Patents

Literature

65results about How to "Meet weight requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intermittent spring expansion hinge reducing mechanism

ActiveCN103939460AAvoid excessive expansion speedAvoids problems prone to lock-up shockPivotal connectionsHinge angleTime segment

The invention discloses an intermittent spring expansion hinge reducing mechanism and relates to a hinge reducing mechanism. The invention aims at solving the problem that locking impact is likely to occur at the expansion end of an existing solar wind expansion hinge driven by a volute spiral spring due to overlarge expansion speed. The intermittent spring expansion hinge reducing mechanism comprises a hinge assembly and a switching assembly, a locking assembly and a sourceless automatic self-unlocking mechanism which are arranged at the upper end of the hinge assembly from bottom to up in sequence. On the premise that the exiting expansion hinge structure remains the same, the continuous rotating of a hinge without the reducing mechanism is converted to the following motion: rotating-locking-unlocking-rotating; in the short locking period, the hinge stops rotating, therefore, the original continuous rotating becomes an intermittent motion and the locking impact force is reduced; the intermittent spring expansion hinge reducing mechanism is used for speed reducing of the solar wing expansion hinge.

Owner:HARBIN INST OF TECH

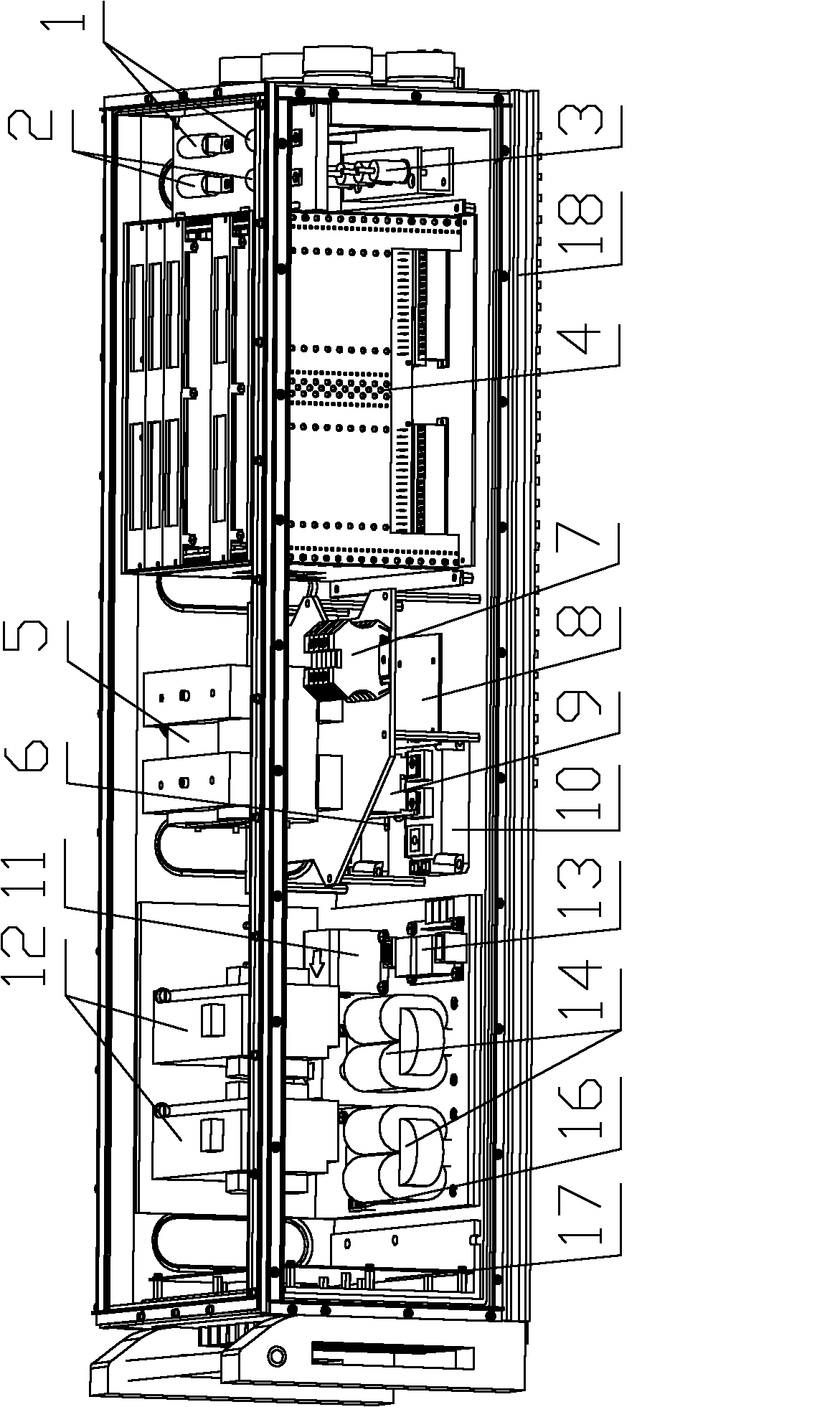

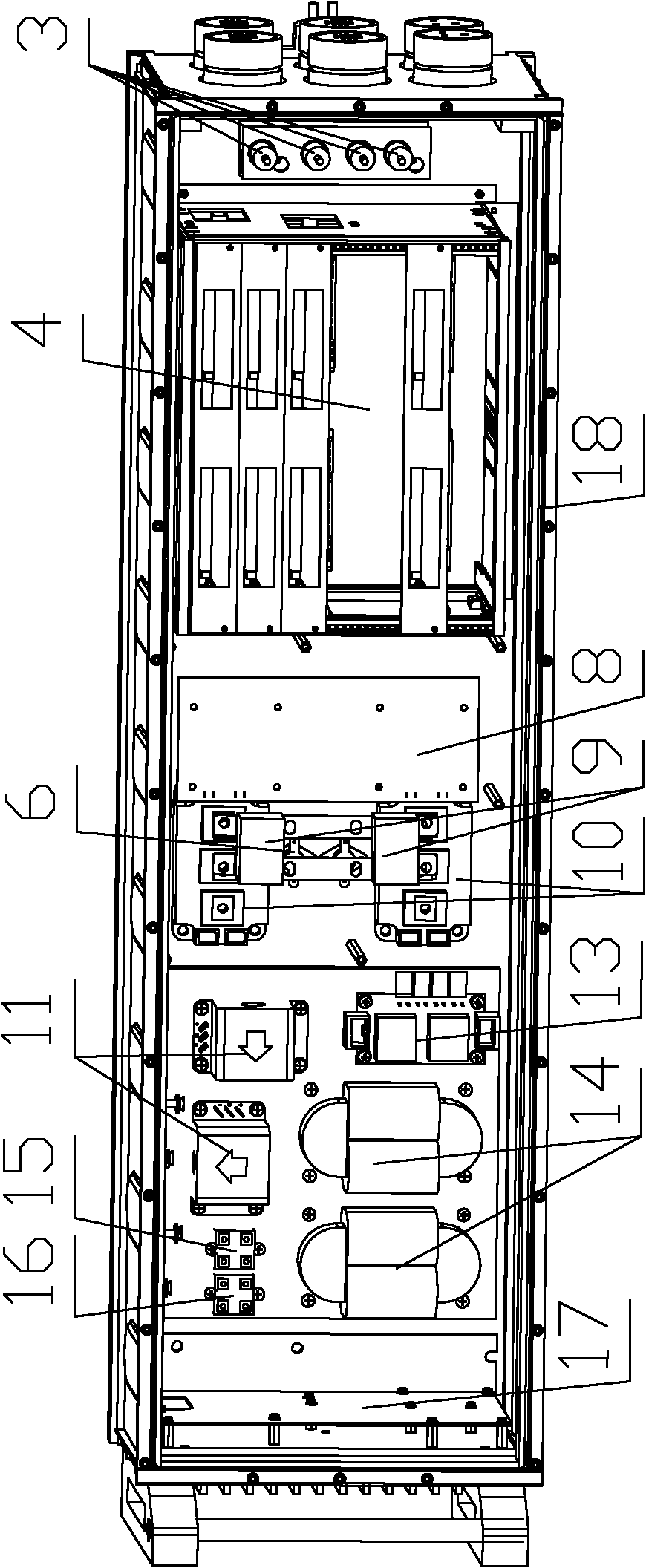

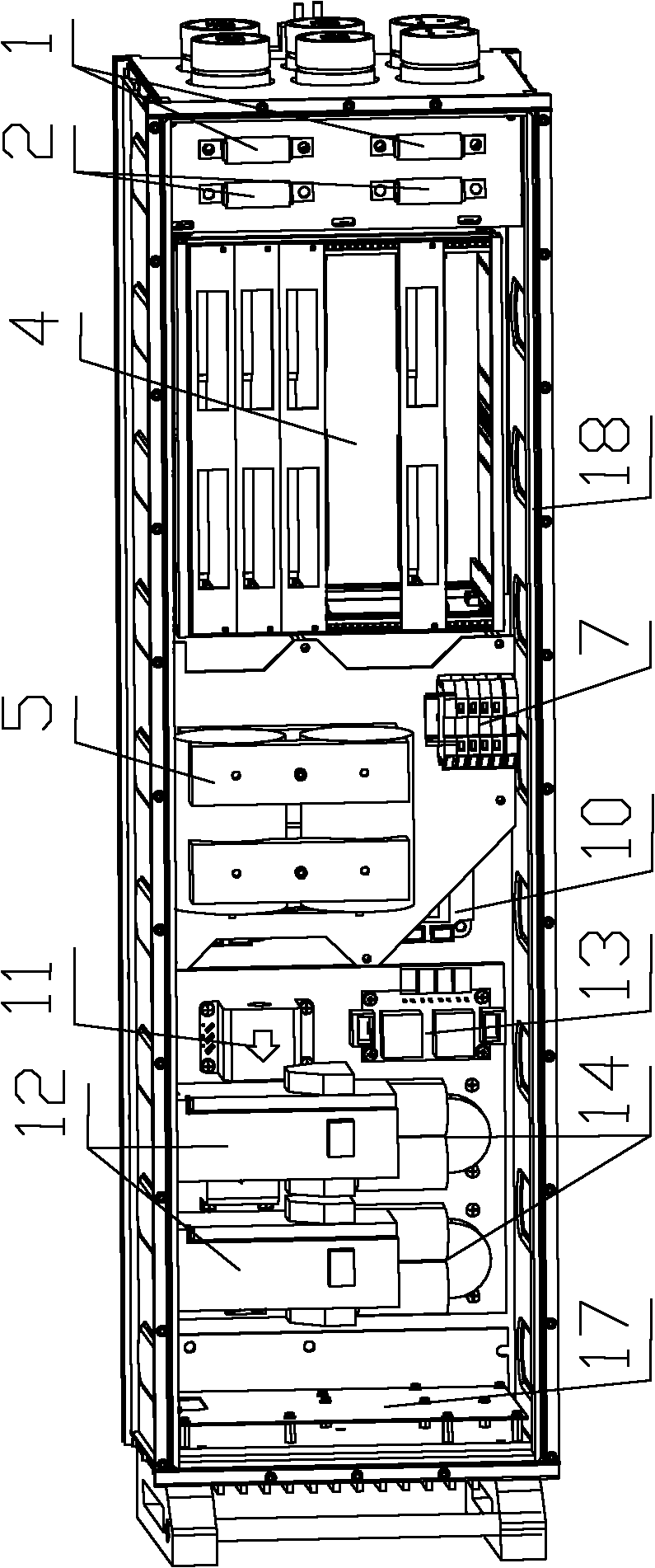

Suspension controller of magnetic suspension train

InactiveCN102005989ASave spaceReduce weightMagnetic holding devicesCooling/ventilation/heating modificationsMaglevResistor

The invention discloses a suspension controller of a magnetic suspension train, which comprises a box body and electric elements such as insulated gate bipolar transistor (IGBT), wherein the box body is cast by using an aluminum material, and the bottom of the box body is provided with radiation fins; a main circuit input end protective fuse and a control circuit input end protective fuse are arranged on an insulation board to form an insulation board component; a supported capacitor and a wiring terminal are mounted on an aluminum mounting board to form a mounting board component; and a current sensor, a voltage sensor circuit board, an output filter reactor, a charging resistor and a discharging resistor are mounted on the bottom face of an 'L'-shaped mounting board, a charging contact and a main contact are mounted on the side face of the 'L'-shaped mounting board, and thus, an 'L'-shaped mounting board component is formed. In the invention, the heating electric elements such as the IGBT are mounted on the bottom face of the box body and the heat of the electric elements can be dissipated by the box body, so it is unnecessary to configure a special radiator for the IGBT with the box body as the radiator; and thus, space is saved, and the suspension controller meets requirements on electrical performance as well as size and weight.

Owner:CHINA CNR CORPORATION

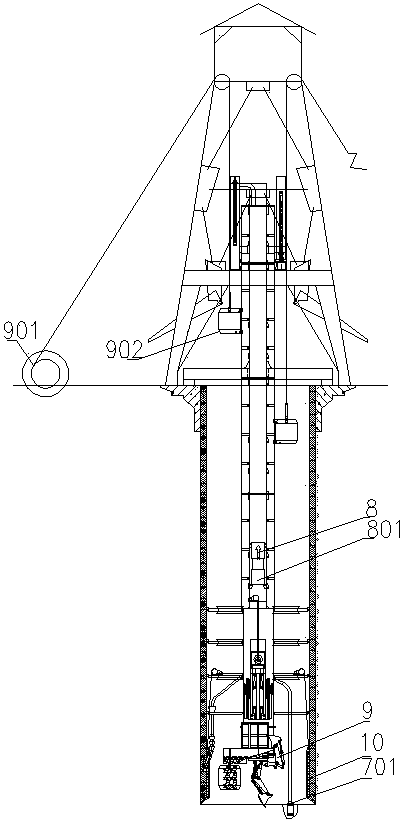

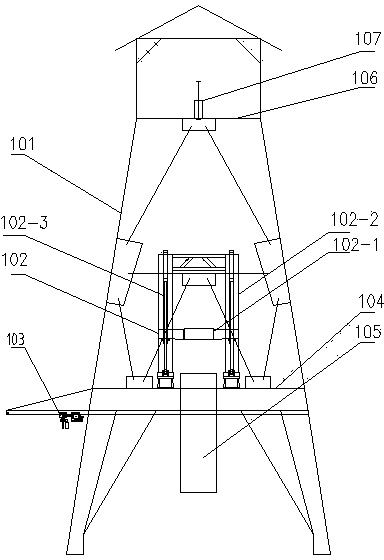

Novel drilling and blasting method vertical shaft drilling machine

The invention discloses a novel drilling and blasting method vertical shaft drilling machine. The machine mainly comprises a derrick, a numerical control umbrella drill, a loading machine, an equipment suspension system, a drainage system, a ventilation system, a slag discharge system, a shaft wall casting system, a shaft bottom hanging scaffold, a hydraulic station and a control room, wherein the equipment suspension system comprises a center vertical column, a vertical column lifting mechanism and a sealing flatcar; the center vertical column is connected with the vertical column lifting mechanism, and extends underground; the lower part of the center vertical column is connected with the shaft bottom hanging scaffold; the derrick and the sealing flatcar are mounted in a shaft mouth; the vertical column lifting mechanism is fixed and mounted on the derrick; the loading machine is mounted at the lower end of the center vertical column; the numerical control umbrella drill is mounted in the center vertical column; and the hydraulic station, the drainage system and the control room are mounted on the shaft bottom hanging scaffold. The machine adopts the reinforced derrick and the equipment suspension system, so that the equipment connection is reliable, and the construction is safer. The construction of the numerical control umbrella drill needs no shaft lifting, and is full-automatically controlled, so that the construction efficiency is improved; the slag loading efficiency of the loading machine is higher; the operation is more convenient; and the slag discharge efficiency is further improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

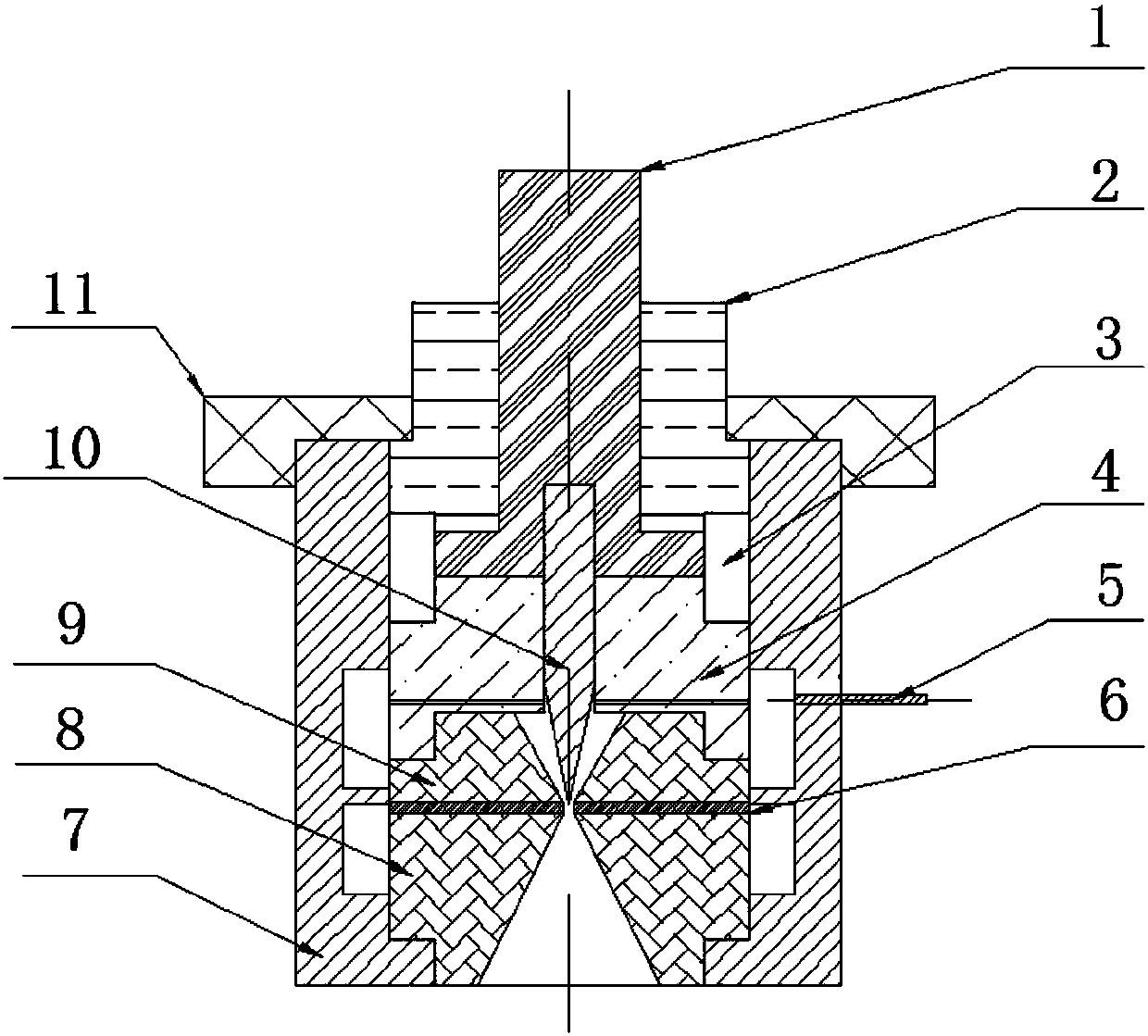

Low-power electric arc heating propeller

ActiveCN107605687AConvenient power supplySimple structureMachines/enginesUsing plasmaElectricityPropeller

The invention discloses a low-power electric arc heating propeller which is mainly applied to a power system for a micro satellite, and belongs to the field of electric propulsion. The low-power electric arc heating propeller aims to solve the problem that an existing micro satellite does not have a propelling system, and a set of complete electric propeller structure is designed according to an electric arc discharge principle between an anode and a cathode. The propeller structure mainly comprises a first cathode clamp seat 1, an upper insulator 2, a middle insulator 3, a lower insulator 4,an air inlet 5, the anode 6, a lower cover 7, a lower nozzle 8, an upper nozzle 9, the cathode 10 and an upper cover 11. According to the low-power electric arc heating propeller, when a voltage between the anode and the cathode achieves an arc-striking voltage, an introduced propellant is heated and expanded, under the action of the nozzles, supersonic gas is generated and ejected, and then reaction thrust is formed; and the low-power electric arc heating propeller has the advantages that integral structure is small in size and light in weight.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Steel tank plastic-pasting internal lining antisepsis method

InactiveCN101250701AWon't spread quicklyClosely connectedLiquid surface applicatorsSuperimposed coating processAdhesiveEngineering

The invention relates to a method for preventing corrosion of plastic stuck inside lining of a steel-made tank body, which comprises following steps: removing an oxide layer and an oil stain layer on the inner surface of the steel-made tank body, mixing phosphating solution to phosphatize the surface of the steel-made tank body, using clear water to clean the steel-made tank body after phosphatizing, drying, mixing adhesive, evenly coating the adhesive on the inner surface of the steel-made tank body, clinging a plastic plate whose thickness is 0.5-30mm on the inner surface of the steel-made tank body, leaving joints of 0.1-10cm between different plastic plates, using a stop plate to seal each interface of the steel-made tank body, injecting compressed air into the steel-made tank body, achieving the curing time of the adhesive under the condition of constant pressure 0.03-0.1MPa, curing the adhesive, and then using welding rods to fill the joints between each plastic plate through welding. The method of the invention has the advantages that firstly, an adhesive layer is provided between the steel-made tank body and a plastic anti-corrosion layer, which enables the steel-made tank body and the plastic anti-corrosion layer to be compactly connected, corrosion medium can not be rapidly dispersed by any possibility that leakage happens, secondly, the plastic layer has a comparatively big regulating range, which can satisfy the demands of different users, thirdly, the joints between each plastic plate can be adapted to the changes of the environmental temperature after being filled with the welding rods, and the reliability of products is increased.

