Patents

Literature

44results about How to "Runs smoothly up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

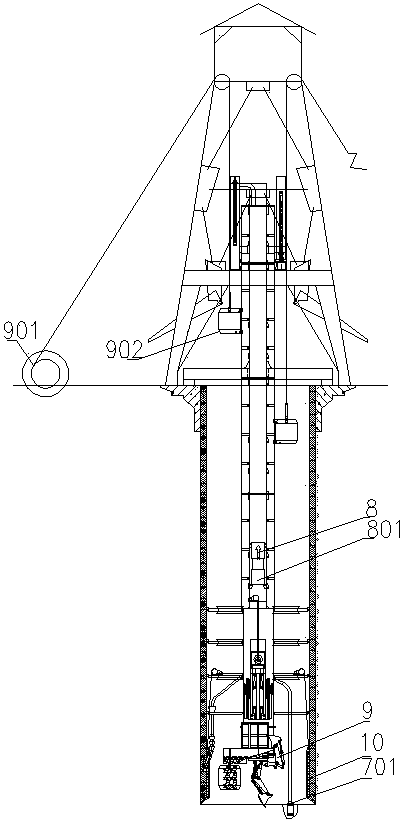

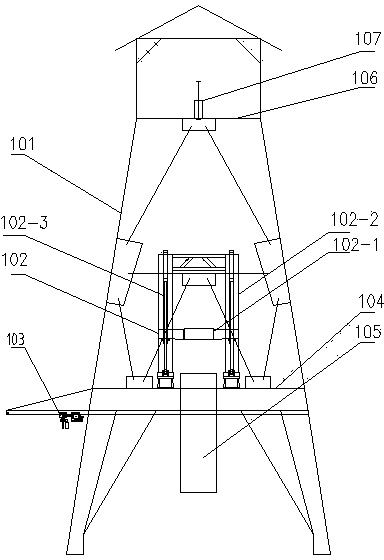

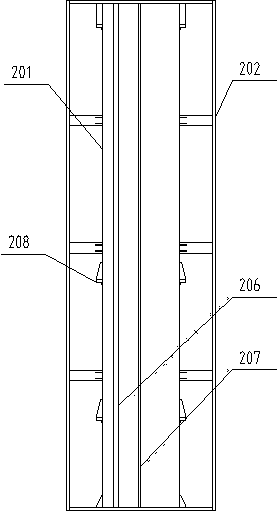

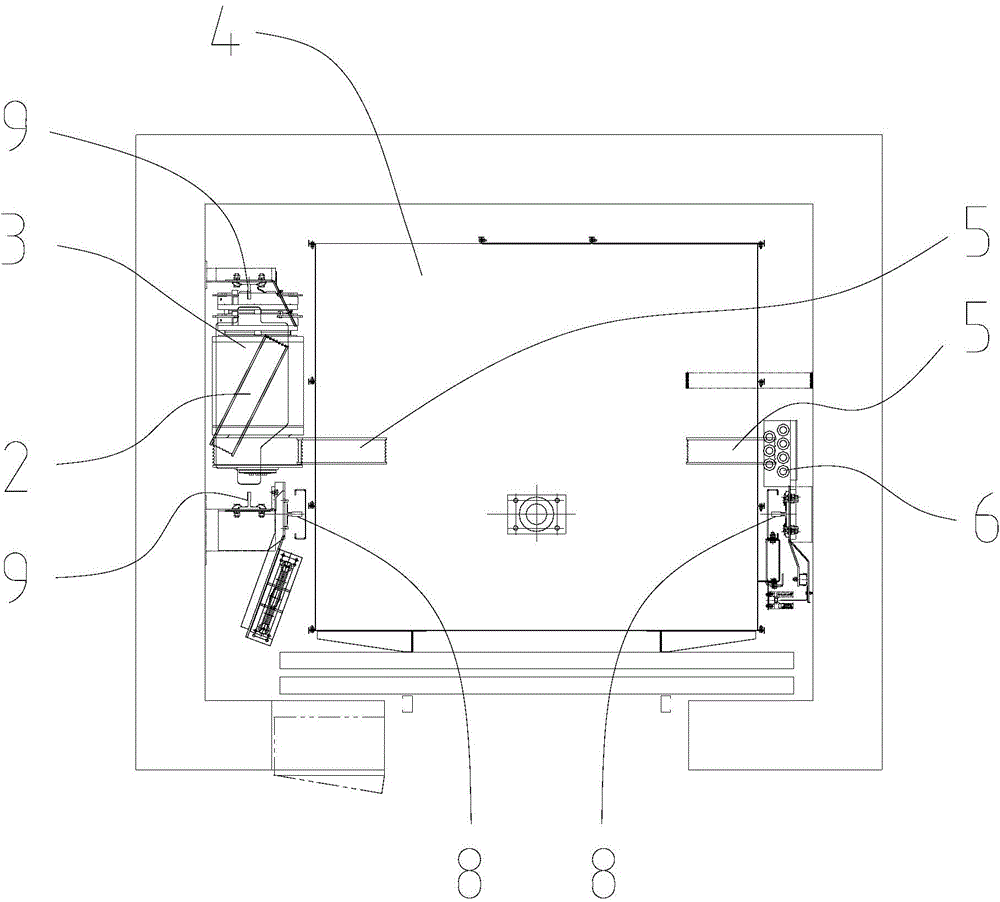

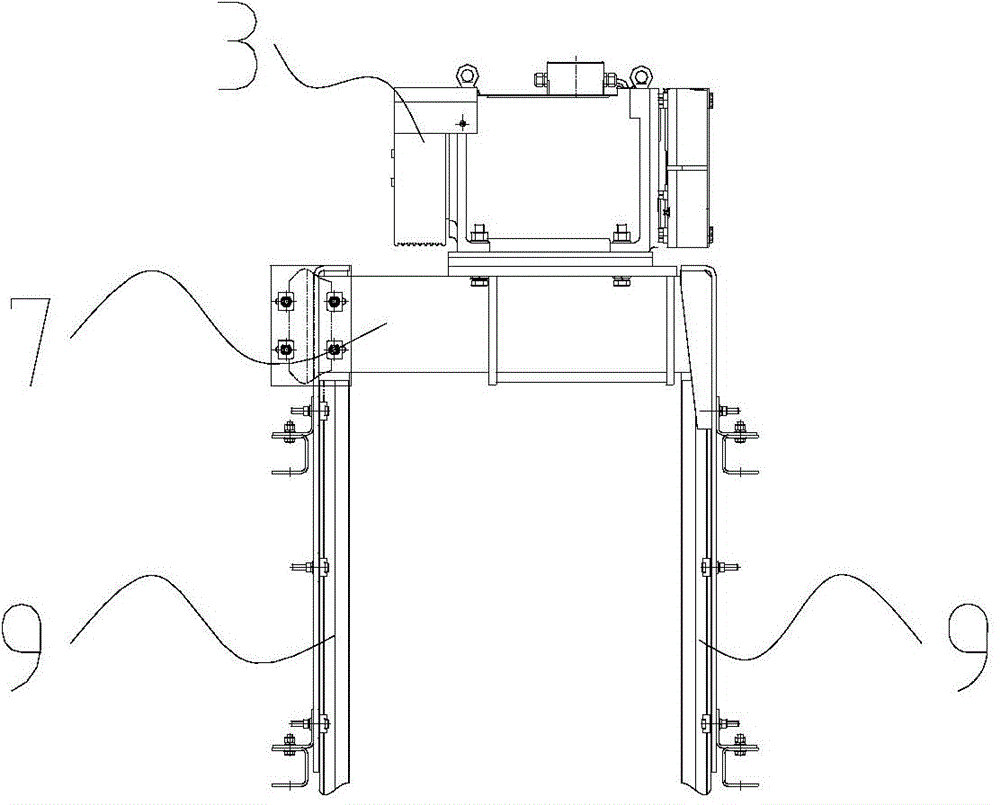

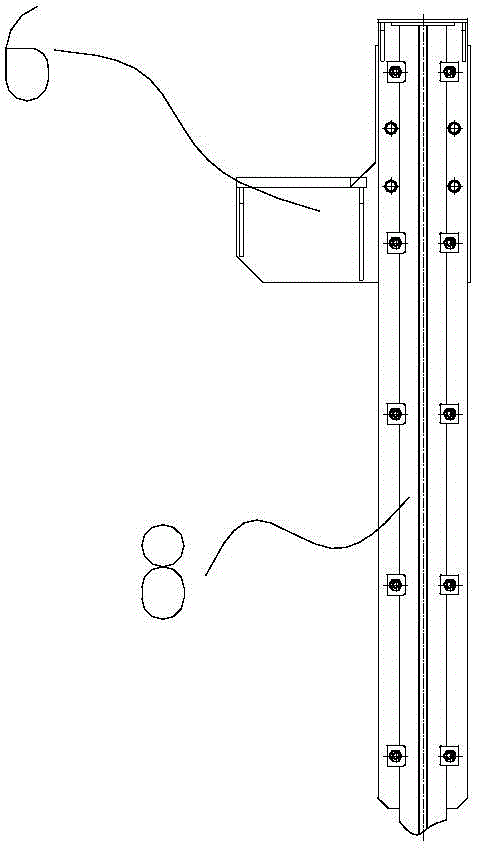

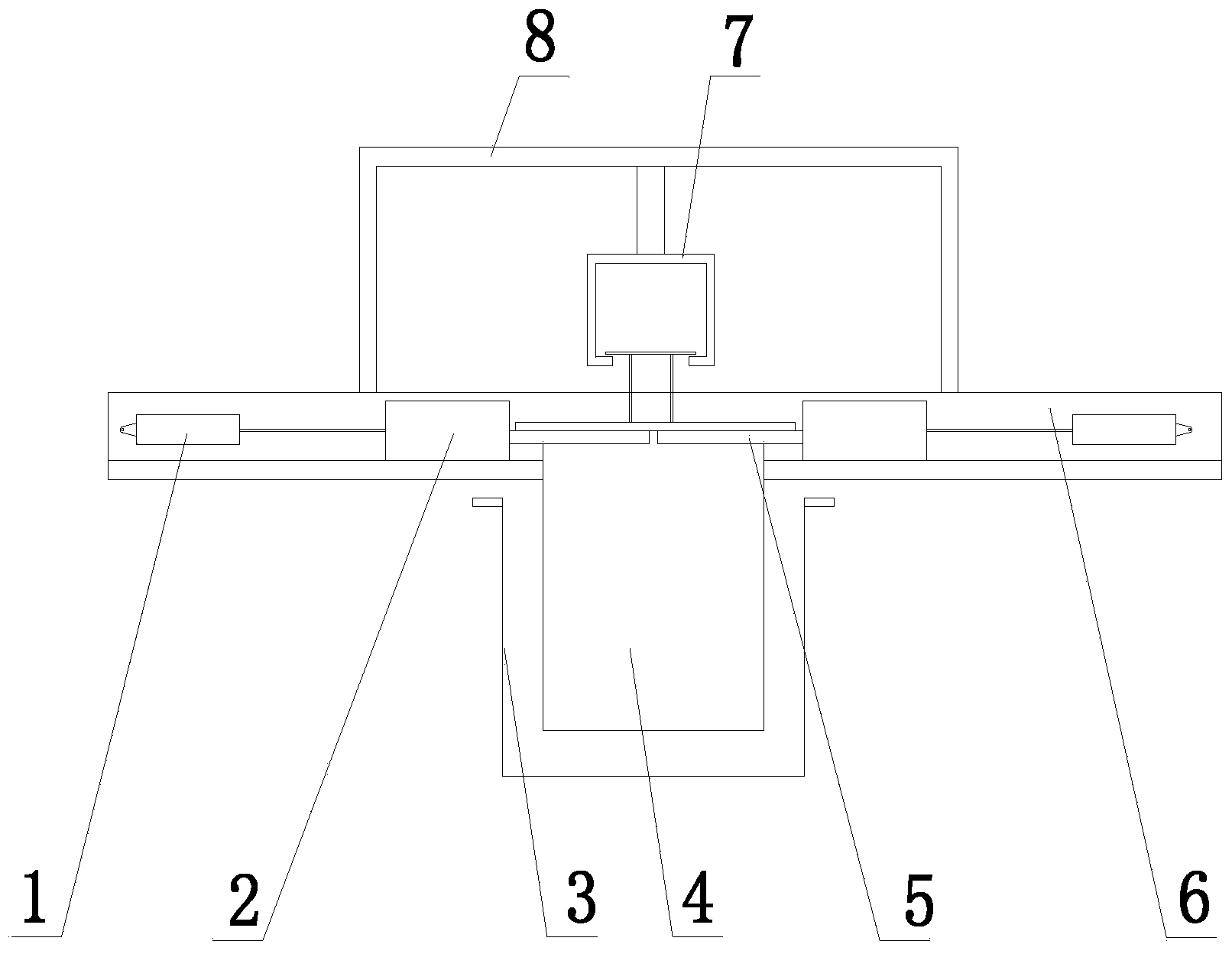

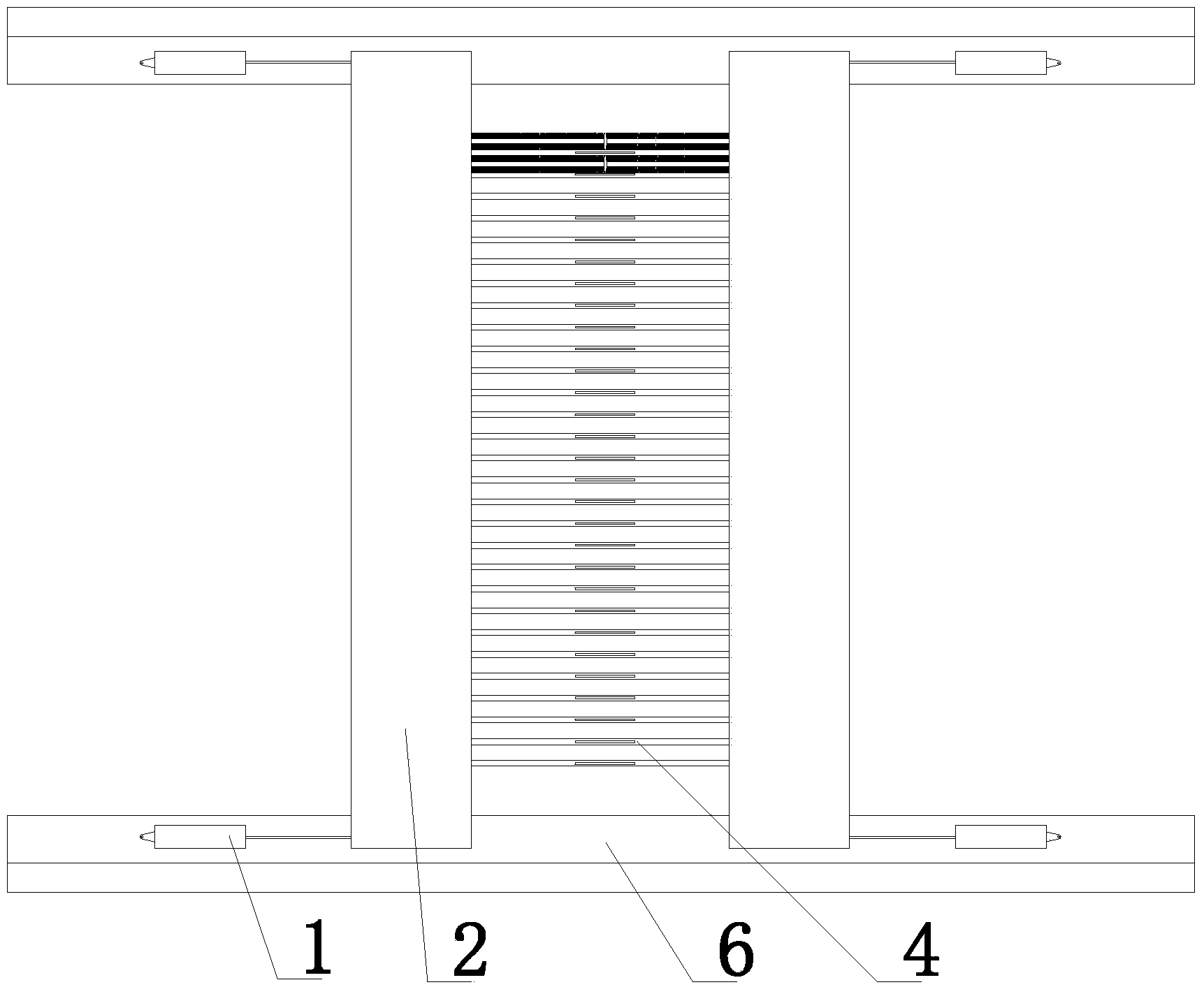

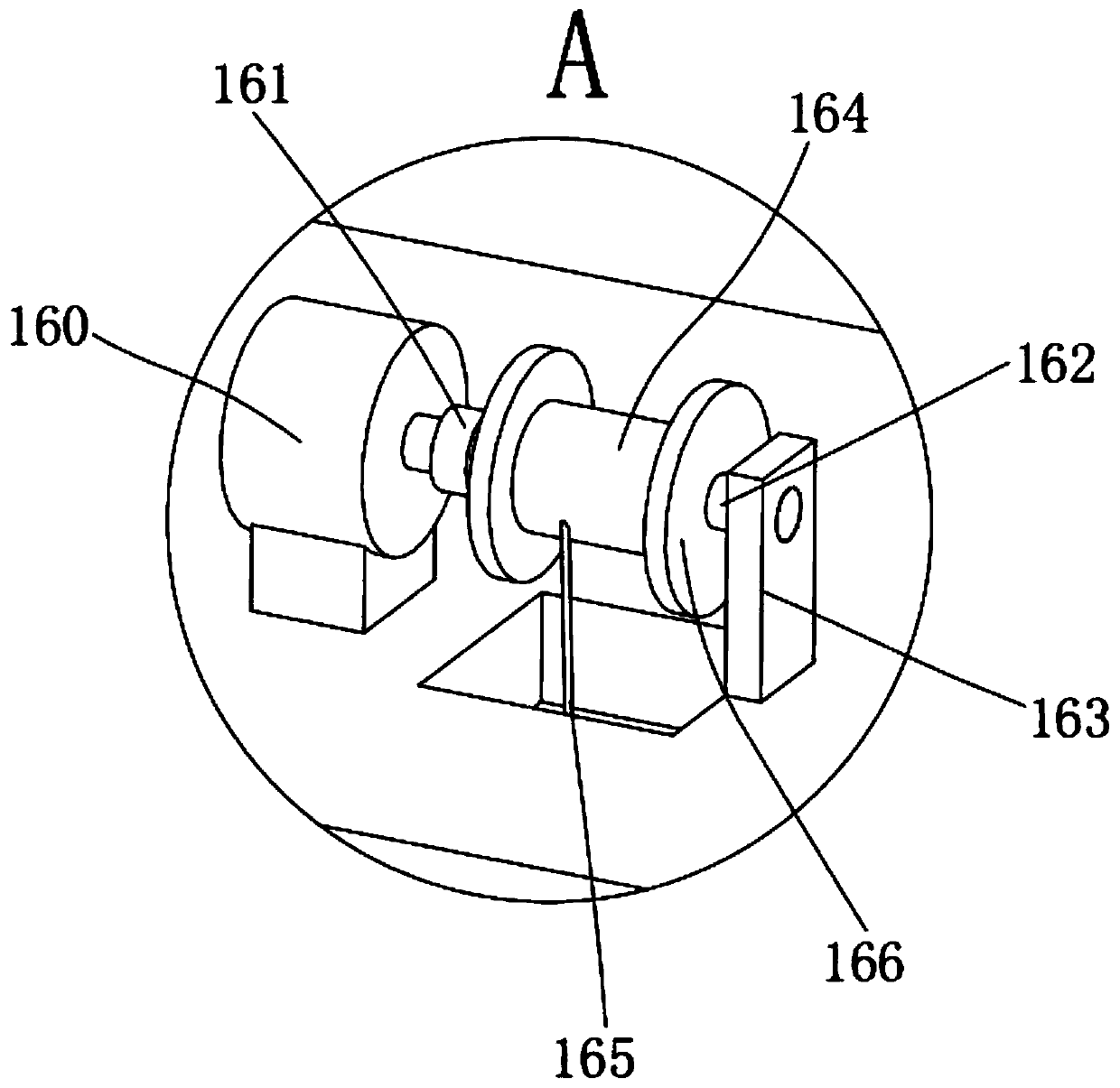

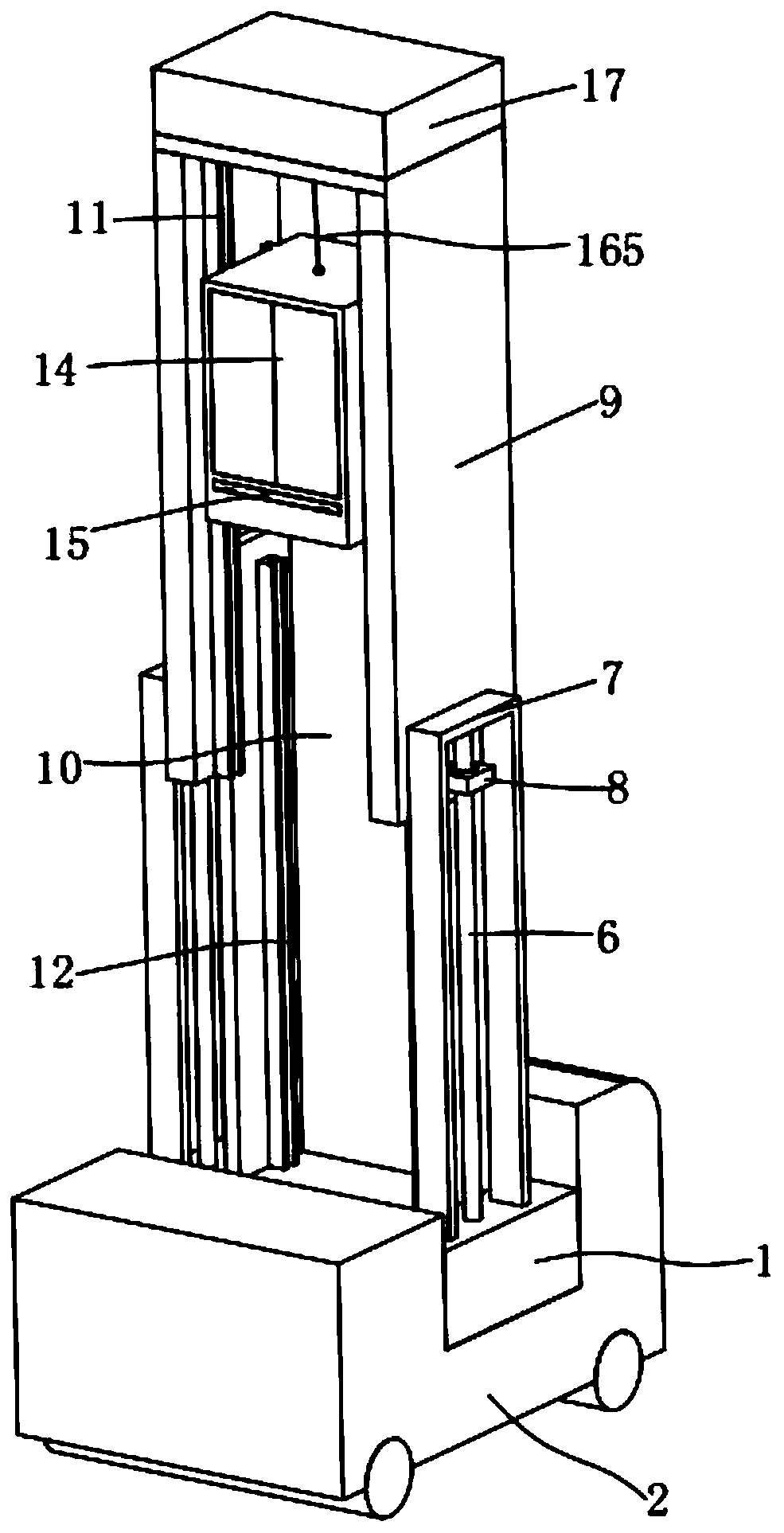

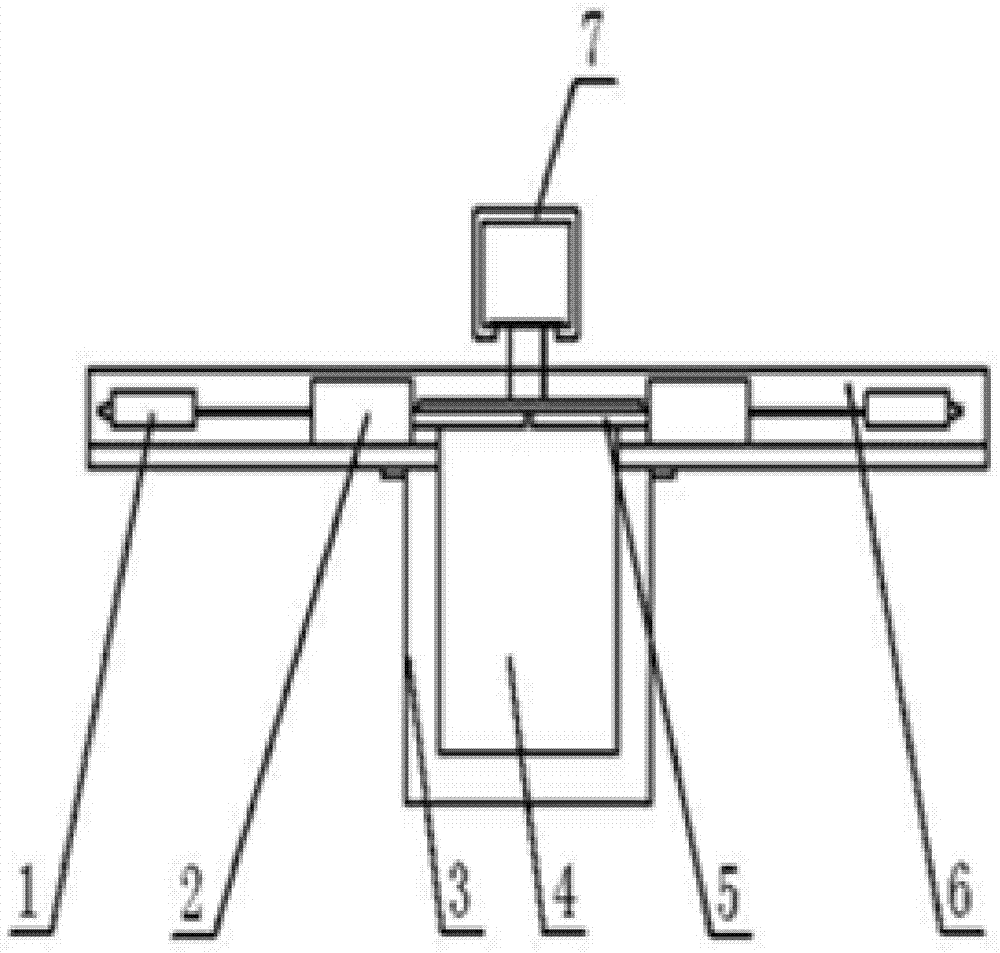

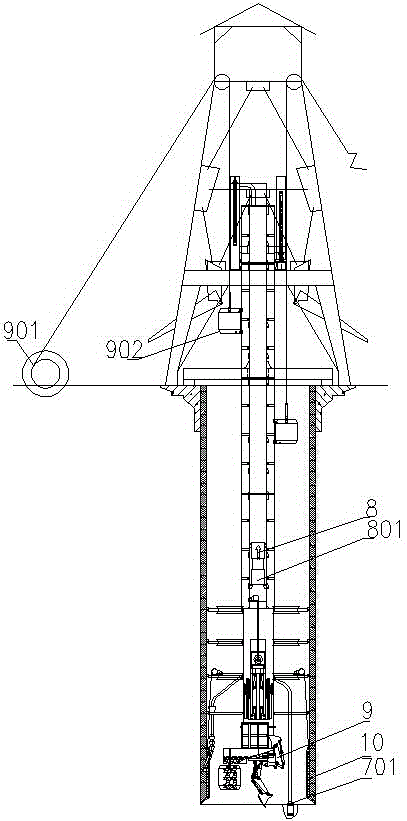

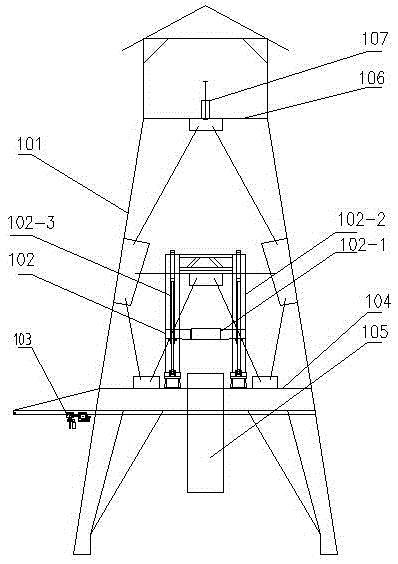

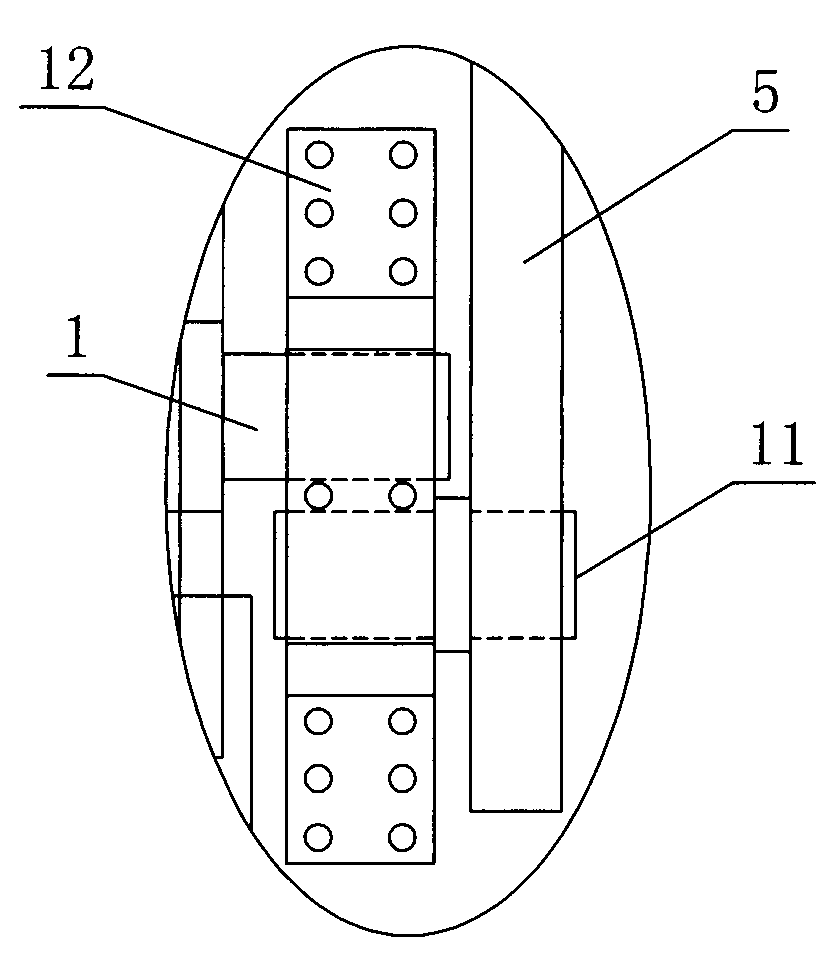

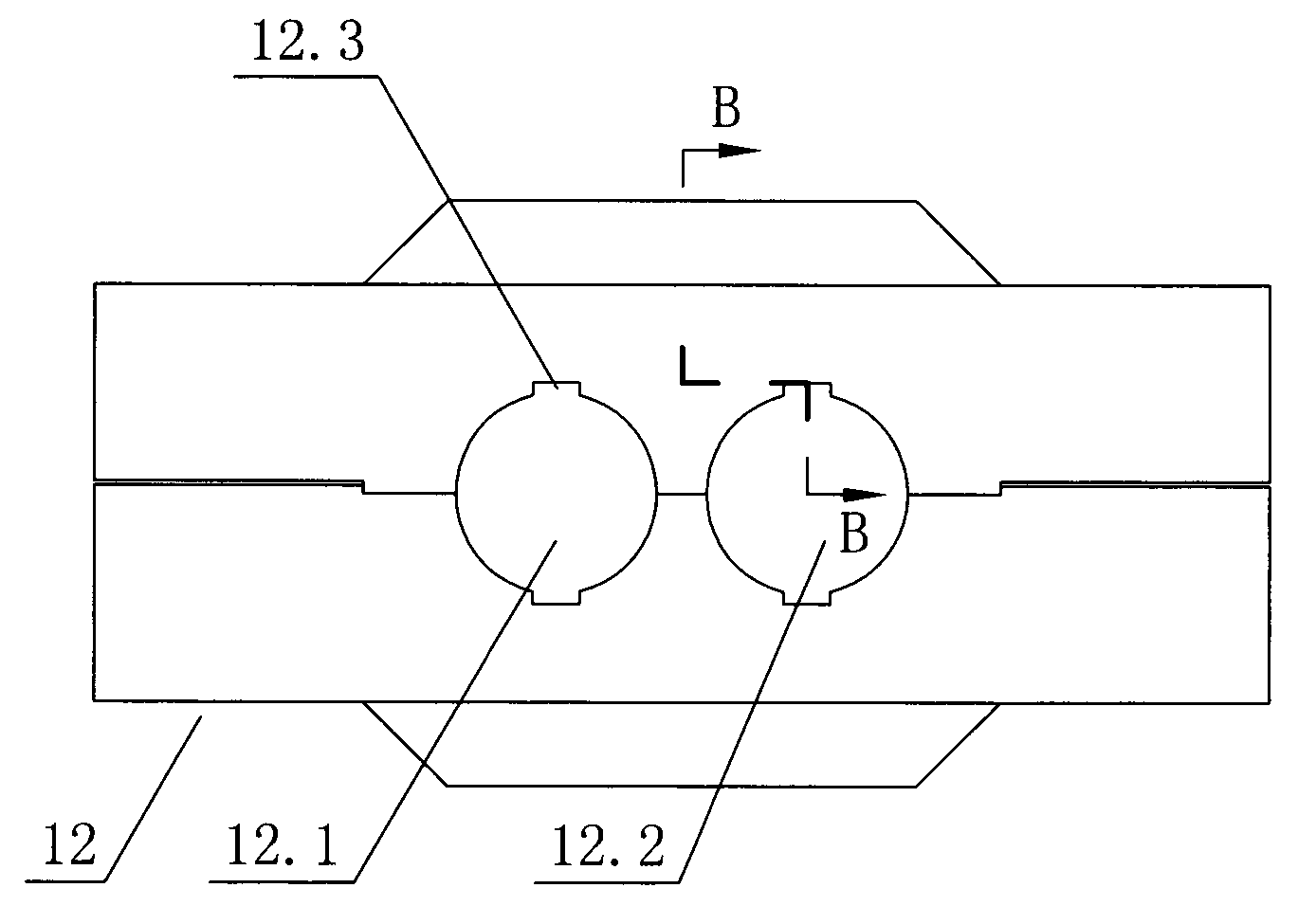

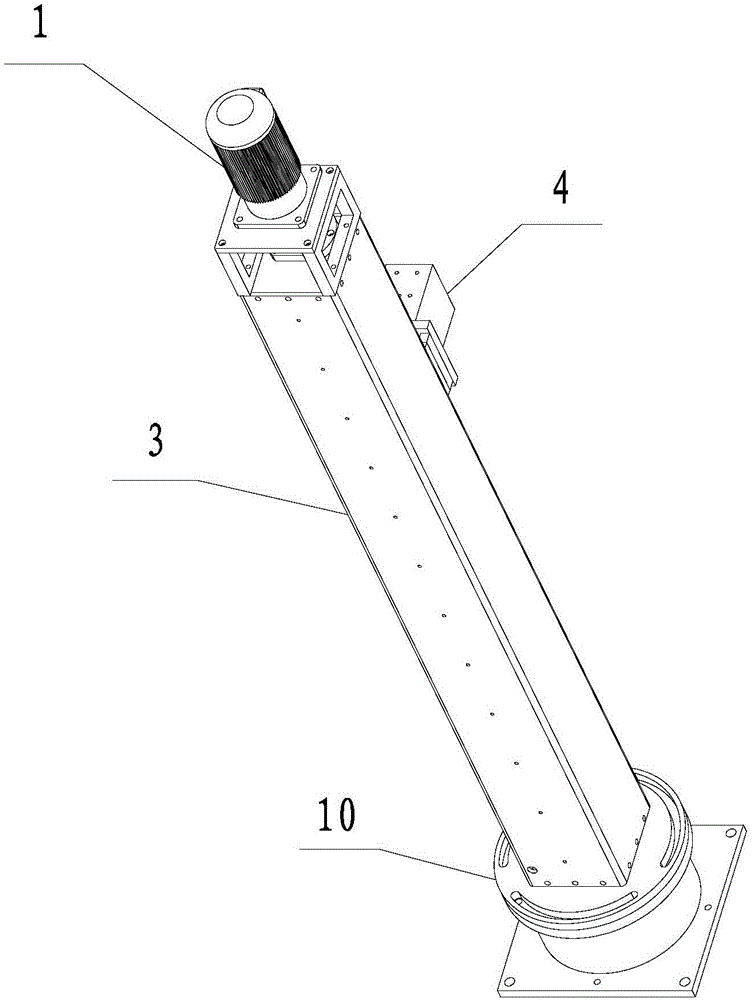

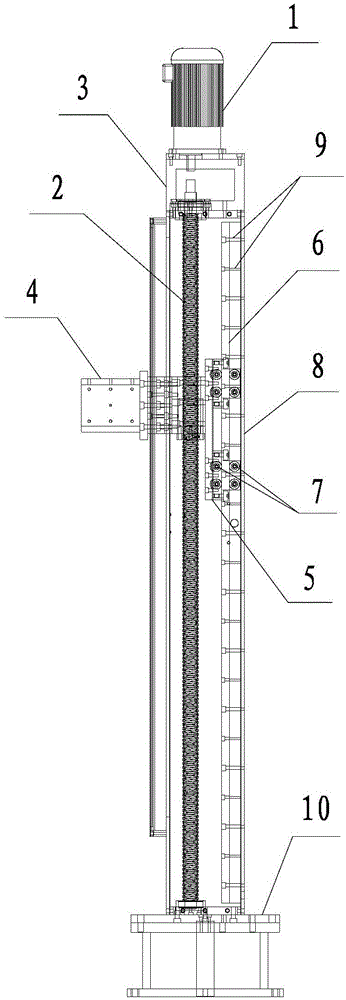

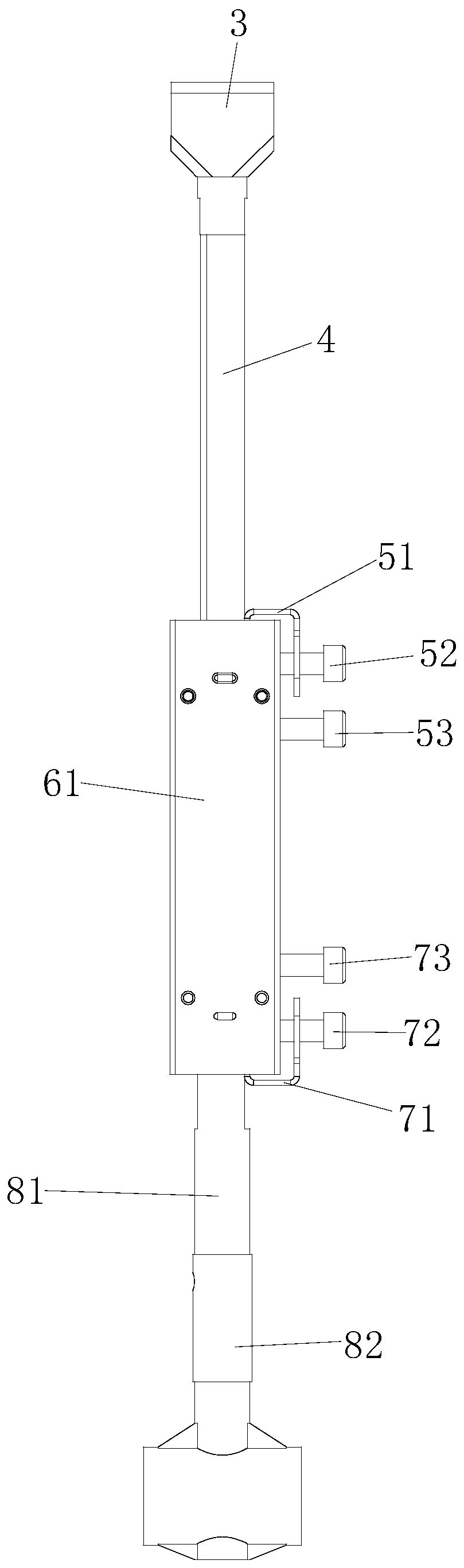

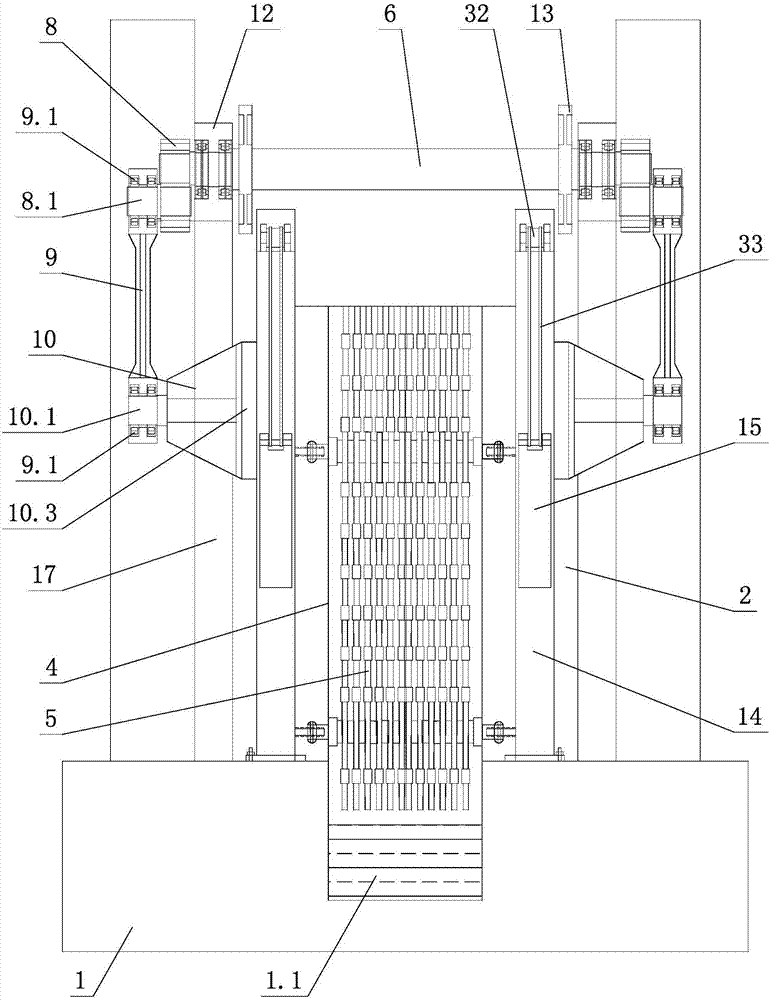

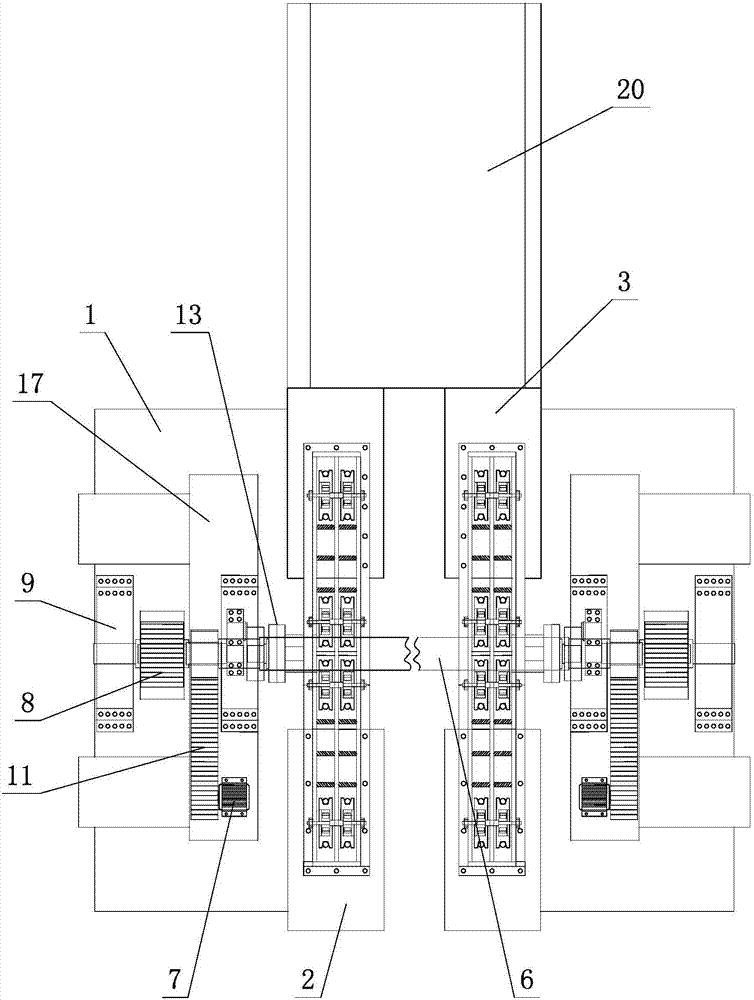

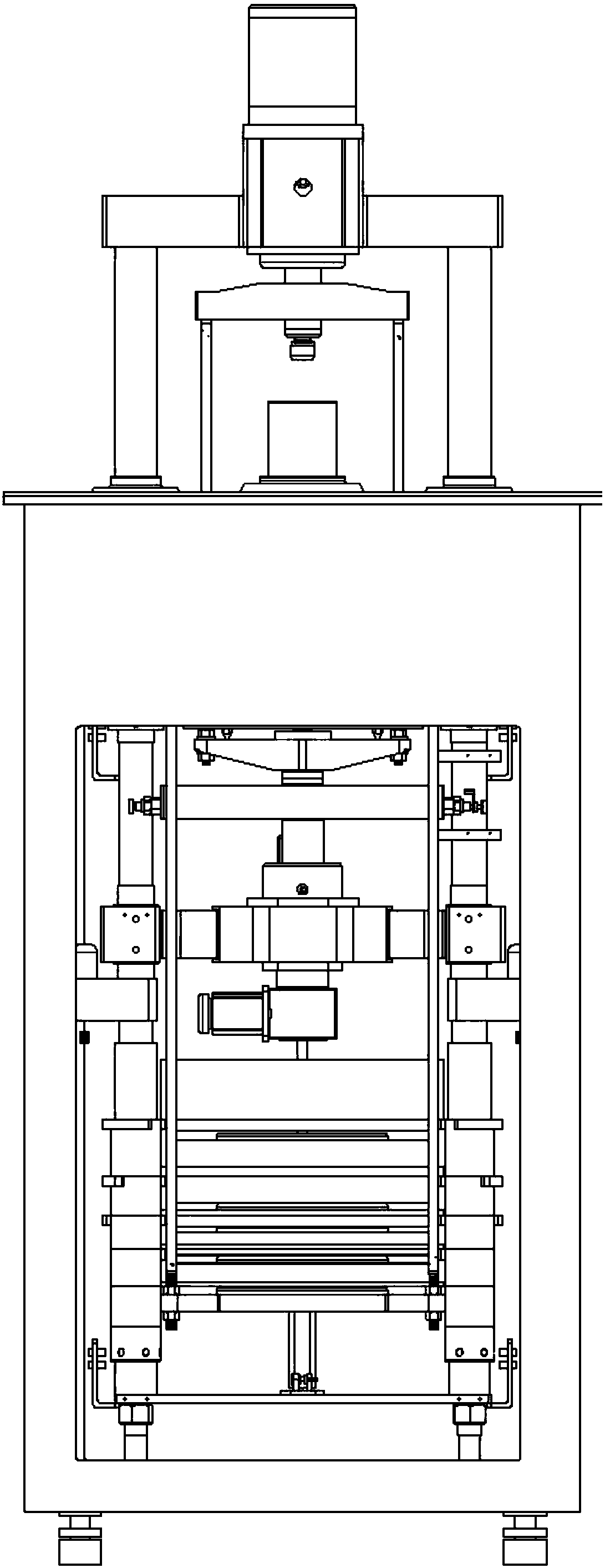

Novel drilling and blasting method vertical shaft drilling machine

The invention discloses a novel drilling and blasting method vertical shaft drilling machine. The machine mainly comprises a derrick, a numerical control umbrella drill, a loading machine, an equipment suspension system, a drainage system, a ventilation system, a slag discharge system, a shaft wall casting system, a shaft bottom hanging scaffold, a hydraulic station and a control room, wherein the equipment suspension system comprises a center vertical column, a vertical column lifting mechanism and a sealing flatcar; the center vertical column is connected with the vertical column lifting mechanism, and extends underground; the lower part of the center vertical column is connected with the shaft bottom hanging scaffold; the derrick and the sealing flatcar are mounted in a shaft mouth; the vertical column lifting mechanism is fixed and mounted on the derrick; the loading machine is mounted at the lower end of the center vertical column; the numerical control umbrella drill is mounted in the center vertical column; and the hydraulic station, the drainage system and the control room are mounted on the shaft bottom hanging scaffold. The machine adopts the reinforced derrick and the equipment suspension system, so that the equipment connection is reliable, and the construction is safer. The construction of the numerical control umbrella drill needs no shaft lifting, and is full-automatically controlled, so that the construction efficiency is improved; the slag loading efficiency of the loading machine is higher; the operation is more convenient; and the slag discharge efficiency is further improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

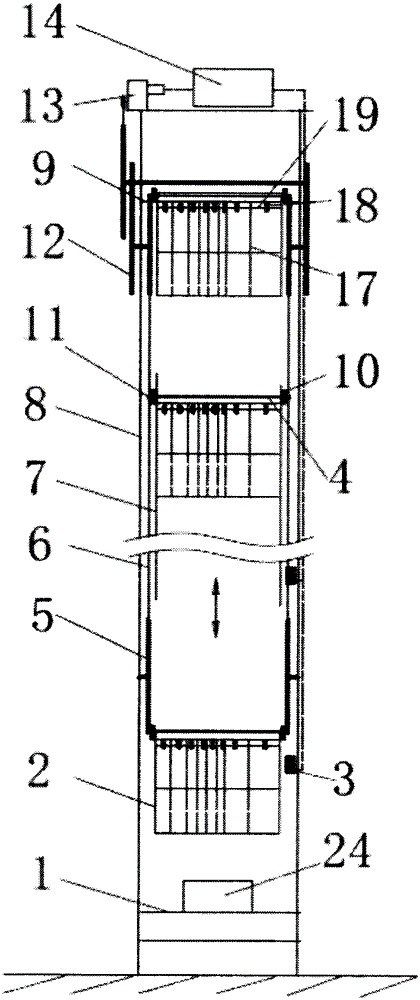

Arrangement structure for elevator without machine room

InactiveCN104555660ARuns smoothly up and downLower the altitudeBuilding liftsMine liftsEngineeringTractor

