MACHINERY CO LTD

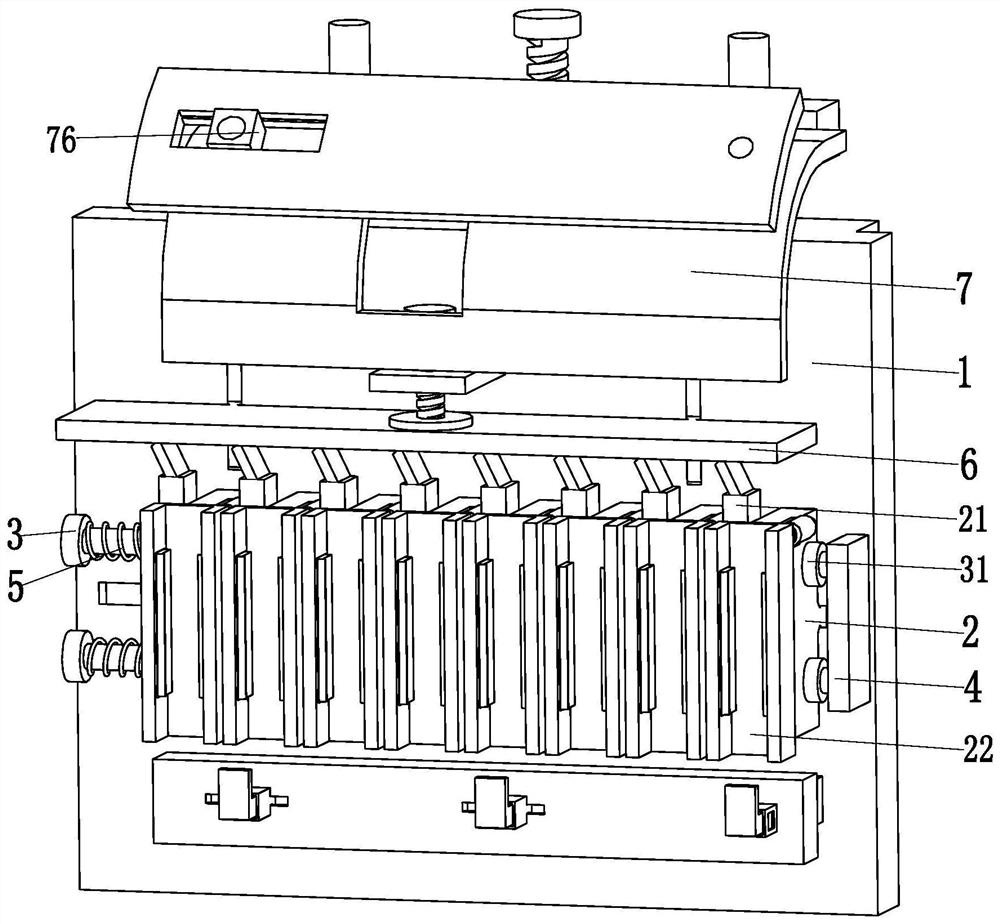

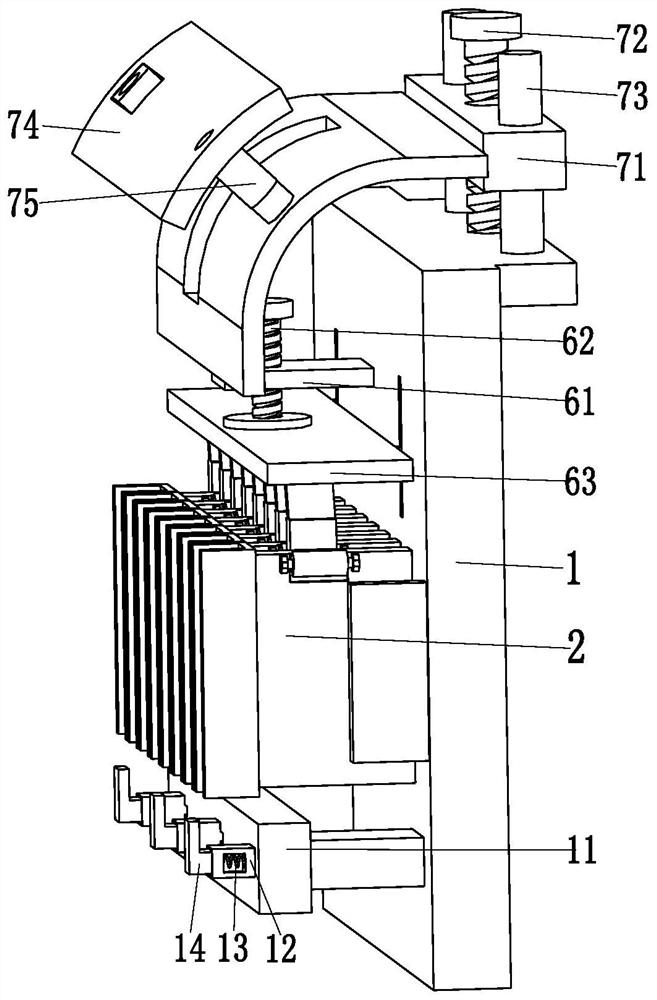

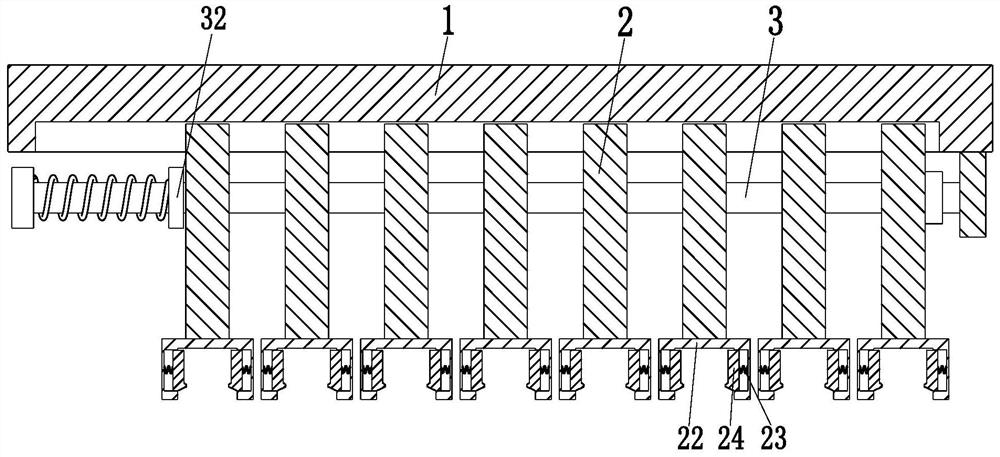

Manufacturing and processing equipment for transformer heat dissipation structure

ActiveCN111292946BFirmly connectedImprove applicabilityTransformers/inductances coolingInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a manufacturing and processing equipment for a heat dissipation structure of a transformer. The rear end of the isolation plate is connected with a sliding rod through a sliding fit, the outer end of the sliding rod passes through the isolation plate, the right side of the sliding rod is installed on the right front side of the supporting vertical plate through the sliding support plate, and the adjustment mechanism Located above the isolation plate, the adjustment mechanism is installed on the support vertical plate, and the locking mechanism is connected with the top of the support vertical plate. The present invention can solve the problems existing in the connection between the existing communication pipe and the heat dissipation pipe: the locking position of the heat dissipation pipe and the communication pipe is prone to deviation, and a certain degree of vibration will occur when the heat dissipation pipe is locked; the distance between the heat dissipation pipes cannot be adjusted accurately , and the butt effect between the heat dissipation pipe and the connecting pipe is poor.

Owner:西安新天干建筑安装有限公司

Electrode wire and medical equipment

PendingCN113457016AImprove use comfort performanceImprove smoothness of rotationHeart stimulatorsBiomedical engineeringElectrical connection

The invention discloses an electrode wire and medical equipment, wherein the electrode wire comprises a wire main body section, an electrode tip and a connector, and the electrode tip is arranged at the first end of the wire main body section; the connector is arranged at the second end of the wire main body section and is suitable for being inserted into a connecting interface of medical equipment; a first signal connecting piece of the connector is rotatably inserted into the other end of the communication channel and is connected with the inner multi-strand wire; a second signal connecting piece is arranged in the connector body and is connected with the outer multi-strand wire, wherein the electric contact section of the first signal connecting piece is suitable for being electrically connected with a connecting interface of medical equipment, and the insertion section of the first signal connecting piece is inserted into the communicating channel and is connected with the inner multi-strand wire. According to the invention, the connector structure of the electrode lead is improved, parts of the electrode lead connector are reduced, the assembling convenience of the connector is improved, the connector needle can smoothly transmit torque, the bending degree of the connector needle relative to the connector ring is reduced, and the insulation reliability of the electrode lead is enhanced.