Owner:陈晓宇

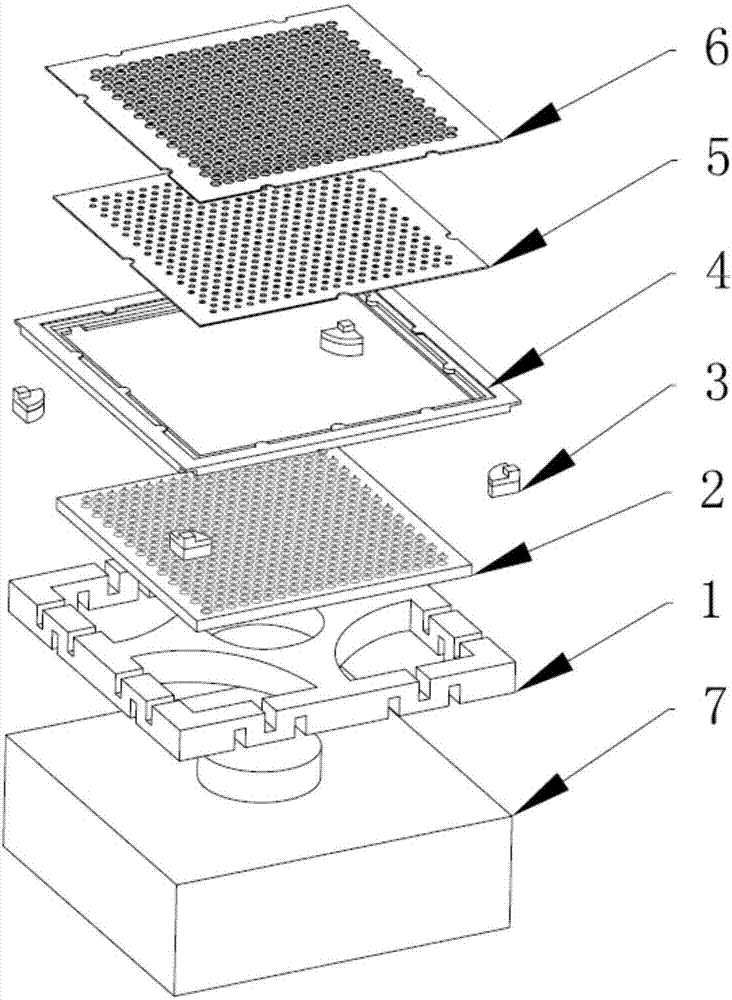

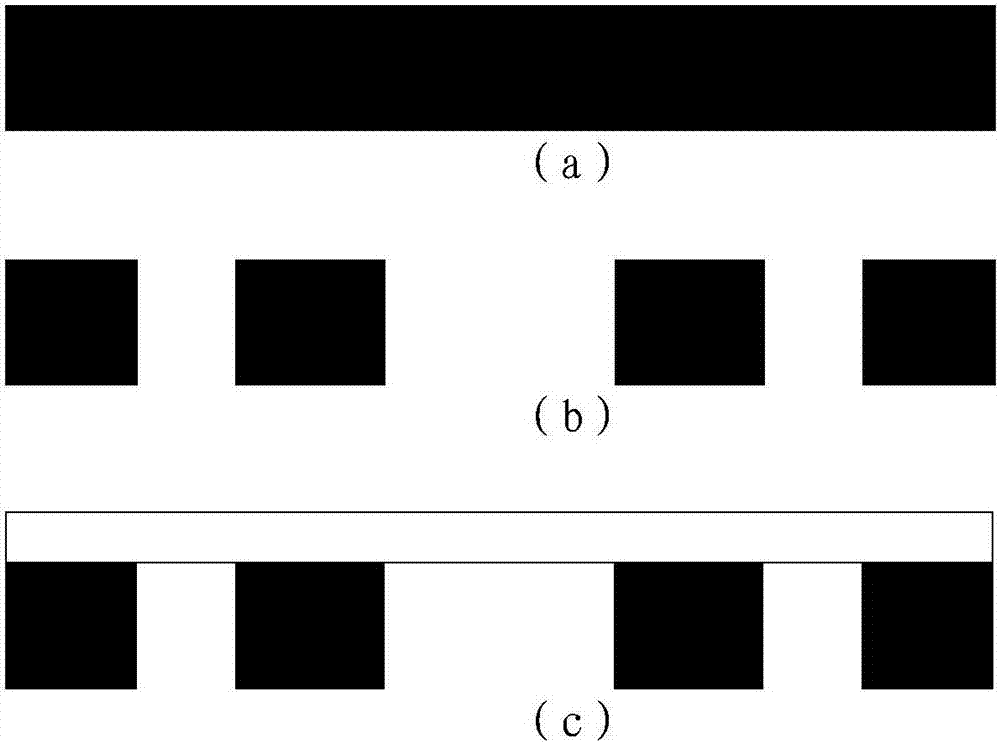

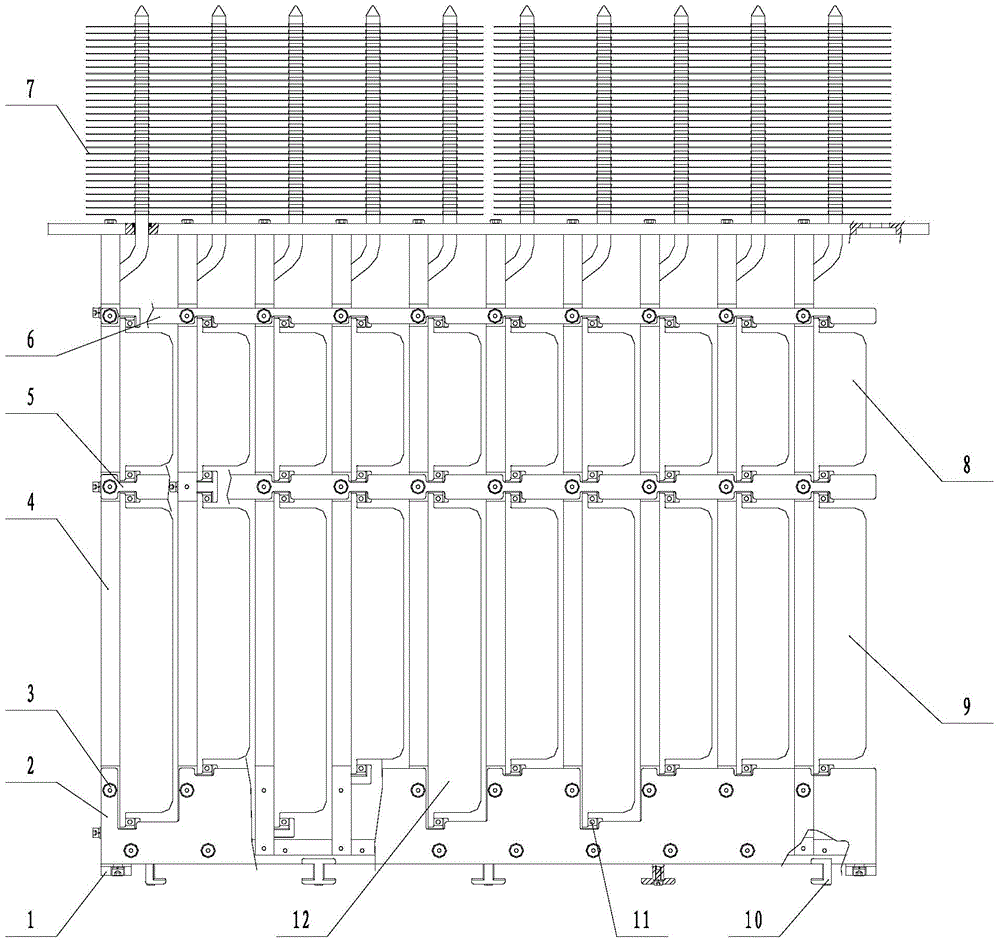

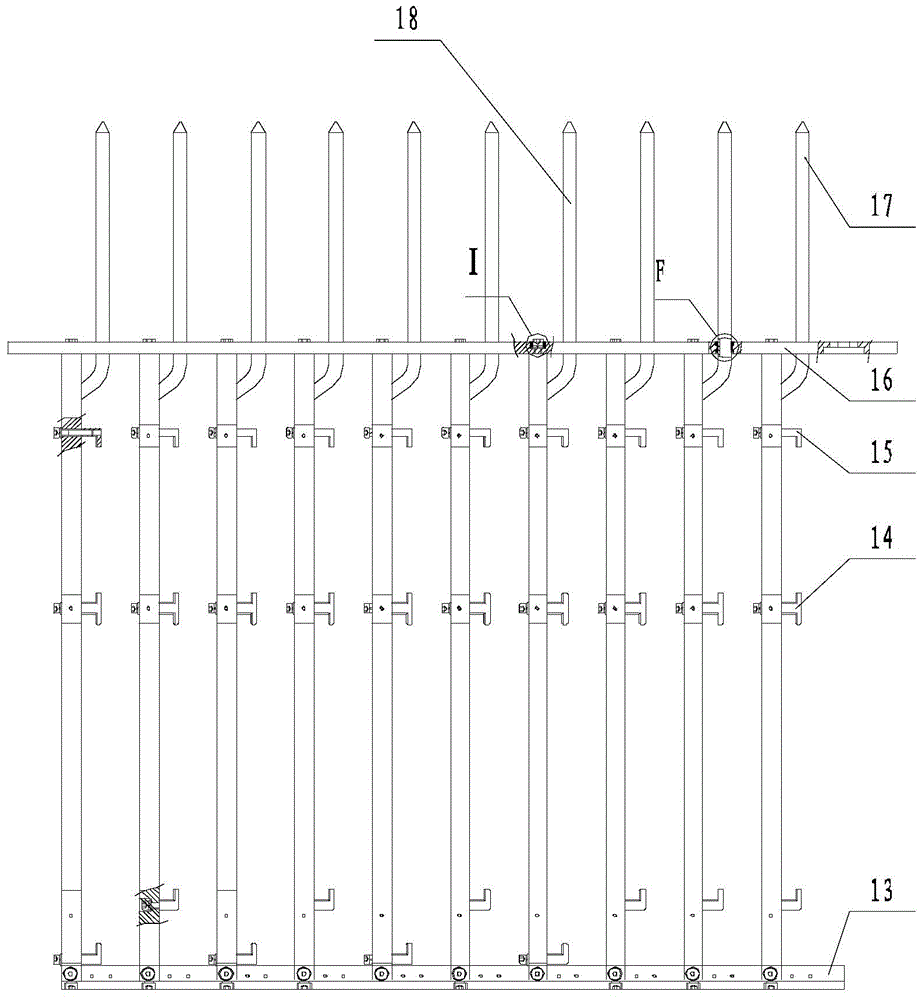

Array structure and realization method of MEMS electro-spray thruster

InactiveCN107472556ASimple structureReduce volumeTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEpoxyInsulation layer

The invention provides an array structure and a realization method of an MEMS electro-spray thruster. The realization method comprises the following steps that 101, deep silicon etching and wet etching are conducted on a silicon wafer to obtain a mounting base (1); 102, an emitter (2) is obtained by conducting electrochemical etching on porous materials; 103, the emitter (2) is bonded on the mounting base (1); 104, a positioning and insulation layer (3) is obtained through silicon-glass-silicon anode bonding, glass etching and deep silicon etching; 105, the positioning and insulation layer (3) is bonded and connected to four corners of the mounting base (1) through an epoxy resin; 106, an electrode mounting frame (4) is obtained through deep silicon etching and wet etching conducted on the silicon wafer, and the electrode mounting frame (4) is bonded to the positioning and insulation layer (3) through the epoxy resin; 107, an extracting pole (5) and an accelerating pole (6) are obtained by conducting metal sputtering and electroplating on silicon based materials; and 108, a storing tank (7) storing propellants is connected with the emitter (2) through a boss on the storing tank (7).

Owner:BEIJING INST OF CONTROL ENG

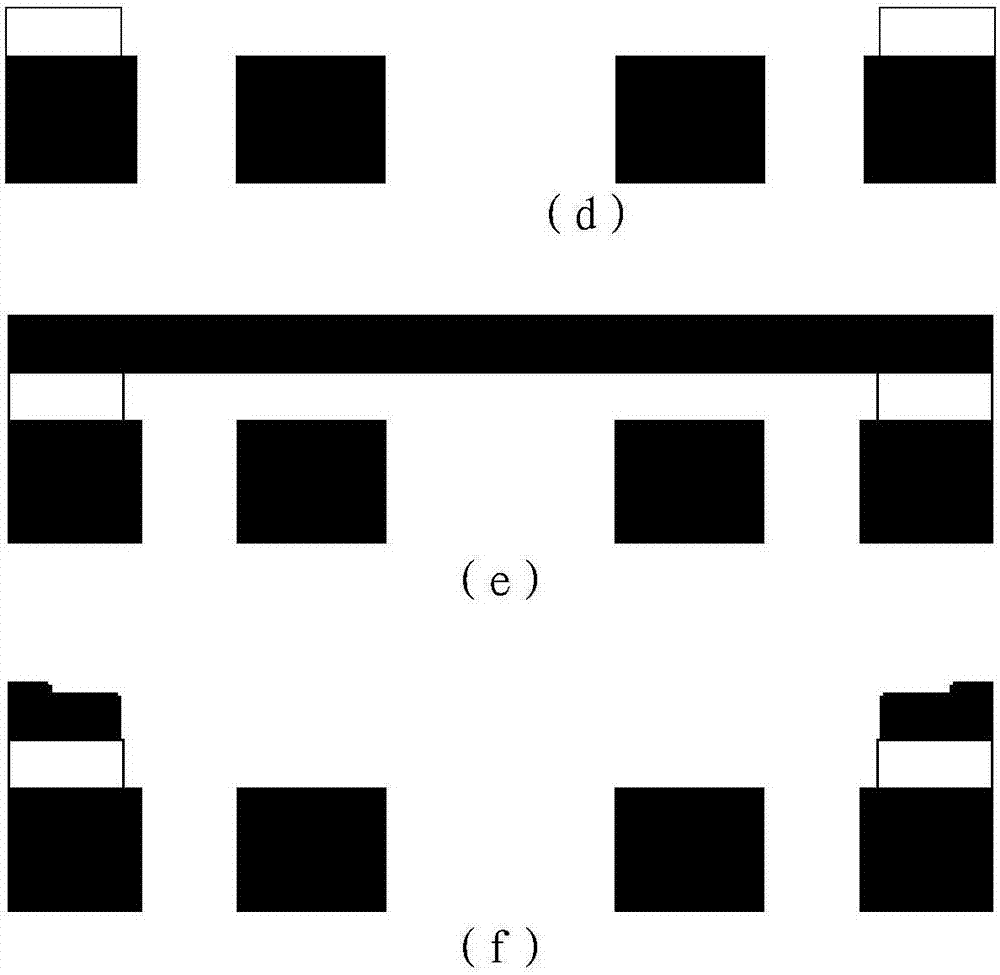

High-efficiency carbon-absorbing tower

InactiveCN103418225AIncrease profitWell mixed absorption reactionPurification using alkaline earth metal compoundsDispersed particle separationProcess engineeringSugar refinery

The invention discloses main equipment: a high-efficiency carbon-absorbing tower, for recovering low-content CO2 of flue gas of a cane sugar factory boiler to be applied to a modified sugar manufacturing process by a sulfurous acid method. The high-efficiency carbon-absorbing tower comprises a tower shell, a boiler flue gas extraction and discharge system, a filling system, a spraying absorption system device, a demister system device, a cleaning system device, a monitoring system and a material conveying system. The high-efficiency carbon-absorbing tower is a high-efficiency forced absorption reactor; the utilization ratio of carbon dioxide is increased more quickly when compared with that of the traditional natural saturation equipment; a structure in the tower is designed innovatively and optimally, so that the gas liquid mixing ratio and the retention time are reasonable, the low-content carbon dioxide is gathered by the high-efficiency carbon-absorbing tower and reacts with lime milk to form calcium carbonate solution, emission is reduced, and the carbon dioxide can be recovered to be applied to an improved traditional sugar manufacturing process by the sulfurous acid method. The high-efficiency carbon-absorbing tower is characterized in that the structure is simple; the mounting is convenient; airflow resistance is small; the carbon dioxide is easy to gather and absorb; is the maintance is convenient;, the operation is reliable; the cost is low; the recovery rate of the carbon dioxide is high.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

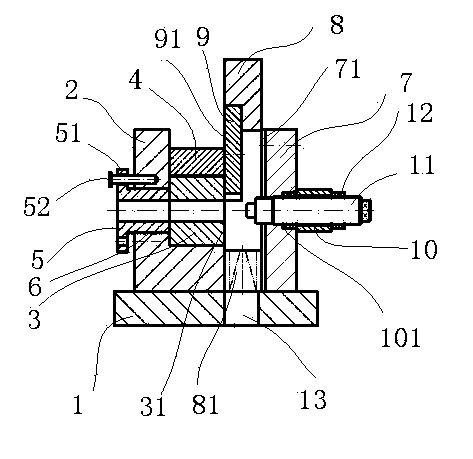

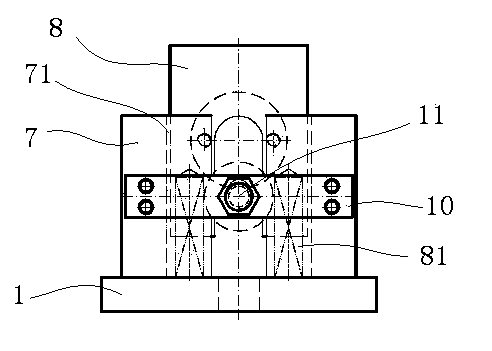

Cold extrusion blanking die for cross shaft blanks

The invention discloses a cold extrusion blanking die for cross shaft blanks. The cold extrusion blanking die comprises a base plate. A die holder is fixed onto the base plate, a lower cutting board is arranged on the die holder and is connected with the die holder by a gland, an adjusting screw tube is abutted to the rear end of the lower cutting board and is matched with an adjusting screw hole in the die holder, and a shoulder of the rear end of the adjusting screw tube is locked by a pin; a guide rail seat is arranged at the front end of the die holder and is fixedly connected with the base plate, guide rails are arranged on the back of the guide rail seat, an upper cutting board is embedded in a movable die plate which is arranged in the guide rails in a sliding fit manner, the outer end of the upper cutting board is in sliding fit with the front end of the lower cutting board, two compression springs are arranged at the lower end of the movable die plate, and the other end of each compression spring is abutted onto the base plate; a back plate is fixedly connected to the front end of the guide rail seat, a regulating screw hole is formed in the middle of the back plate, a blank length control screw is arranged in the regulating screw hole and is locked with the back plate by two locking nuts, and the tail end of the blank length control screw is opposite to the lower cutting board. The cold extrusion blanking die has the advantages that a gap between the upper cutting board and the lower cutting board can be accurately adjusted; a slider of a press machine is prevented from being directly impacted with the upper cutting board, and a vertex position of a bar can be instantly broken; materials can be discharge conveniently, and each cutter of the cold extrusion blanking die is provided with multiple blades.