The invention discloses an arrangement structure for an elevator without a machine room. The arrangement structure comprises counter-weight, a counter-weight rope wheel, a tractor, a cab, car inverted rope wheel, a car rope head plate component, a tractor rack, a car guide rail, counter-weight guide rails and a steel wire rope, wherein the counter-weight and the tractor are positioned at the same side of the car; the pair of the counter-weight guide rails are positioned at the same side of the car; the tractor rack is arranged between the pair of the counter-weight guide rails; an axis direction of a traction wheel of the tractor is perpendicular to a car of the cab; a superposed part is not provided between the tractor and projection, in a vertical direction, of the cab; the car rope head component is fixed at one side opposite to the tractor; one end of the steel wire rope is fixed on the tractor rack; the other end of the steel wire rope downwards extends to get across the counter-weight rope wheel, then upwards extends to get across the traction wheel, downwards extends to get across the car inverted rope wheel and finally upwards extends for being fixed on the car rope head plate component. According to the arrangement structure disclosed by the invention, occupation of a well top-layer space is effectively reduced, the elevator cost and the building cost are lowered.

Owner:三六零安全科技股份有限公司

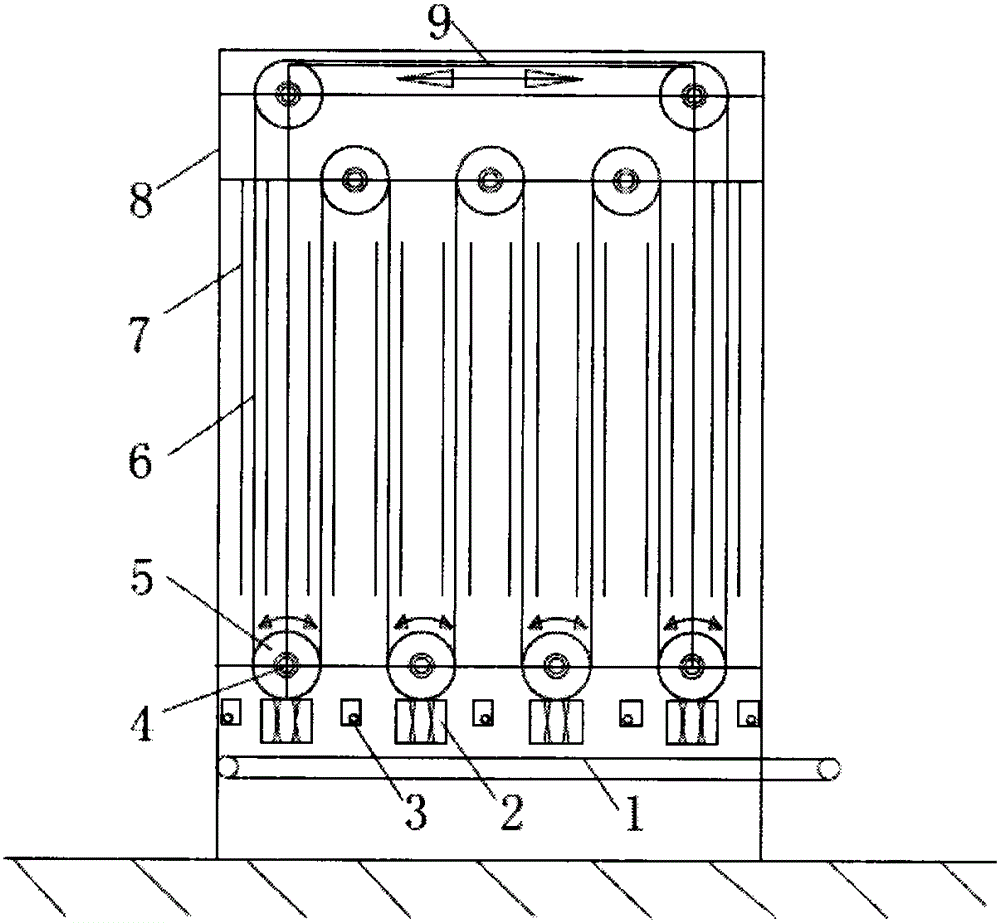

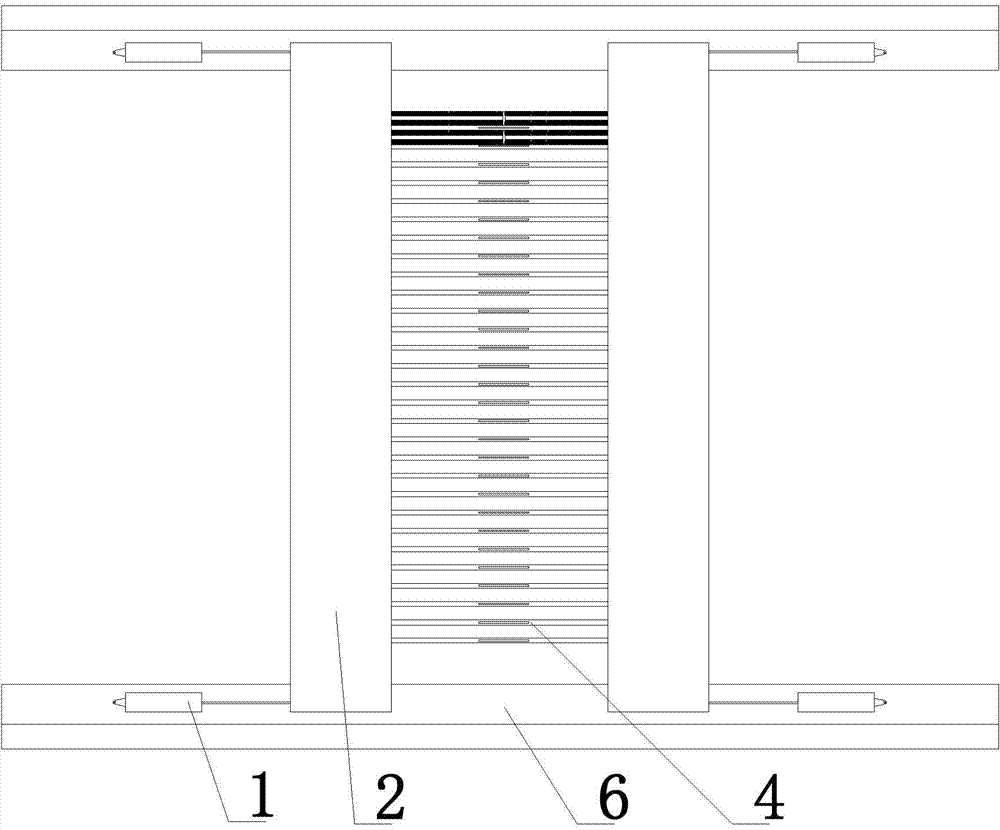

Express delivery terminal warehouse machine and automatic service method

InactiveCN105151616ARuns smoothly up and downFast and convenient deliveryStorage devicesPasswordConveyor belt

The invention relates to an express delivery terminal warehouse machine and automatic service method and belongs to the technical field of machinery and computers. According to the scheme, proper changes are made according to a warehouse machine applied in the application with numbers being CN104444016A, characteristics of express delivery and demands, and the warehoused machines with different size specifications are made by microminiaturizing the warehouse machines. The appearance of each warehouse machine is a sealed rectangular hexahedron, and two rows of parallel warehouse chain rope synchronous driving systems are arranged in each machine body. A chain rope (or a chain) connects a plurality of rotating shafts which are equidistantly distributed. Cargo boxes are suspended on the rotating shafts and driven by the rotating shafts to place a cargo required to be given out in a conveyor belt according to the instruction of a computer, and the cargo is sent to the position of a customer out of the warehouse through the conveyor belt. The method for receiving and delivering the cargo is that one side of each warehouse machine is a front stage of a delivering area facing the customer, and the other side of each warehouse is a back stage of a cargo loading operation area of express delivery persons by taking the warehouse machine as the dividing line. In each front stage, an order number is input and pictorial information is provided for the customer, and the delivering of the cargo is conducted through the correct cargo picking password. Each back stage allows the express delivery person to load cargos rapidly and intensively, process and record relative information of the cargos.