Owner:丹源医学科技(杭州)有限公司

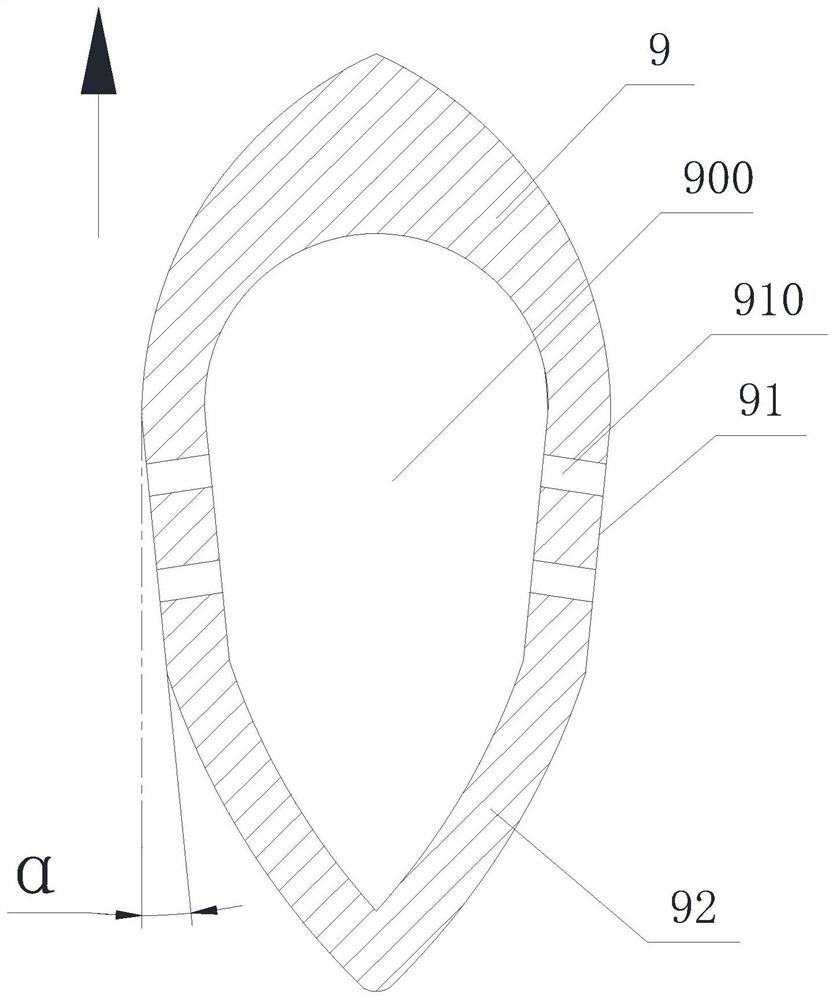

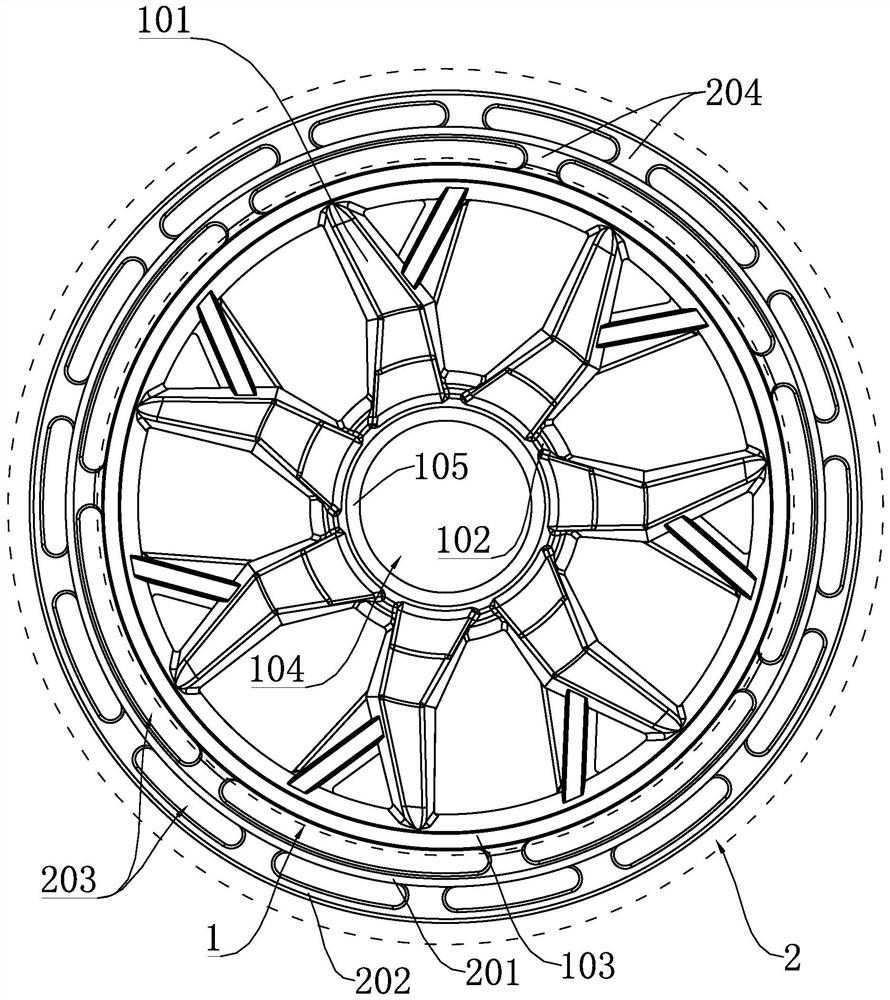

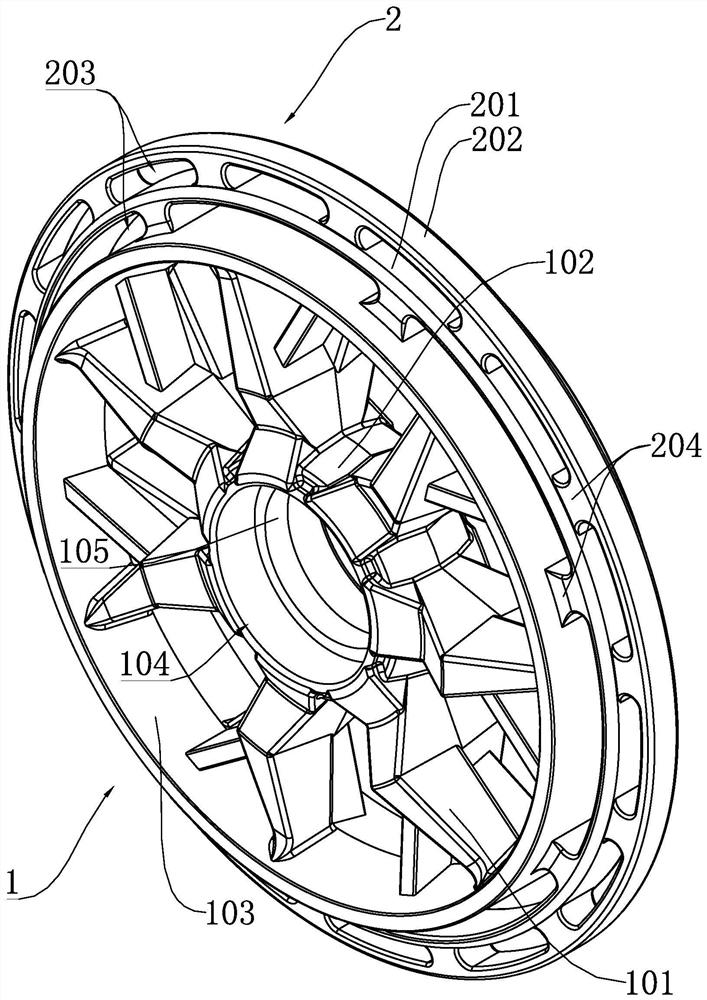

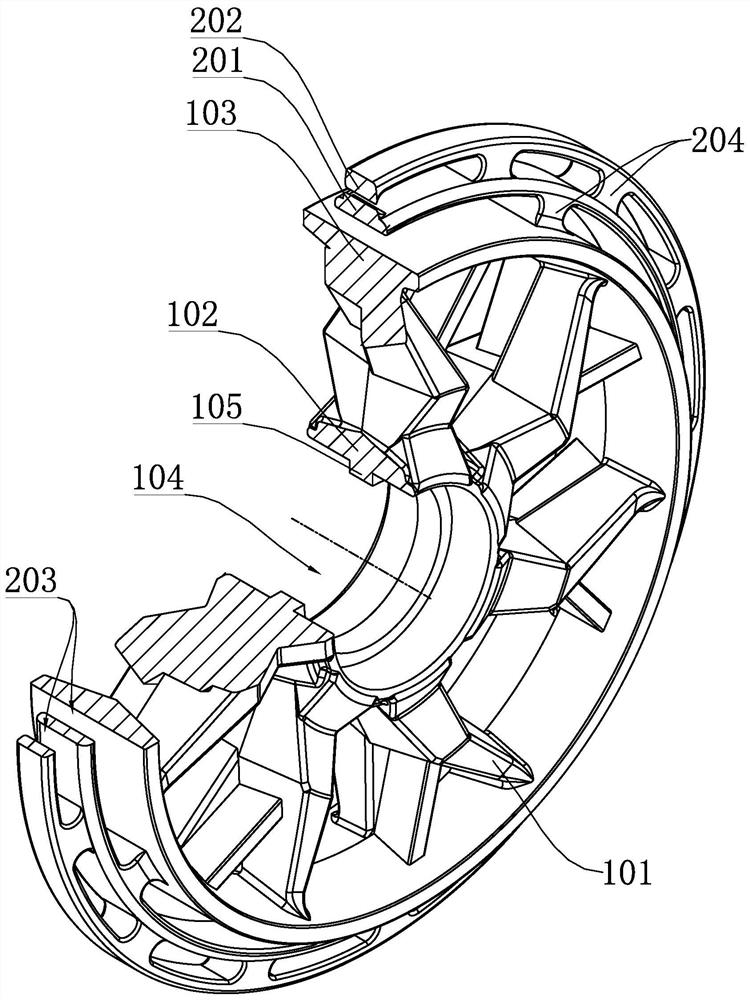

Wheel core capable of preventing tread from peeling off and roller skate

The invention discloses a wheel core capable of preventing a tread from peeling off and a roller skate. The wheel core comprises a body and a fastening structure for preventing a high polymer materialfrom peeling off due to lateral stress. The body comprises spokes, a hub and a rim, the spokes are connected with the hub and the rim, and the fastening structure is arranged on the rim in the circumferential direction of the body. The fastening structure is of a kidney-shaped hole structure with at least two layers. The roller skate comprises a wheel carrier and the wheel core capable of preventing a tread from peeling off, a high polymer material is poured outside a wheel rim to form a tread, the thickness of the wheel core is 15-21mm, and a body is rotationally connected with the wheel carrier. Compared with the prior art, the thin wheel core has the advantages that the weight is reduced, the roller skate is more competitive in a match, the material cost is reduced, and resources are saved; due to the existence of the double-layer kidney-shaped holes, when the high polymer material is poured outside the rim, the combination area of the wheel core and the high polymer material is greatly increased, the anti-peeling performance is improved, and the roller skating wheel is more stable when the included angle between the roller skating wheel and the ground is changed.