Owner:WANXIANGQIANCHAO CO LTD +1

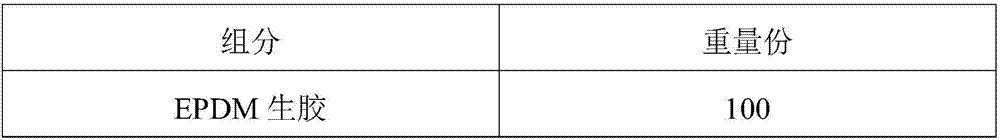

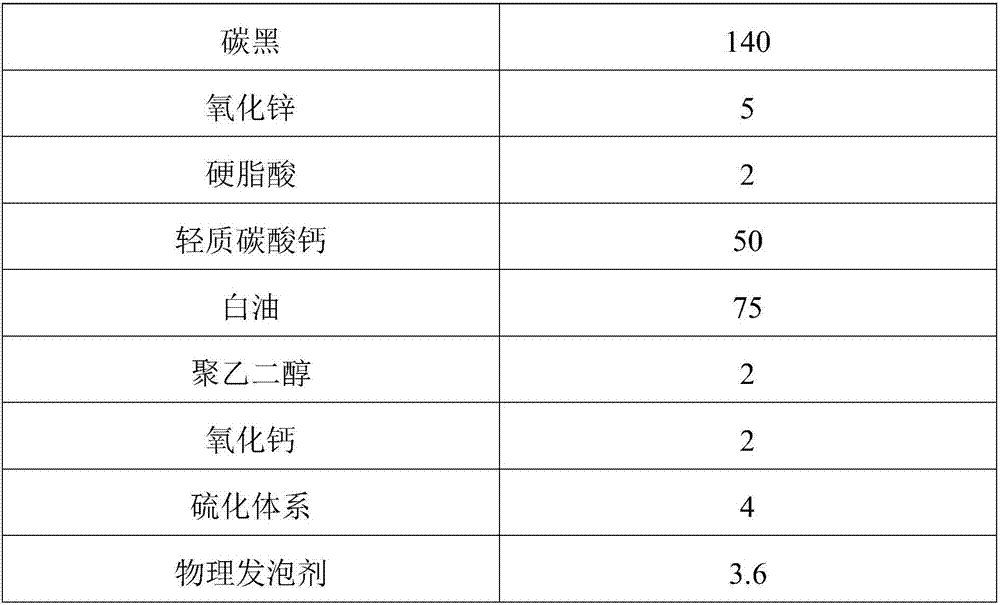

Application of physical foaming agent and chemical foaming agent in skylight sealing strip non-porous rubber microcellular foaming

The invention relates to an automobile skylight sealing strip non-porous rubber microcellular foaming rubber. The rubber is made from EPDM raw rubber, carbon black, zinc oxide, stearic acid, light calcium carbonate, white oil, polyethylene glycol, calcium oxide, a vulcanization system, a physical foaming agent and a chemical foaming agent. The invention also provides a foaming agent composition, an application thereof, and a preparation method of the microcellular foaming rubber. The foaming agents are used to reduce the density of the rubber by 15% or above, makes the rubber meet the sealing strip weight requirement of automobile lightweighting, energy saving and consumption reduction, realizes simple operation and reduces the production cost.

Owner:WUHAN YINAN RUBBER & PLASTIC TECH CO LTD

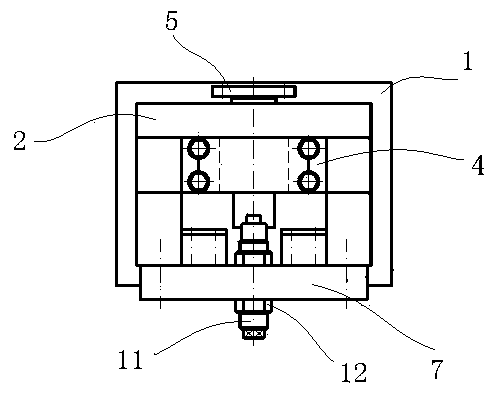

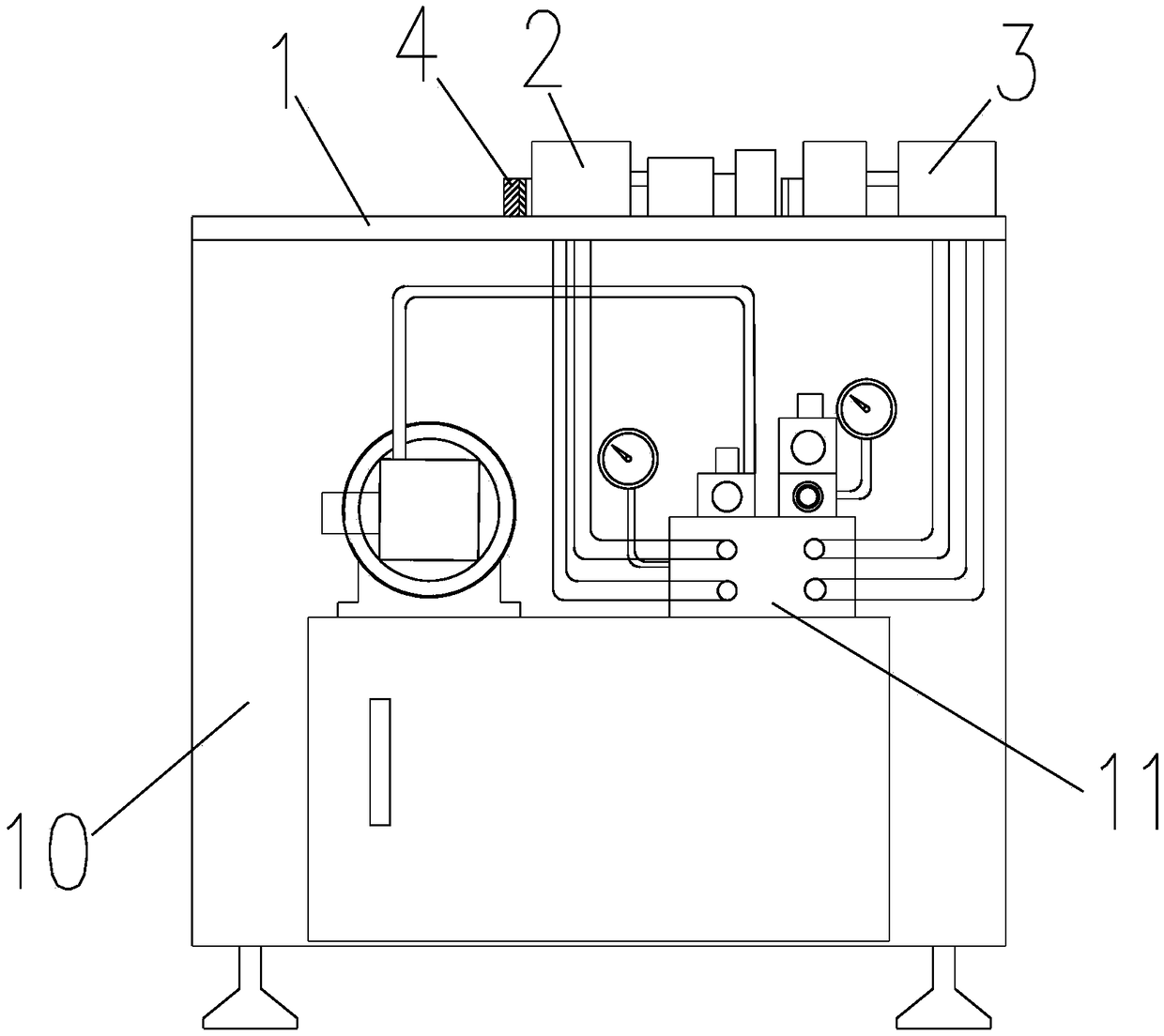

Industrial CT scanner synchronous loading test apparatus and industrial CT scanner

ActiveCN105115995AAchieve synchronous rotationLoad stability compensationMaterial analysis by transmitting radiationFiberCarbon fibers

The invention relates to an industrial CT scanner synchronous loading test apparatus and an industrial CT scanner, and belongs to the field of test detection equipment. The apparatus comprises a single-acting rotating loading oil cylinder, a see-through carbon fiber counterforce frame, a micro-torque rotating mechanism, an oil pressure loading system and a pressure display system; the single-acting rotating loading oil cylinder comprises an oil cylinder body and a rotary oil receiving hole which can conduct relative rotation with the oil cylinder body, the see-through carbon fiber counterforce frame comprises an upper connecting box and a lower connecting plate, as well as a carbon fiber support wound between the upper connecting box and the lower connecting plate, and a test piece is positioned between the upper connecting box and the lower connecting plate. A self-counterforce mechanism is formed by the single-acting rotating loading oil cylinder and the see-through carbon fiber counterforce frame jointly. The see-through carbon fiber counterforce frame almost has no absorption of X-rays, and the X-rays pass through carbon fiber to irradiate the test piece without generating energy loss. The industrial CT scanner synchronous loading test apparatus provided by the invention works together with the industrial CT scanner, and can achieve loading of the test piece, and real-time scanning of change conditions such as the damage to the test piece can be realized.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

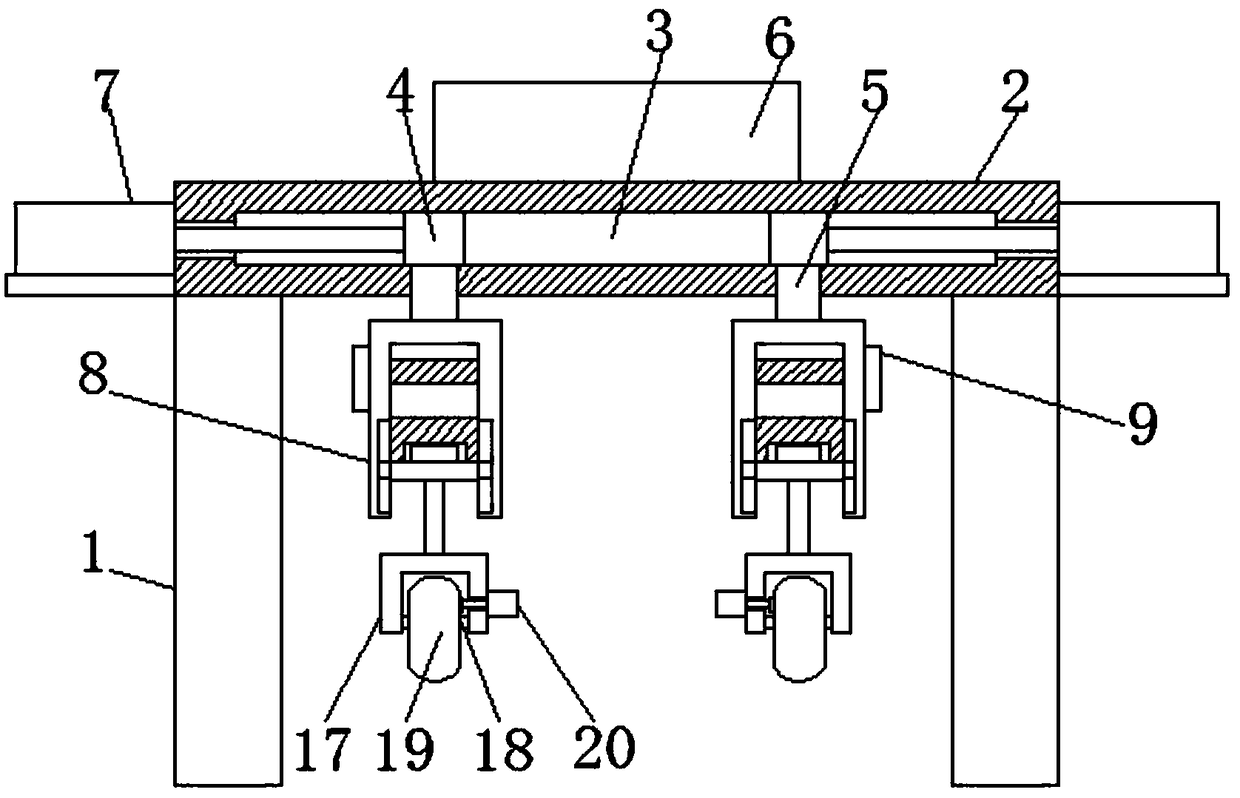

Force application load device suitable for running machine

ActiveCN109490003APrecisely control the magnitude of the electromagnetic forceMeet weight requirementsStructural/machines measurementEngineeringElectromagnetism

The invention discloses a force application load device suitable for a running machine. The device comprises a support, a beam is fixedly connected to the top of the support, and a guide groove is formed in the beam; guide blocks are movably connected to the interior of the guide groove; movable rods are fixedly connected to the bottoms of the guide blocks, a processor is fixedly connected to thetop of the beam, and mounting plates are fixedly connected to the two ends of the beam; first electric push rods are fixedly connected to the tops of the mounting plates, fixing racks are fixedly connected to the bottom of the movable rods, and a PCB is fixedly connected to one side of each fixing rack. According to the force application load device suitable for the running machine, the current magnitude is adjusted according to a button on a control panel, through an electromagnetism working principle, the electromagnetism force application magnitude can be precisely controlled, the weight and speed demands are met, through the corresponding power and / or current magnitude, running of normal people is simulated, and testing data is more accurate.

Owner:FANGGUANG INSPECTION & TESTING CO LTD

Heat pipe radiating module for ship power supply

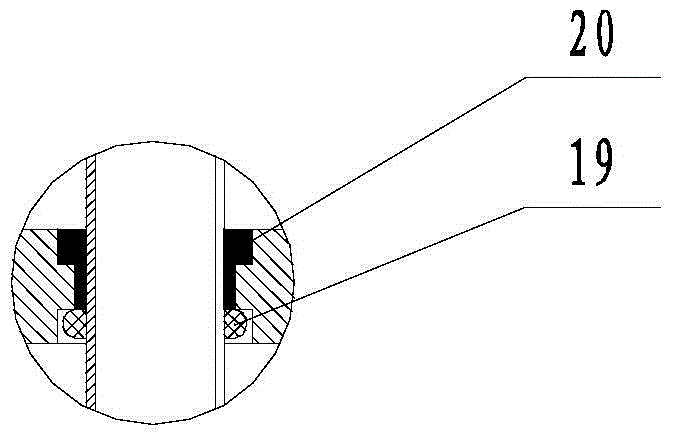

ActiveCN104869791AAchieving conduction to external space heat dissipation requirementsImprove thermal efficiencyHermetically-sealed casingsCooling/ventilation/heating modificationsInterference fitLocking mechanism

The invention relates to a heat pipe radiating module for a ship power supply. The heat pipe radiating module comprises a fixed base plate, a protection plate, locking screws, a heat pipe radiating unit module, positioning beams I, positioning beams II, radiating fins, a power supply module I, a power supply module II, fan beams, locking mechanisms, and a power supply module III. According to the invention, a protection flange plate is connected to an external case to form an upper heat radiation part and a lower sealing heat conduction part, and the lower part provided with the ship power supply is disposed inside a sealing case, so that sealing, moisture resistance and corrosion resistance problems are solved. Efficient heat pipes arranged on heat conduction substrates in a submerged-arc welding manner extend to the upper portion of the protection flange plate via through holes having a sealing structure in the protection flange plate, and are in interference fit with the radiating fins exposed on the upper portion of the protection flange plate, and the heat generated when the ship power supply works is transmitted outside the sealing chamber, so that the heat of the ship power supply can be rapidly radiated. The heat pipe radiating module has beneficial effects of high heat radiation efficiency, small size and high sealing performance.