Owner:安徽三汇电子科技有限公司

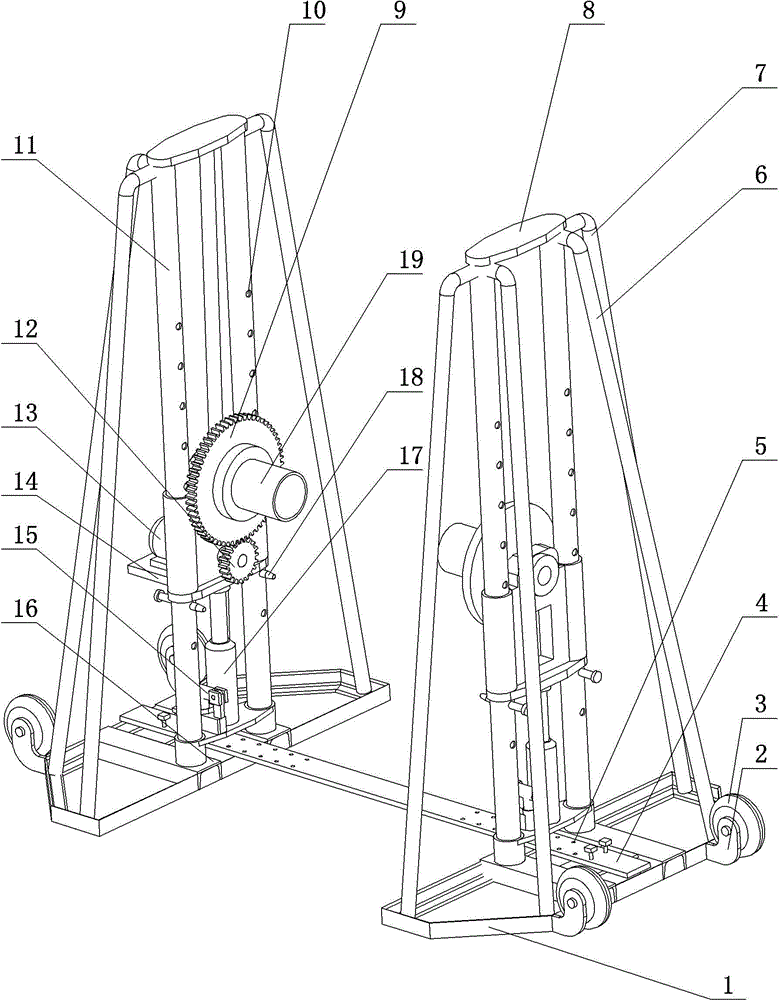

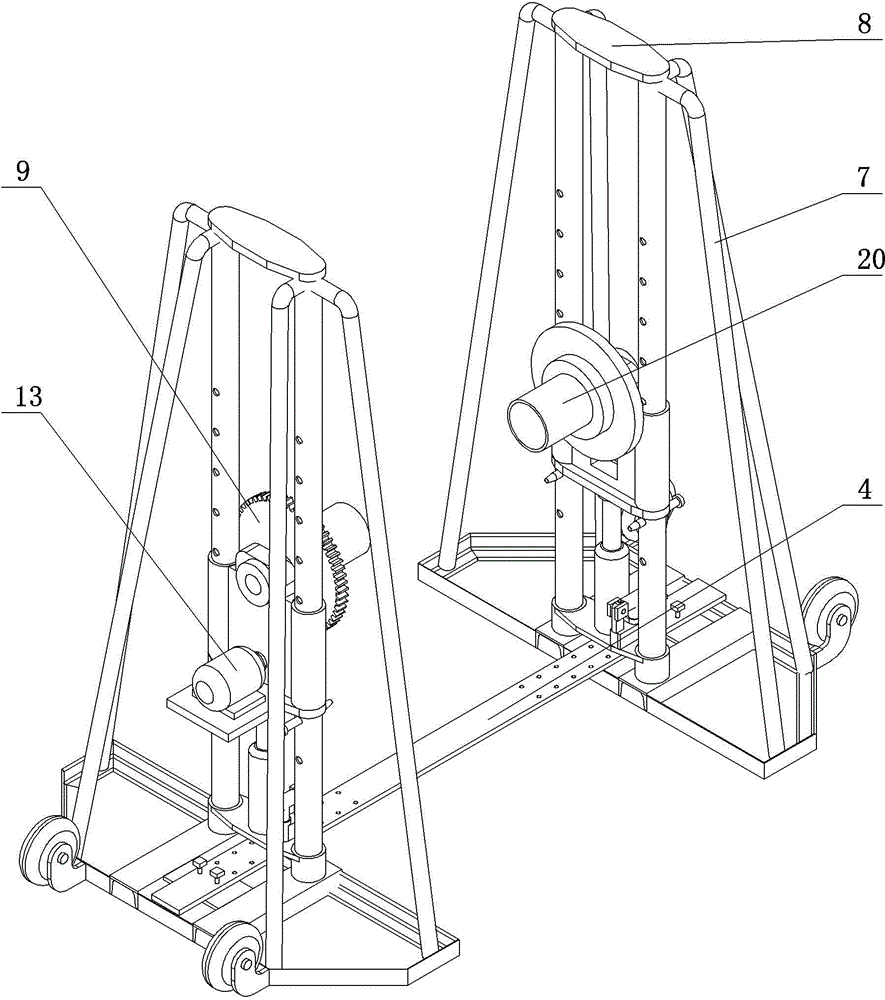

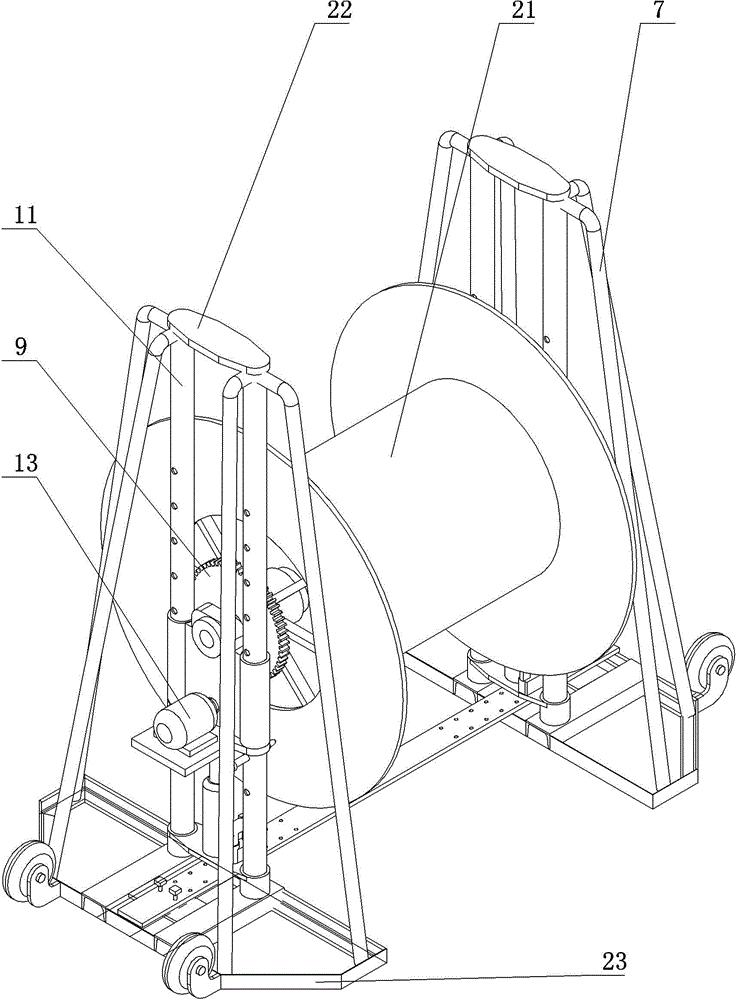

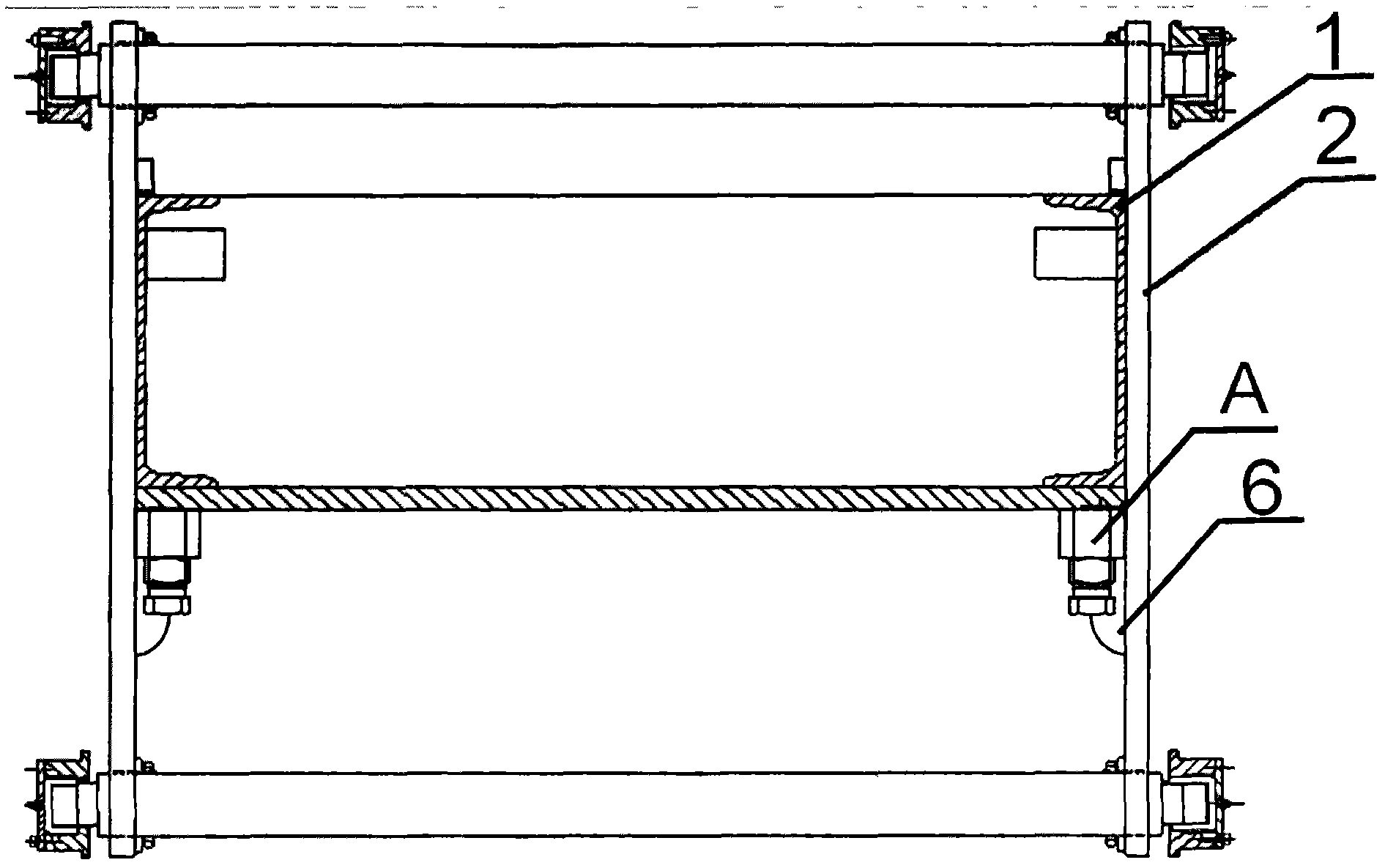

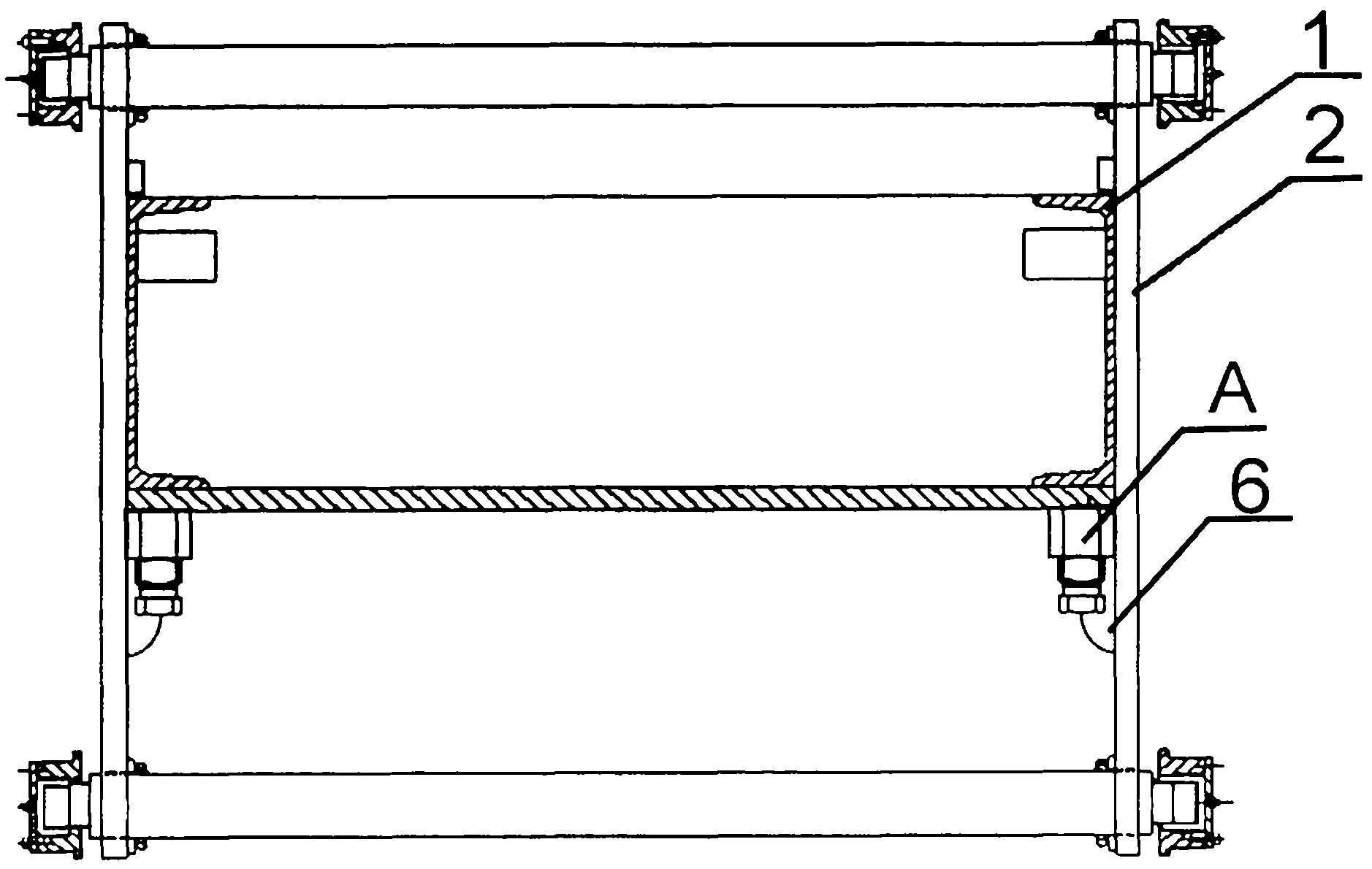

Power wire winding device

ActiveCN105314457AFirmly connectedRuns smoothly up and downFilament handlingPower gridConductor Coil

The invention relates to a power wire winding device, belongs to the technical field of power grid power construction equipment. The power wire winding device has convenience in line winding and is high in construction efficiency. The power wire winding device comprises a first vertical frame and a second vertical frame which are oppositely arranged. The power wire winding device is characterized in that a first supporting plate is arranged in the middle of the bottom end of the first vertical frame, and first guide pillars are arranged between the two sides of the first supporting plate and the upper end of the first vertical frame. The first guide pillars are provided with first guide sleeves, the two first guide sleeves are connected through a first vertical plate, the lower end of the first vertical plate is provided with a first horizontal supporting plate extending towards the outer side, a motor is fixed to the first horizontal supporting plate, a driving bearing is arranged on the lower portion of the first vertical plate, and a shaft rod of a driving gear penetrates the driving bearing and is connected with a motor output shaft. The upper end of the first vertical plate is provided with a driven bearing, a shaft rod of a driven gear penetrates the driven bearing, and the driven gear is meshed with the driving gear.

Owner:STATE GRID CORP OF CHINA +1

Rotation, lifting and supporting device for advertising board

The invention discloses a billboard rotary lifting support device, which belongs to the field of billboard support devices, and includes a support frame and a transmission mechanism. The support frame is provided with a placement plate, and the placement plate is fixedly connected with the support frame. The servo motor It is fixedly connected with the support frame, the output shaft of the servo motor is provided with a pulley 1, the rotating column is rotatably connected with the upper top plate of the support frame, the lower end of the rotating column is provided with a pulley 2, and the pulley 1 It is connected with the pulley 2 through a belt. The top of the rotating column is provided with a telescopic rod, and the telescopic rod is rotatably connected to the top of the rotating column. The cylinder is fixed on the placement plate. The piston rod of the cylinder is connected to the lower end of the adjusting column. Fixedly connected, the front end of the adjustment column is provided with a rotating rod, and the rotating rod is rotatably connected to the top of the adjusting column, and the rotating rod passes through the middle of the pulley 2 and the rotating column. The structure of the invention is simple, and the transmission mechanism can drive the billboard to rotate. It is convenient to watch the content on the advertising box in multiple directions.