Owner:ZHUANGDA TECH & IND HANGZHOU

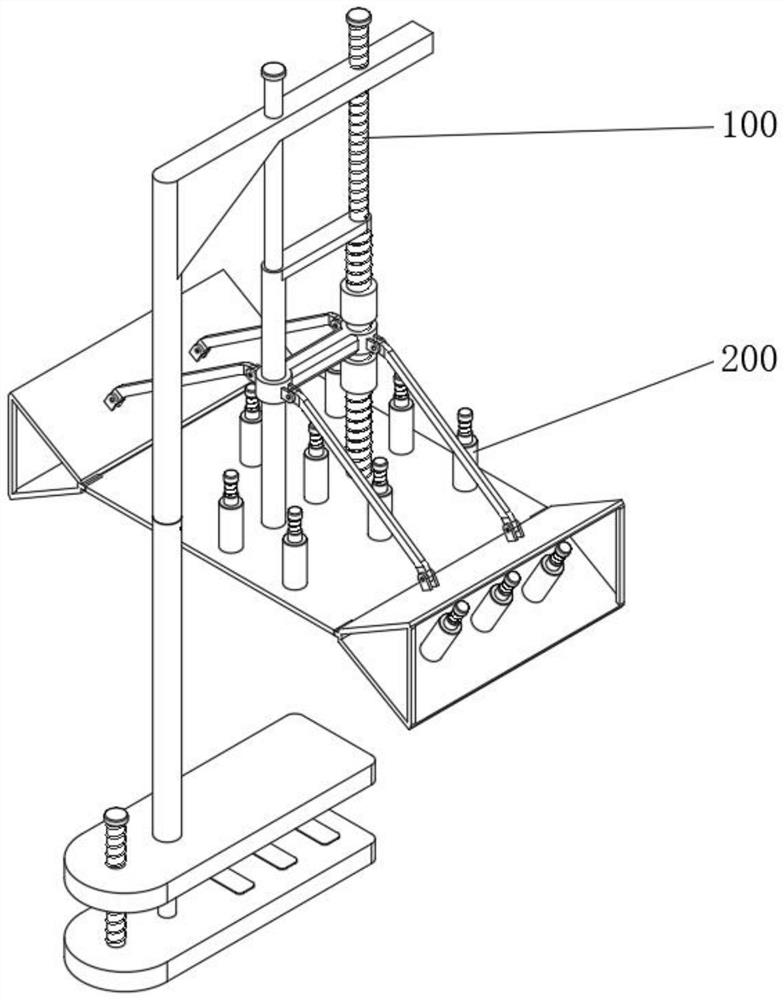

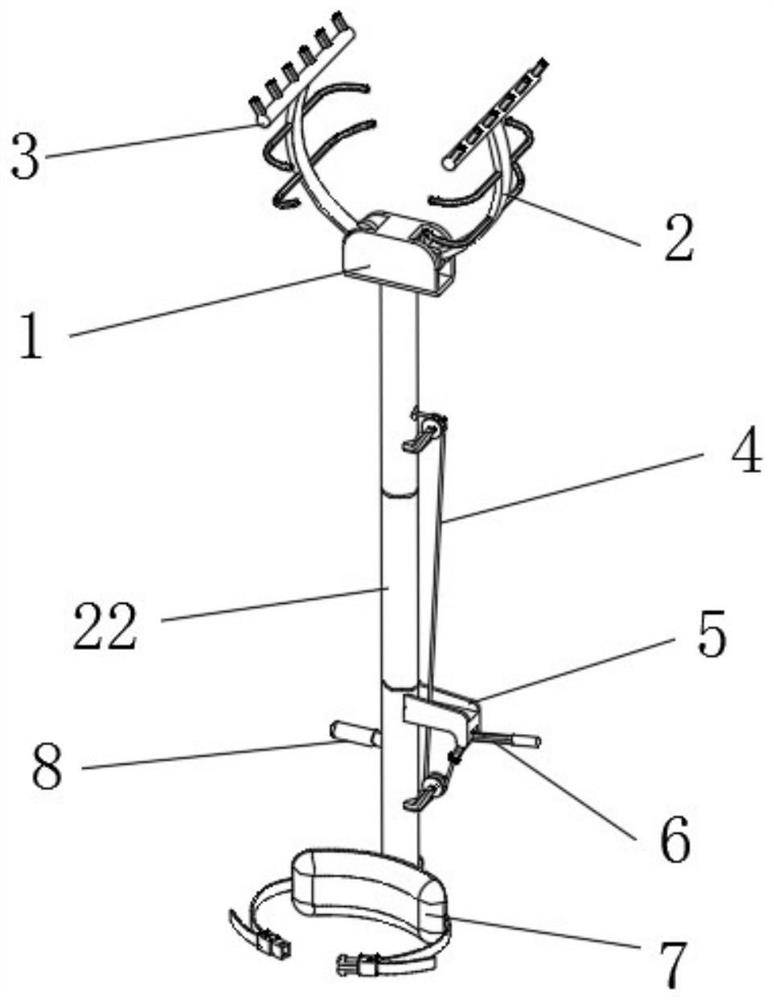

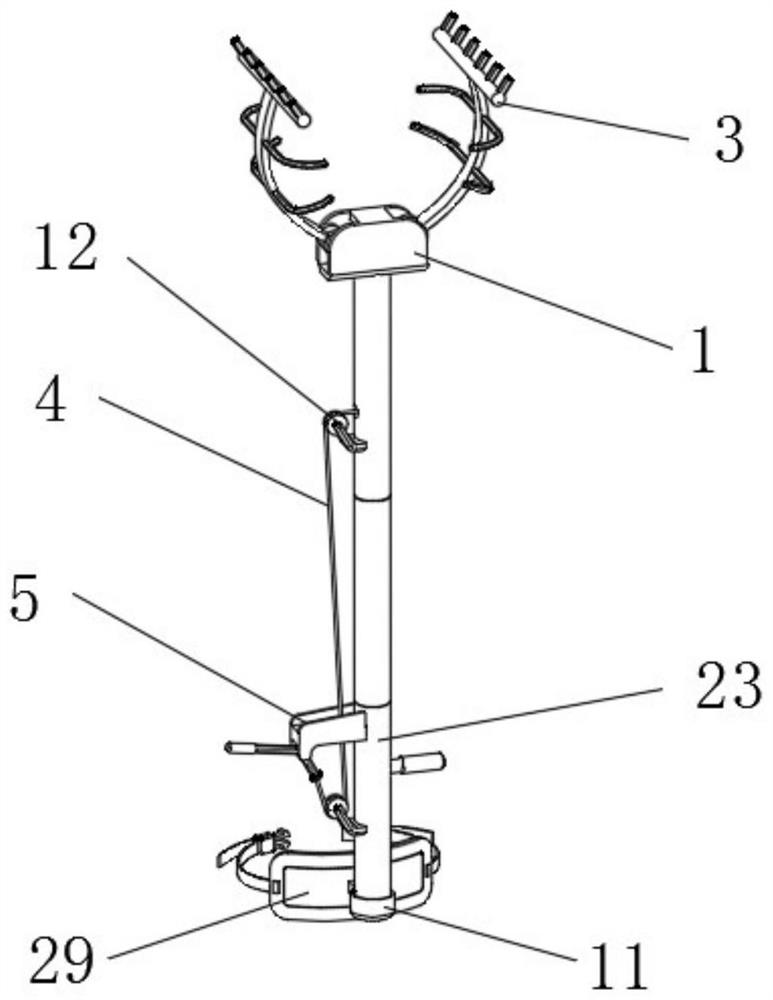

Hemostatic compression device capable of adjusting compression pressure and depth for department of cardiology