Owner:ANSHAN ANMING IND

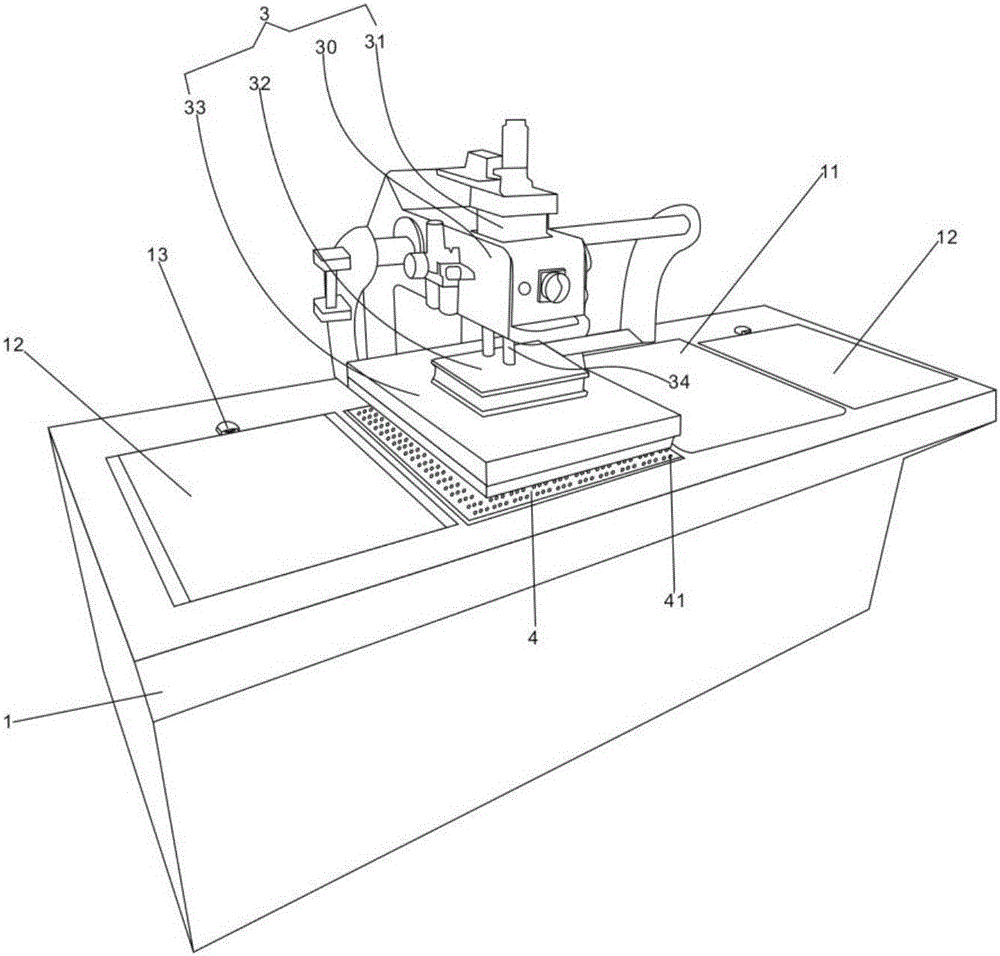

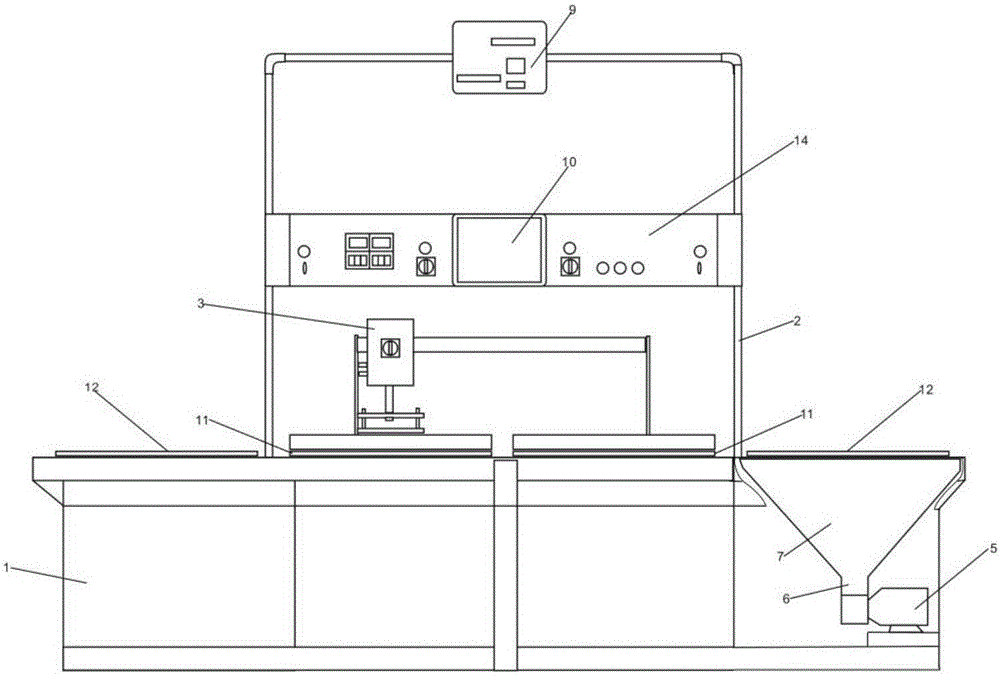

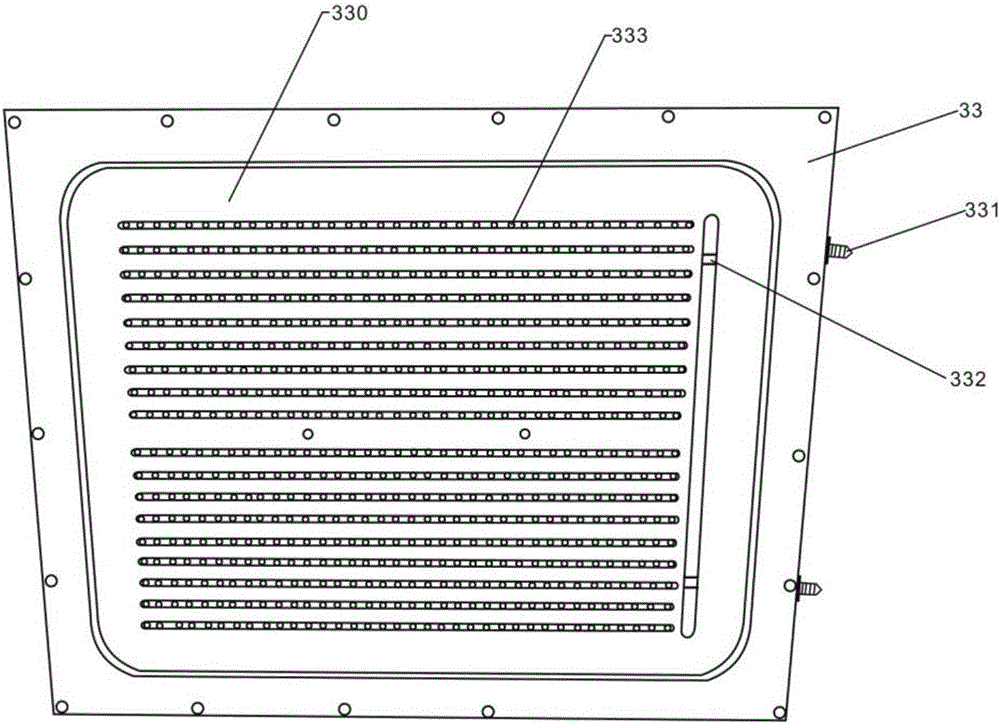

Fully-woven upper sheet ironing setter

InactiveCN106676805AImprove thermal conductivitySmall coefficient of thermal expansionHeating/cooling textile fabricsLight touchSetter

The invention discloses a fully-woven upper sheet ironing setter which comprises a workbench, a machine frame, a steam ironing device and a control device, wherein the machine frame, the steam ironing device and the control device are mounted on the workbench; the surface of the workbench comprises ironing regions and cooling regions; emery sheet fixing plates are mounted in the ironing regions, are thin plates of which the surfaces are coated with an emery coating, and are provided with penetration holes; cover lids, air pipes and cooling fans are connected in the workbench at the lower parts of the cooling regions; the steam ironing device is mounted at the upper parts of the ironing regions, and comprises a cylinder base, a cylinder, a lifting plate and a steam ironing plate; light touch push switches are mounted on the edges of the upper ends of the cooling regions, and are connected with a delay control line to control the cooling fans. The ironing setter also comprises a projection control device and a projector, wherein the ironing regions are covered by a projection region of the projector. The emery sheet fixing plates can be matched with sheet fixing claw pieces. According to the ironing setter, an upper sheet can be set more rapidly and smoothly, operation is convenient, the labor intensity and the production cost are reduced, and the production efficiency and benefits are improved.

Owner:金翰

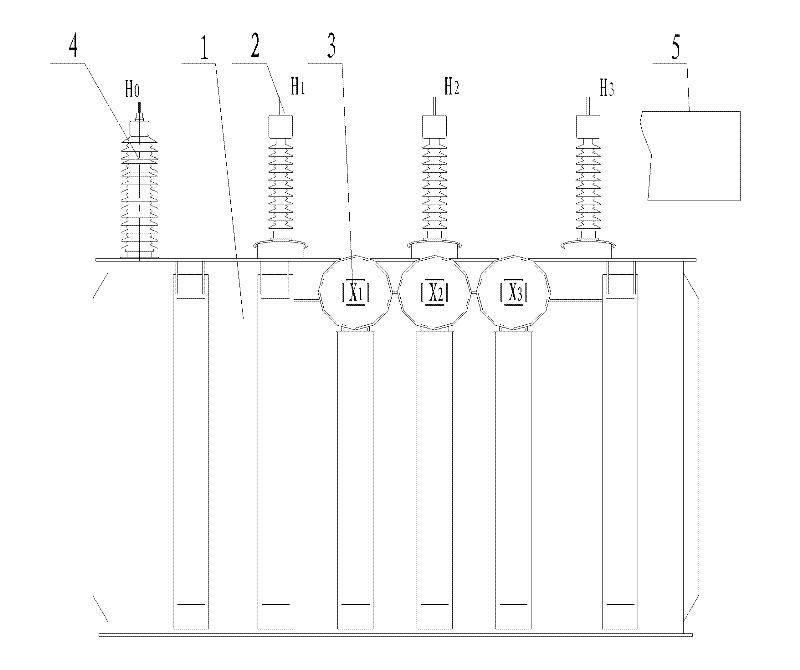

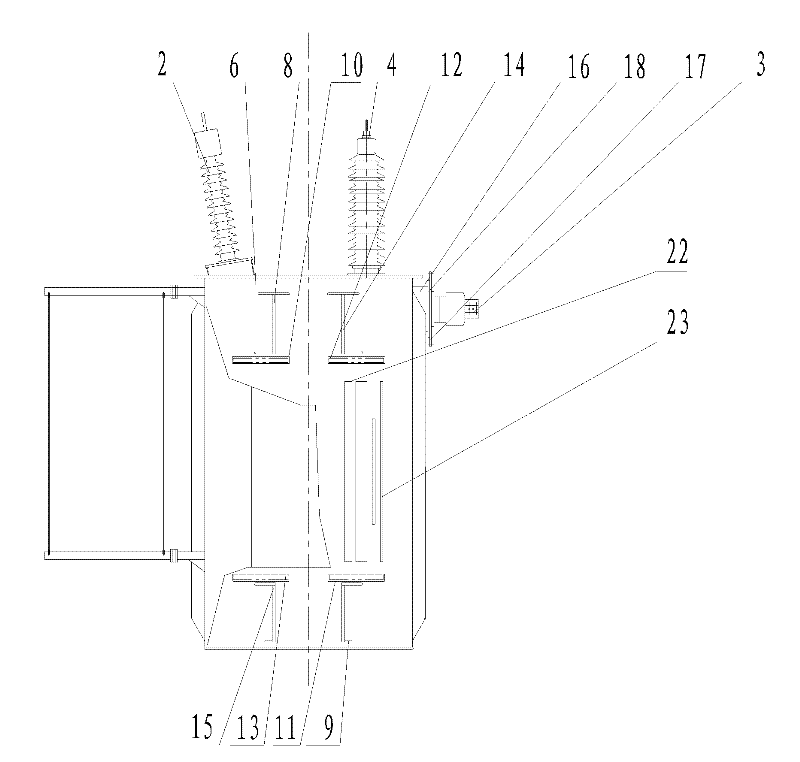

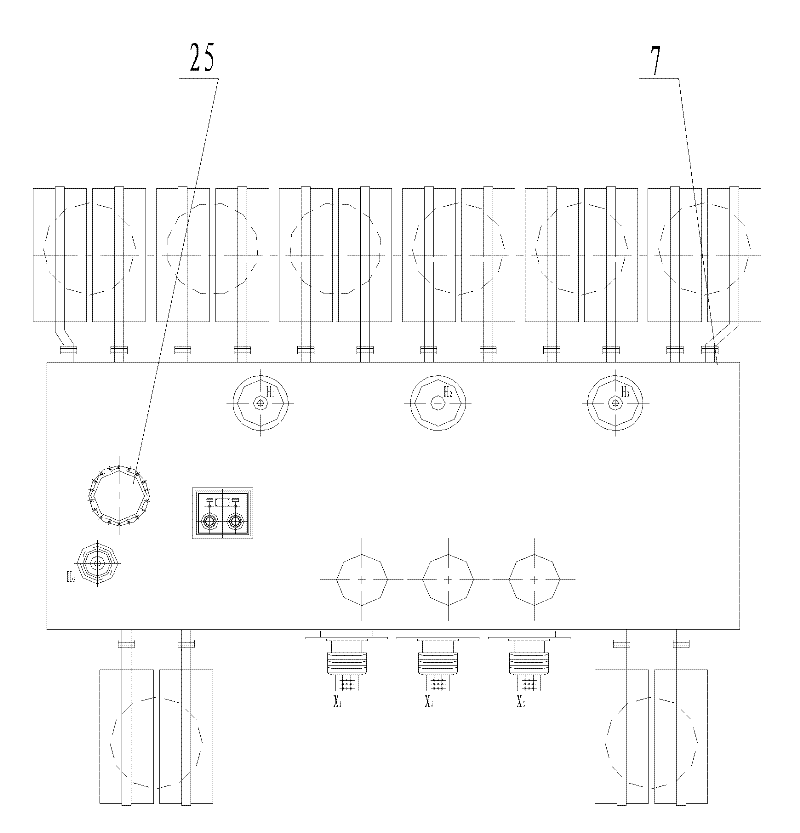

Transformer for realizing voltage change through changeover of leads

ActiveCN102543398AFirmly connectedMeet the technical parametersTransformers/inductances coolingTransformers/inductances coils/windings/connectionsLow voltageFuel tank

The invention relates to a transformer for realizing voltage change through changeover of leads. The transformer comprises a high voltage bushing, low voltage bushings, a high voltage neutral point bushing, an oil storage cabinet, an oil tank, a box cover, a cooling device and a tap-changer without excitation, wherein a three-phase three-column iron core structure is arranged in the oil tank; the three-phase three-column iron core is sleeved with a low voltage winding I, a high voltage winding, a voltage adjusting winding and a low voltage winding II from inside to outside respectively; the low voltage winding I is connected in series with the low voltage winding II; the low voltage winding I is wound leftwards; the low voltage winding II is wound rightwards; the two low voltage windings are connected end to head; the head part of the low voltage winding II is arranged at the upper end; and two low voltage windings are connected with a power generator by three low voltage bushings through changeover of the leads at the upper and lower parts. According to the invention, two low voltages are realized through changeover of two sets of leads, so that the two low voltages can be guaranteed to be connected with the power generator, and the technical parameters, the field external limitations, the foundation bearings and the weight requirements of the transformer in the prior art are satisfied at the same time.

Owner:特变电工山东沈变电气设备有限公司

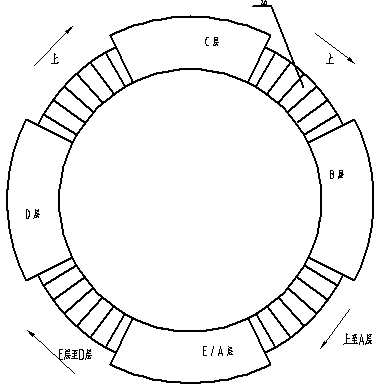

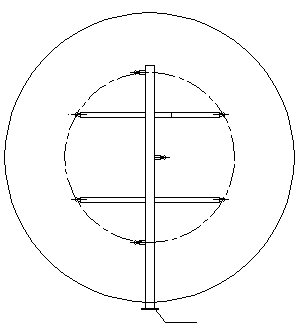

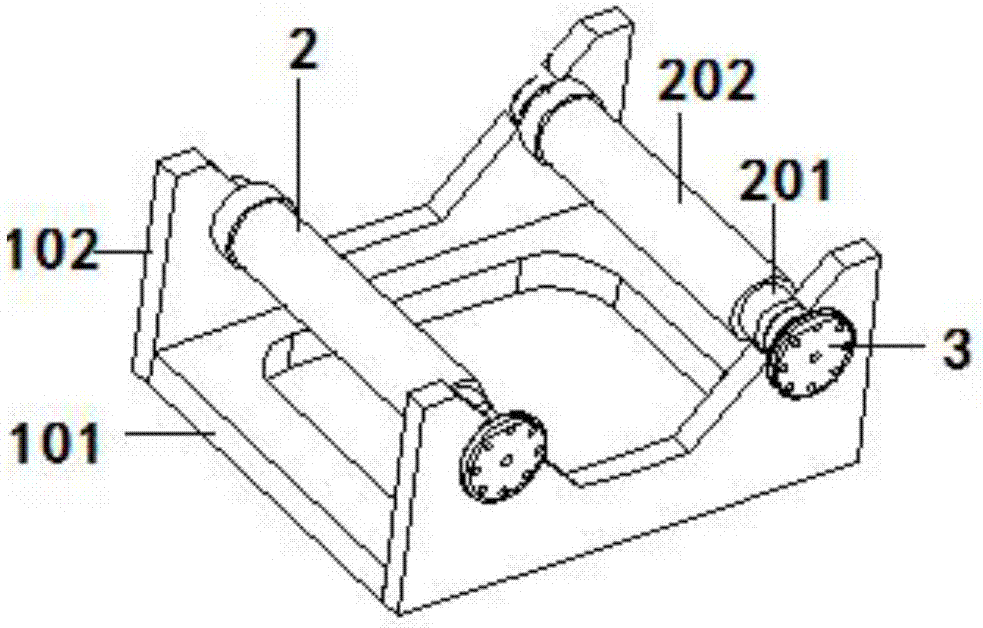

Arranged magnetic steel supporting device for rotor of permanent magnet motor

ActiveCN107017742AConducive to the installation of magnets without supportReduce labor rateManufacturing stator/rotor bodiesCircular discBrake

The present invention discloses an arranged magnetic steel supporting device for the rotor of a permanent magnet motor. The device comprises a positioning support, rolling shafts and a brake pin. The positioning support comprises a base and two opposite bearers fixedly arranged at the two ends of the base. Along the top edge of each bearer, the bearer is provided with an inverted trapezoidal groove configured not to pass through the bottom edge of the bearer. The sidewall of the inverted trapezoidal groove is symmetrically provided with two arc-shaped grooves and rolling shafts are arranged in the arc-shaped grooves. The sidewall of each bearer is provided with a positioning groove and a limiting plate is fixed on the sidewall of the bearer. Each rolling shaft comprises a rotating shaft and an aluminum sleeve sleeved onto the outer surface of the sidewall of the rotating shaft. Bearings are arranged at the two ends of each rotating shaft. One end of each rotating shaft is connected with the limiting plate, and the other end of the rotating shaft is fixedly connected with a limiting circular disc. The limiting circular disc is fixed onto the sidewalls of the bearers through the brake pin. The device is simple in structure and strong in practicality. The problem in the prior art that no special device used for supporting the rotor of an existing permanent magnet motor is available during the production process of the permanent magnet motor can be solved. Meanwhile, the labor intensity of the motor production is greatly relieved, and the production safety is improved.