Owner:湖北逸旭建设科技有限公司

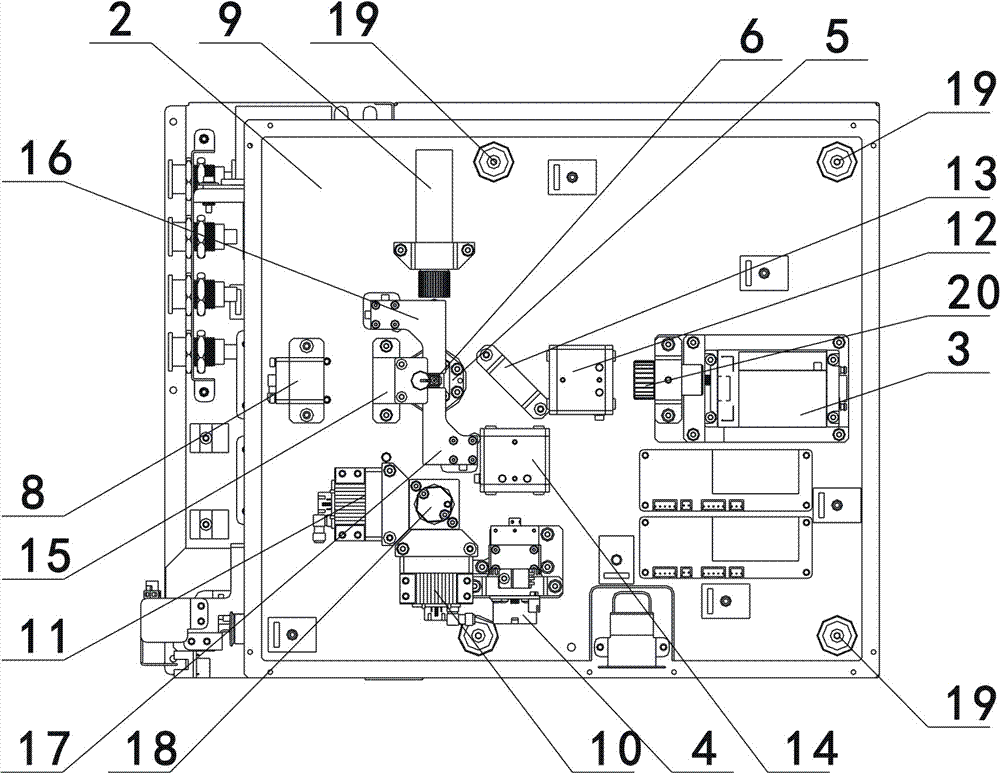

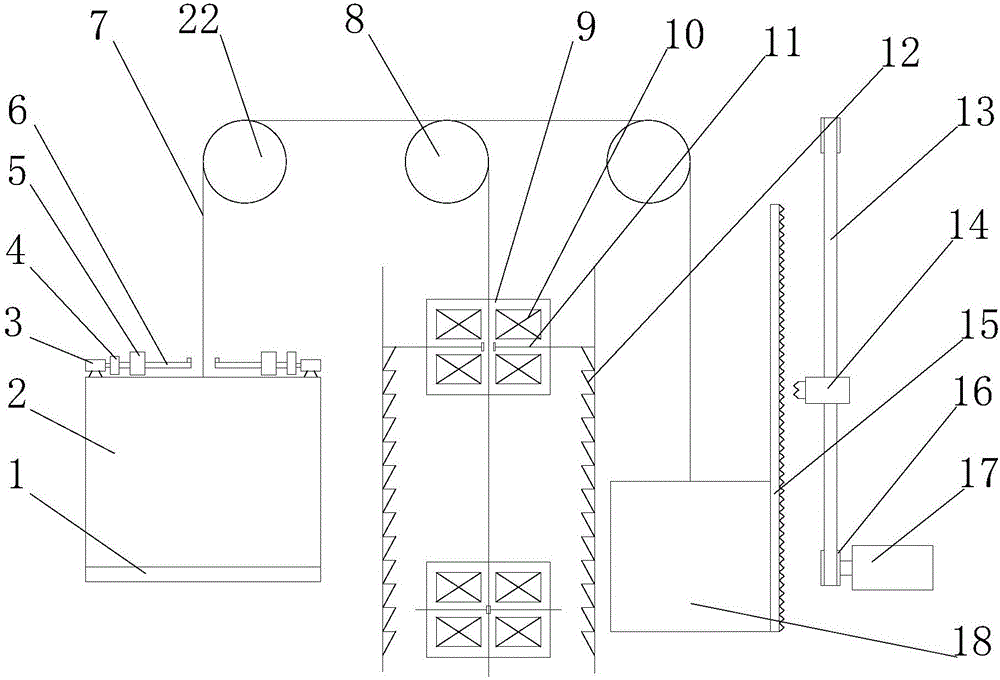

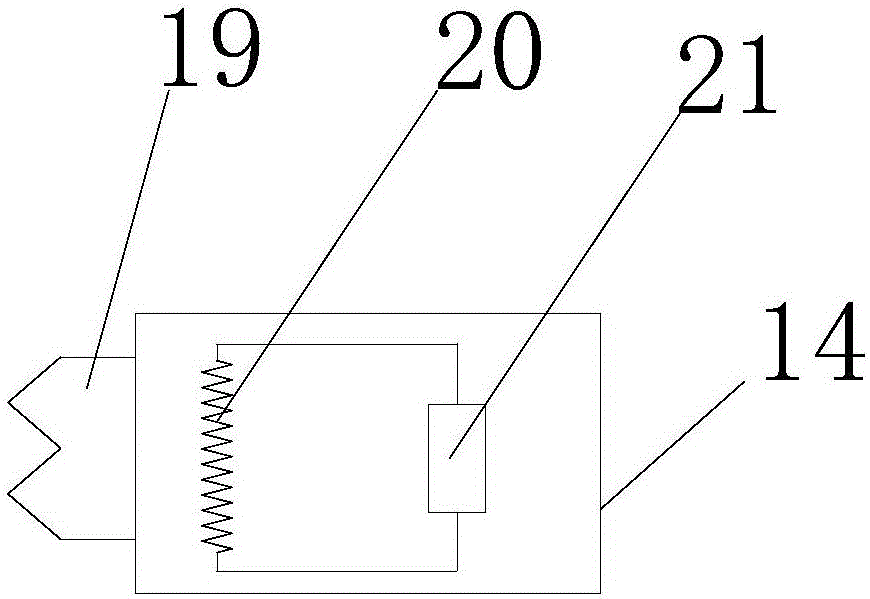

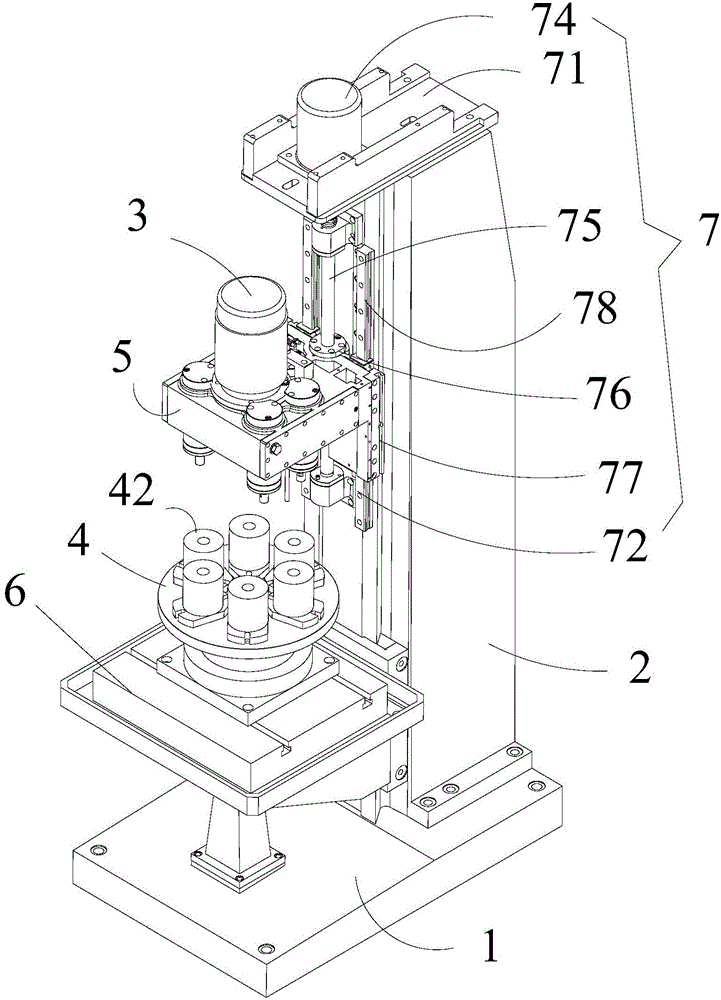

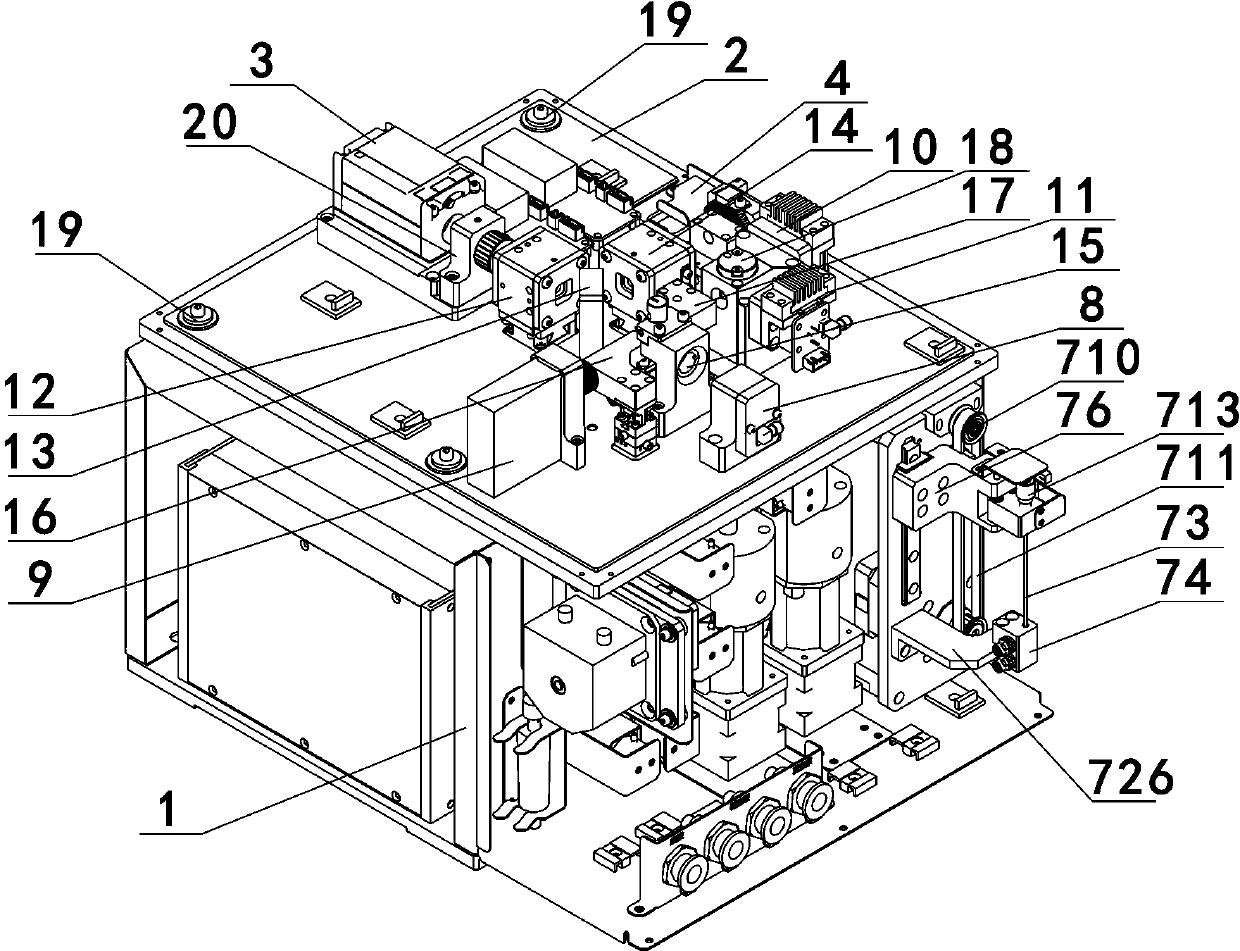

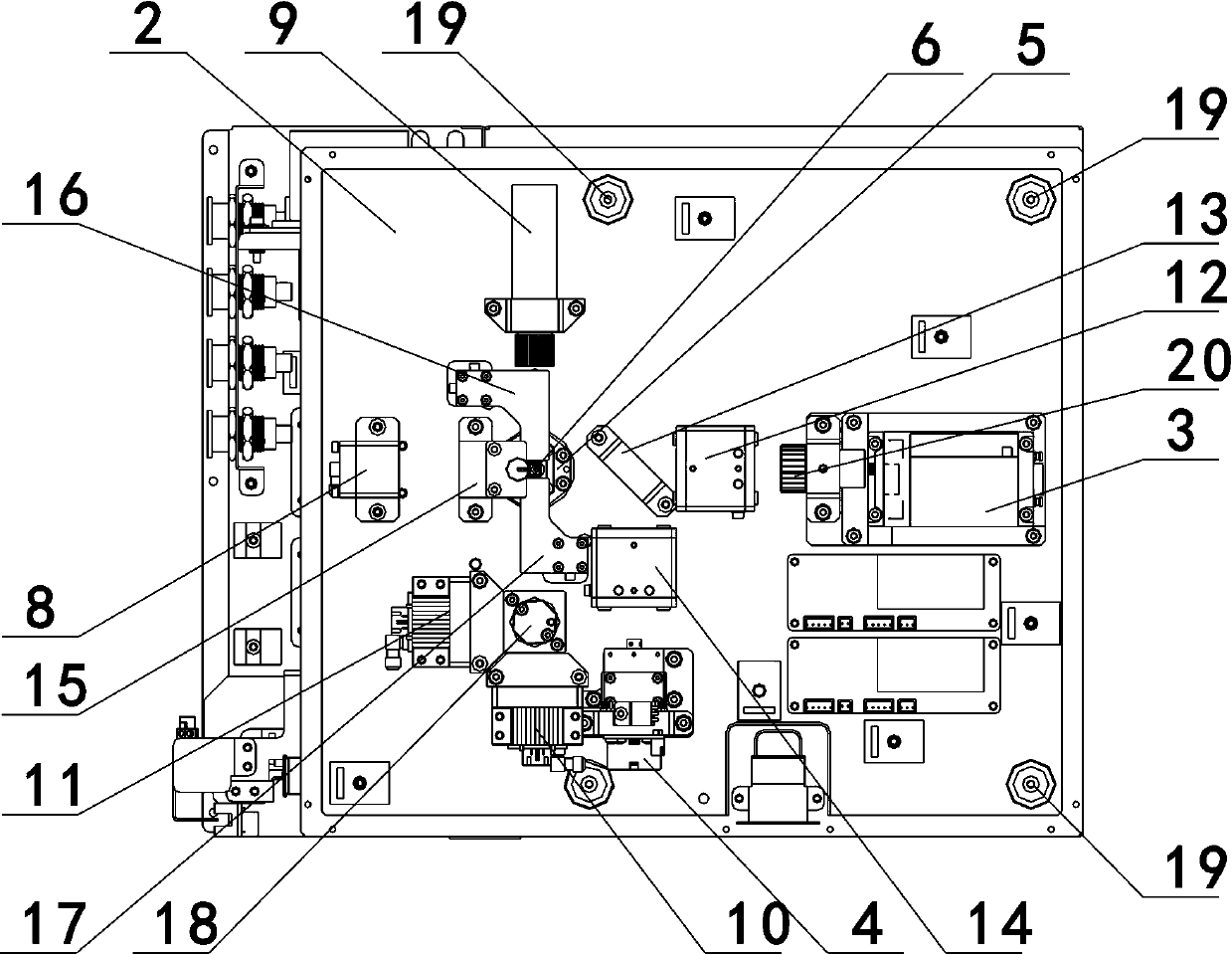

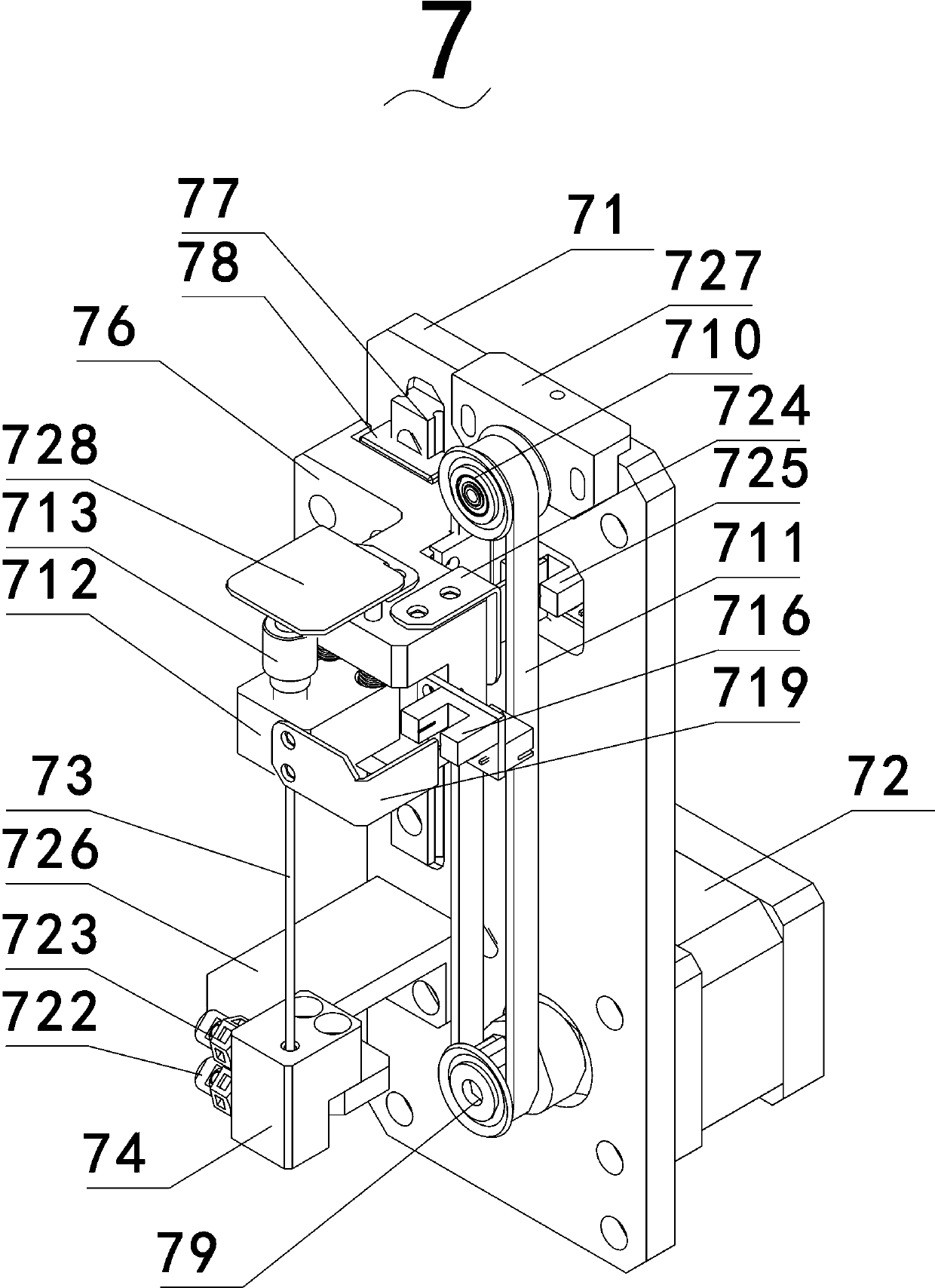

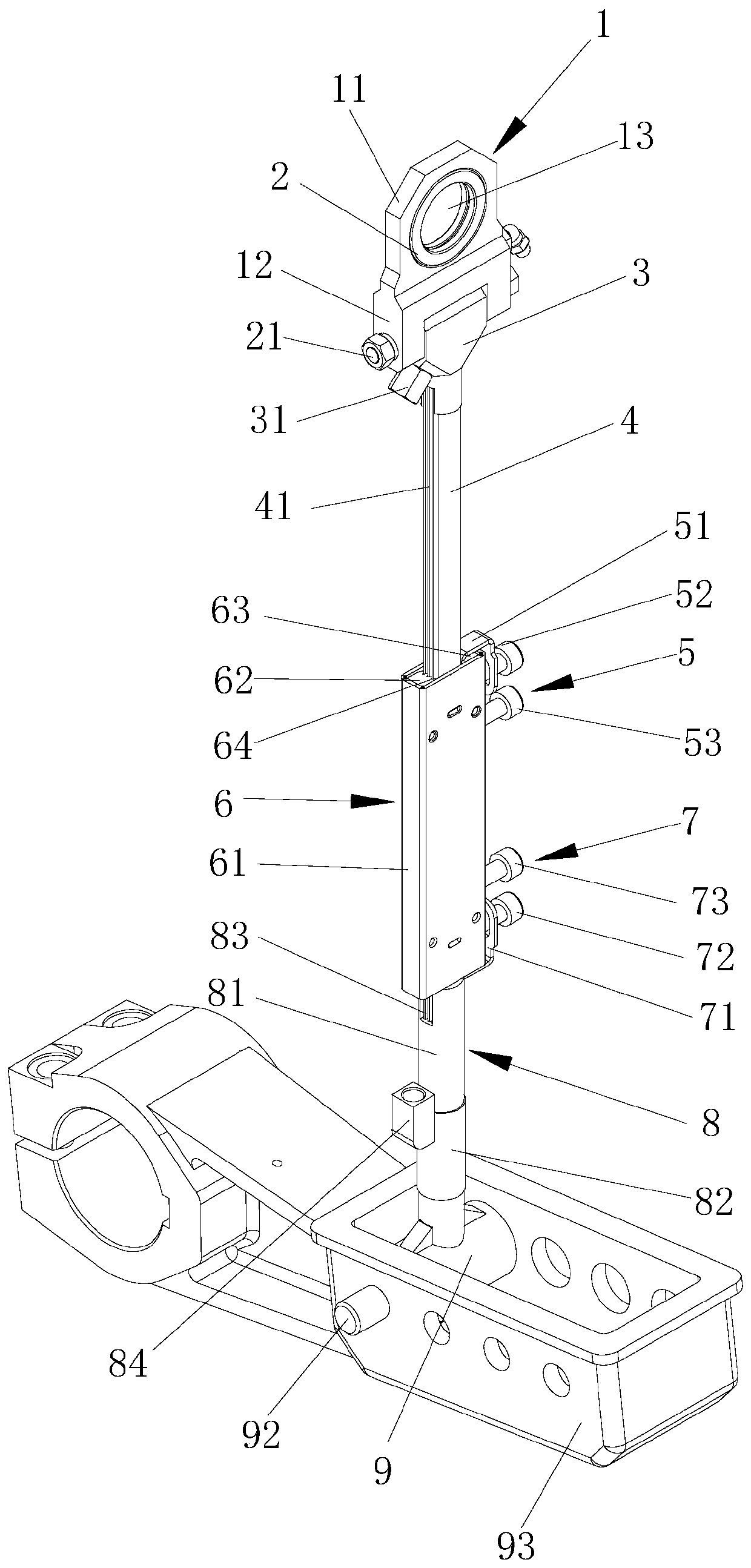

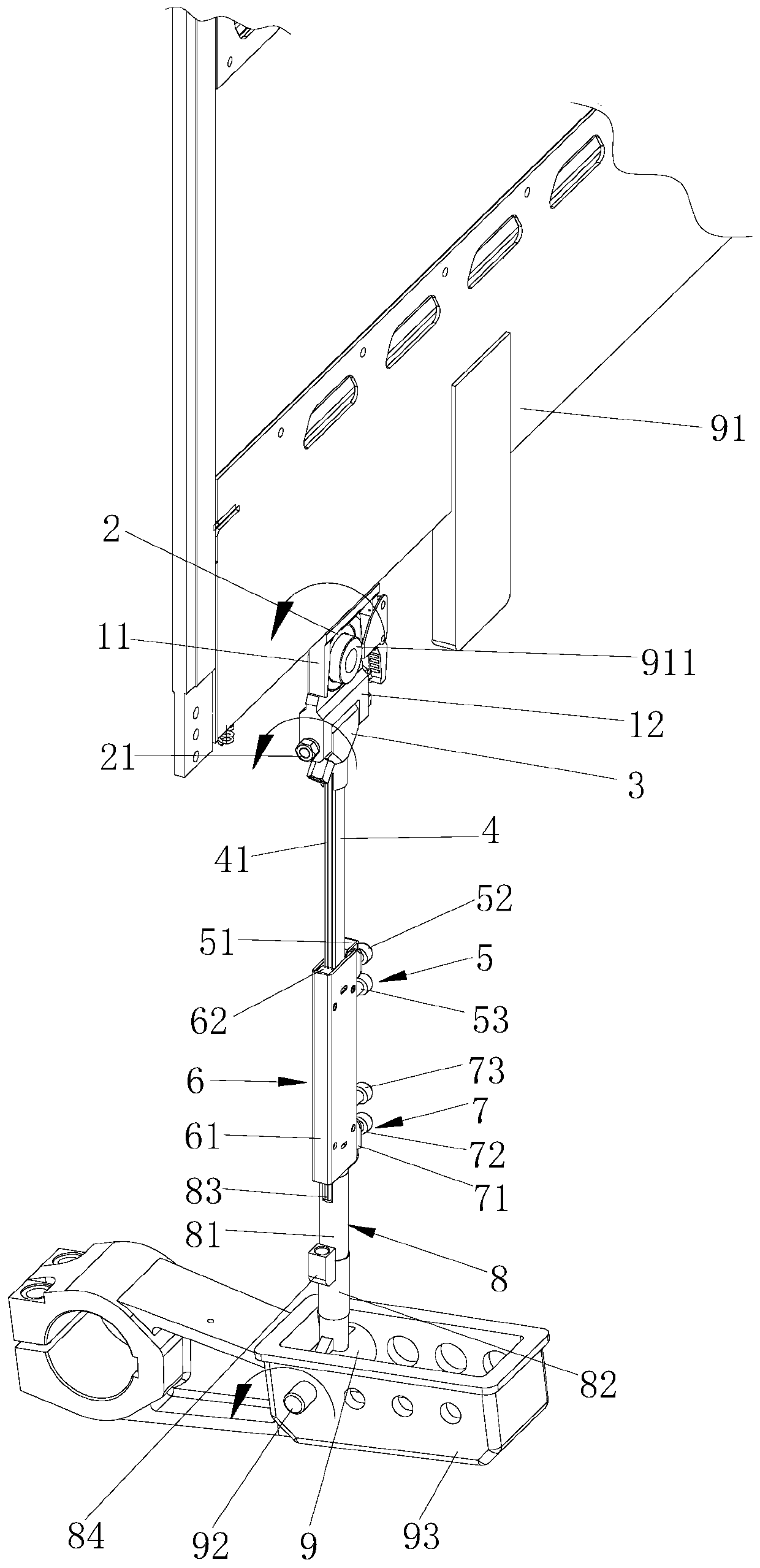

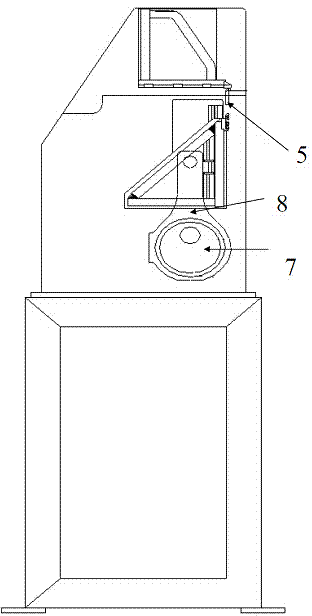

Sample suction device and flow fluorescence detector

ActiveCN105445485ARuns smoothly up and downNot easy to damageIndividual particle analysisFluorescenceBiomedical engineering

The invention relates to the technical field of medical equipment, in particular to a sample suction device and a flow fluorescence detector. The sample suction device is used for sucking a sample in a reaction cup and is characterized in that the sample suction device comprises a bottom plate, a stepping motor, a steel needle and a swab, wherein the swab is located right below the lower end of the steel needle, a needle washing passage is arranged in the vertical direction of the swab, the lower end of the steel needle stretches into the needle washing passage, the steel needle is slidingly connected with the bottom plate by a sliding mechanism, the stepping motor drives the steel needle to move up and down, and the steel needle is connected with the sliding mechanism by a switching block. The invention provides the sample suction device which is simple and stable in structure and full-automatic in sample adding and the flow fluorescence detector.

Owner:JIAXING QUEST LIFE SCI

Method for in situ reducing electrolyte on electrolytic manganese cathode plate

ActiveCN103590074ASolve the problem of carrying electrolyteRealize in-situ groove backPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

The invention relates to a method for in situ reducing electrolyte on an electrolytic manganese cathode plate. A device utilized by the method comprises a brushing and dropping device assembly, a tank discharging device, the cathode plate and an electrolytic tank, wherein the tank discharging device is fixedly connected with the brushing and dropping device assembly, the cathode plate is connected with the tank discharging device, and the electrolytic tank is positioned below the cathode plate. The method comprises steps of electrolysis, tank discharging and brushing and dropping. With utilization of the device and the method, the problem that the cathode plate carries the electrolyte in the tank discharging process in the subsequent section of electrolytic manganese electrolysis is greatly solved. The device and the method can greatly reduce the electrolyte on the cathode plate when the cathode plate is discharged from the tank.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

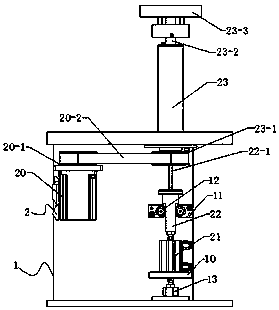

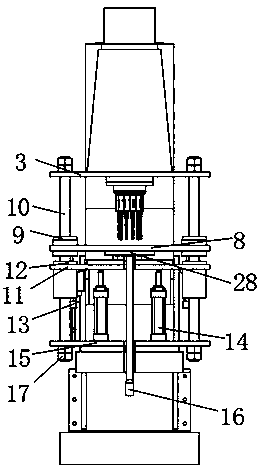

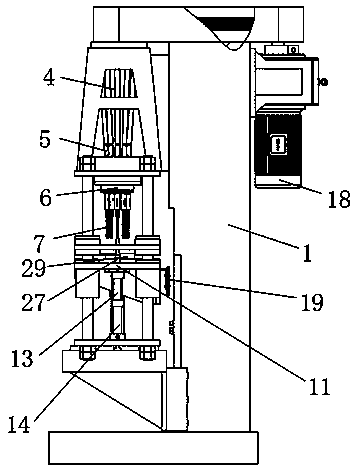

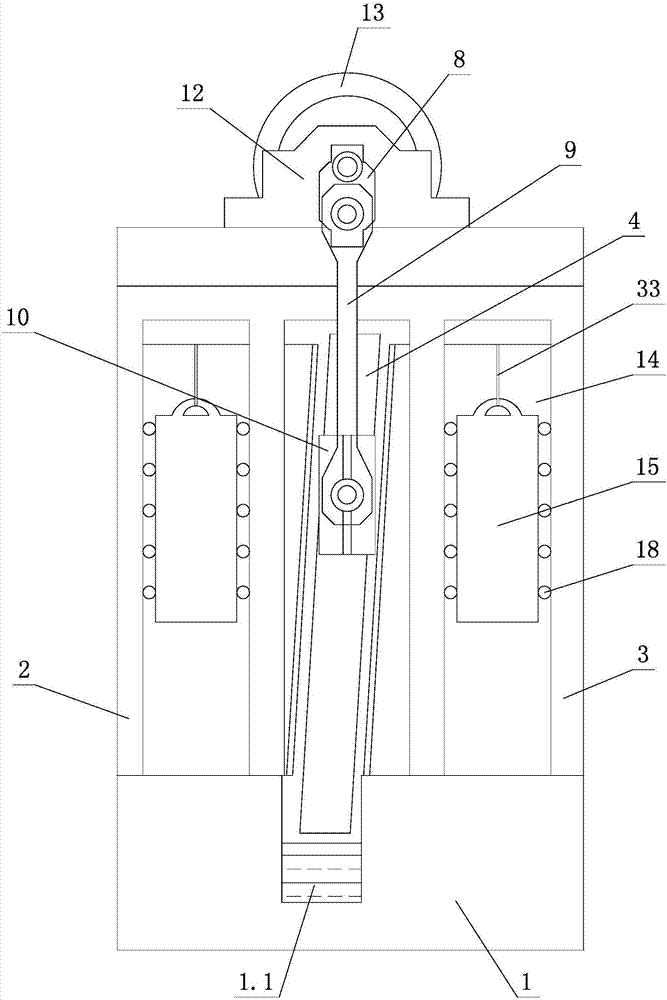

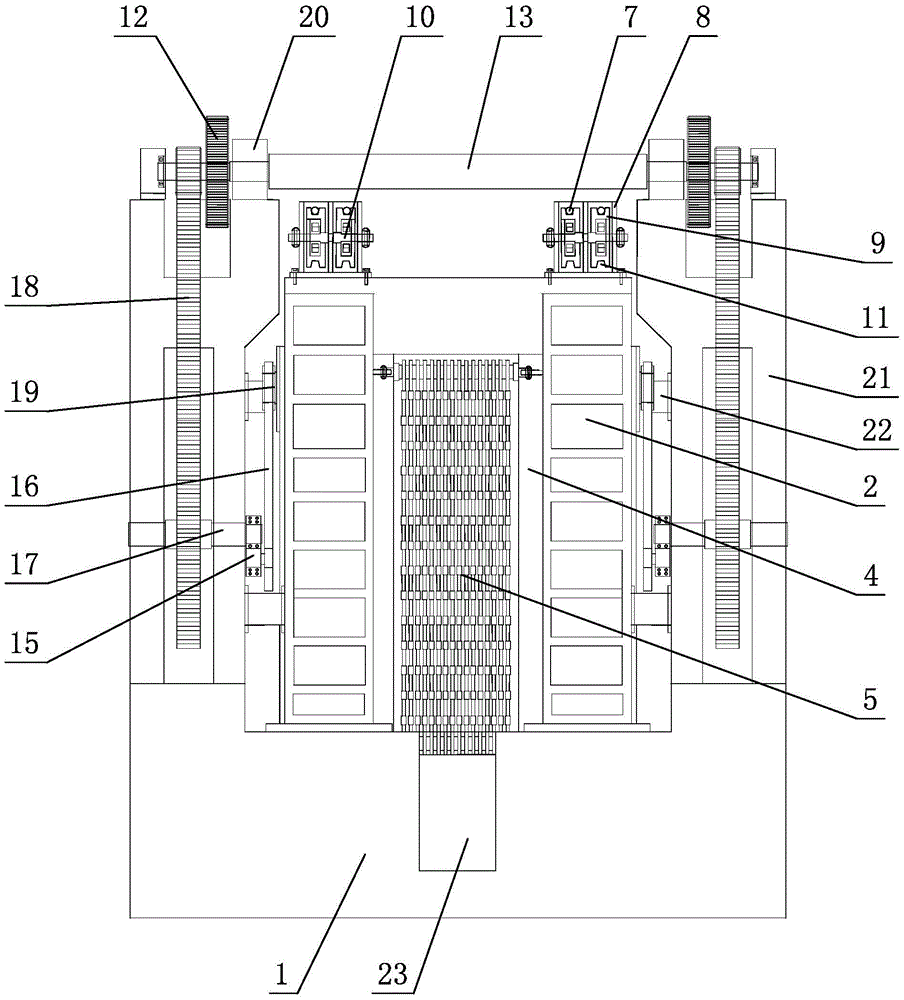

Four-guiding-column multi-hole drilling numerical control machine tool

ActiveCN110315107AImprove rigidityImprove operational safetyLarge fixed membersDrill jigsNumerical controlEngineering

The invention discloses a four-guiding-column multi-hole drilling numerical control machine tool, and relates to the field of numerical control machine tools. A drilling machine body is included, a drilling machine upper fixing frame is fixedly connected with one side of the top of the drilling machine body, a first crossed connecting rod is fixedly connected with the interior of the drilling machine upper fixing frame, one end of the first crossed connecting rod is fixedly connected with a second crossed connecting rod, a multi-spindle tool split body is fixedly connected with the end, away from the first crossed connecting rod, of the second crossed connecting rod, the bottom of the multi-spindle tool split body is fixedly connected with a taper shank twist drill, polished rods are fixedly connected with four corners of the drilling machine upper fixing frame, and drilling template fixing plates movably sleeve the surfaces of the polished rods. The four-guiding-column multi-hole drilling numerical control machine tool has the advantages that the influence of clearance can be compensated through four polished rod structures, the rigidity of the structure is improved, the common difference of the position degree of a processed product is ensured, the use of a programmable controller can not only simply the operation procedure, but also improve the operation safety and reduce the production cost.