The invention relates to the technical field of the department of cardiology, in particular to a hemostatic compression device capable of adjusting compression pressure and depth for the department of cardiology. The hemostatic compression device comprises a depth adjusting device, wherein the depth adjusting device comprises a suspender, the suspender is provided with an internal threaded hole, the internal threaded hole is in threaded connection with an adjusting screw rod, a mounting plate is arranged below the adjusting screw rod, a rotating shaft is arranged below the adjusting screw rod, the adjusting screw rod is rotationally connected to the upper portion of the mounting plate through a rotating shaft, an upper column is connected to one side of the depth adjusting device, a supporting plate is arranged below the upper column, the upper column is fixed above the supporting plate. The hemostatic compression device aims at solving the problem that the compression force during compression is difficult to finely adjust through a common compression device or a manual compression mode.

Owner:宿州市欣通机械科技有限公司

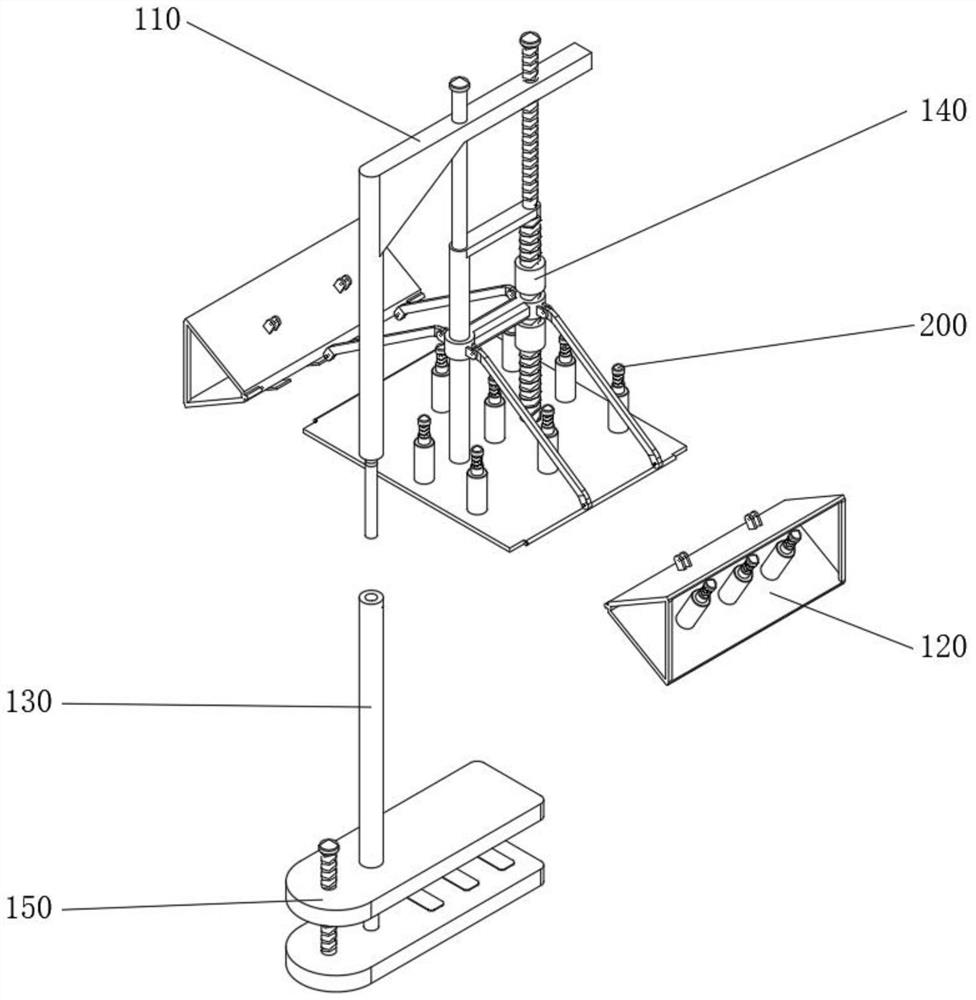

Upside-down bucket type drain valve with universal joint

The invention relates to an upside-down bucket type drain valve with a universal joint. The drain valve comprises a valve body, adjusting units and a hoisting unit. The adjusting units are symmetrically arranged in the middle of the lower end of the valve body in a front and back manner, and the hoisting unit is installed at the upper end of the valve body in a sliding fit manner. The upside-downbucket type drain valve with the universal joint is installed according to the design concept of combining adjusting structures at multiple angles, the arranged adjusting units can enable the valve body and pipelines at multiple angles or in different directions to be in butt joint, and therefore the diversity the overall functions of the drain valve is greatly improved, and the application rangeof the drain valve is greatly broadened; and a structure capable of improving the rotating smoothness of a main rotating structure is additionally arranged in each adjusting unit, so that user experience with the drain valve can be improved, and meanwhile, with the hoisting unit, it can be implemented that the valve body can be quickly hoisted and can be independent disassembled after being hoisted.