Owner:ANHUI ANKAI AUTOMOBILE

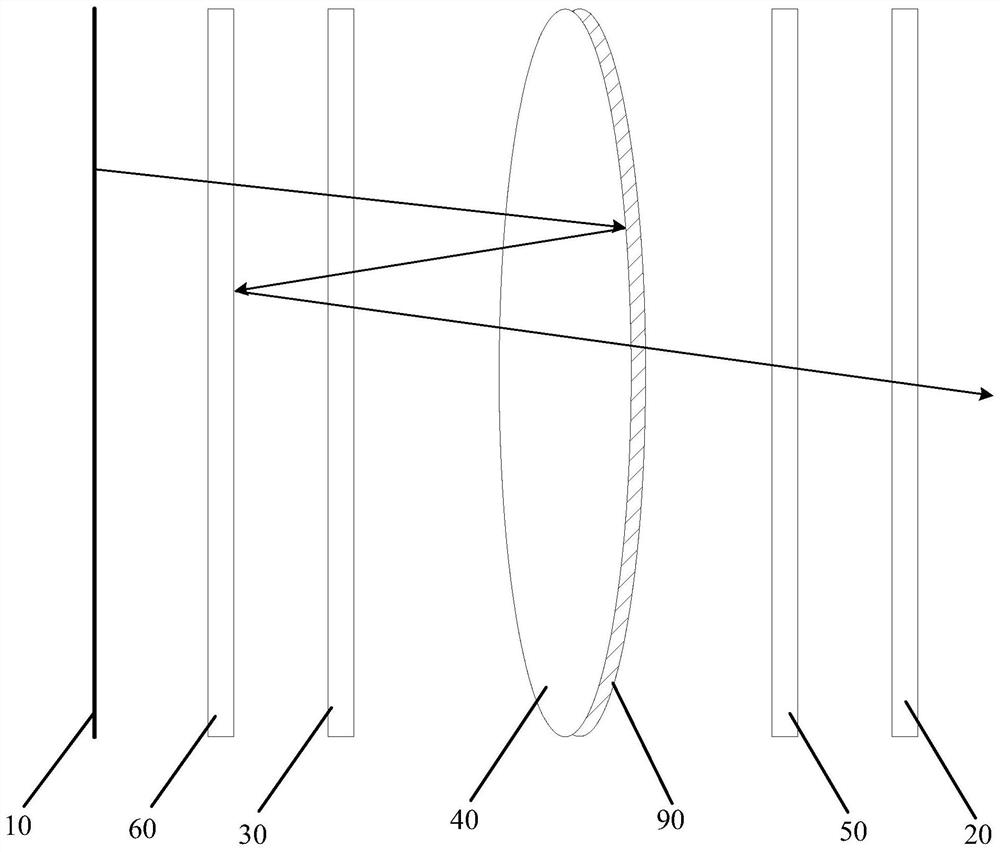

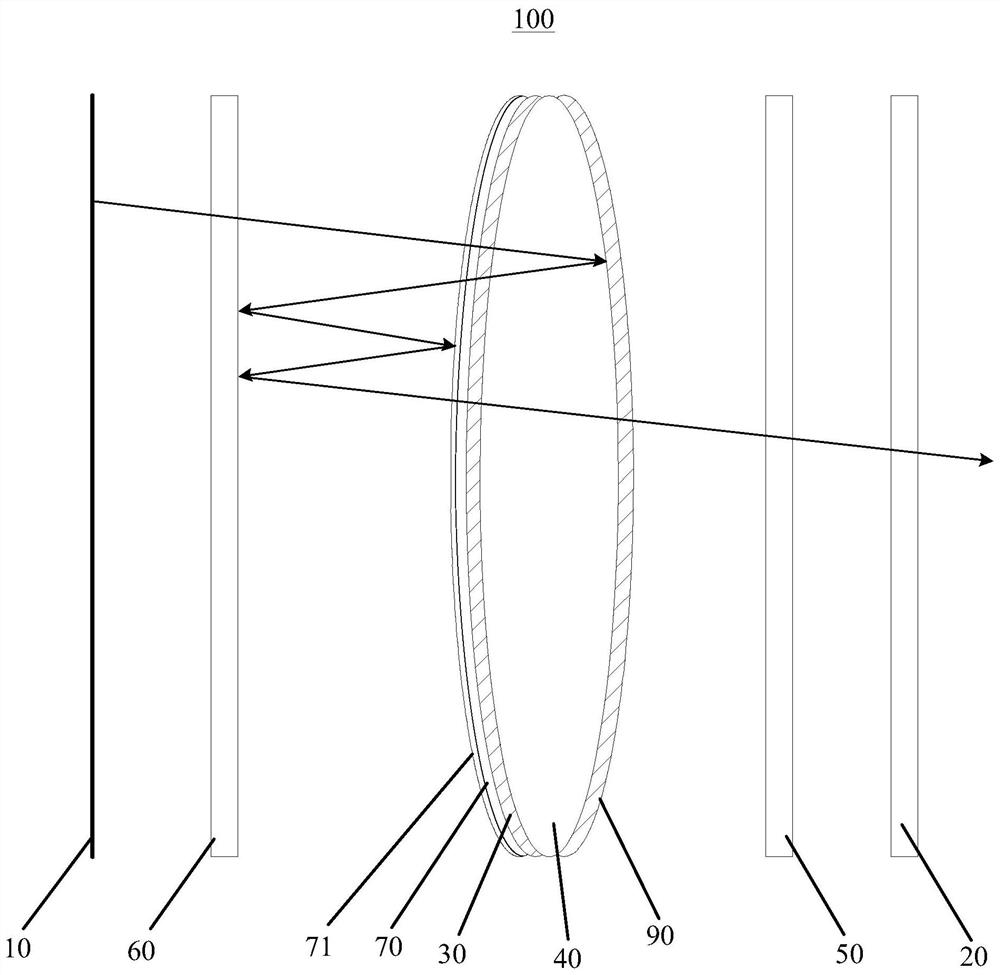

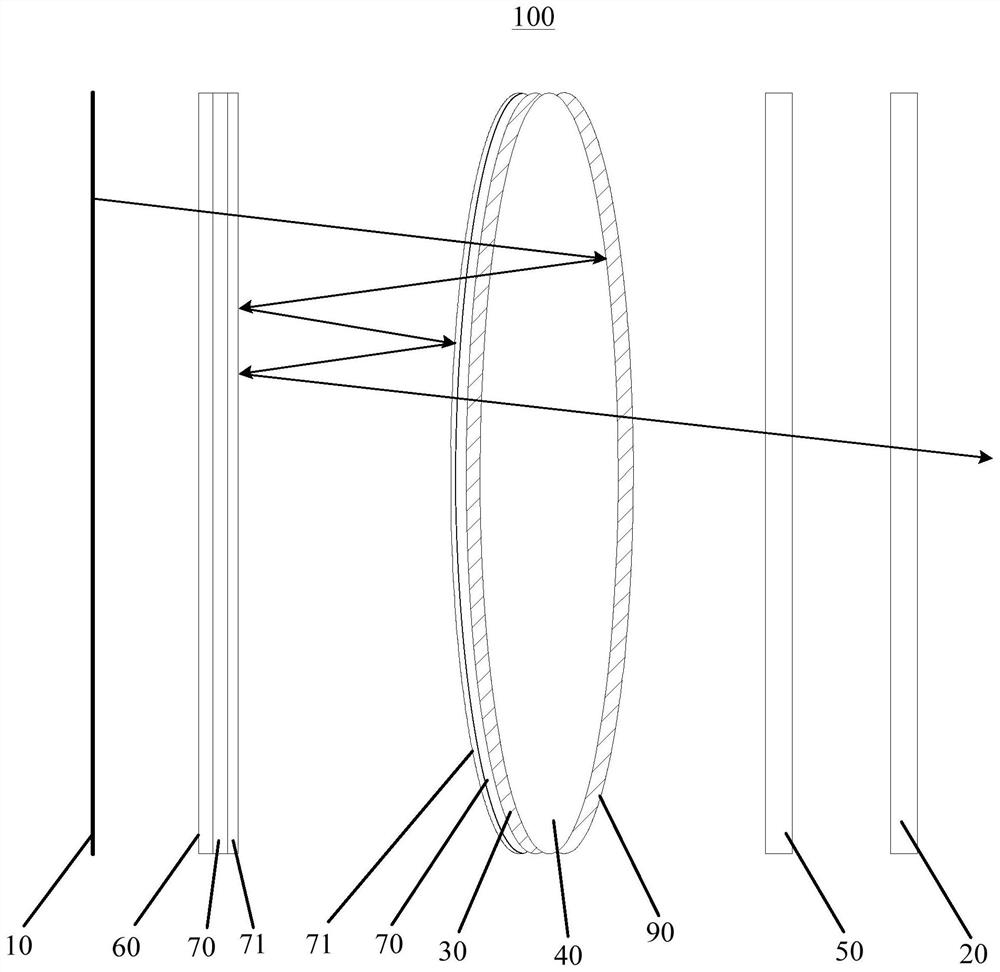

Display optical system for reducing ghosting and head-mounted display device

InactiveCN112305762AAchieve foldingReduce ghostingCoatingsOptical elementsImaging qualityBeam splitting

The invention discloses a display optical system for reducing ghosting and a head-mounted display device. The display optical system for reducing ghosting comprises a display screen, a polarization beam splitting element, a first polarization conversion element, a partial transmission and partial reflection element, a second polarization conversion element and a polarization piece which are arranged in sequence; the display optical system further comprises a lens arranged on the side, facing the display screen, of the partial transmission and partial reflection element; the lens is attached tothe first polarization conversion element, and / or the lens is attached to the polarization light splitting element; the first polarization conversion element and the polarization light splitting element are arranged at intervals, a substrate is arranged on the surface, exposed in the air, of the first polarization conversion element, and an antireflection film is arranged on the substrate. According to the technical scheme, ghosting caused by Fresnel reflection generated when interfaces of different elements in a folded light path are exposed in air can be reduced, so that the image quality of the display optical system is improved, and the display optical system has the characteristic of light weight.

Owner:SHENZHEN HUYNEW TECH CO LTD

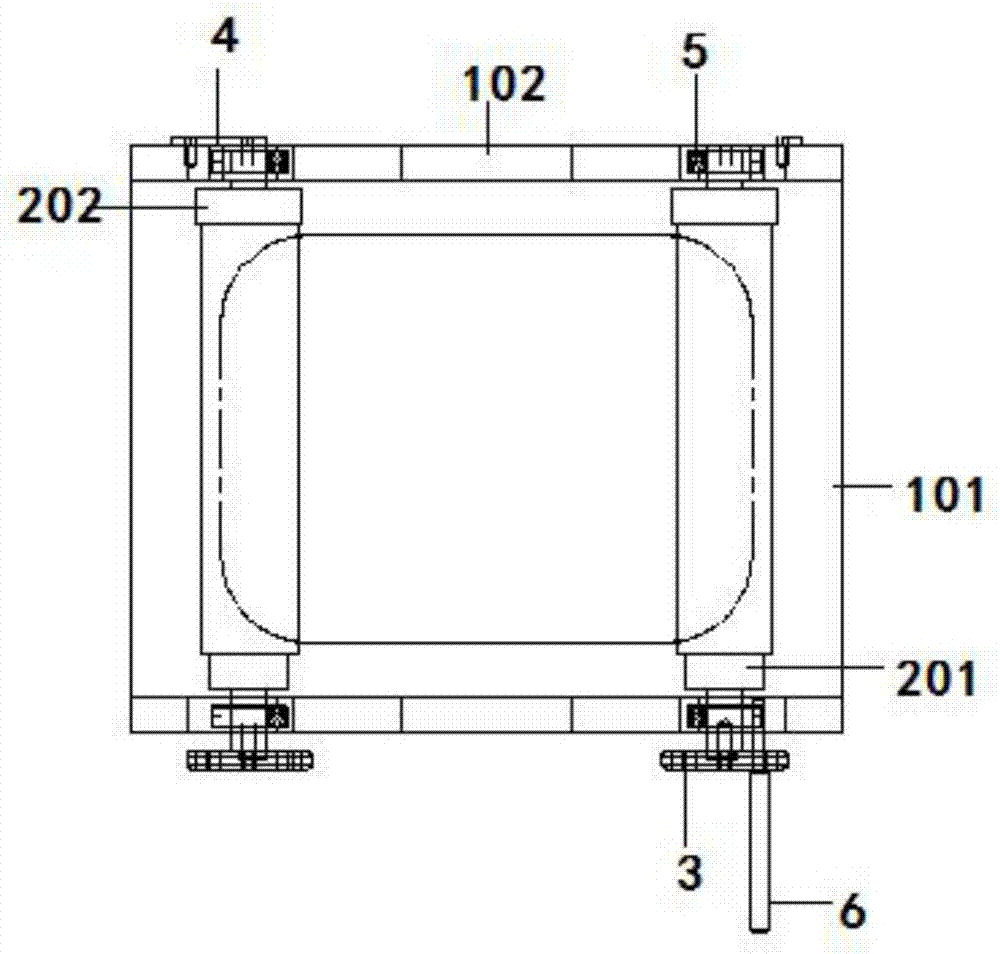

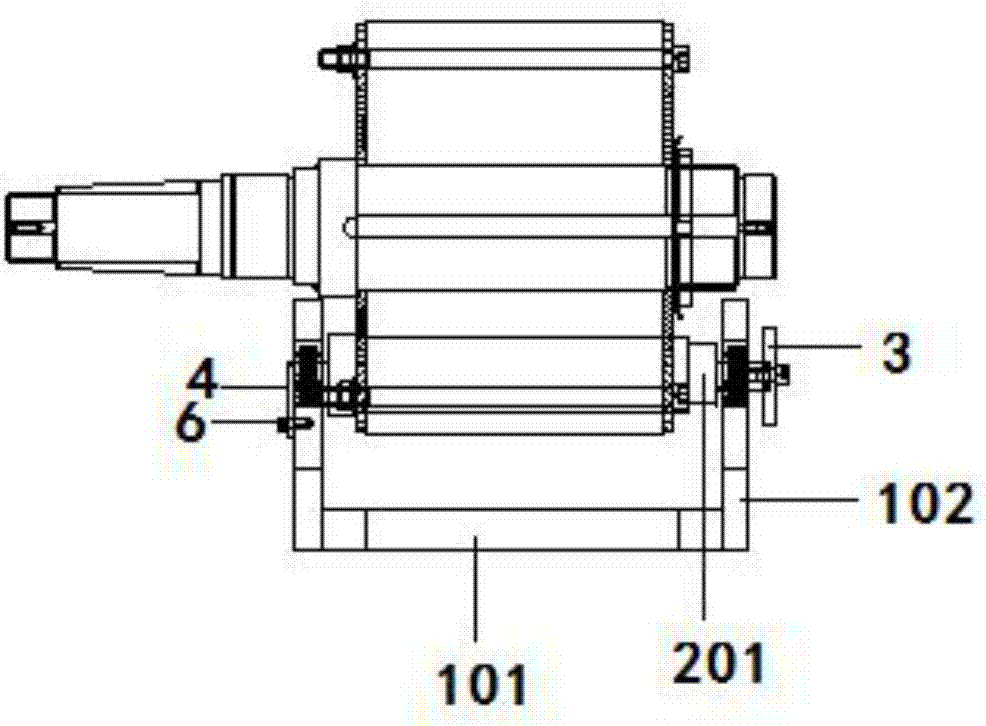

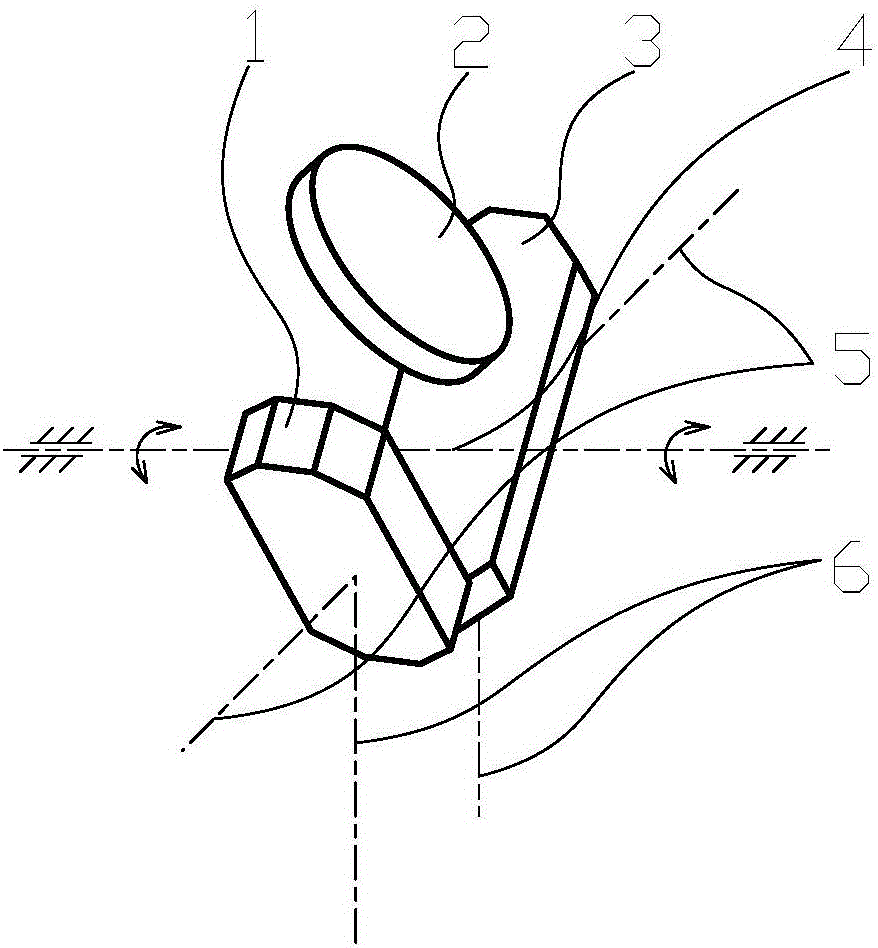

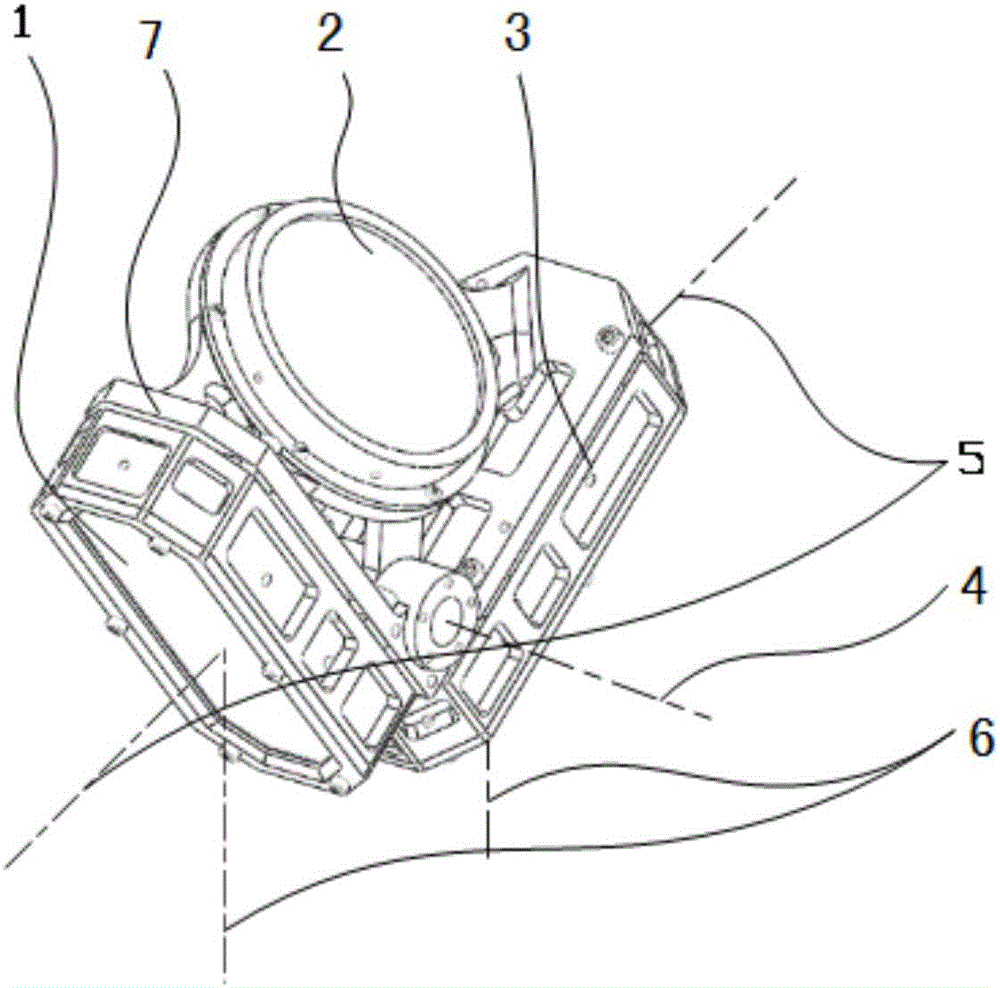

Pendulum sweeping and in-flight calibration assembly for double spectrum imagers

ActiveCN106840402AGuaranteed synchronicityMeet the needs of on-orbit calibrationRadiation pyrometrySpectrum investigationPendulumCalibration function