Owner:莱州市锐泰机械配件有限公司

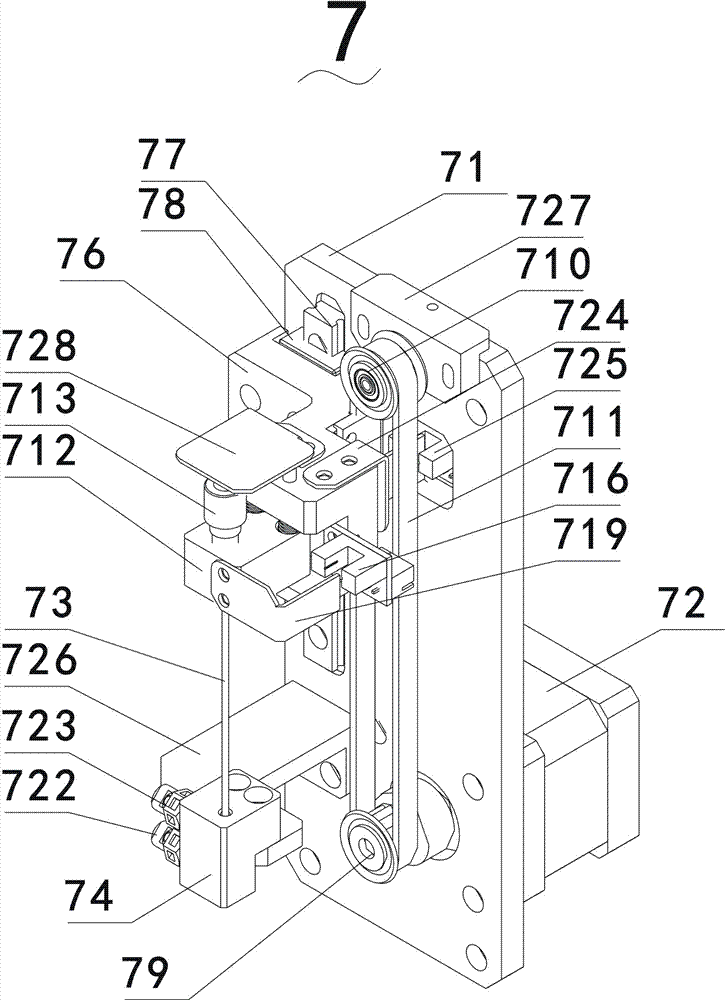

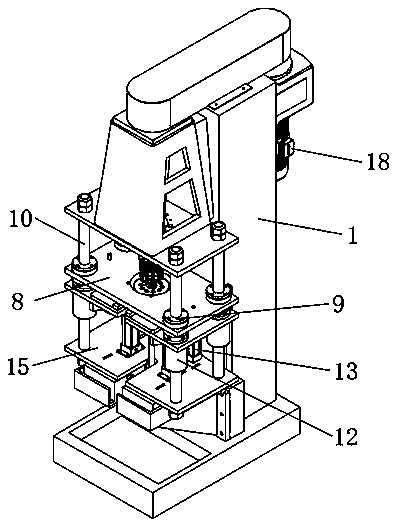

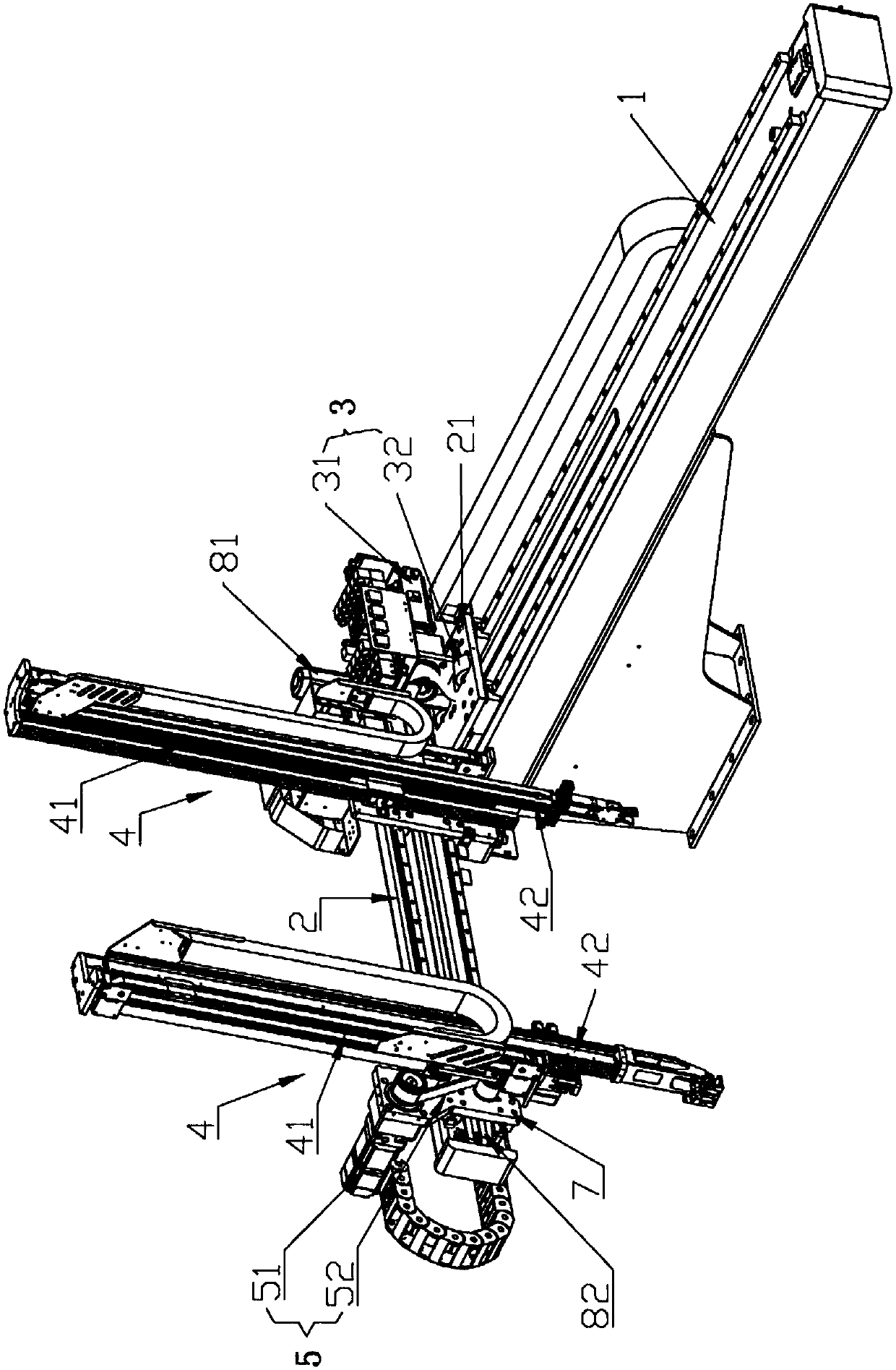

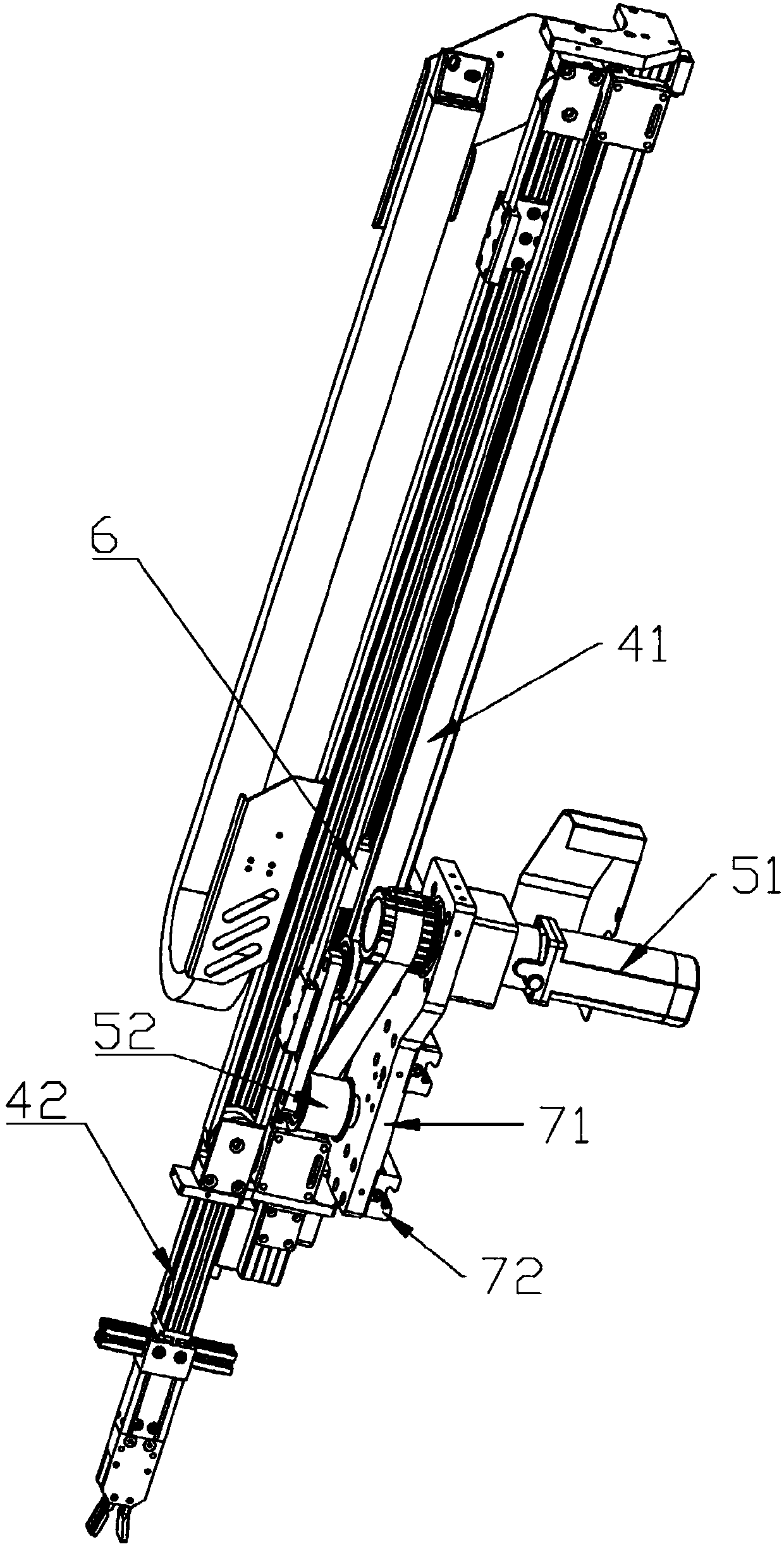

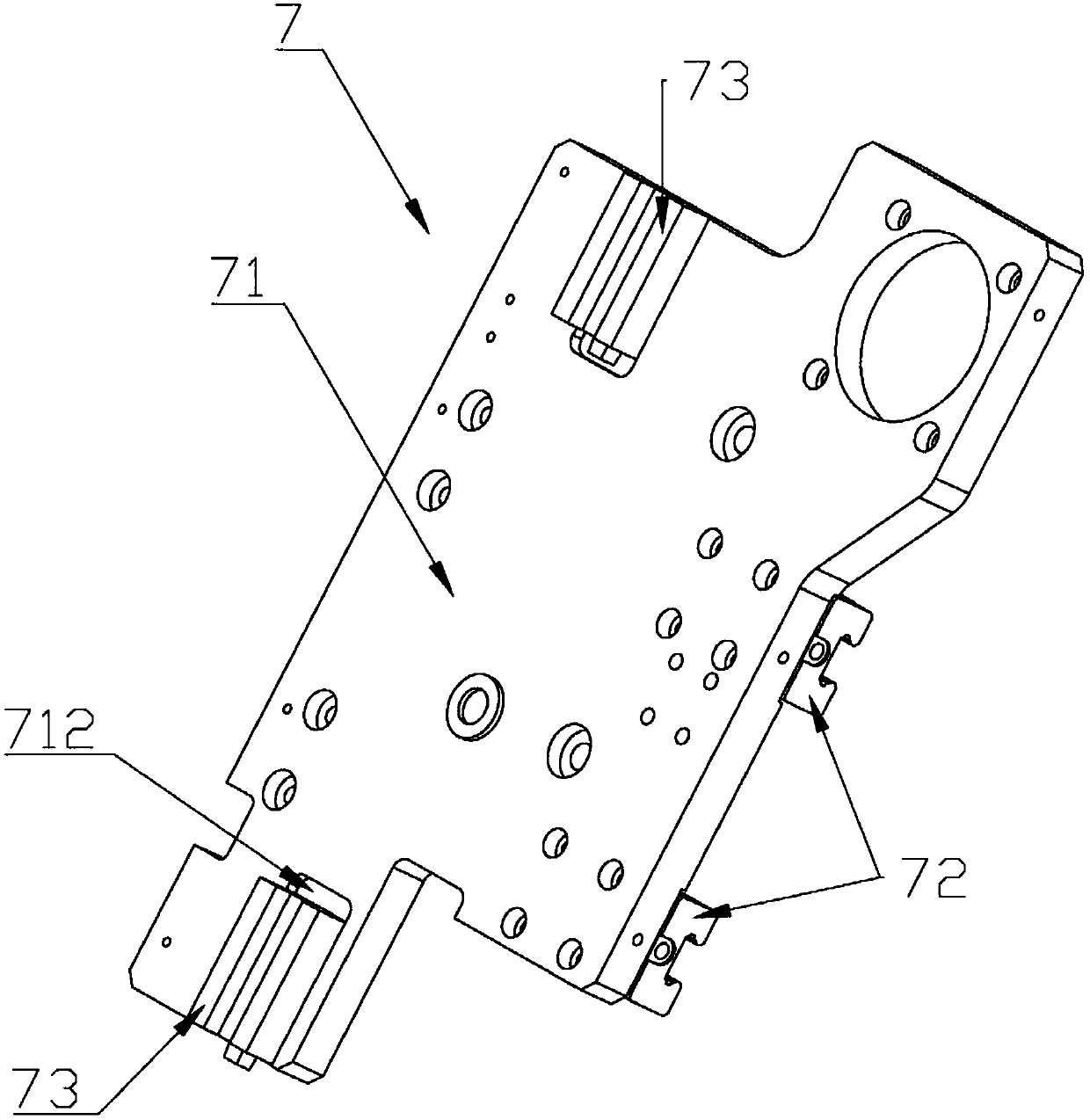

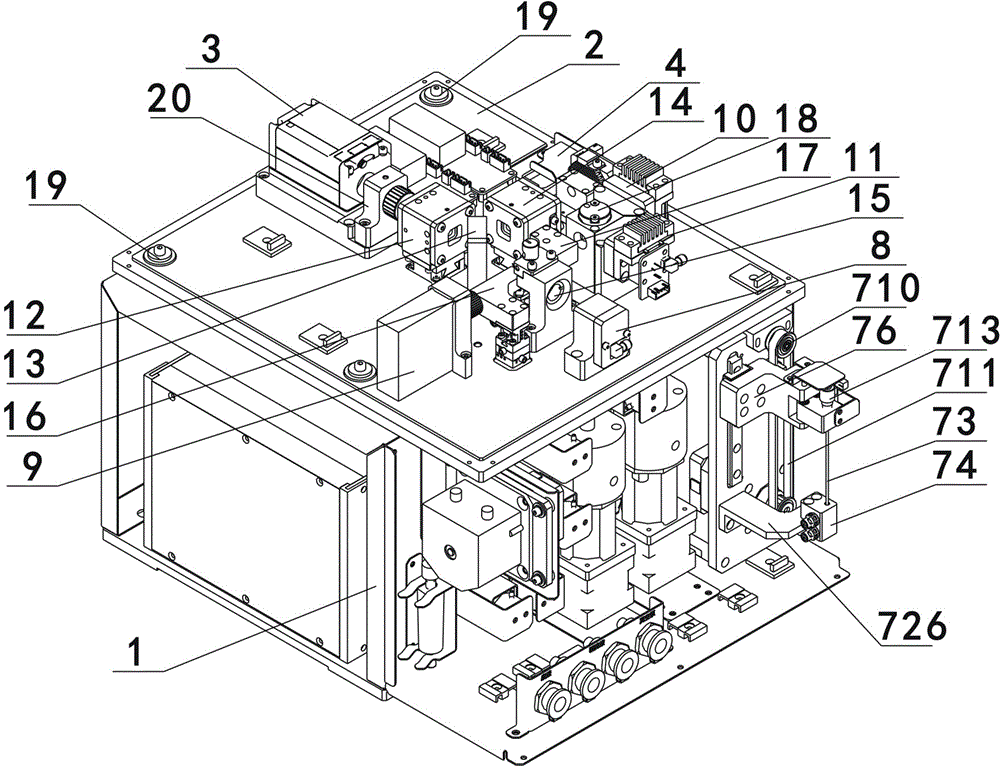

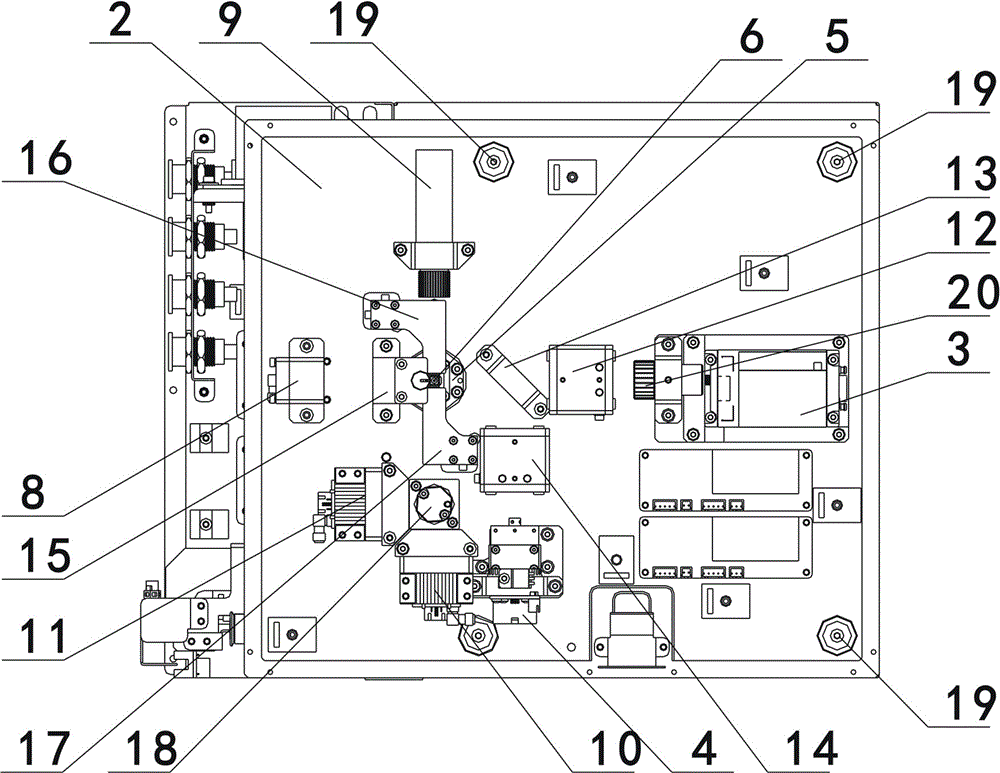

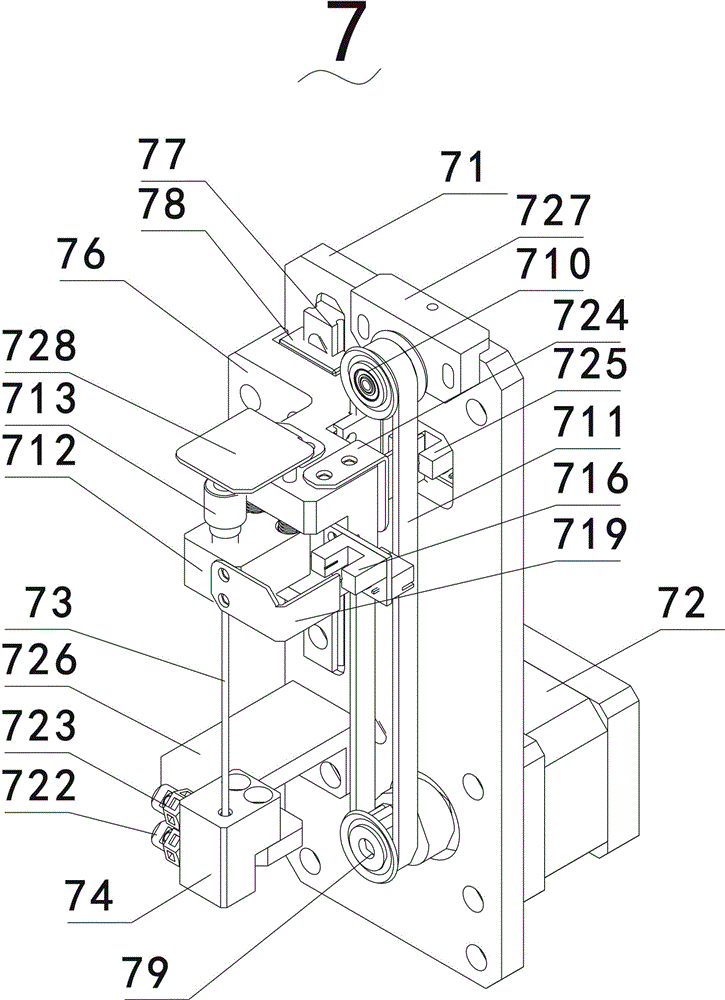

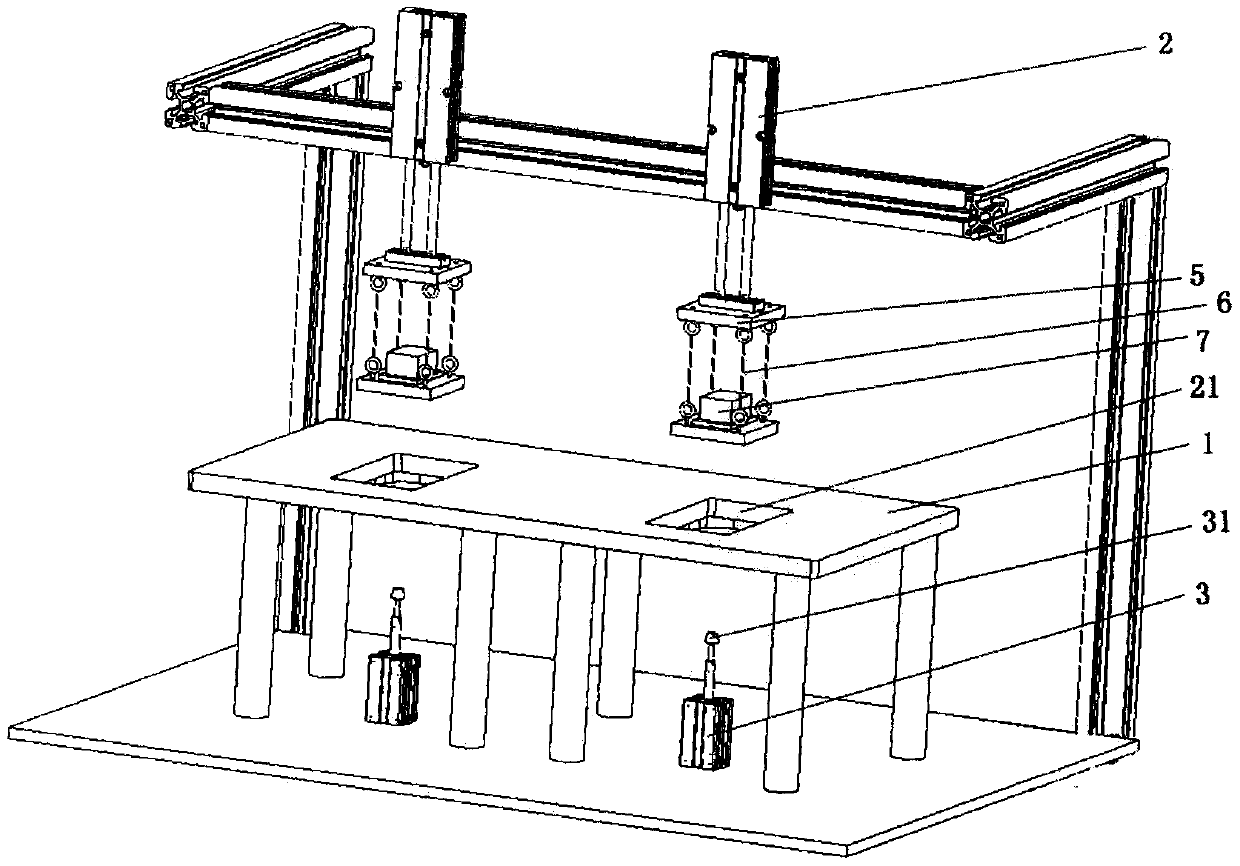

Robot capable of carrying out equilibrium running

PendingCN107696012AOvercome self-respectAvoid failureProgramme-controlled manipulatorControl engineeringElectric machinery

The invention provides a robot capable of carrying out equilibrium running. The robot capable of carrying out equilibrium running comprises a sliding rail, a mechanical arm and an installation plate.The mechanical arm is arranged on the installation plate in a vertically slidable manner. The robot capable of carrying out equilibrium running further comprises a driving mechanism used for driving the mechanical arm to move upwards or downwards. The driving mechanism comprises a motor and a belt pulley assembly which are matched with each other. The motor is fixed to the sliding rail. The belt pulley assembly is connected with the mechanical arm. The installation plate is further provided with a balance cylinder. The balance cylinder comprises a cylinder barrel and a piston rod. The cylinderbarrel and the installation plate are fixedly connected. The piston rod is connected with the mechanical arm. The upper end of the cylinder barrel communicates with the outside. An air inlet is formed in the lower end of the cylinder barrel. The air inlet is connected with a pressure regulation valve, so that the piston rod applies the supporting force of the preset magnitude on the mechanical arm. According to the robot capable of carrying out equilibrium running, compared with the prior art, the balance cylinder can overcome the dead-weight of the mechanical arm, the influence caused by thedead-weight of the mechanical arm on the output torque of the motor is avoided, it can be effectively avoided that a motor fails, the mechanical arm can run stably in the vertical direction, and theworking efficiency is improved.

Owner:GUANGDONG TOPSTAR TECH

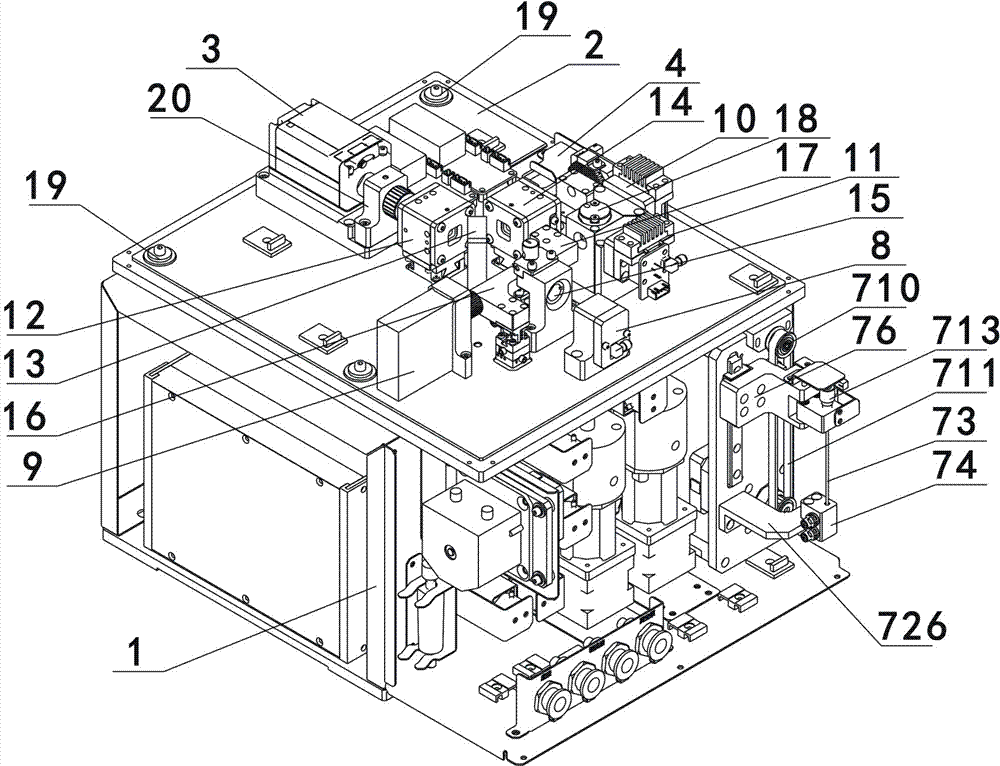

Flow-type fluorescence detector

ActiveCN105388139ASimple structureStable structureFluorescence/phosphorescenceMedical equipmentFluorescence

The invention relates to the technical field of medical equipment, in particular to a flow-type fluorescence detector. The flow-type fluorescence detector is used for sucking samples in a reaction cup for detection. The flow-type fluorescence detector is characterized in that the detector comprises a frame body, an optical table, a first laser device, a second laser device, a flow chamber, a flow pond, a plurality of optical receivers and a sample sucking device; the first laser device, the second laser device, the flow chamber, the flow pond and the optical receivers are all arranged on the optical table; the flow chamber is located below the flow pond; light generated by the first laser device and the second laser device passes through the flow pond to be received by the optical receivers; the sample sucking device is vertically arranged on the frame body and located above the reaction cup. The flow-type fluorescence detector is simple and stable in structure, high in detection sensitivity, wide in detection range and stable in optical detection.