Owner:艾肯(江苏)工业技术有限公司

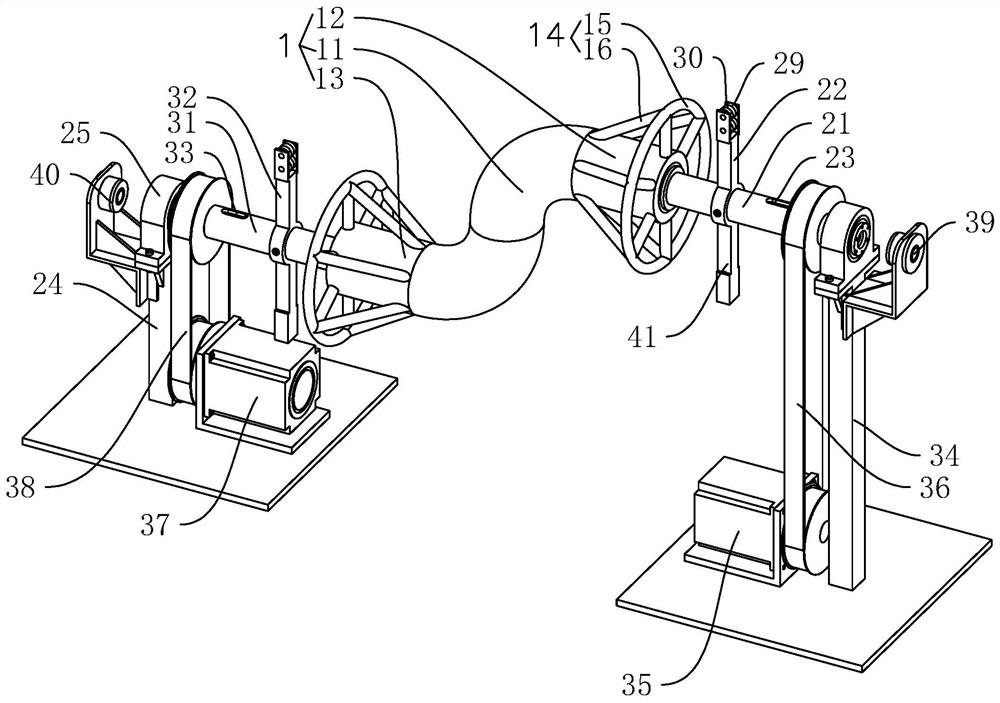

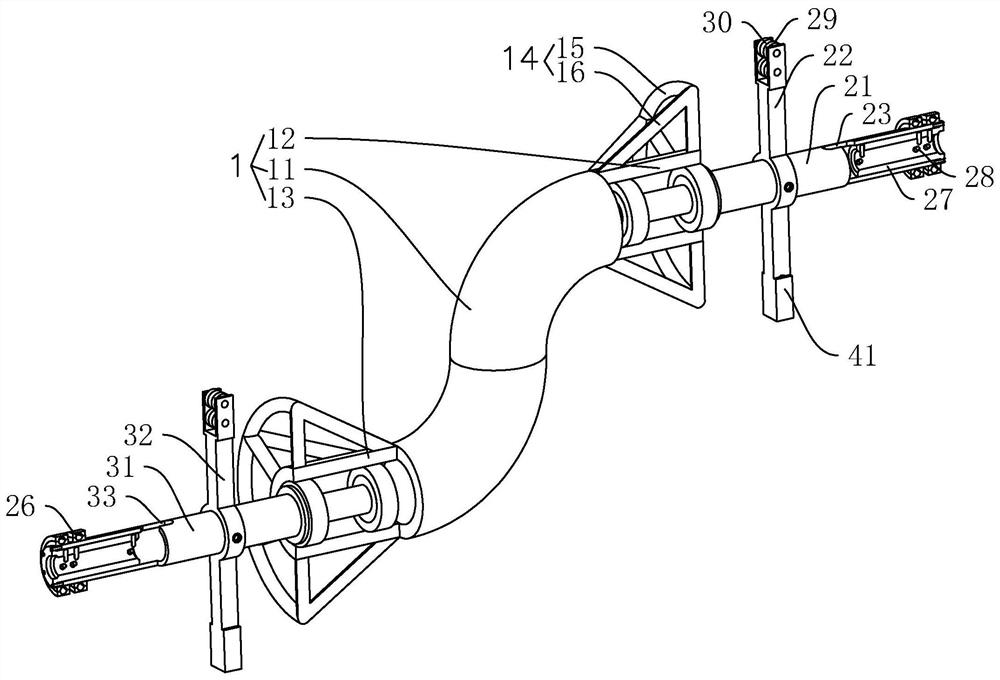

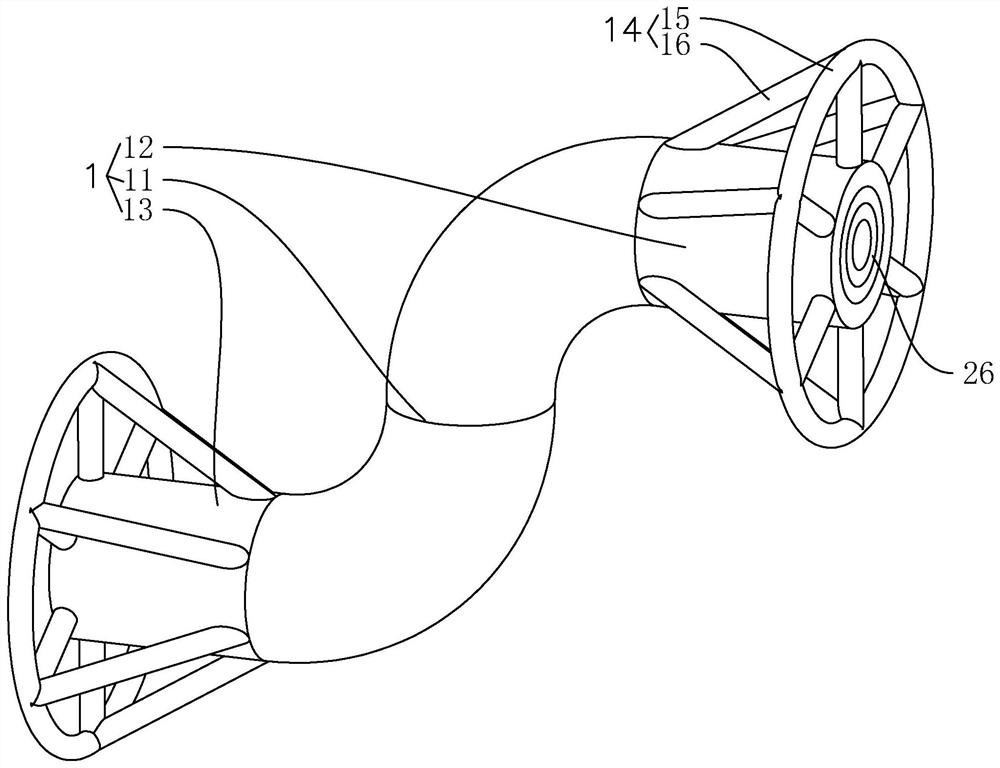

Wire storage device for wire winding

InactiveCN111646302AAchieve tension controlReduce output speedFilament handlingWire rodStructural engineering

The invention discloses a wire storage device for wire winding, and relates to wire winding. The wire storage device for the wire winding aims at solving the problem that the wire storage amount is lower, according to the technical solution key points of the wire storage device, the wire storage device for the wire winding comprises a wire storage barrel, an inlet wire winding mechanism and an outlet wire winding mechanism, wherein the wire storage cylinder comprises a bent section, a horizontal wire inlet section and a horizontal wire outlet section, the bent section is bent in an arc shape twice, the wire inlet winding mechanism comprises a wire inlet hollow shaft and a wire inlet swing arm, a wire outlet hole is formed in the shaft wall of the wire inlet hollow shaft in a penetrating mode, the wire outlet winding mechanism comprises a wire outlet hollow shaft and a wire outlet swing arm, and a wire inlet hole is formed in the shaft wall of the wire outlet hollow shaft in a penetrating mode. According to the wire storage device for the wire winding, the storage capacity of wires is effectively improved, and mutual influences of tension at the two ends of the wires are avoided.

Owner:JIAXING JIECHENG MACHINERY

Fruit paper bag bagging device facilitating bagging

PendingCN114711074AReduce in quantityPrecise trapPackage recyclingPlant protective coveringsAdhesive beltMechanical engineering

The invention discloses a fruit paper bag bagging device facilitating bagging, and relates to the technical field of bagging device structures, the fruit paper bag bagging device comprises a U-shaped base, a triangular wedge block is arranged in the U-shaped base, and two rotating arms are rotationally installed on the two inner side walls, close to each other, of the U-shaped base through first rotating shafts correspondingly; one end of each rotating arm is fixedly provided with a transverse rod, and the other ends of the two rotating arms are matched with the two inclined faces of the triangular wedge-shaped block respectively. The fruit picking device is reasonable in structure and easy to operate, the edge opening of a paper bag is fixed to the two transverse