The invention discloses a pendulum sweeping and in-flight calibration assembly for double spectrum imagers. The assembly comprises two reflection pendulum mirrors which are arranged in a V shape and an aslant arranged calibration reflection mirror, the relative location between the two pendulum mirrors and the reflection mirror is fixed, and the two pendulum mirrors and the reflection mirror can rotate at plus or minus 90 degrees along a rotary shaft and are used for achieving a high-precision synchronous pendulum sweeping and in-flight calibration function of the double spectrum imagers. The pendulum sweeping and in-flight calibration assembly for the double spectrum imagers is compact in structure and easy to install and adjust because only one motion component is needed, and meets the requirements for weight, volume and reliability of board equipment well.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

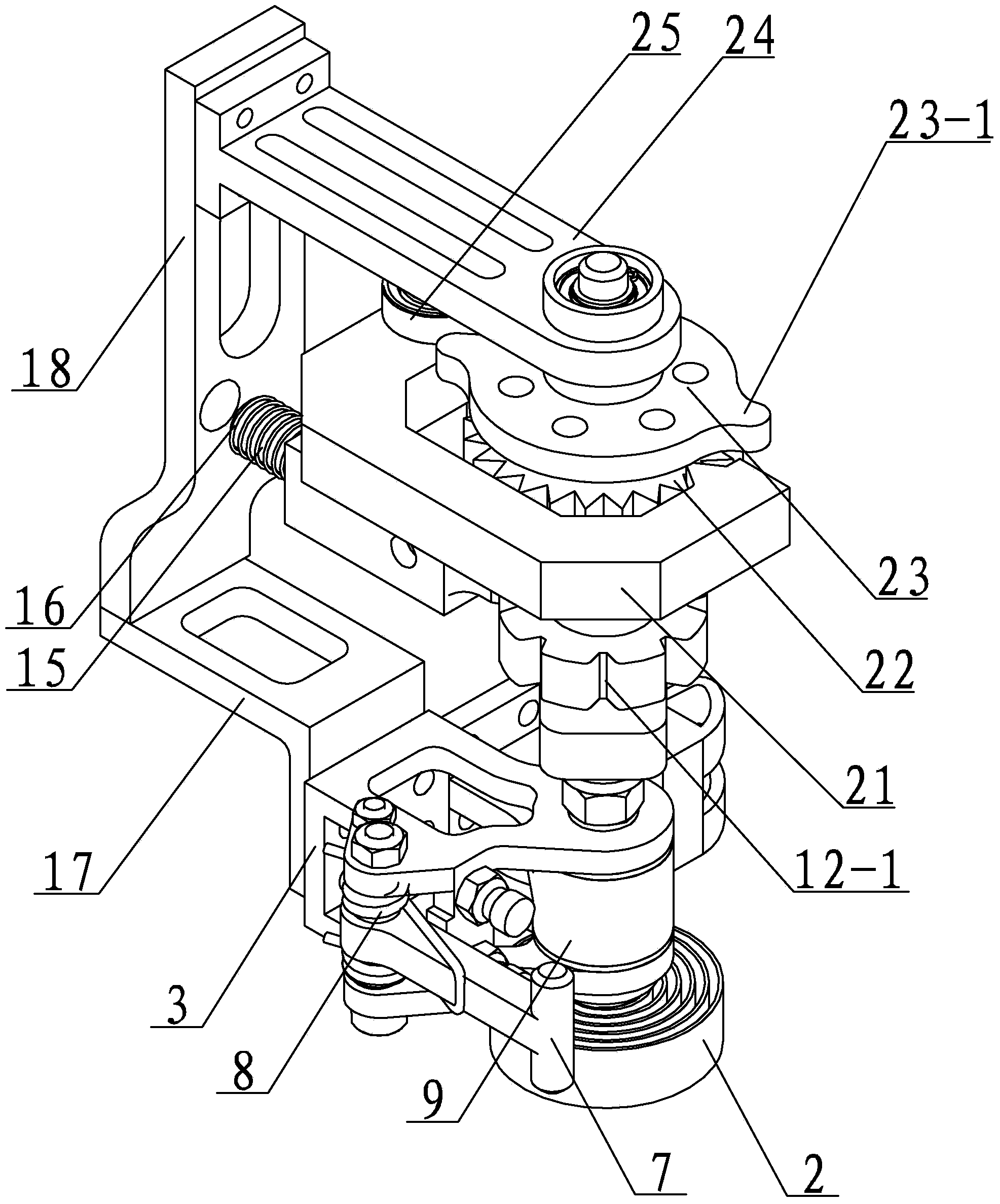

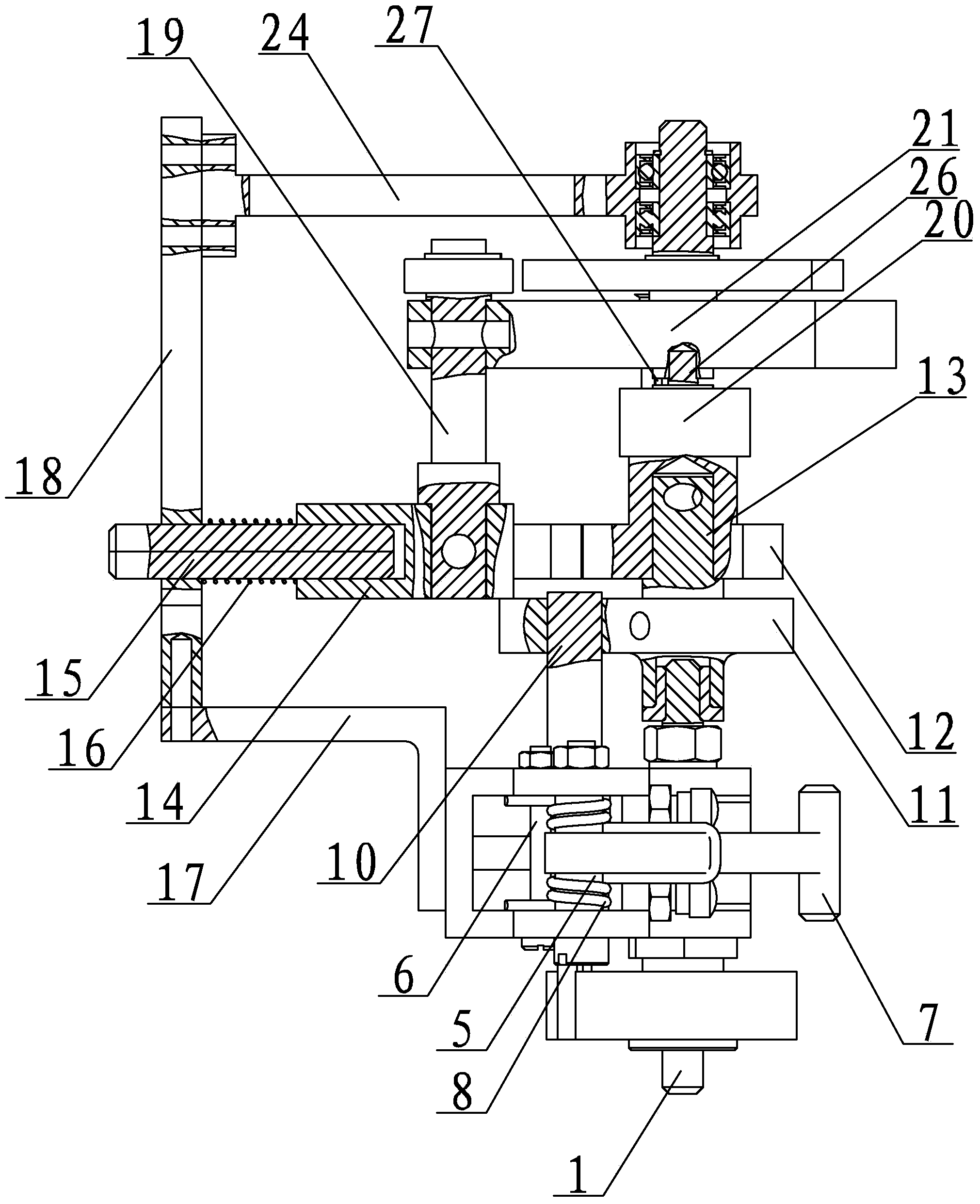

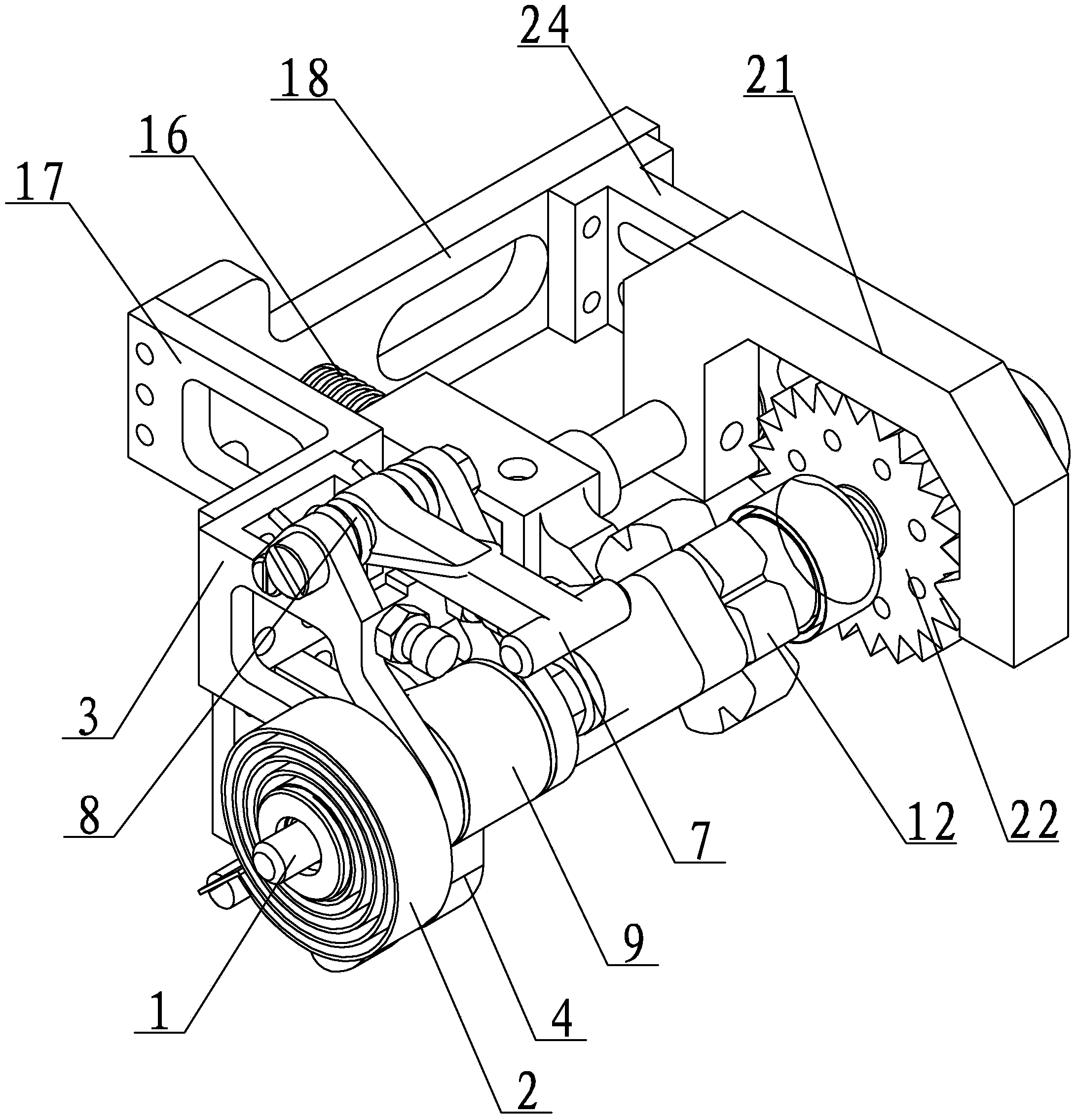

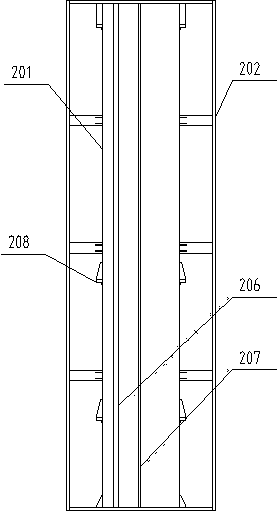

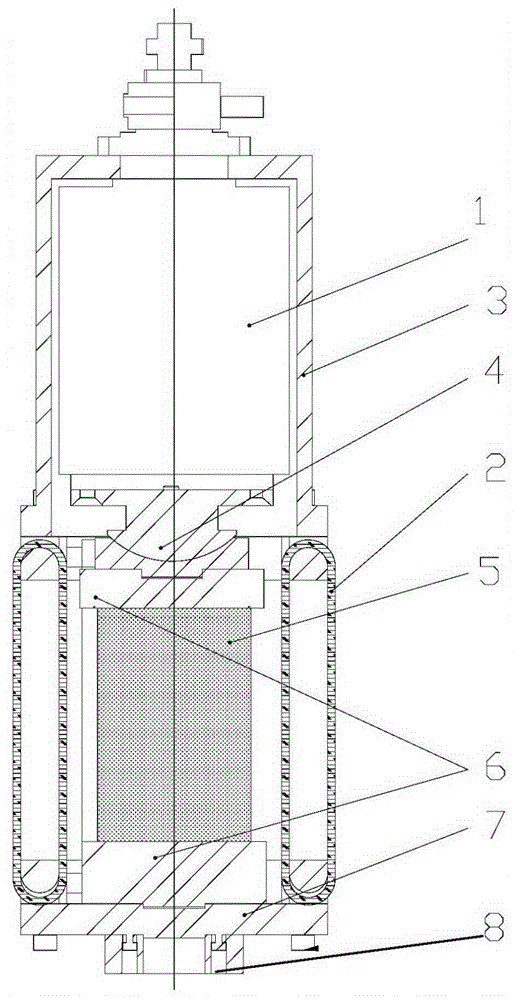

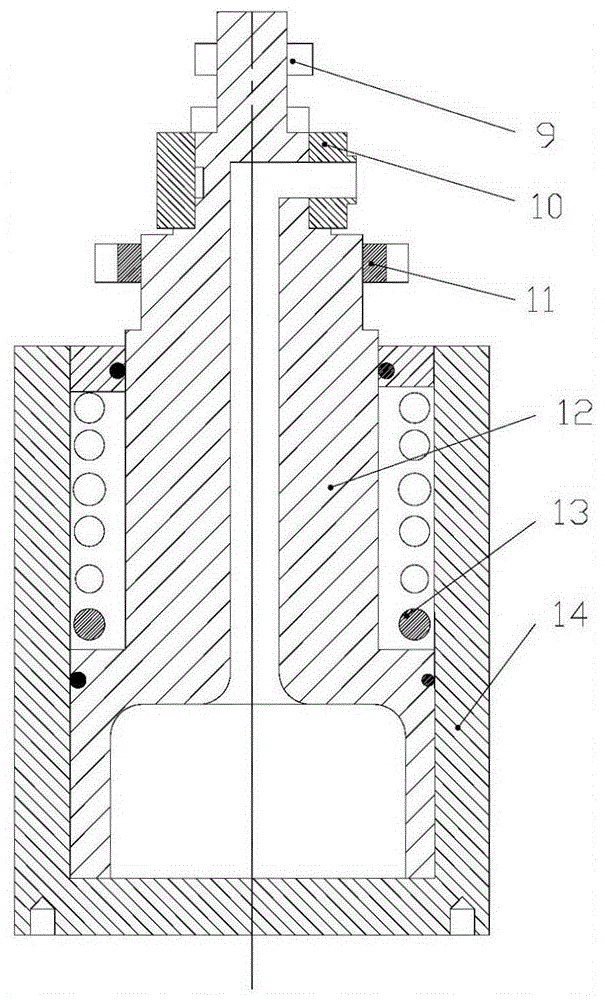

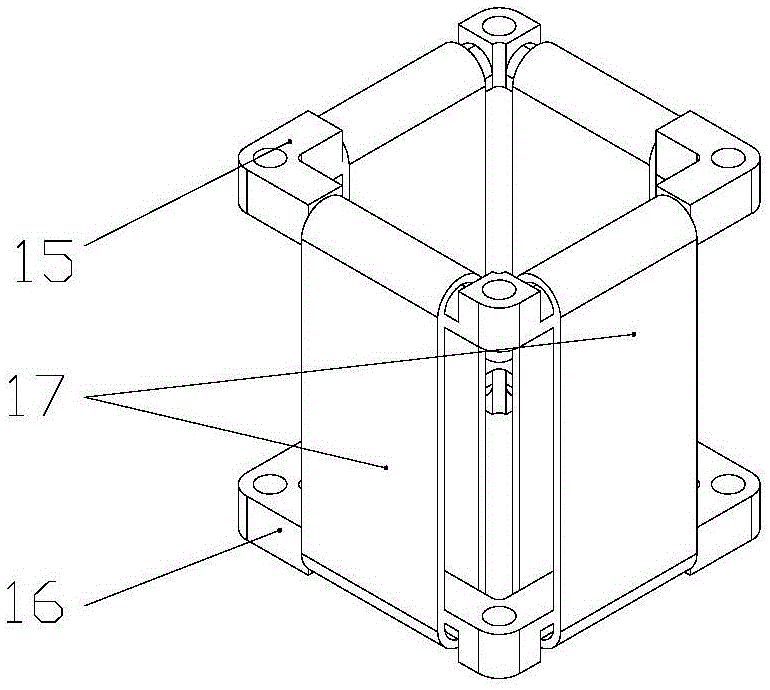

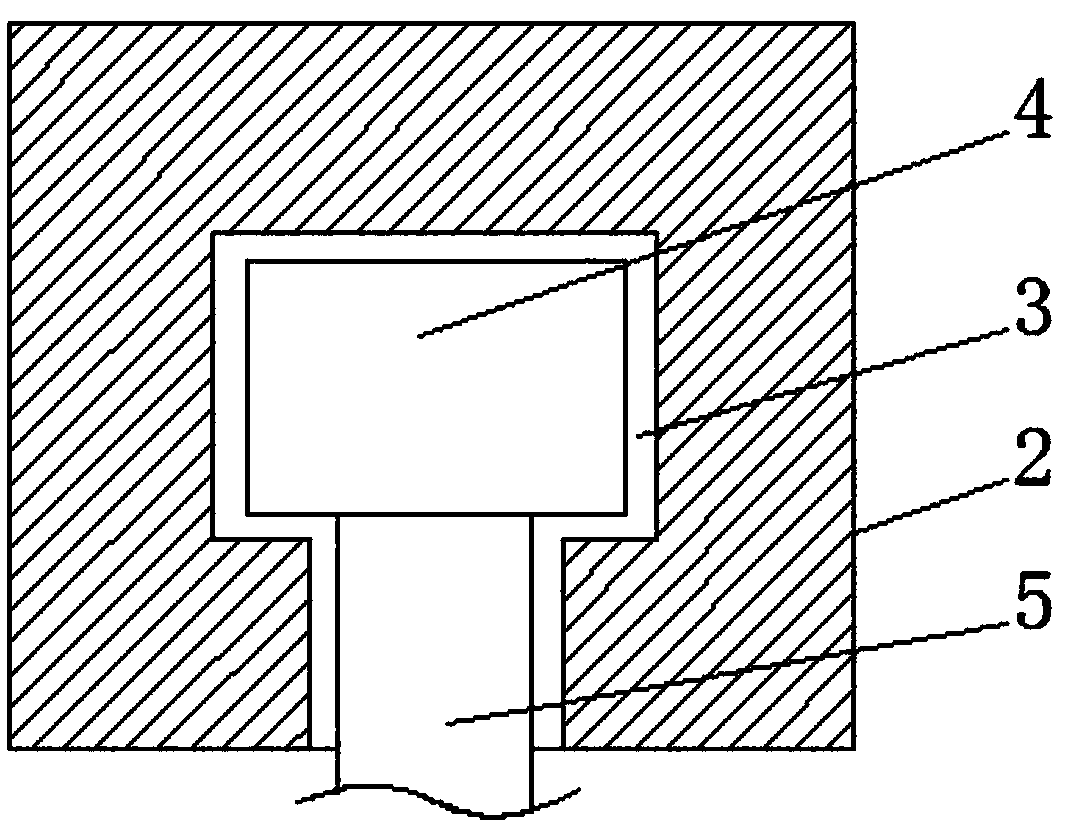

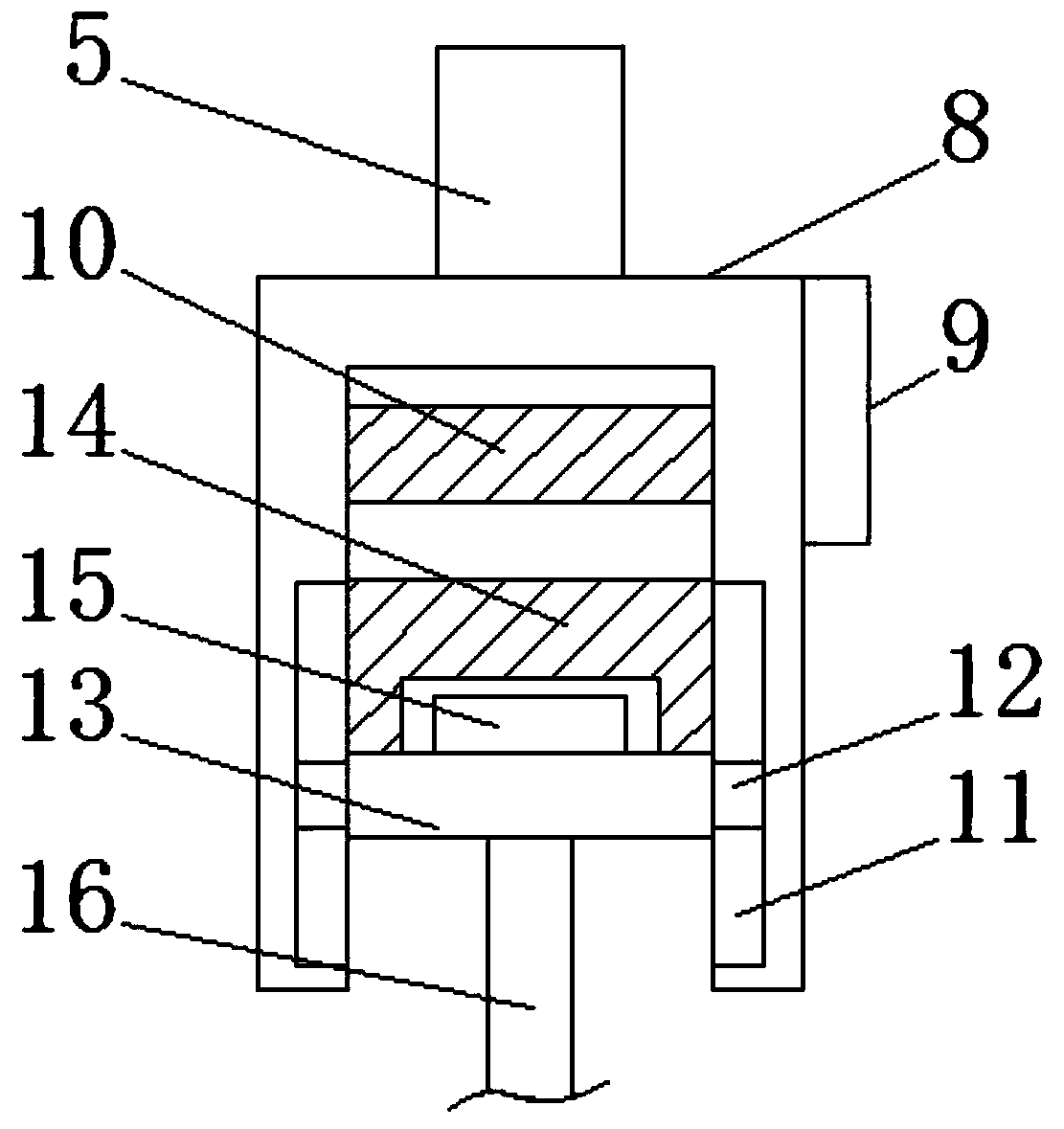

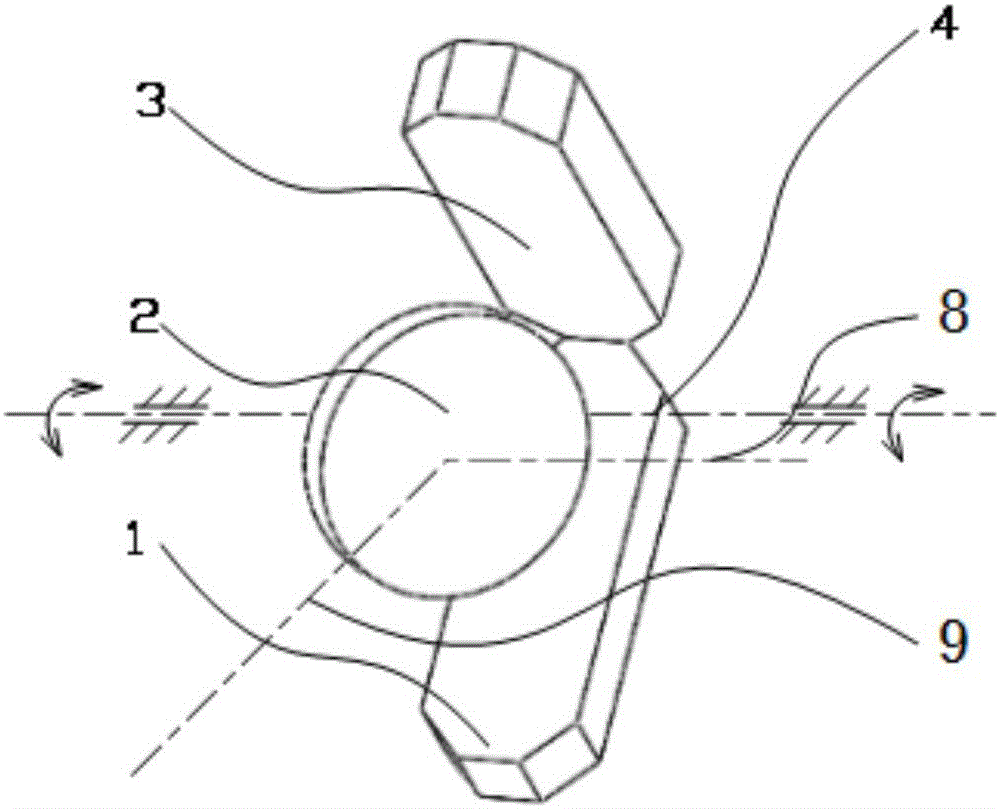

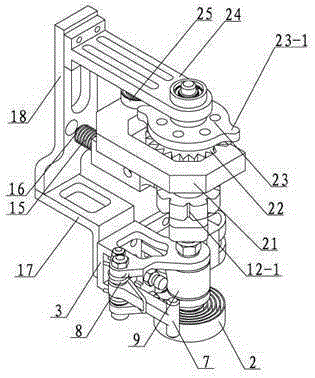

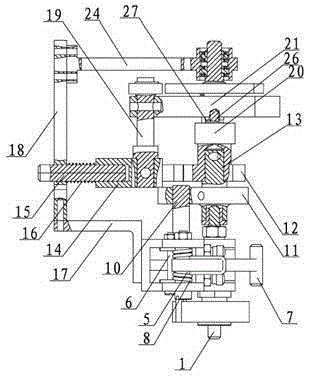

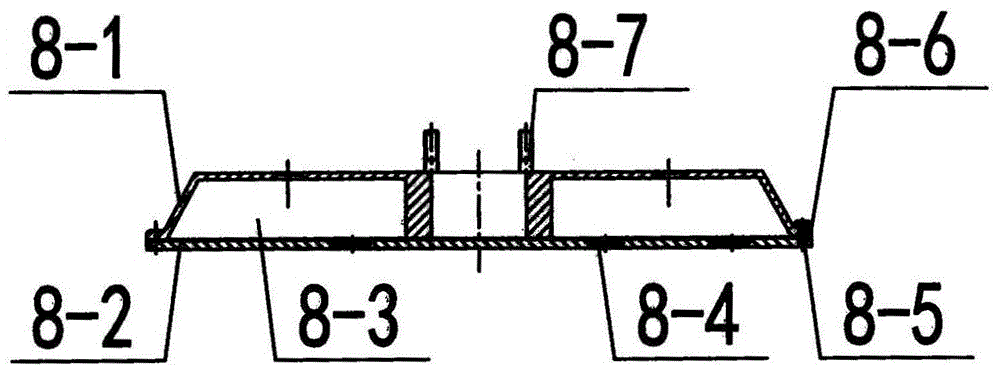

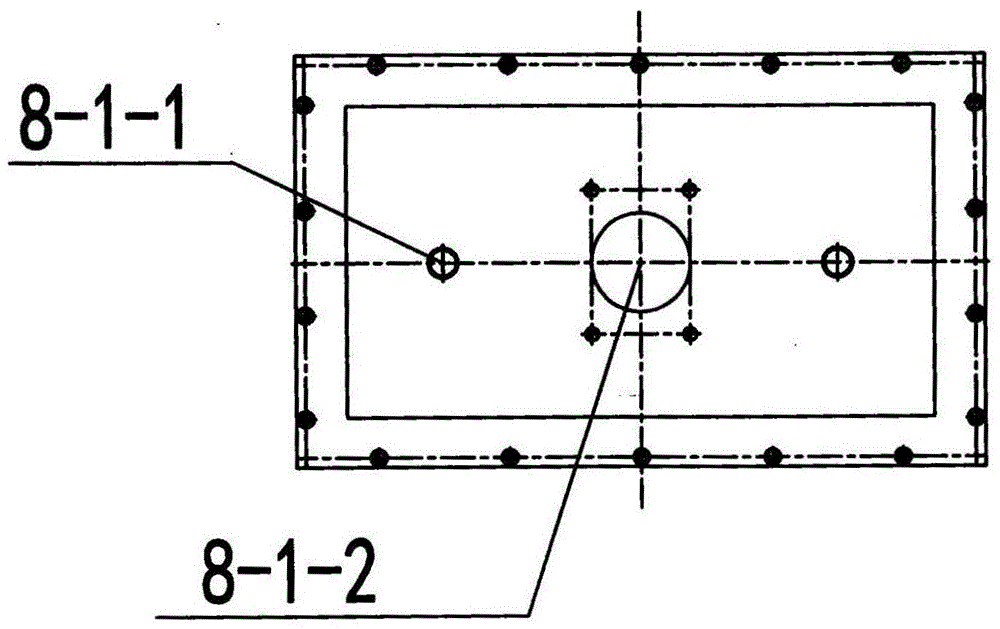

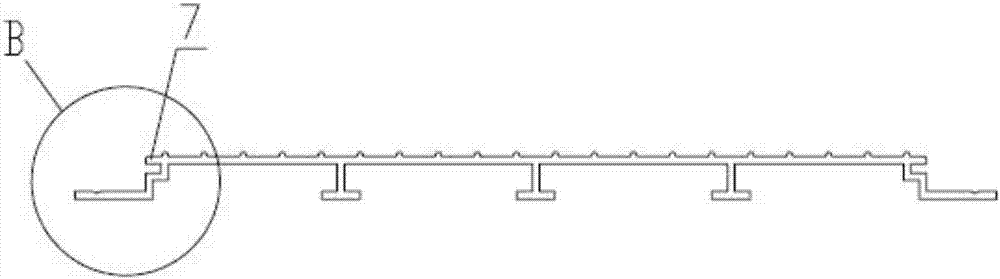

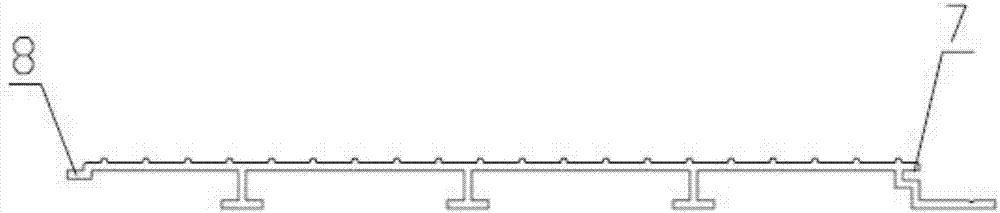

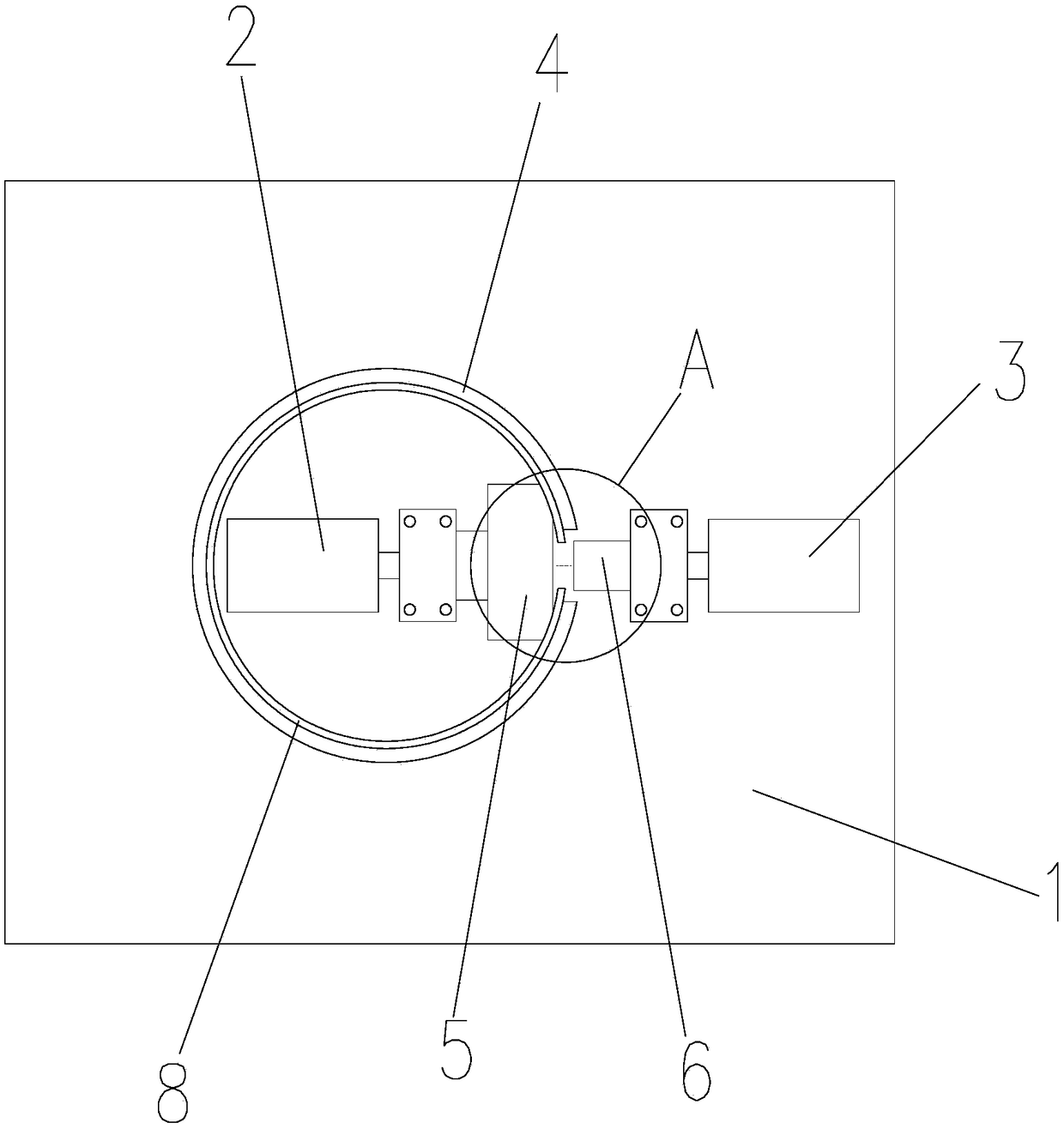