Owner:JIAXING QUEST LIFE SCI

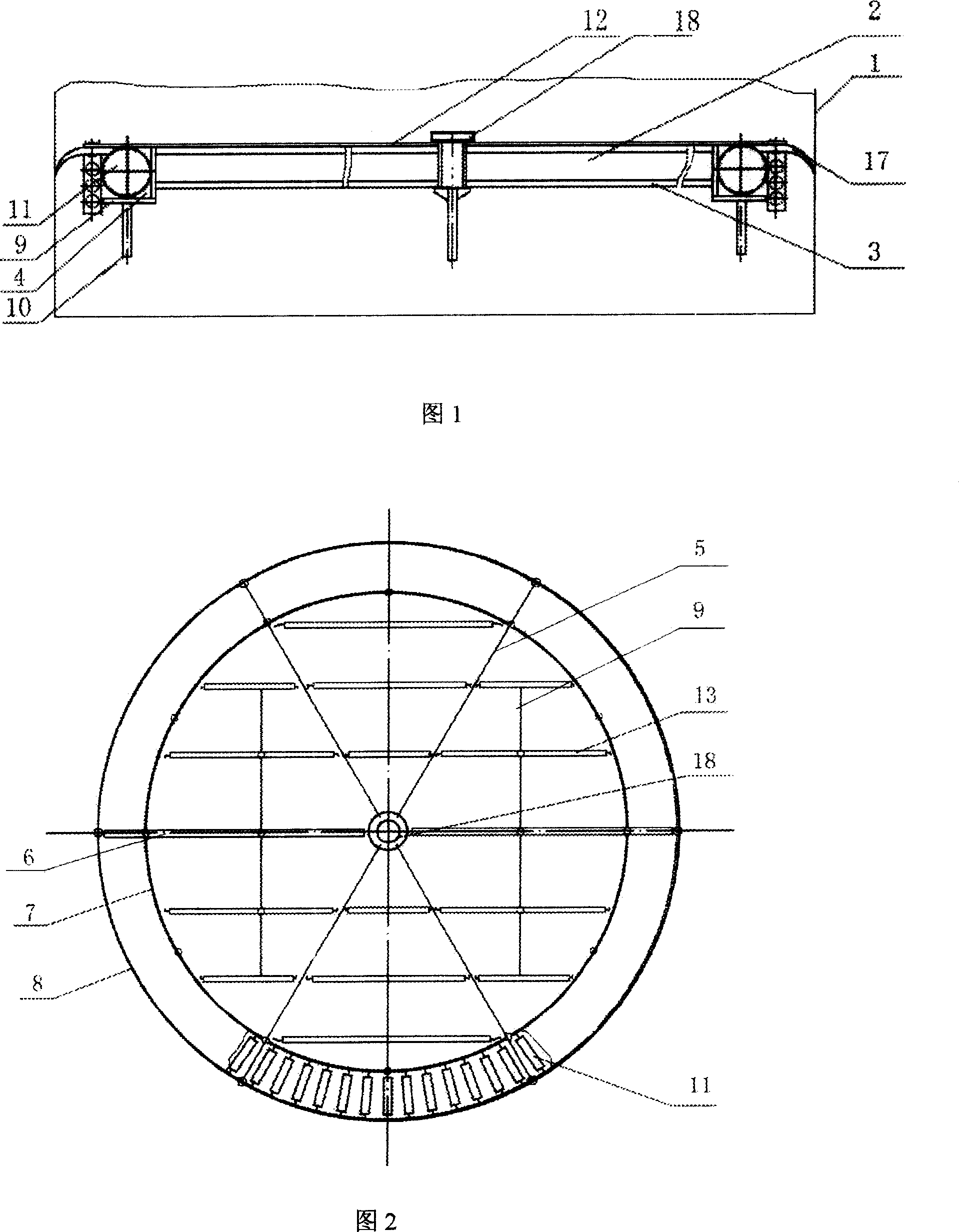

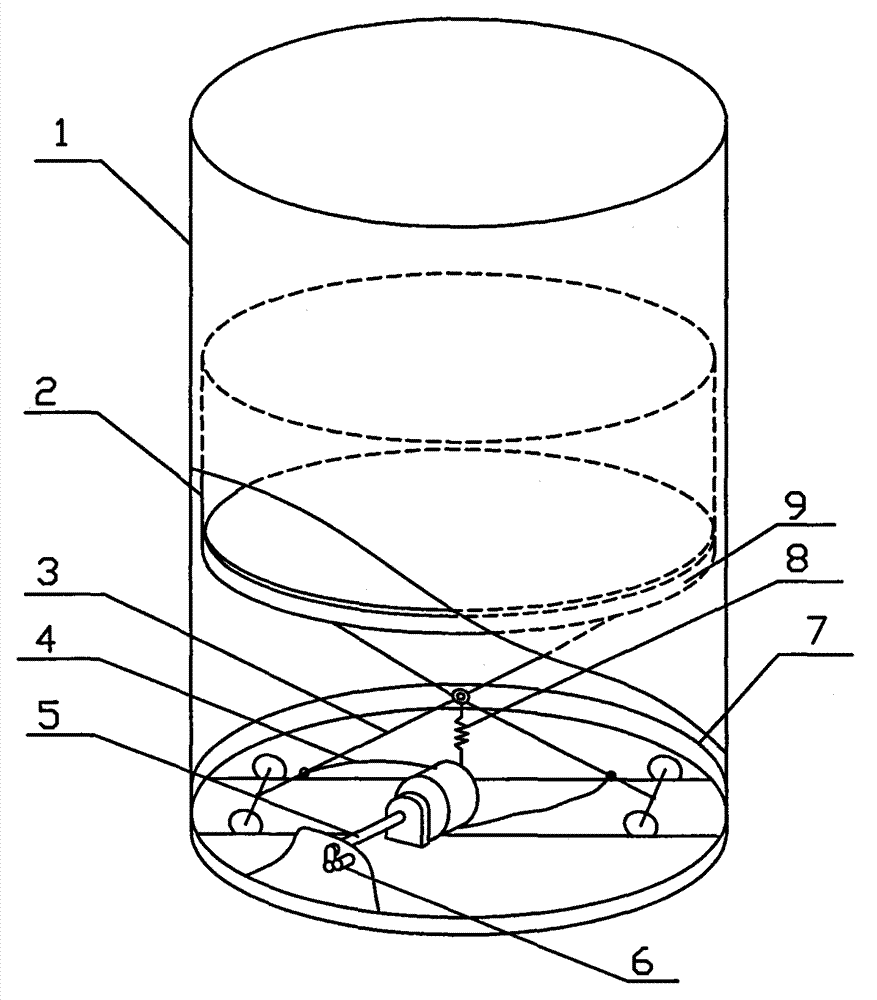

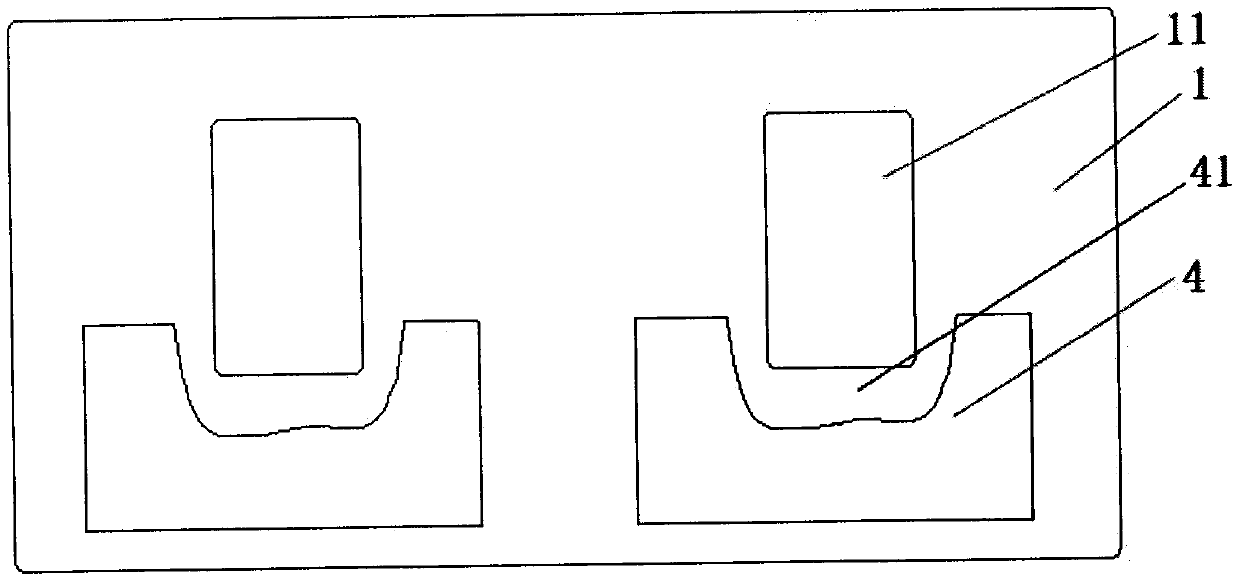

Metal structural buoyancy pontoon type inner floating tray for storage tank

The invention discloses a metal structure displacer-typed internal floating disc for a storage tank. The invention consists of a radioactivity metal framework and a camel arranged in the metal framework; the floating disc (2) is arranged in a shell (1) of the storage tank and consists of a middle floating disc (3) and a peripheral cabin (4); the middle floating disc (3) consists of 6 main beams and a U-shaped floating disc (13); one end of the middle floating disc (3) is fixed to a central plate (18) while the other end of the middle floating disc (3) is fixed to an external ring beam (8) by an internal ring beam (7); a stiffener (9) is arranged between the internal ring beam (7) and the external ring beam (8); a supporting leg (10) is fixed to the stiffener (9); one end of a cylindrical floating disc (11) is fixed to the peripheral cabin (4) consisting of the external ring beam (8) and the middle of the internal ring beam (7). The invention has the advantages that the beam and the camel is injected into a whole as the U-shaped camel is arranged in the middle of the floating disc, the material is saved; the oil gas space is small, and the sealing performance is improved; the upper part of the floating disc is a rectangle; the strength of the floating disc is improved and the stability is good.

Owner:张凤球

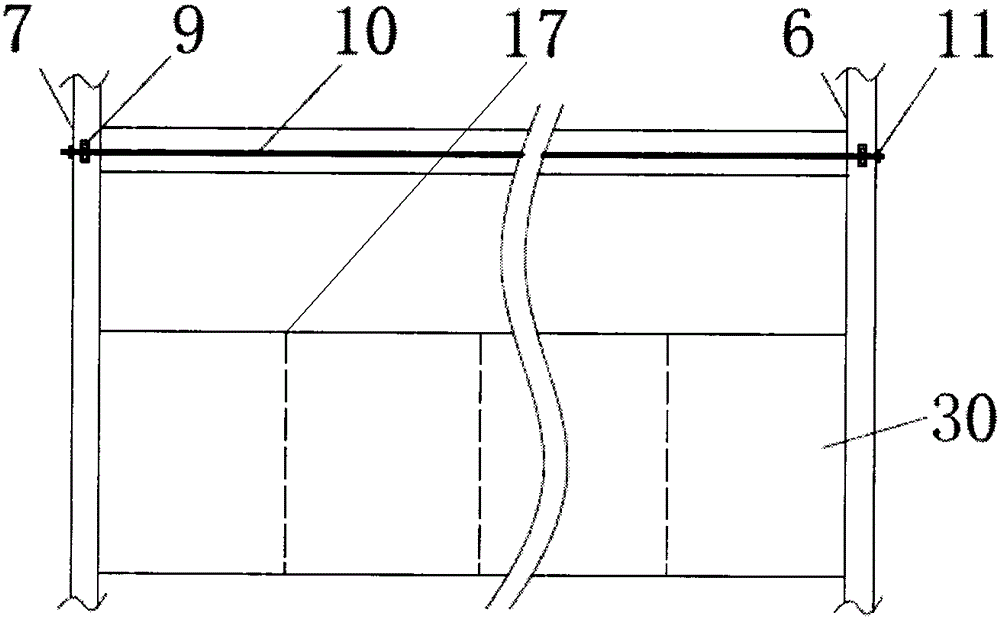

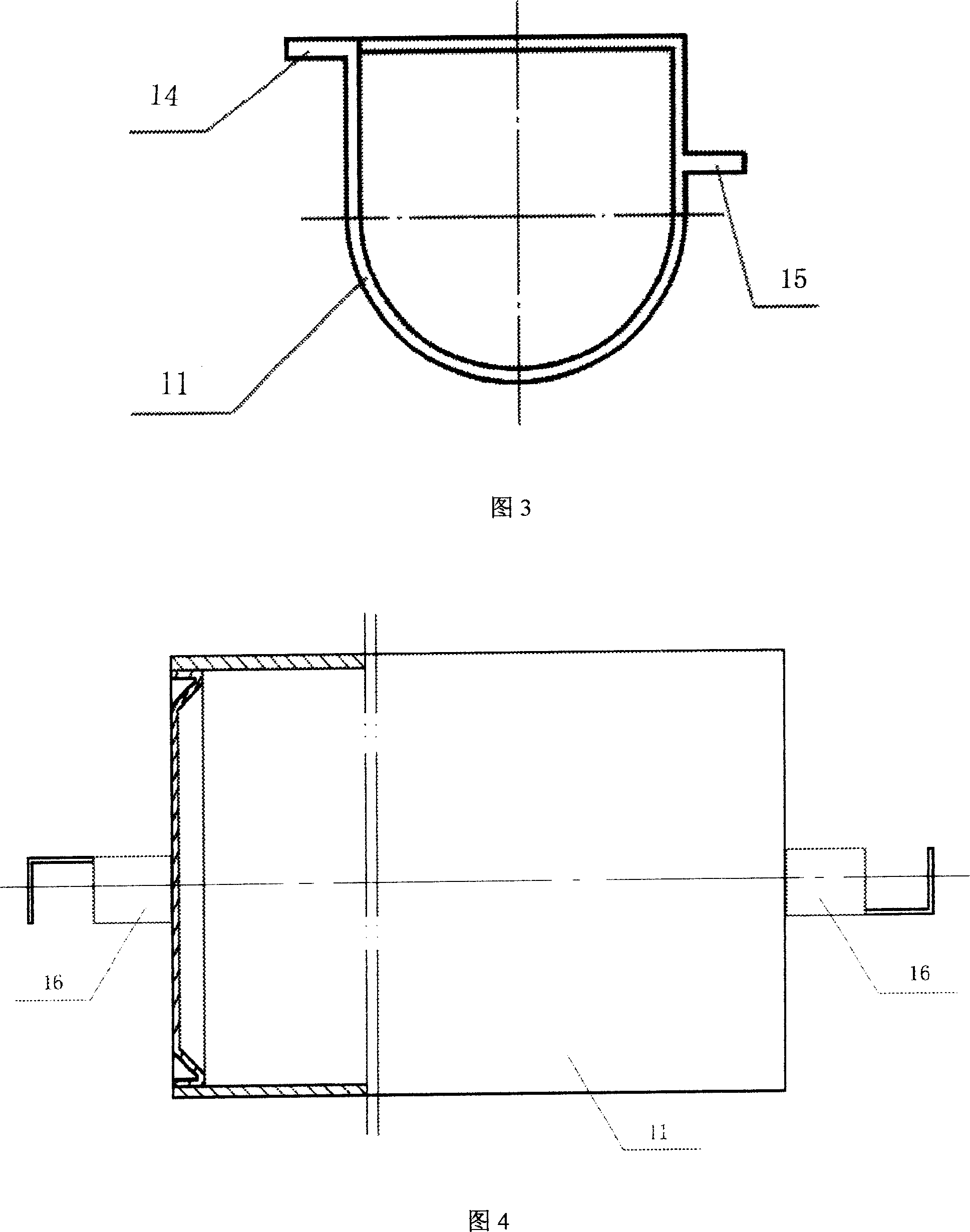

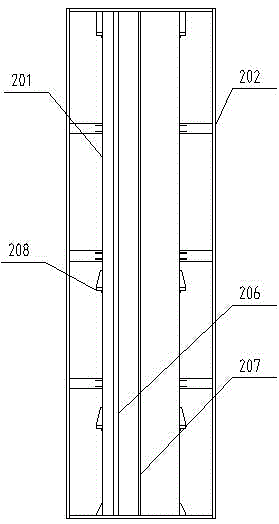

Hoistway height-adjustable double-guide straight elevator

PendingCN110498323AImprove mobility and flexibilityRuns smoothly up and downPassenger handling installationsBuilding liftsAirplaneEngineering

The invention discloses a hoistway height-adjustable double-guide straight elevator. The hoistway height-adjustable double-guide straight elevator comprises a first mounting box and a vehicle assembly; the first mounting box is mounted on the vehicle assembly; a first servo motor is fixed in the first mounting box, and is fixed with a first belt wheel; the first belt wheel is in transmission connection with a second belt wheel; the second belt wheel is in key connection with a first lead screw; the first lead screw is in transmission connection with a first fixed block; the first fixed block is fixed with a movable hoistway; a fixed hoistway is arranged in the movable hoistway; a first slide rail is fixed in the movable hoistway; a second slide rail is fixed in the fixed hoistway; first slide blocks are arranged in the first slide rail and the second slide rail, and are fixed on the two sides of a car; a pedal extension mechanism is arranged at the bottom end of the car; and a tractionmechanism is arranged between the car and the movable hoistway. The heights of the hoistways are adjustable; and at least two slide rails are arranged between the car and the hoistways to meet boarding of aircrafts with different heights.

Owner:BEIJING SUBLIMATION ELEVATOR CO LTD

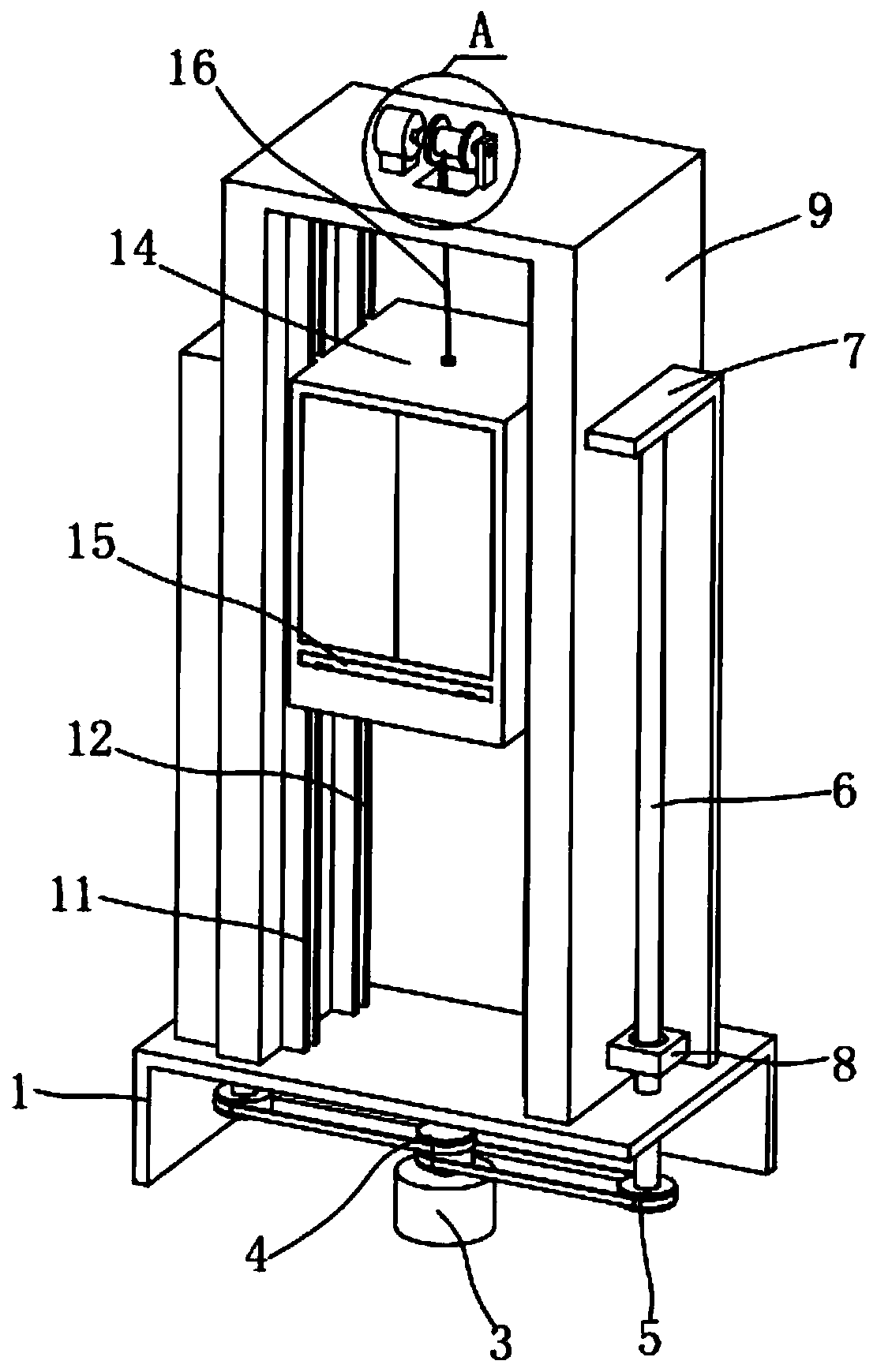

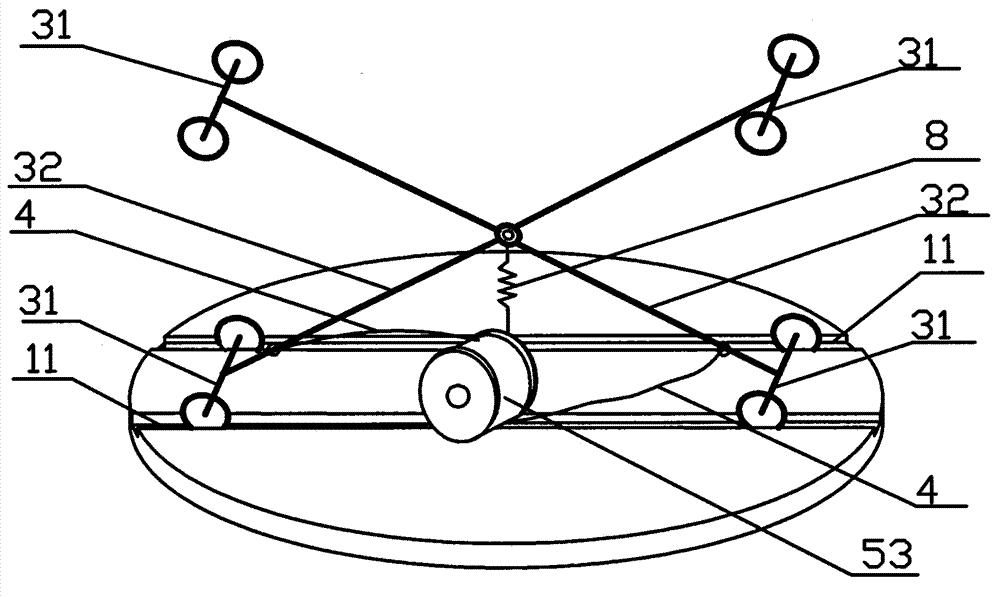

Capacity-changing trash can

InactiveCN104291044AReasonable structureRuns smoothly up and downRefuse receptaclesEngineeringIdler-wheel

The invention discloses a capacity-changing trash can which comprises an outer cylinder, an inner cylinder, a support component, a metal wire component, a rotating mechanism, a blocking nail, a falling-stopping ring, a spring and an upper bottom plate. The rotating mechanism is arranged at the bottom of the outer cylinder. One end of a rotating shaft is bent by 90 degrees and penetrates through the cylinder wall of the outer cylinder to be used as an operation handle. The other end of the rotating shaft penetrates through a fixing base and a rotating wheel and is connected with a blocking ring. The support component comprises two rod pieces and four idler wheel frames, and the middle portions of the two rod pieces are hinged together. The two ends of each rod piece are in contact with sliding grooves in the bottom of the outer cylinder and the bottom of the upper bottom plate through the idler wheel frames. The positions, close to the idler wheel frames, of the lower ends of the two rod pieces are connected with the rotating wheel through metal wires. The rotating wheel is driven to rotate through the operation handle, a metal wire component pulls the two rod pieces to drive the idler wheel frames to move in the sliding groove in the bottom of the outer cylinder, so that the two rod pieces are closed together or separated, the other ends of the rod pieces lift the upper bottom plate and the inner cylinder or put the upper bottom plate and the inner cylinder down, and accordingly the capacity of the trash can is changed.

Owner:HUZHOU TEACHERS COLLEGE

Outer rearview mirror detection device

InactiveCN107727361AOvercome the problem that the installation height is too high and it is not convenient for workers to operateAdapt to testing needsOptical apparatus testingEngineeringMechanical engineering

The present invention aims to provide a detection device for an exterior rearview mirror, comprising a workbench, a cylinder I, and a cylinder II. A limit plate is installed on the lower bottom surface of the workbench, and a limit groove is arranged on the limit plate. The opening of the limiting groove faces the outside of the workbench; the cylinder II is located below the limiting groove, and the upper end of the piston rod of the cylinder II is provided with a limiting block. When the rearview mirror is installed, the rearview mirror snaps into the limiting groove. The cylinder II drives the limit block to move upwards to withstand the rearview mirror to complete the installation; the corresponding position of the limit groove opening on the workbench is provided with a work port; the cylinder I is hoisted above the work port, and the piston of the cylinder I Rod direction is downward, and the end of the piston rod of the cylinder I lifts the connection block; the bottom of the connection block is connected to the sensor base by a flexible rope, and the sensor base is provided with an angle sensor. The device overcomes the defects of single function and low efficiency in the prior art, and has the advantages of complete functions and high efficiency.

Owner:LIUZHOU TONGSHUN AUTO PARTS

Energy-saving counter-weight-adjustable elevator

InactiveCN106081814ARuns smoothly up and downImprove securityElevatorsBuilding liftsTransmission beltWeight adjustment

The invention discloses an energy-saving counter-weight-adjustable elevator. The elevator comprises a box body, power generation systems and a traction machine, wherein a steel wire rope is arranged at the top end of the box body, one end of the steel wire rope is fixedly connected with the box body, and the other end of the steel wire rope sequentially winds around the traction machine and a transmission wheel to be fixedly connected with a counter-weight system and a main counter-weight; the counter-weight system comprises multiple counter-weights and a counter-weight channel, and each counter-weight comprises an iron core and an electromagnet; the multiple power generation systems are arranged on the outer side of the main counter-weight; and each power generation system comprises a transmission belt, a connecting gear block, a rack, rollers and a power generator, the main counter-weight is fixedly connected with the rack, the rollers are arranged inside the upper end and the lower end of the transmission belt, the power generator is fixedly connected with the roller on the lower side of the transmission belt, and the connecting gear block is arranged on the transmission belt. According to the elevator, centroid adjustment of the box body is realized, the safety and the comfort degree of the elevator are improved, counter-weight adjustment is realized according to the actual load of the elevator, the energy consumption of the elevator is reduced, and energy is saved by the aid of the power generation systems.

Owner:新疆天山电梯制造有限公司

Method for in site reduction of passivation solution carried by electrolytic manganese negative plate

ActiveCN103572320AAchieve a complete brushing effectImprove fitElectrolysis componentsPhotography auxillary processesWastewaterEngineering

The invention relates to a method for in site reduction of a passivation solution carried by an electrolytic manganese negative plate. The device used in the invention comprises a drop brushing device component, a passivation groove, the negative plate and a lifting device, wherein the drop brushing device component is positioned at the top of the passivation groove and is fixedly connected with the passivation groove, the negative plate is positioned above the passivation groove, and the lifting device is positioned above the negative plate and is connected with the negative plate to drive the negative plate to move upwards and downwards. The method comprises the steps of passivation, discharge and drop brushing. Through the utilization of the method provided by the invention, the problems of waste water chromium pollution and the waste of chromium resource are solved, and the passivation solution carried by the negative plate and flowing into a waste water system is greatly reduced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

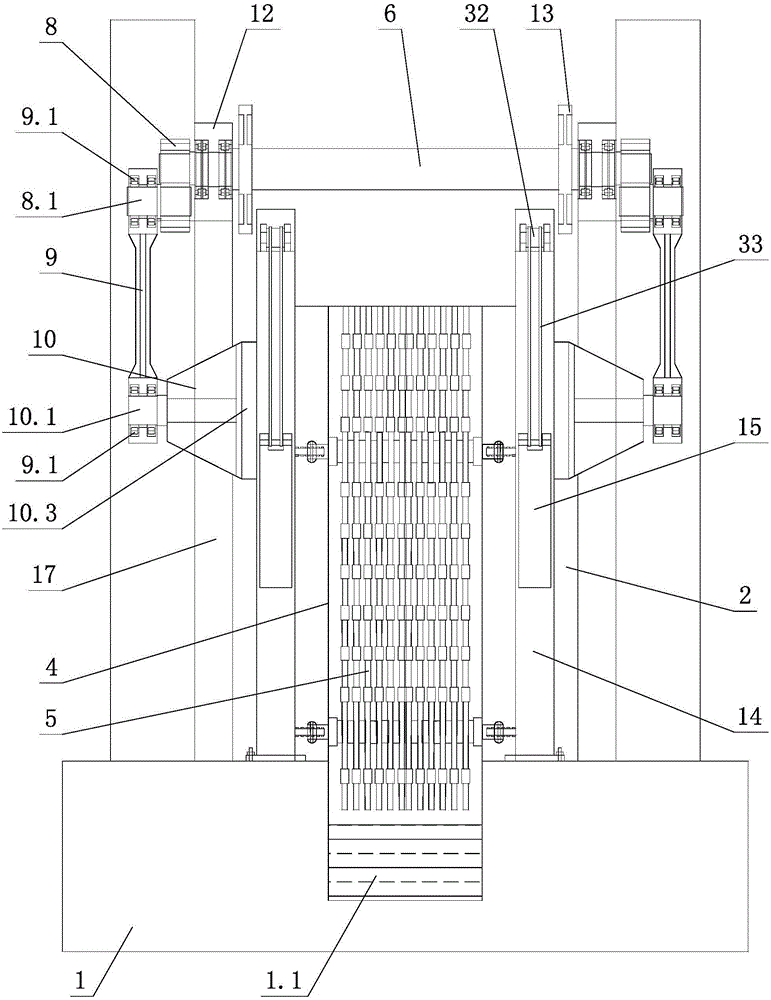

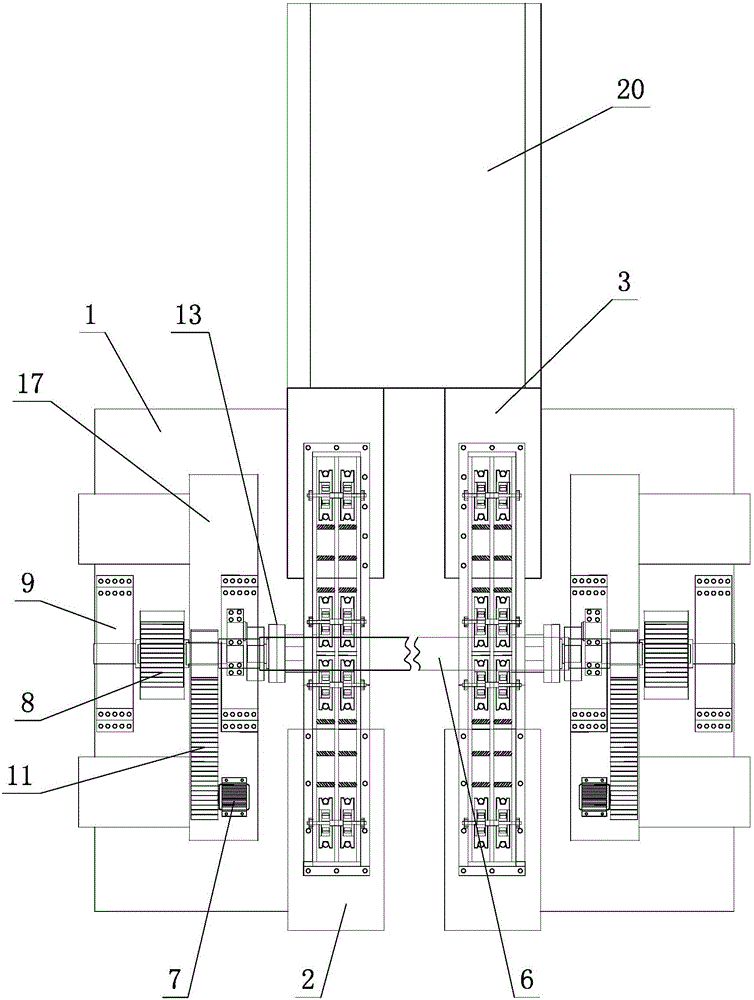

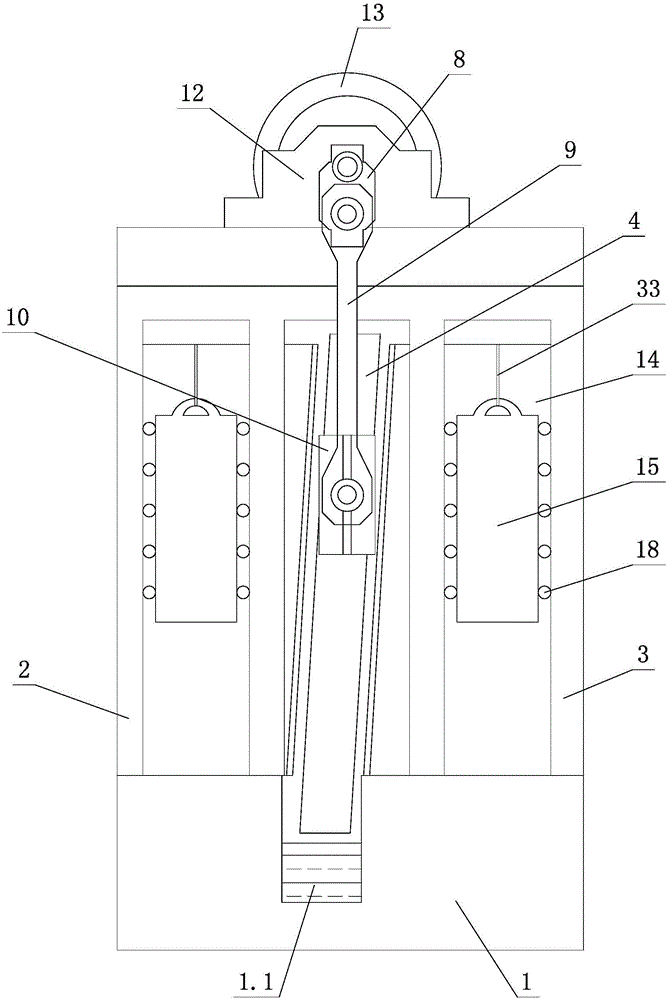

New Drill and Blast Shaft Drilling Rig

ActiveCN104389607BBig spaceOptimize layoutShaft sinkingDrilling machines and methodsDischarge efficiencyNumerical control