rods, meanwhile, the edge opening of the paper bag is opened along with mutual separation of the two transverse rods, the U-shaped base is supported by the connecting pipe, the U-shaped base reaches a certain height, corresponding fruits are sleeved with the paper bag, mechanism movement is generated through one end of the traction wire harness, and the paper bag is pulled to move. And the two cross rods are close to each other, so that the edge openings of the paper bags are close to each other and are adhered to each other through adhesive tapes to sleeve the fruits.

Owner:杭州燃意文化创意有限公司

Heald frame connecting device of crank shedding loom

The invention discloses a heald frame connecting device of a crank shedding loom. The heald frame connecting device of the crank shedding loom comprises a first upper connecting seat, wherein a firstconnecting bush is arranged in the first upper connecting seat; the lower end of the first upper connecting seat is rotatably connected with a first upper rotating block through a first connecting pin; the lower end of the first upper rotating block is connected with a first upper toothed rod, and the lower end of the first upper toothed rod is movably connected with a first middle connecting seatthrough a first pressing mechanism; the lower portion of the first middle connecting seat is connected with a first lower toothed rod through a second pressing mechanism; and the lower end of the first lower toothed rod is connected with a first lower connecting seat. The first middle connecting seat comprises a first square shell, a first strip-shaped block and a second strip-shaped block are fixedly connected to the left and right inner side end walls of the first square shell respectively, and a plurality of parallel first strip-shaped tooth grooves are vertically formed in the inner sideend face of the first strip-shaped block. The device is conveniently used for connecting heald frames in the shedding loom, and is adjustable in length, rotatable, and convenient and simple to use.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

H-shaped steel conveying and jacking mechanism

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Gushing arm assembly and dish washing machine with same

ActiveCN113907681AImprove washing effectReduce frictional resistanceTableware washing/rinsing machine detailsHome appliance efficiency improvementFriction reductionEngineering

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com