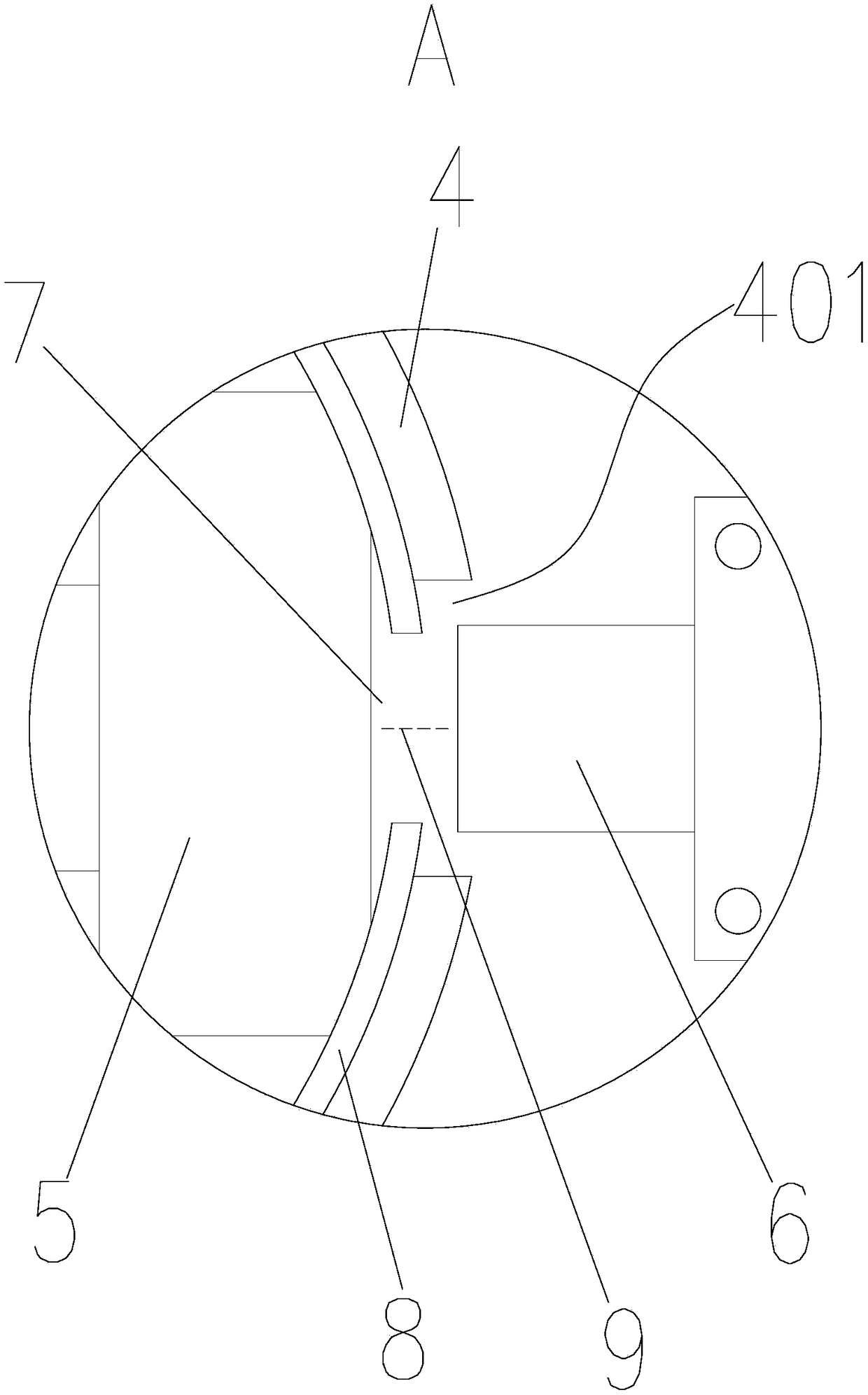

Intermittent type spring unfolding hinge speed reduction mechanism

InactiveCN106609793ALocking shock reductionMeet weight requirementsPivotal connectionsIntermittent motionContinuous rotation

The invention relates to a hinge speed reduction mechanism, in particular to an intermittent type spring unfolding hinge speed reduction mechanism, and aims to solve the problem that locking impact is easily caused by extremely high unfolding speed as the tail end is unfolded by an existing solar wing unfolding hinge driven by a volute spiral spring. The intermittent type spring unfolding hinge speed reduction mechanism comprises a hinge assembly, an adaptor assembly, a locking assembly and a passive automatic unlocking mechanism, wherein the adaptor assembly, the locking assembly and the passive automatic unlocking mechanism are arranged at the upper end of the hinge assembly in sequence from bottom to top. The invention provides the intermittent type spring unfolding hinge speed reduction mechanism which enables the continuous rotation of a hinge without the speed reduction mechanism to be converted into the following motions: rotation, locking, unlocking and rotation on the premise of not changing the existing unfolding hinge structure. The hinge does not rotate within a transient locking time period, so that the original continuous rotation of the hinge is converted into an intermittent motion, and the locking impact force is reduced. The intermittent type spring unfolding hinge speed reduction mechanism is used for speed reduction of the solar wing unfolding hinge.