The invention discloses a novel drilling and blasting method vertical shaft drilling machine. The machine mainly comprises a derrick, a numerical control umbrella drill, a loading machine, an equipment suspension system, a drainage system, a ventilation system, a slag discharge system, a shaft wall casting system, a shaft bottom hanging scaffold, a hydraulic station and a control room, wherein the equipment suspension system comprises a center vertical column, a vertical column lifting mechanism and a sealing flatcar; the center vertical column is connected with the vertical column lifting mechanism, and extends underground; the lower part of the center vertical column is connected with the shaft bottom hanging scaffold; the derrick and the sealing flatcar are mounted in a shaft mouth; the vertical column lifting mechanism is fixed and mounted on the derrick; the loading machine is mounted at the lower end of the center vertical column; the numerical control umbrella drill is mounted in the center vertical column; and the hydraulic station, the drainage system and the control room are mounted on the shaft bottom hanging scaffold. The machine adopts the reinforced derrick and the equipment suspension system, so that the equipment connection is reliable, and the construction is safer. The construction of the numerical control umbrella drill needs no shaft lifting, and is full-automatically controlled, so that the construction efficiency is improved; the slag loading efficiency of the loading machine is higher; the operation is more convenient; and the slag discharge efficiency is further improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

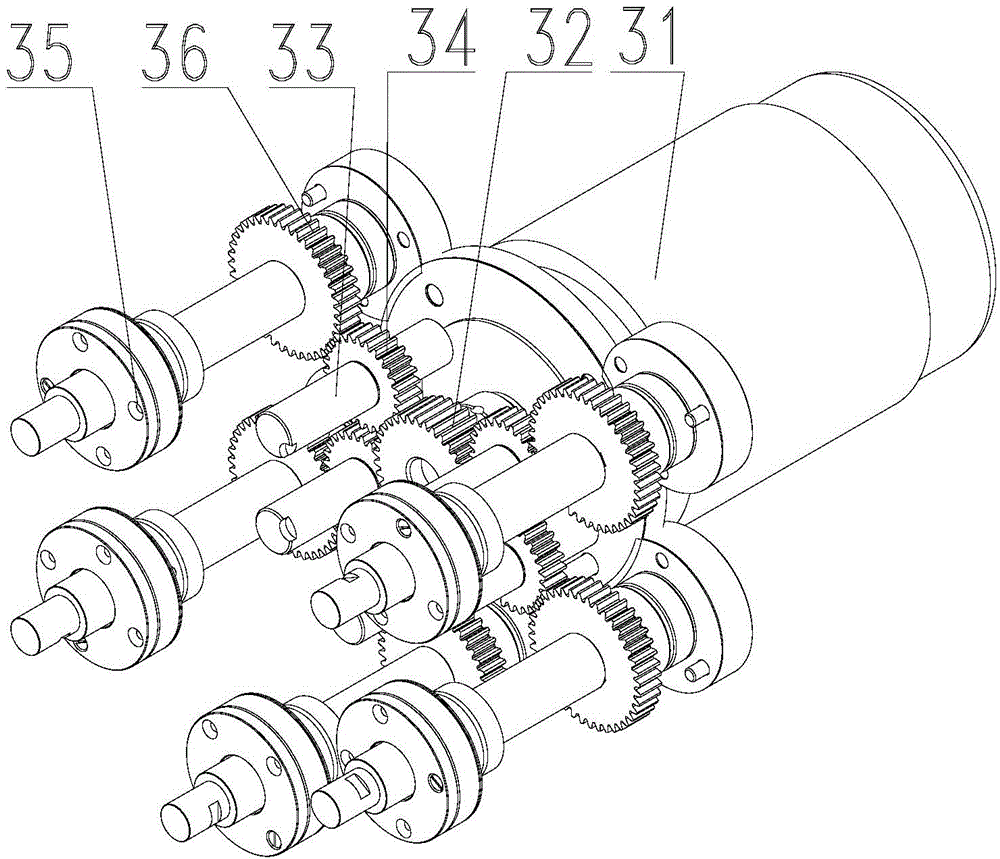

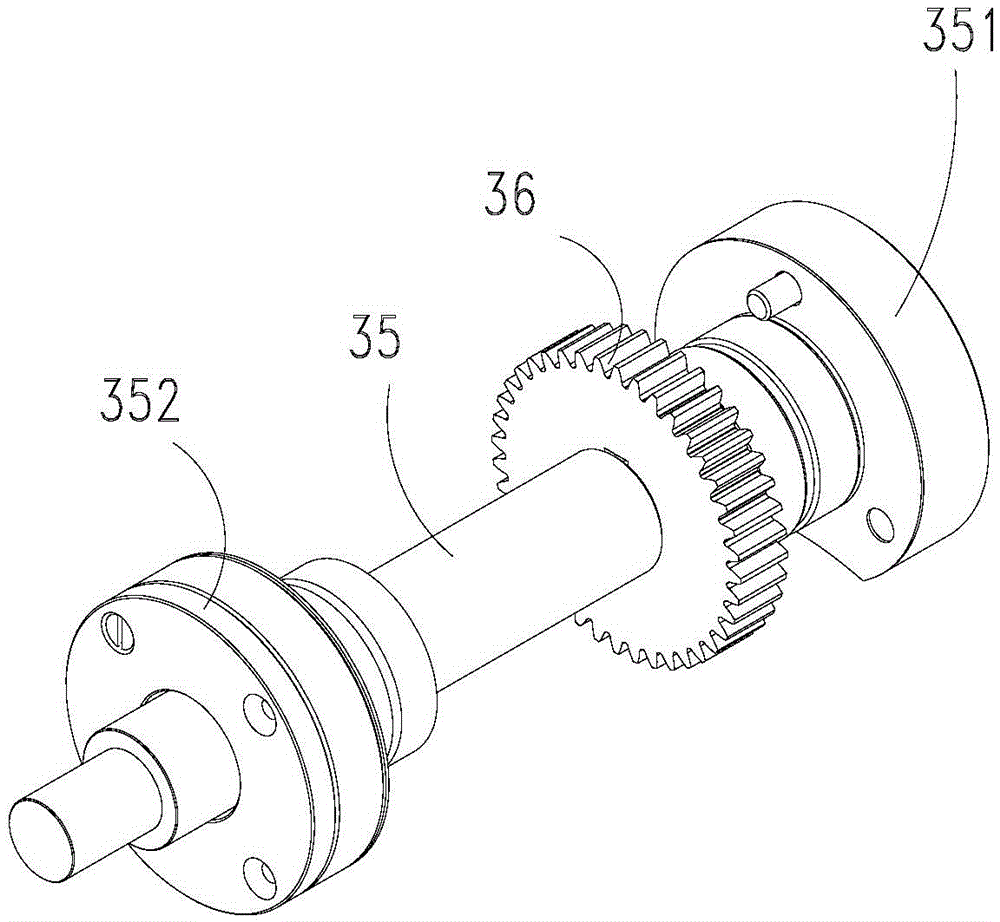

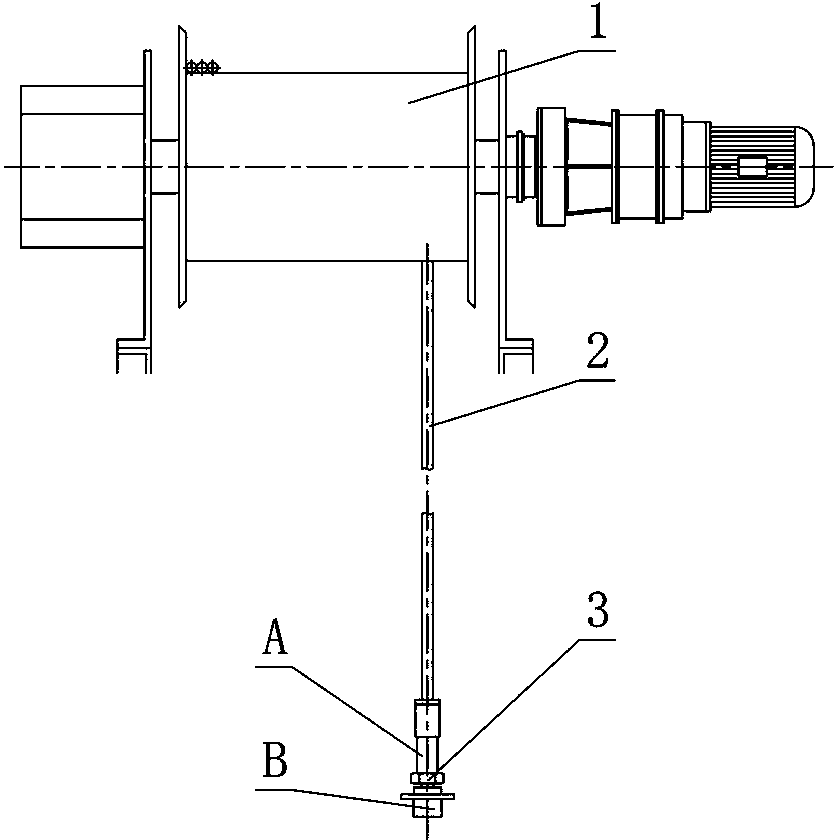

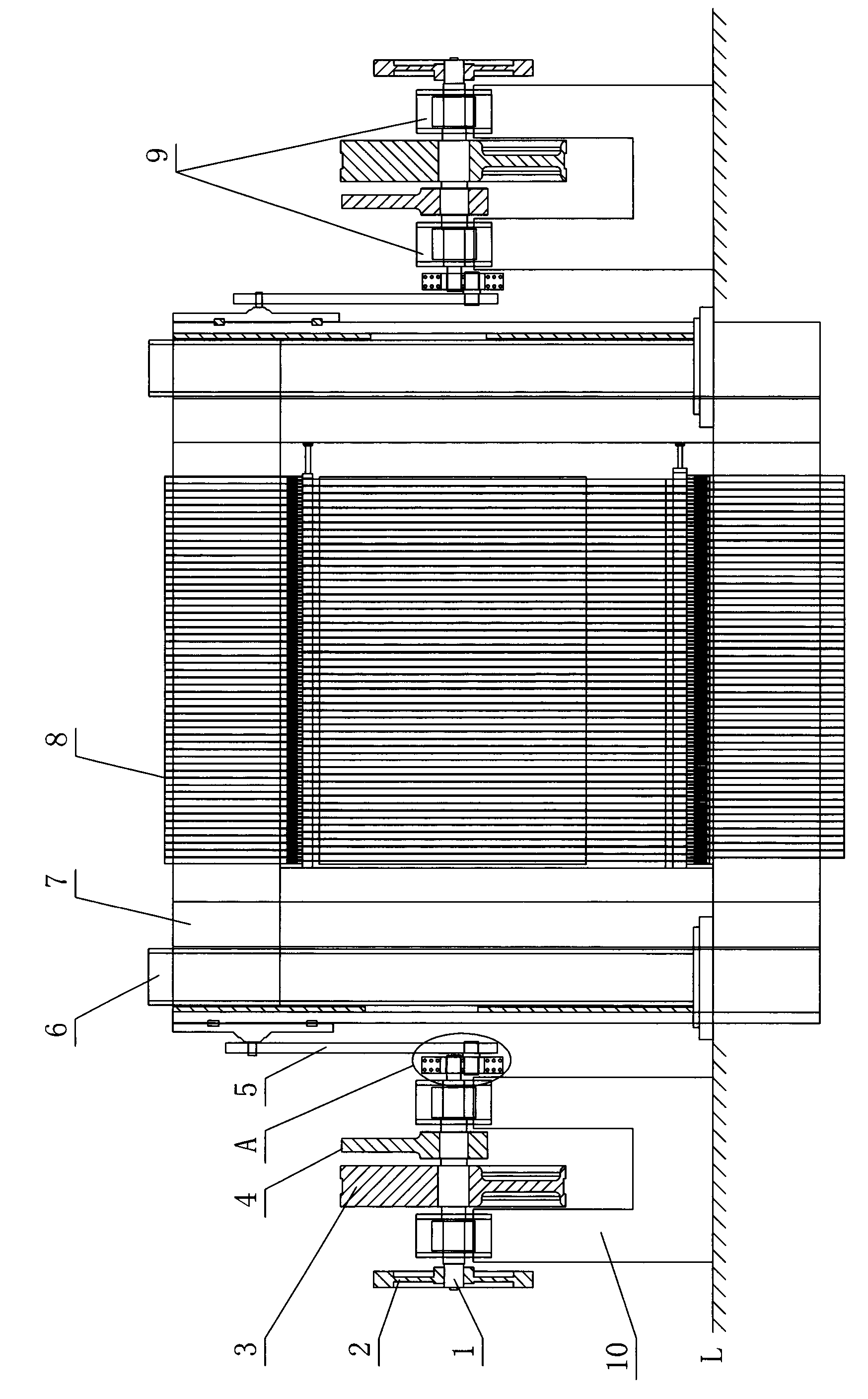

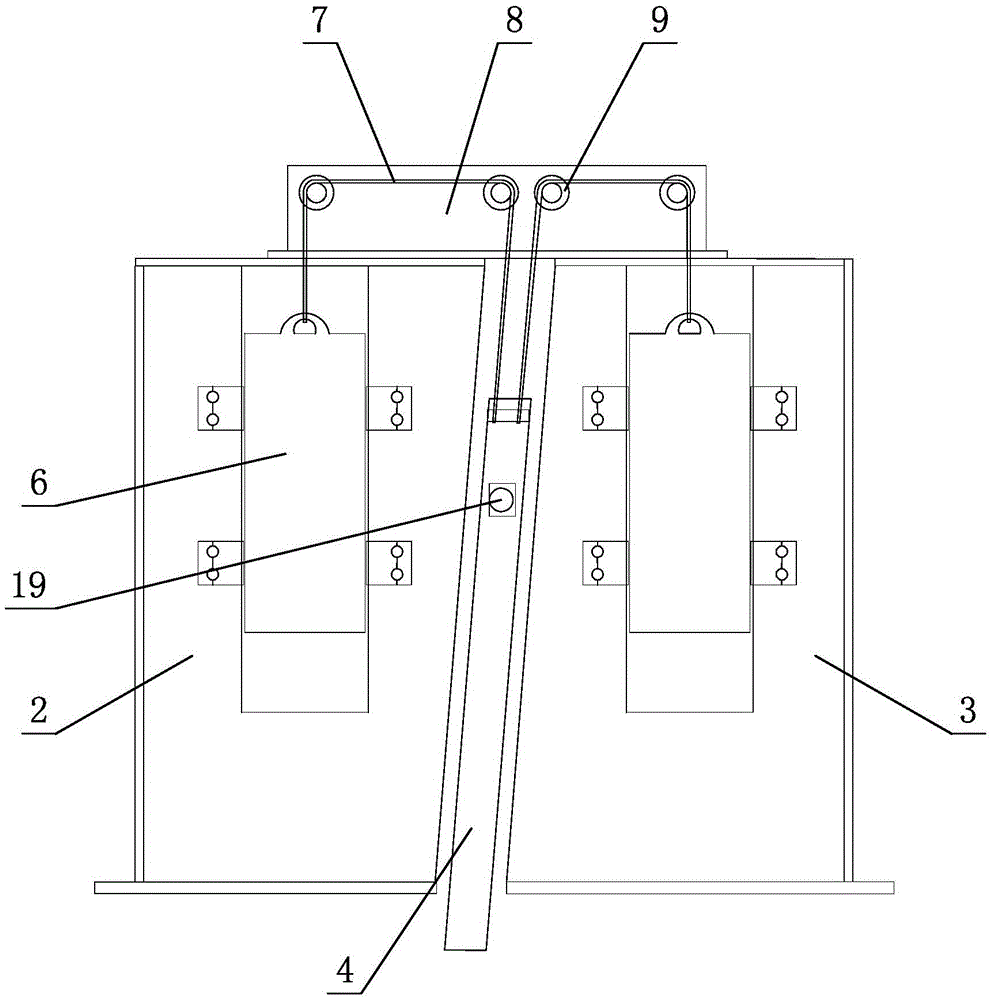

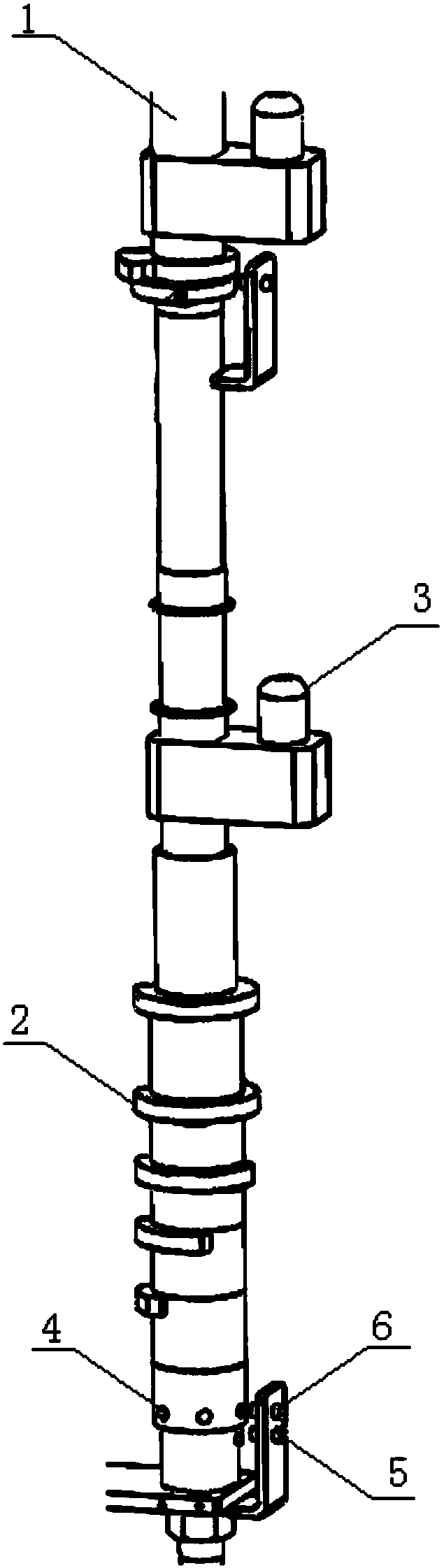

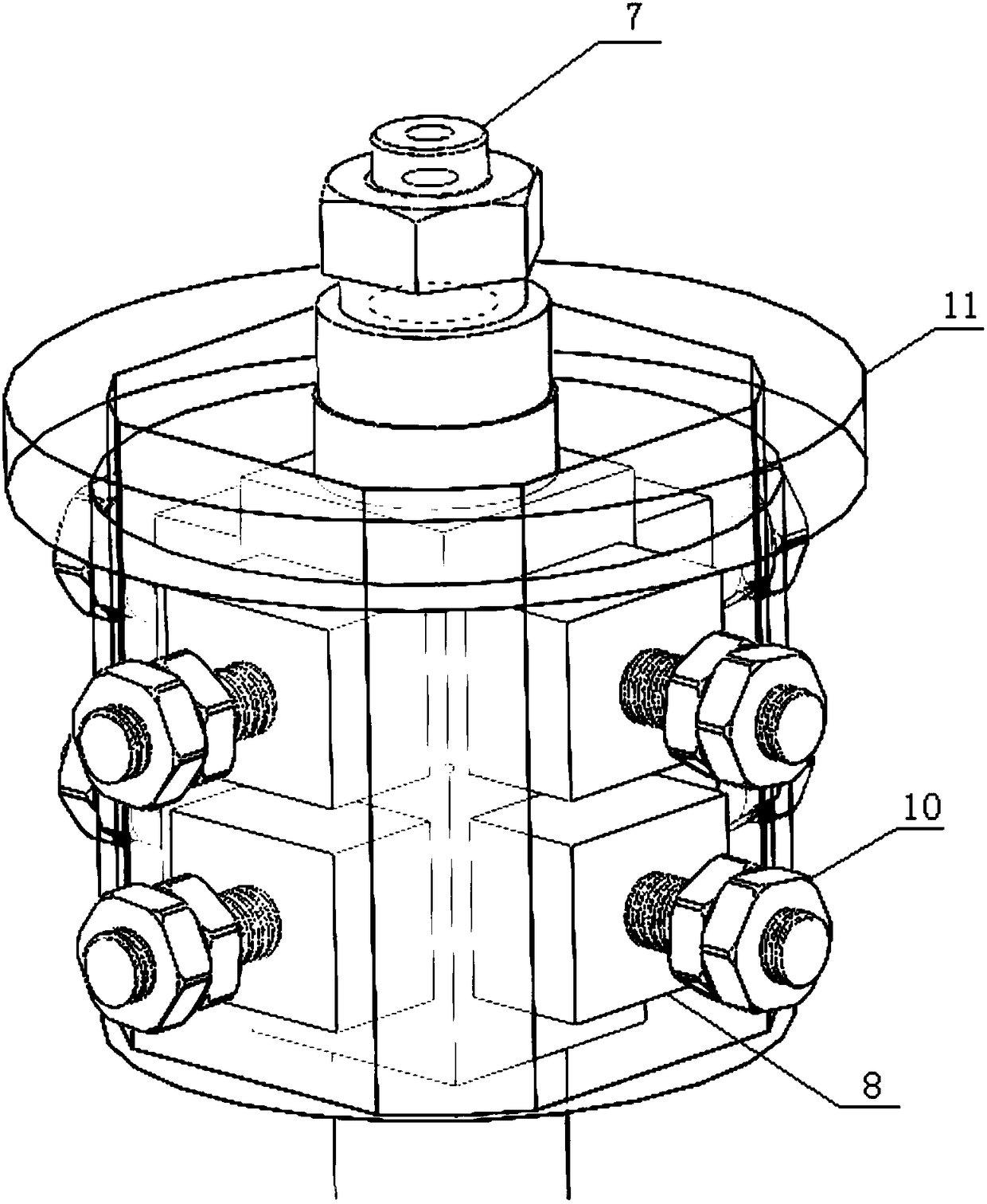

Positioning spindle device for reaming and honing machine

InactiveCN104942311ASimple structureNo jitterGrinding machine componentsLarge fixed membersEngineeringProcessing accuracy

A positioning spindle device for a reaming and honing machine comprises spindles (35) and spindle gears (36) installed on the spindles. The positioning spindle device is characterized in that an upper end cover (351) and a lower end cover (352) are further installed at the upper end and the lower end of each spindle (35), sleeve the spindle (35) respectively through an upper bearing (353) and a lower bearing (357), and are fixed on an upper cover plate and a lower cover plate of each fixed disc (5) which is of a box-shaped structure respectively. The positioning spindle device has the advantages that the shaking of a reaming and honing cutter bar does not occur due to the structural improvement of the spindle device, the vertical operation is stable, the workpiece processing accuracy is guaranteed, and a certain production quality is improved.

