Power wire winding device

A technology of winding device and power line, which is applied in the directions of transportation and packaging, thin material processing, and transportation of filamentous materials, etc., can solve the problems of prolonged construction period, low efficiency, cumbersome and laborious winding process, etc., to provide construction efficiency, The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

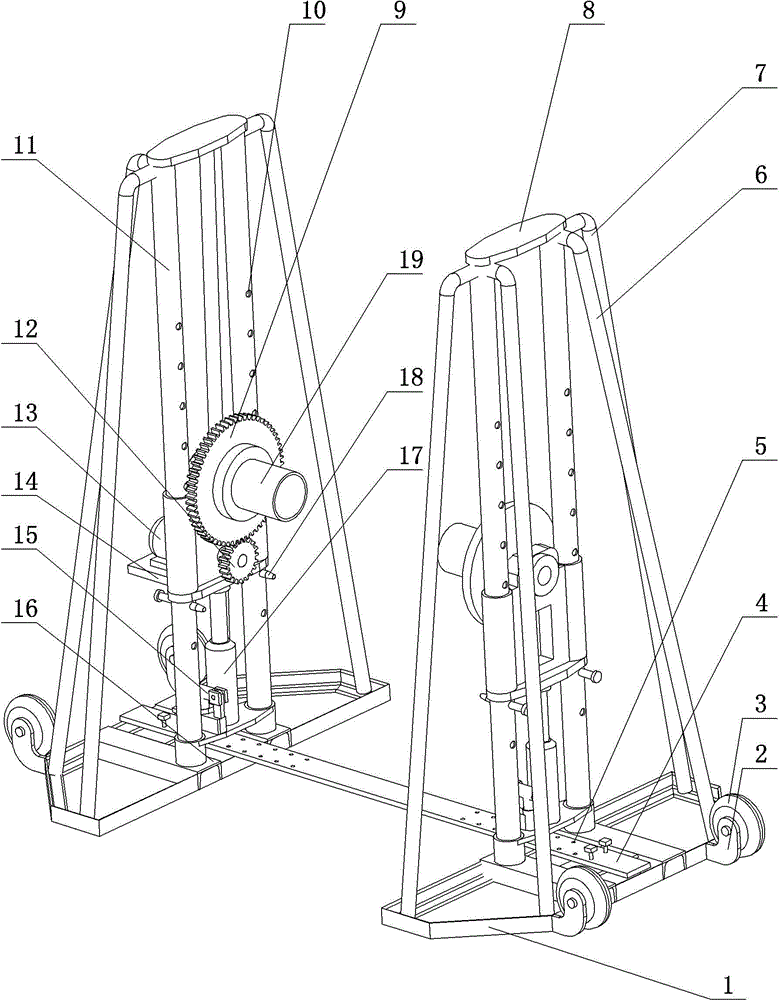

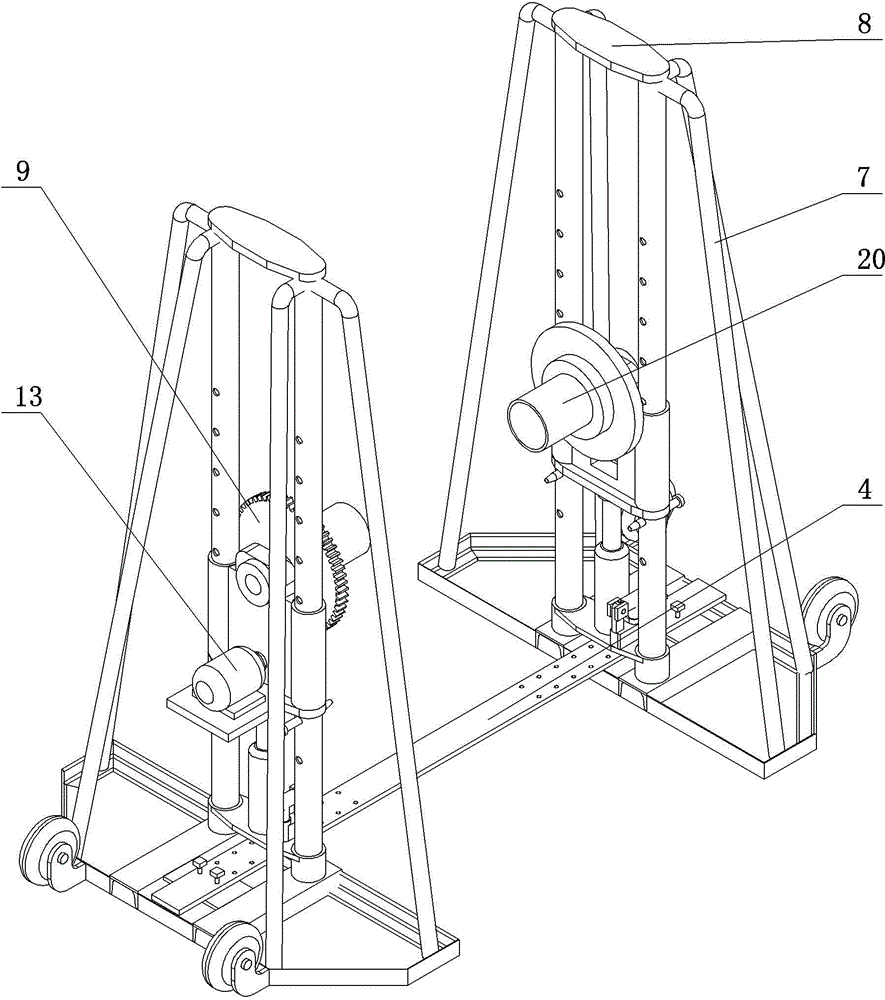

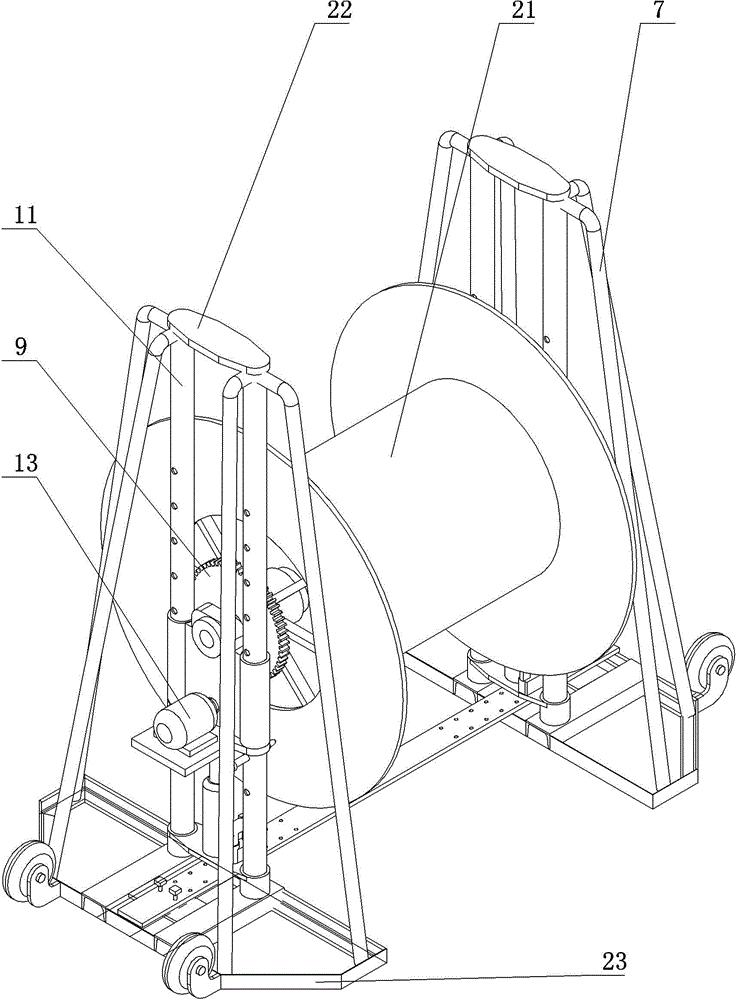

[0021] As shown in the figure, the present invention includes a first stand and a second stand oppositely arranged, and its structural points are provided with a first support plate in the middle of the bottom end of the first stand. The first guide pillars are arranged between them, and the first guide bushes are arranged on the first guide pillars. The two first guide bushes are connected by the first vertical plate, and the lower end of the first vertical plate is the first horizontal support extending outward. plate, a motor is fixed on the first horizontal support plate, an active bearing is arranged at the lower part of the first vertical plate, and the shaft rod of the driving gear is passed through the driving bearing, and the shaft rod of the driving gear is connected with the output shaft of the motor; There is a driven bearing, the shaft of the driven gear is passed through the driven bearing, the driven gear meshes with the driving gear, and the middle part of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com