Owner:ANQING LIANKONG ELECTROMECHANICAL TECH DEV

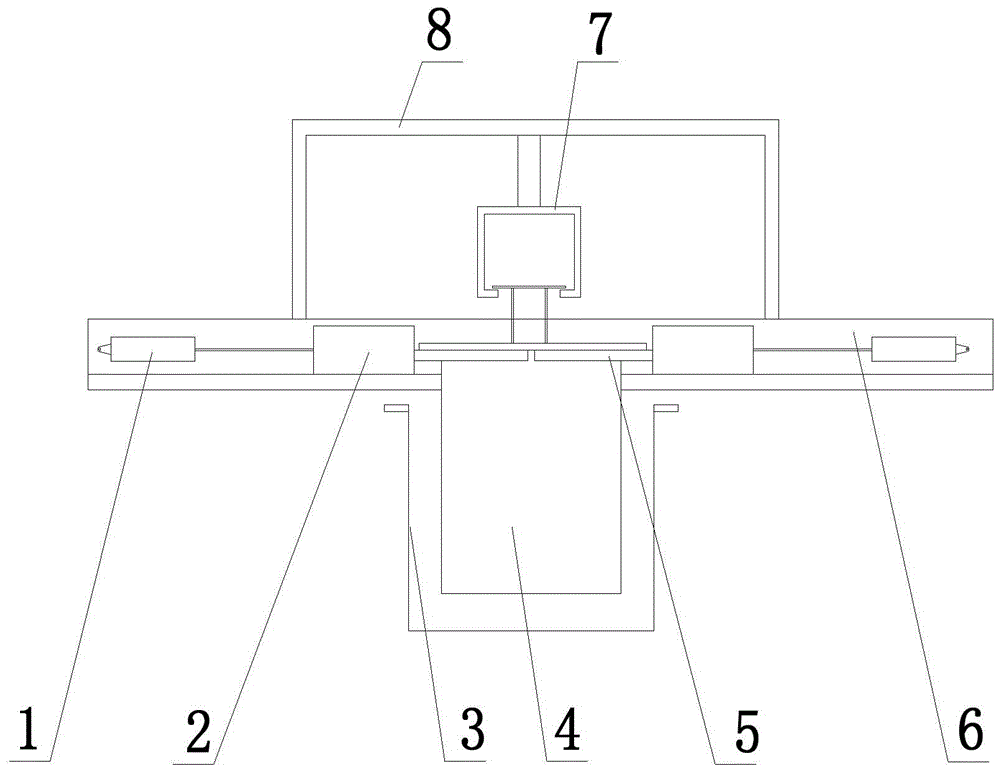

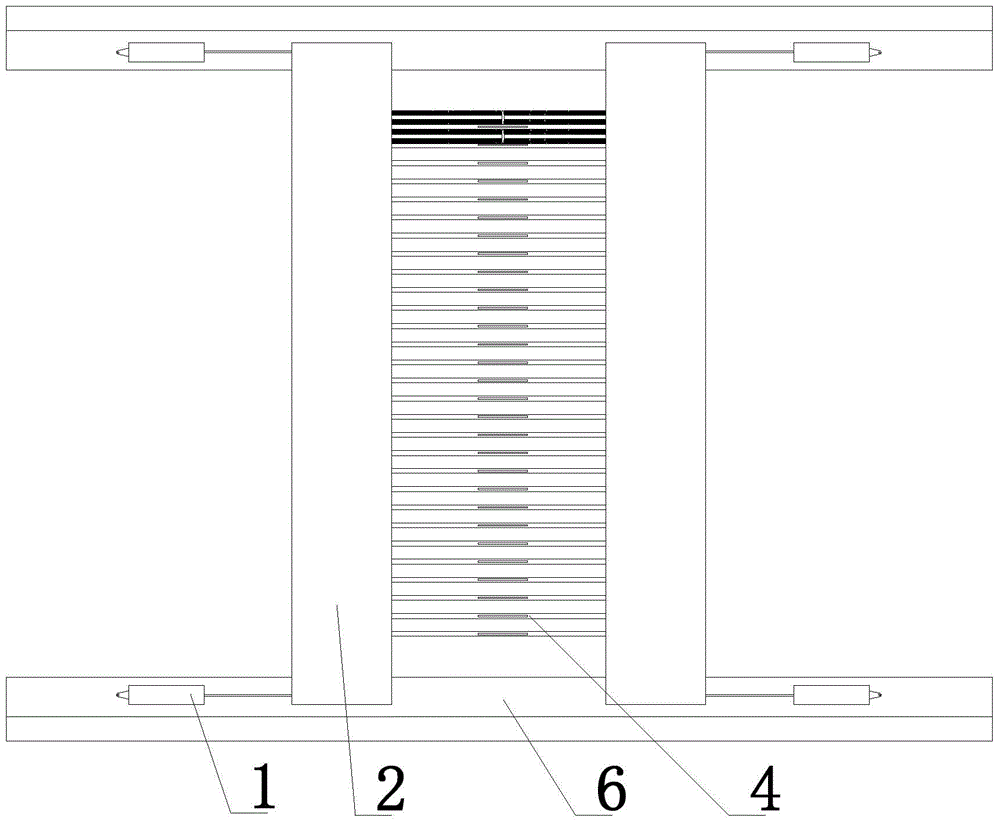

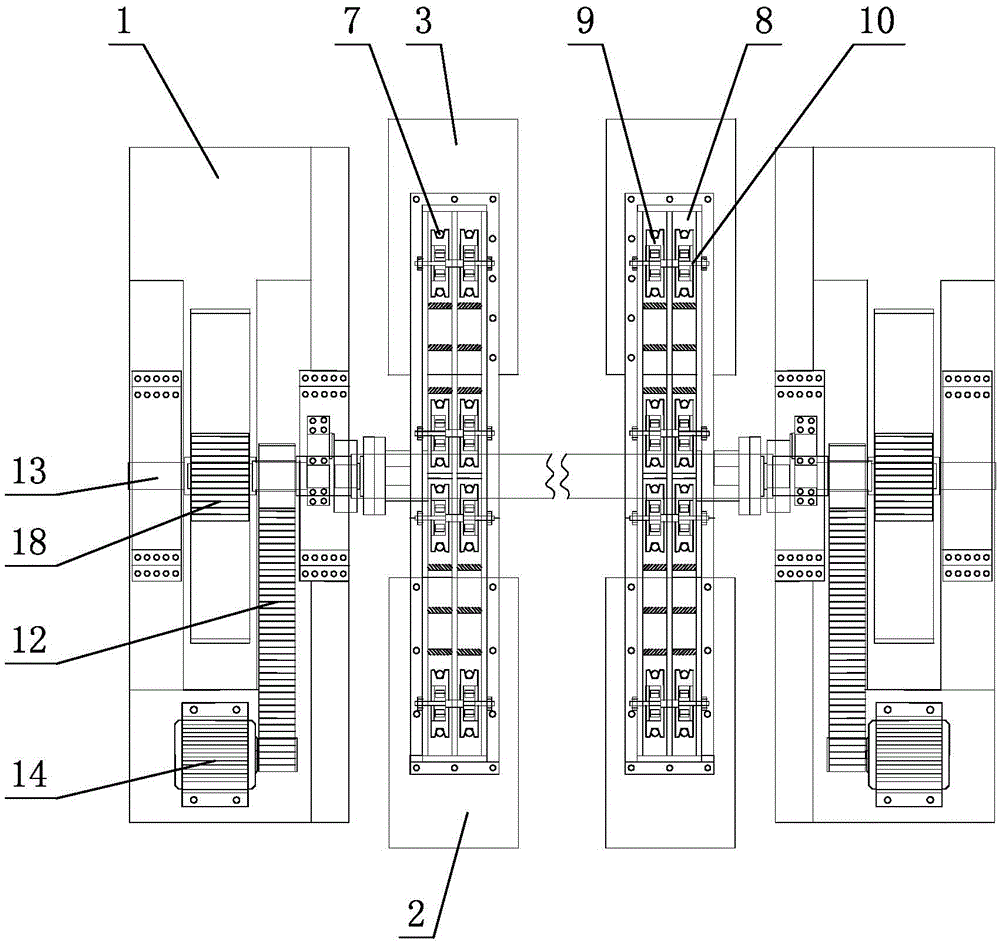

Integrated optimization structure of stone sawing machine

InactiveCN105904594ARuns smoothly up and downReduce the required powerWorking accessoriesStone-like material working toolsDrive wheelDrive shaft

An integrated optimization structure of a stone sawing machine comprises a fixed base. A left side column and a right side column are arranged on the fixed base. A saw frame is movably arranged between the left side column and the right side column. A plurality of saw webs are arranged on the saw frame. A driving device used for driving the saw frame to move up and down in a reciprocating mode is arranged on the left side column and the right side column. The driving device comprises a spindle and a spindle driving motor. A feeding device is further arranged between the left side column and the right side column. The feeding device comprises a feeding table, a feeding table driving motor, a feeding table driving shaft and a driving wheel assembly. The driving wheel assembly is arranged on the feeding table driving shaft and is in transmission connection with the feeding table driving motor. The feeding table and the feeding table driving shaft are connected in a matched mode. The feeding table moves between the left side column and the right side column back and forth in a mode of advancing slowly and retracting rapidly through the cooperation of the feeding table driving motor and the driving wheel assembly. The integrated optimization structure has the characteristics of being simple and reasonable in structure, safe, reliable, low in production cost, high in production efficiency, high in transmission efficiency during work, low in noise, small in swing amplitude and vibration, capable of saving energy, environmentally friendly, high in practicability and the like.

Owner:佛山市顺德区悍天睿数控机械有限公司

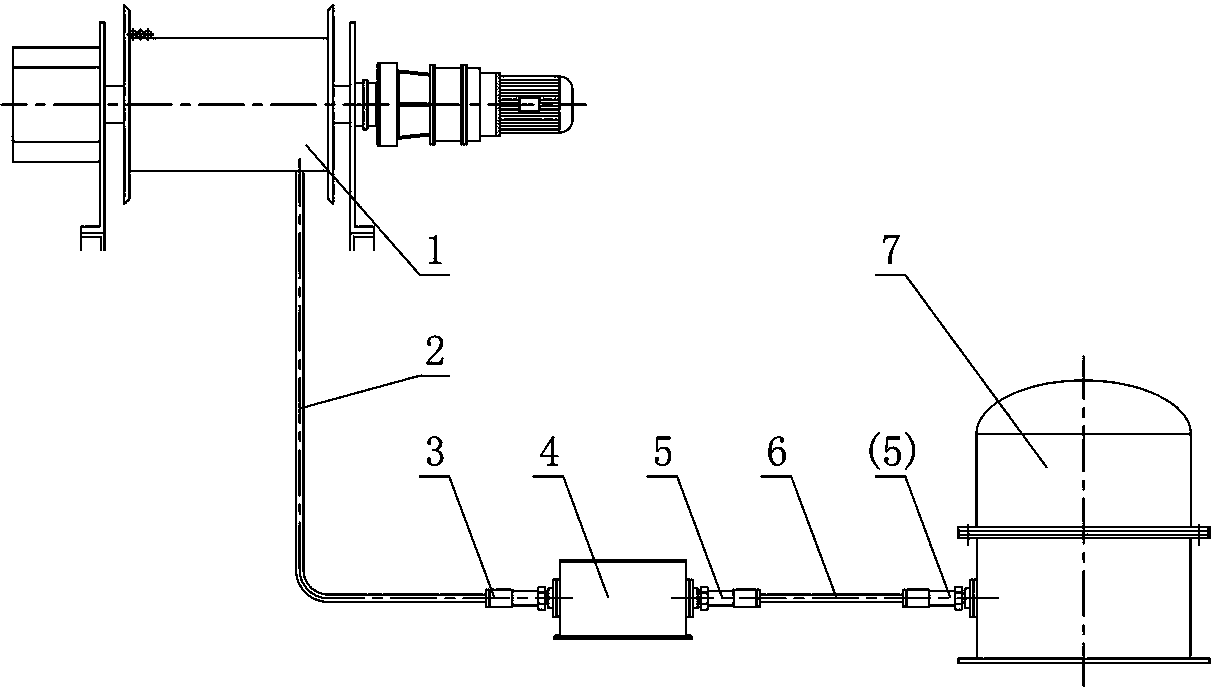

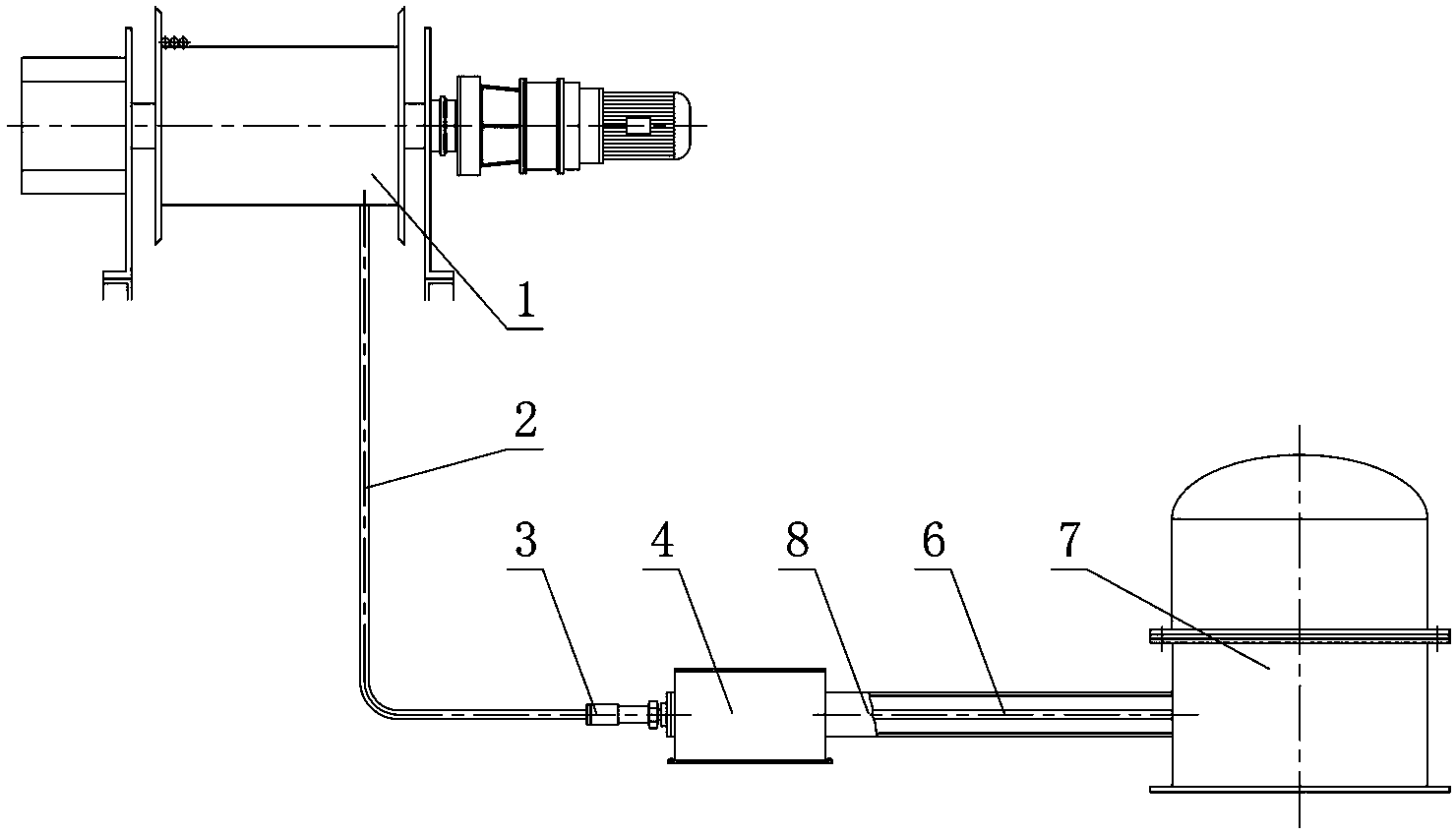

High tensile cable electrical transmission device for hydraulic grab bucket

InactiveCN104283078AGood flexibilityLarge elongation deformationCoupling device connectionsInsulated cablesElectrical connectionEngineering

The invention discloses a high tensile cable electrical transmission device for a hydraulic grab bucket, which performs electrical connection between a host machine of a decontamination machine and the hydraulic grab bucket. The high tensile cable electrical transmission device is composed of the components of: a cable (2) for performing electrical connection, a cable reel (1) on which the cable is coiled, and a waterproof electrical connecting device (3) which electrically connects the cable (2) with the hydraulic grab bucket. The difference between the high tensile cable electrical transmission device of the invention and a previous electrical transmission device of the hydraulic grab bucket is characterized in that: the cable (2) used for the device is a composite wire rope cable which is obtained through intertwisting a plurality of wire ropes outside the cable; because the wire ropes are intertwisted outside the cable (2), the wire ropes which are intertwisted outside the cable (2) effectively protects the cable, so that cable scratch does not easily occur; because the wire ropes have relatively high tensile strengths, drawing breakage of the cable (2) does not easily occur; because tensile strength of the cable is improved, a larger winding force can be applied on the cable reel (1), so that the cable (2) is pulled more tightly, and no easy sag of the cable (2) easily generates under the larger pulling force; therefore cable damage caused by hooking or squeezing of a decontamination grab bucket to the cable does not easily occur, so that the hydraulic decontamination grab bucket can operate reliably.

Owner:郑州华林清污起重设备有限公司

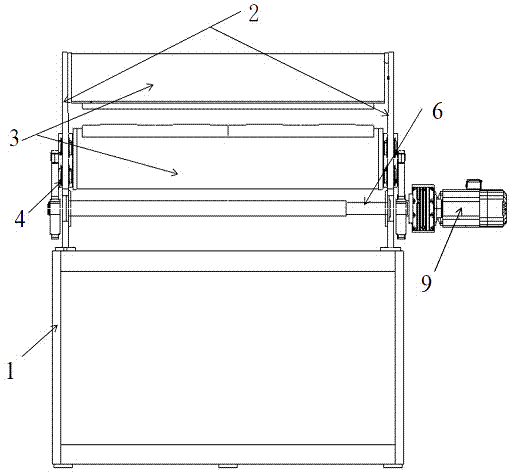

Main shaft structure of large-scale stone sawing machine

InactiveCN102172987BRuns smoothly up and downSimple structureStone-like material working toolsElectric machineDrive motor

The invention relates to a main shaft structure of a large-scale stone sawing machine, the large-scale stone sawing machine comprises a saw frame which is arranged between a front upright post and a rear upright post in a way of sliding up and down, and a plurality of saw blades are arranged on the saw frame; a main transmission structure comprises main shafts in transmission connection with the saw frame, and the main shafts are in transmission connection with driving motors; and the main shafts are connected with the saw frame through eccentric blocks and connecting rods. The left side and right side of the saw frame are in transmission connection with the driving motors through the main shafts respectively; and the two main shafts are consistent in rotational speed. The main shafts are in transmission with the saw frame through the eccentric blocks and the connecting rods, thereby realizing up and down operation of the saw frame; furthermore, the two sides of the saw frame are in transmission connection with the main shafts which operate synchronously, and each main shaft is driven by the driving motor respectively, thereby enabling load to be shared on each driving motor; and simultaneously, a balancing wheel, a balancing weight and a belt pulley with a weight balancing function are arranged on each main shaft, thereby enabling the vertical up and down operation of the saw frame to be smoother. The structure is simple and reasonable, the operation is smooth, the stone sawing speed is fast, and the effects are good.

Owner:周金生 +1

High-stability lifting mechanism

InactiveCN105108557AImprove job stabilityThe drive runs smoothlyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

Owner:KUNSHAN LIMAHE AUTOMATION SCI & TECH

A Flow Fluorescence Detector

ActiveCN105388139BHigh sensitivityStrong opennessFluorescence/phosphorescenceMedical equipmentFluorescence

The invention relates to the technical field of medical equipment, in particular to a flow-type fluorescence detector. The flow-type fluorescence detector is used for sucking samples in a reaction cup for detection. The flow-type fluorescence detector is characterized in that the detector comprises a frame body, an optical table, a first laser device, a second laser device, a flow chamber, a flow pond, a plurality of optical receivers and a sample sucking device; the first laser device, the second laser device, the flow chamber, the flow pond and the optical receivers are all arranged on the optical table; the flow chamber is located below the flow pond; light generated by the first laser device and the second laser device passes through the flow pond to be received by the optical receivers; the sample sucking device is vertically arranged on the frame body and located above the reaction cup. The flow-type fluorescence detector is simple and stable in structure, high in detection sensitivity, wide in detection range and stable in optical detection.

Owner:JIAXING QUEST LIFE SCI

Process for assembling heat contact rod end part of billet hold-out rod

InactiveCN102490386ARestraining the Spinning TendencyRuns smoothly up and downPressesEngineeringPulley

The invention relates to the technical scheme of preventing the rotary offset of a headstock, in particular to a process for assembling a heat contact rod end part of a billet hold-out rod. The heat contact rod end part consists of a headstock (1), a carriage (2), a hexagon bolt (3), hexagon nuts (4) and an elastic washer (5). According to the technical scheme of the assembly process, a steel plate on the lower side of a guide slot formed on the upper part of the carriage (2) is widened, and threaded holes are tapped uniformly on the steel plate, so that the threaded holes are perpendicular to the upper surface and lower surface of the steel plate; and when the headstock (1) and the carriage (2) are assembled, the hexagon bolt (3) are screwed in from bottom to top, so that the hexagon bolt (3) runs through a bottom plate of the headstock (1), and the hexagon nuts are in transitional fit and screwed fixedly to prevent the bolt from loosening. By the process, the headstock is jacked between the lower surface of the steel plate on the upper side of the guide slot of the carriage and the end face of the bolt firmly by the bolt, so that a gap between a pulley and a guide rail is basically consistent, the situation of undersized gap and even interference is avoided, and the headstock runs smoothly up and down.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

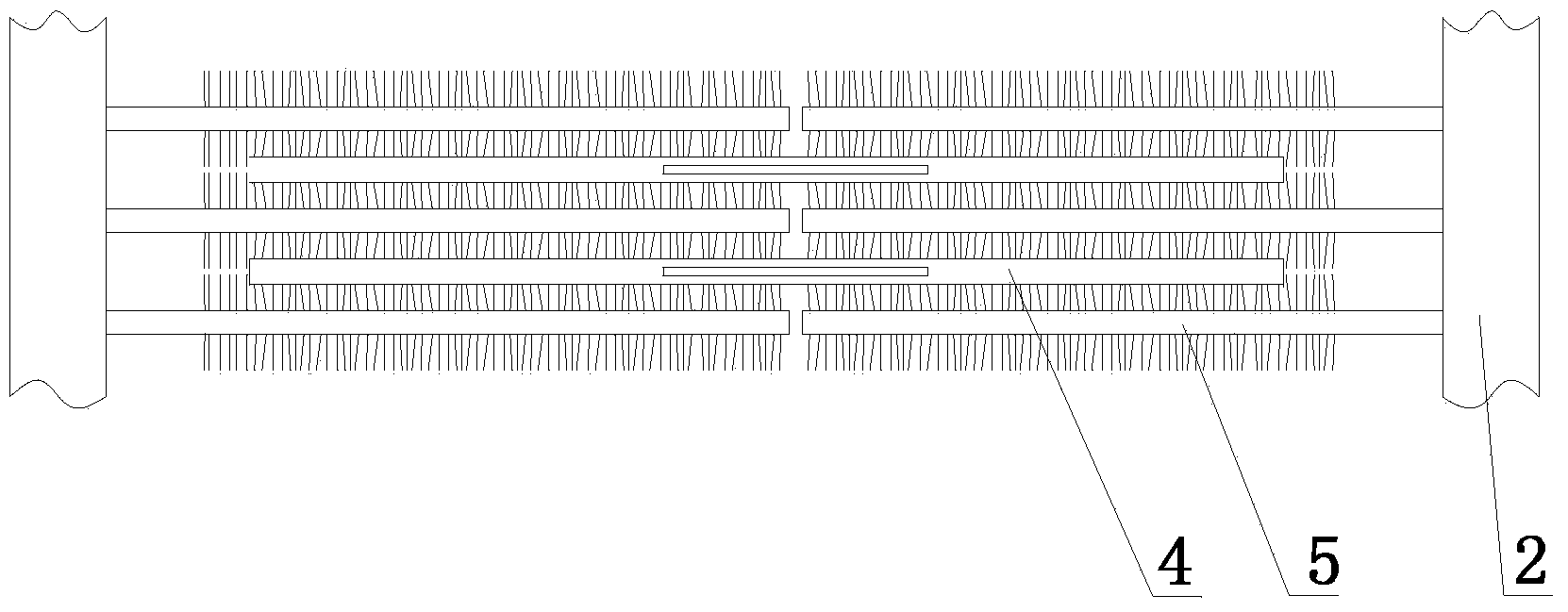

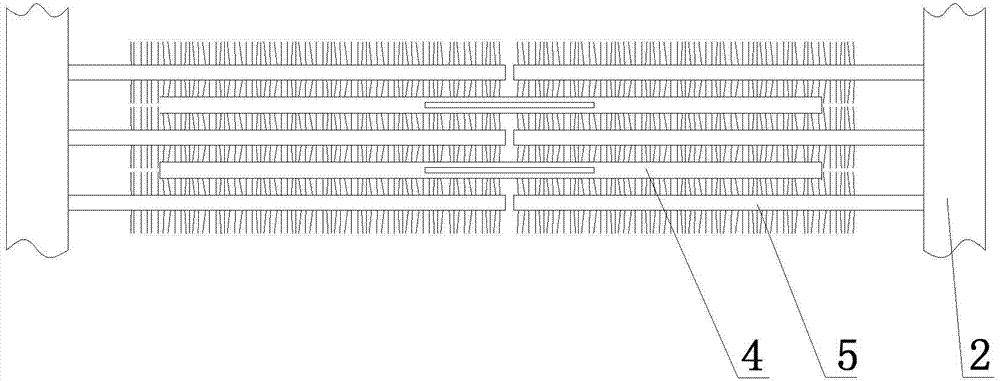

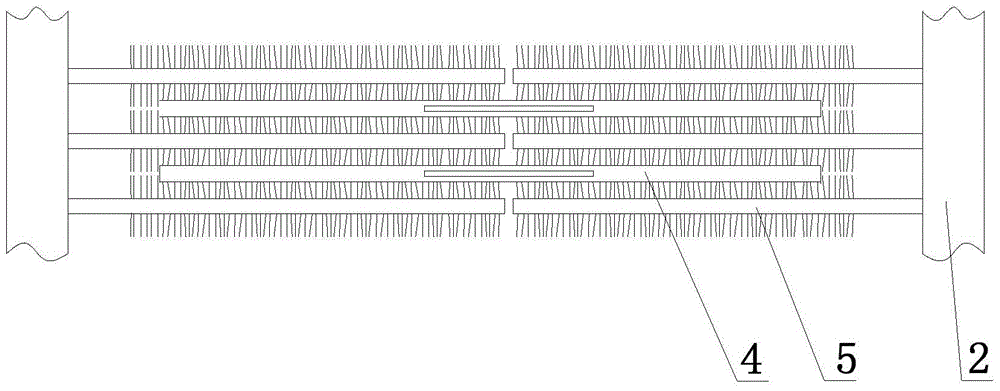

Heald frame connecting device of crank shedding loom

The invention discloses a heald frame connecting device of a crank shedding loom. The heald frame connecting device of the crank shedding loom comprises a first upper connecting seat, wherein a firstconnecting bush is arranged in the first upper connecting seat; the lower end of the first upper connecting seat is rotatably connected with a first upper rotating block through a first connecting pin; the lower end of the first upper rotating block is connected with a first upper toothed rod, and the lower end of the first upper toothed rod is movably connected with a first middle connecting seatthrough a first pressing mechanism; the lower portion of the first middle connecting seat is connected with a first lower toothed rod through a second pressing mechanism; and the lower end of the first lower toothed rod is connected with a first lower connecting seat. The first middle connecting seat comprises a first square shell, a first strip-shaped block and a second strip-shaped block are fixedly connected to the left and right inner side end walls of the first square shell respectively, and a plurality of parallel first strip-shaped tooth grooves are vertically formed in the inner sideend face of the first strip-shaped block. The device is conveniently used for connecting heald frames in the shedding loom, and is adjustable in length, rotatable, and convenient and simple to use.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

A method for in-situ reduction of electrolytic manganese cathode plate carrying electrolyte

ActiveCN103590074BImprove fitEasy to separatePhotography auxillary processesElectrolysis componentsElectrolysisEngineering

The invention relates to a method for in situ reducing electrolyte on an electrolytic manganese cathode plate. A device utilized by the method comprises a brushing and dropping device assembly, a tank discharging device, the cathode plate and an electrolytic tank, wherein the tank discharging device is fixedly connected with the brushing and dropping device assembly, the cathode plate is connected with the tank discharging device, and the electrolytic tank is positioned below the cathode plate. The method comprises steps of electrolysis, tank discharging and brushing and dropping. With utilization of the device and the method, the problem that the cathode plate carries the electrolyte in the tank discharging process in the subsequent section of electrolytic manganese electrolysis is greatly solved. The device and the method can greatly reduce the electrolyte on the cathode plate when the cathode plate is discharged from the tank.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Integrated optimization structure of stone sawing machine

InactiveCN105904594BRuns smoothly up and downReduce the required powerWorking accessoriesStone-like material working toolsDrive wheelDrive shaft

An integrated optimization structure of a stone sawing machine comprises a fixed base. A left side column and a right side column are arranged on the fixed base. A saw frame is movably arranged between the left side column and the right side column. A plurality of saw webs are arranged on the saw frame. A driving device used for driving the saw frame to move up and down in a reciprocating mode is arranged on the left side column and the right side column. The driving device comprises a spindle and a spindle driving motor. A feeding device is further arranged between the left side column and the right side column. The feeding device comprises a feeding table, a feeding table driving motor, a feeding table driving shaft and a driving wheel assembly. The driving wheel assembly is arranged on the feeding table driving shaft and is in transmission connection with the feeding table driving motor. The feeding table and the feeding table driving shaft are connected in a matched mode. The feeding table moves between the left side column and the right side column back and forth in a mode of advancing slowly and retracting rapidly through the cooperation of the feeding table driving motor and the driving wheel assembly. The integrated optimization structure has the characteristics of being simple and reasonable in structure, safe, reliable, low in production cost, high in production efficiency, high in transmission efficiency during work, low in noise, small in swing amplitude and vibration, capable of saving energy, environmentally friendly, high in practicability and the like.

Owner:佛山市顺德区悍天睿数控机械有限公司

Saw frame counterweight structure of stone sawing machine

ActiveCN104044215BRuns smoothly up and downLow powerStone-like material working toolsDrive motorEngineering

Owner:HUOHUANG METAL MFG

Novel refrigerator liner trimming device

InactiveCN104760175AGuaranteed punching forceRuns smoothly up and downAgricultural engineeringCutting force

The invention discloses a novel refrigerator liner trimming device and belongs to the technical field of refrigerator liner manufacturing. The trimming device comprises a pedestal, left and right vertical plates arranged at two sides of the pedestal, and upper and lower blade mounting racks fixed on the left and right vertical plates, wherein the lower blade mounting rack is fixed on the left and right vertical plates through a linear guide rail; upper and lower blades are mounted on the upper and lower blade mounting racks; a main shaft is fixedly arranged at the lower end of the left and right vertical plates; eccentric wheels are fixedly arranged at two ends of the main shaft; a pendulum rod is connected with the eccentric wheels and fixed on the lower blade mounting to drive the lower blades to move; a motor is connected with the main shaft. The novel refrigerator liner trimming device has the advantages of being simple in structure, convenient to mount and low in trimming noise; the linear guide rail is connected with the lower blade rack and a vertical column, the friction is small and the linear guide rail is used for ensuring that the lower cutting blades smoothly move upwards and downwards; cam mechanisms are connected with two ends of the main shaft; the motor drives the cam mechanisms to lift up and down synchronously; the lower blades moves up and down in parallel and completes trimming with the cooperation of the lower cutting blades; the upper and lower blades are arranged in a wave-like style, so as to guarantee cutting force of the cutting blades.

Owner:ANHUI XINMENG EQUIP CO LTD

Dead weight Rockwell hardness machine adopting screw type weight gradation loading technology

InactiveCN108362592AHigh measurement accuracyReduce frictionInvestigating material hardnessMotor driveElectric machinery

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com