Owner:崔立晶

Method and special device for implementing tobacco leaf product online cooling in threshing and re-drying production

ActiveCN106628334AReduce air pressureMeet weight requirementsTobacco preparationPackaging by pressurising/gasifyingVacuum pumpingMoisture condensation

A method and special device for implementing tobacco leaf product online cooling in threshing and re-drying production are characterized in that a plastic sleeve film packaging box with cigarette blanks is pre-pressed and re-weighed, and enters to a packaging process; vacuum-pumping treatment is performed on the cigarette blanks in the plastic sleeve film packaging box while packaging, the temperature of a cigarette packet is decreased, and a gap between the cigarette blanks and the plastic sleeve film is removed; when the system performs vacuum pumping and a preset temperature is reached, a temperature sensor feeds information back to the system, the system stops vacuum pumping, a pressing head raises, and the cigarette blanks move along a roller channel and enter a sealing process. The packaging machine has a vacuum pumping function, the air pressure in the cigarette blanks is reduced through vacuum pumping, the water boiling point is decreased, water in the cigarette blanks are evaporated, heat is brought away, the products are cooled, and then a packet cooling process can be canceled. The method can balance product water; the air pressure in the sleeve film is reduced through vacuum pumping; the gap between the cigarette blanks and the plastic sleeve film is automatically eliminated; moisture condensation on the inner wall of the sleeve film can be avoided; mildew of the cigarette blanks can be prevented; and the safety of the products can be ensured in storage and transportation.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

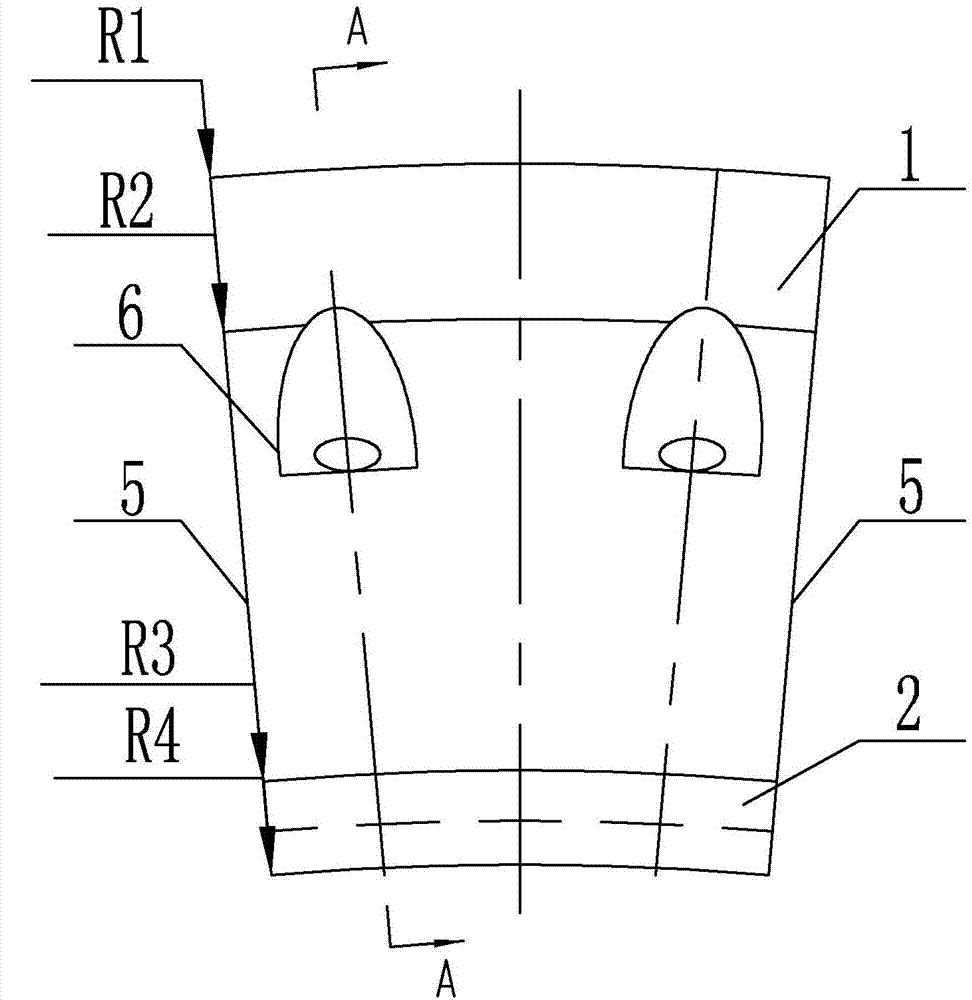

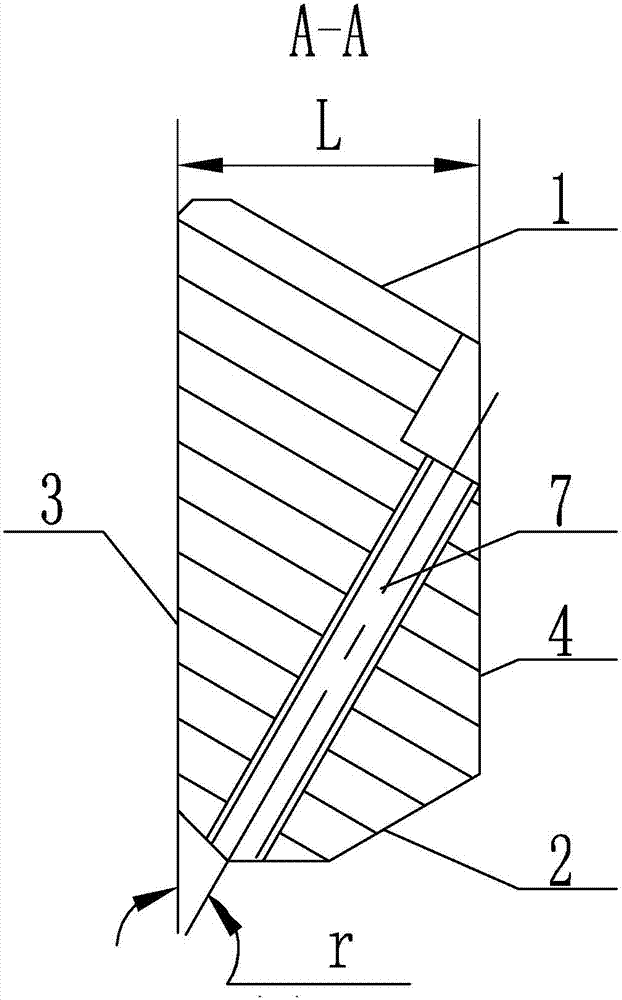

Counter balance for turbine high-speed dynamic balance

InactiveCN103592080AFast installationMeet weight requirementsStatic/dynamic balance measurementDynamic balanceEngineering

The invention relates to a counter balance for turbine high-speed dynamic balance. The counter balance for turbine high-speed dynamic balance resolves the problems that a process counter balance in the prior art needs on-site assembly and grinding when installed, wastes time and is low in work efficiency, the weight of the counter balance is too small, and balance of a rotor with a large initial unbalance amount can not achieved. The counter balance for turbine high-speed dynamic balance is provided with six surfaces, namely a top surface, a bottom surface, a front surface, a back surface and two lateral surfaces, wherein the top surface is an inclined curved surface which protrudes upwards, the bottom surface is an inclined curved surface which is concaved downwards, the front surface, the back surface and the lateral surfaces are flat surfaces, two notches are machined in the intersecting position of the top surface and the back surface, threaded holes are machined in the intersecting positions of the front surface and the bottom surface along the bottoms of the notches, the radius of the arc at the top of the top surface is R1, the radius of the arc at the bottom of the top surface is R2, the radius of the arc at the top of the bottom surface is R3, the radius of the arc at the bottom of the bottom surface is R4, and the distance between the front surface and the back surface is L. The counter balance for turbine high-speed dynamic balance is applied to turbine high-speed dynamic balance experiments.

Owner:HARBIN TURBINE

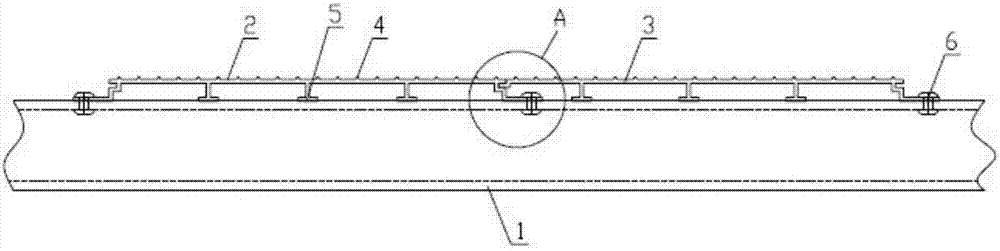

All-aluminum van vehicle ribbed floor and manufacturing and mounting method thereof

PendingCN106926906AObvious weight loss effectMeet weight requirementsSuperstructure subunitsSuperstructure connectionsAluminium alloyArtificial aging

The invention discloses an all-aluminum van vehicle ribbed floor and a manufacturing and mounting method thereof. The all-aluminum van vehicle ribbed floor is characterized in that the ribbed floor comprises a symmetrical floor unit and an asymmetrical floor unit which are fixedly connected with a cross beam of a compartment chassis through rivets correspondingly. The bottoms of the symmetrical floor unit and the asymmetrical floor unit are each provided with a plurality of reinforcing ribs. The two ends of the symmetrical floor unit are provided with inserting mechanisms. The manufacturing method of the ribbed floor comprises the steps that aluminum alloy rods are subjected to extrusion forming through an extruder; the aluminum alloy rods are then subjected to artificial aging and machining to manufacture the ribbed floor units; and then the ribbed floor units are spliced and mounted. According to the all-aluminum van vehicle ribbed floor and the manufacturing and mounting method thereof, structural design and the profile section of the compartment floor are optimized to ensure that the compartment floor meets the loading capacity and safety performance requirements of a vehicle, energy consumption reduction is achieved, and energy is saved; and the compartment floor is resistant to water, skid and corrosion and free of maintenance.

Owner:ALNAN ALUMINIUM CO LTD +2

Tooling for machining internal sinking amount of piston ring and using method thereof

ActiveCN108772503APrecise inset sizeQuality improvementMetal-working apparatusPiston ringEngineering

The invention belongs to the field of tooling fixtures, and particularly relates to a tooling for machining internal sinking amount of a piston ring and a using method thereof. The tooling comprises acontrol console, and a clamping oil cylinder, a working feed cylinder and a positioning ring gauge are fixed on the control console; the clamping oil cylinder is disposed on the inner side of the positioning ring gauge, the working feed oil cylinder is disposed on the outer side of the positioning ring gauge, and a top pressure notch is formed in the circumference surface of the positioning ringgauge; an inner top block is fixed to the extension end of a piston of the clamping oil cylinder, and an outer top block is fixed to the extension end of a piston of the working feed oil cylinder; thewidth of the inner top block, the length of the top pressure notch and the width of the outer top block are successively decreased, and an internal sinking gap is formed between the cambered surfacesof the inner top block and the top pressure notch in the top pressure state; and the internal sinking gap is greater than the radial direction thickness of the piston ring. The tooling has the beneficial effects that the tooling can be used for manufacturing and forming by cold bending, and the piston ring with a certain internal sinking amount is obtained, time and labor are saved, automation level is high, and production efficiency is improved.

Owner:CRRC CHANGZHOU DIESEL ENGINE COMPONENTS CO LTD +1

High-impact high-density PC/ABS alloy and preparation method thereof

InactiveCN104610720AOvercome the impact of reduced impact toughnessMaintain processing fluidityAntioxidantAlloy

The invention relates to a high-impact high-density PC / ABS alloy and a preparation method thereof. The PC / ABS alloy is prepared from the following raw materials in percentage by weight: 45-55 percent of polycarbonate, 15-30 percent of an acrylonitrile butadiene styrene copolymer, 3-5 percent of an ABS maleic anhydride-grafted polymer, 3-5 percent of a methyl methacrylate-styrene-butadiene copolymer, 15-25 percent of pigment level barium sulfate, 0.3-0.8 percent of a lubricating agent and 0.2-0.4 percent of an antioxidant, wherein the granularity of the pigment level barium sulfate is 8000-12000 meshes. The alloy provided by the invention has good impact toughness and processing fluidity and also has high density, and the requirements on high impact resistance and high density of PC / ABS alloy materials in certain special parts can be met.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

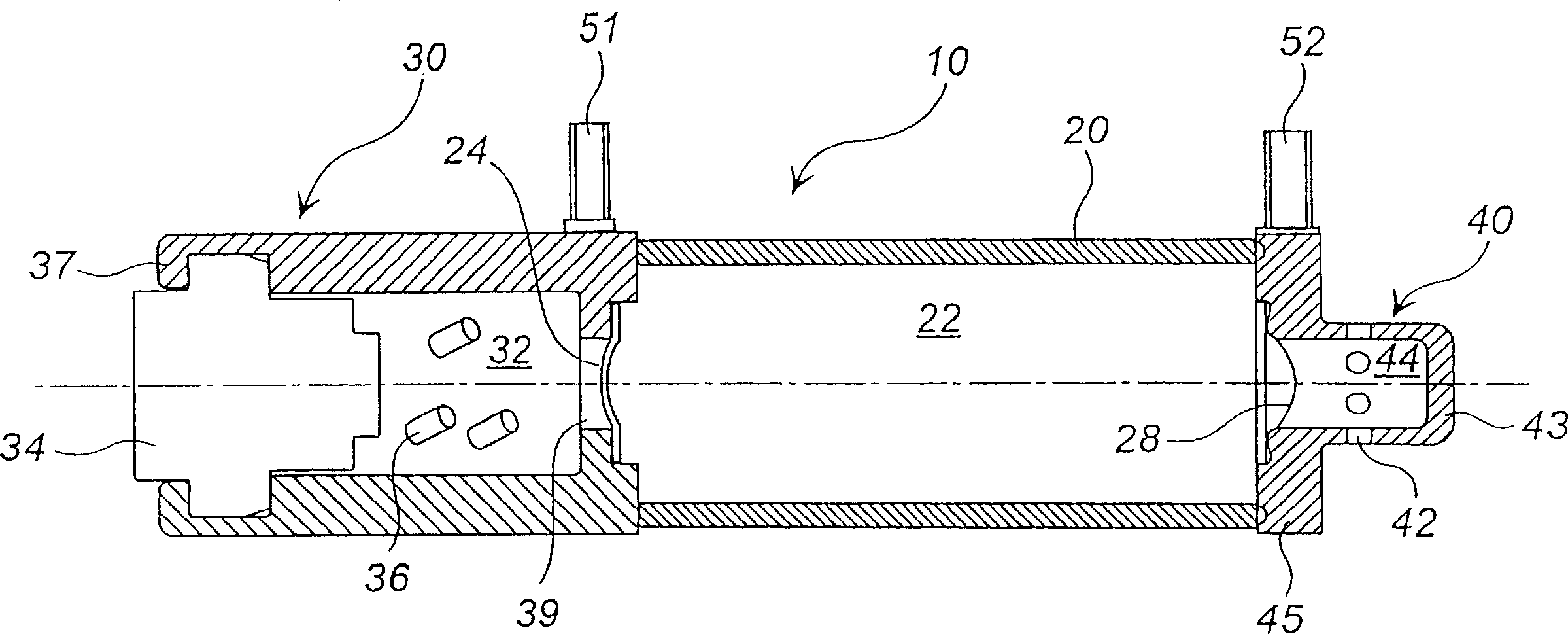

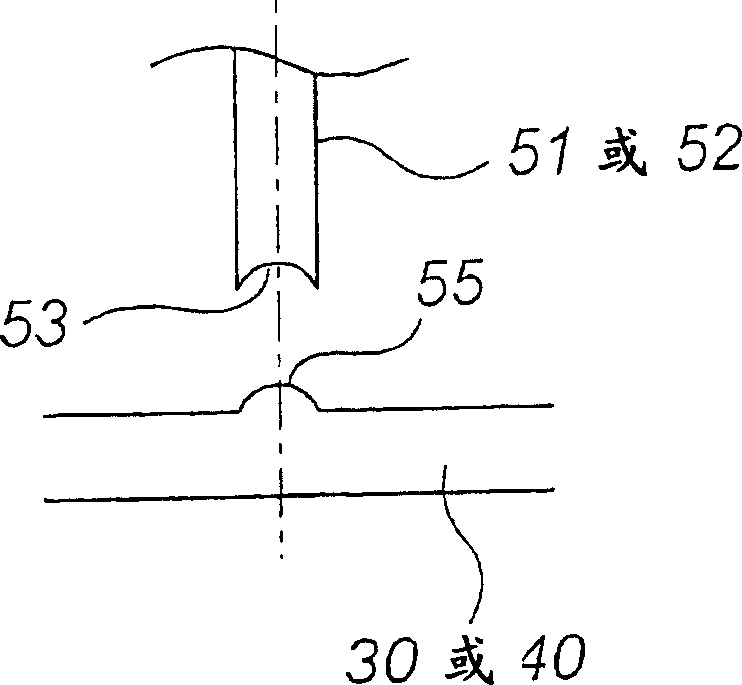

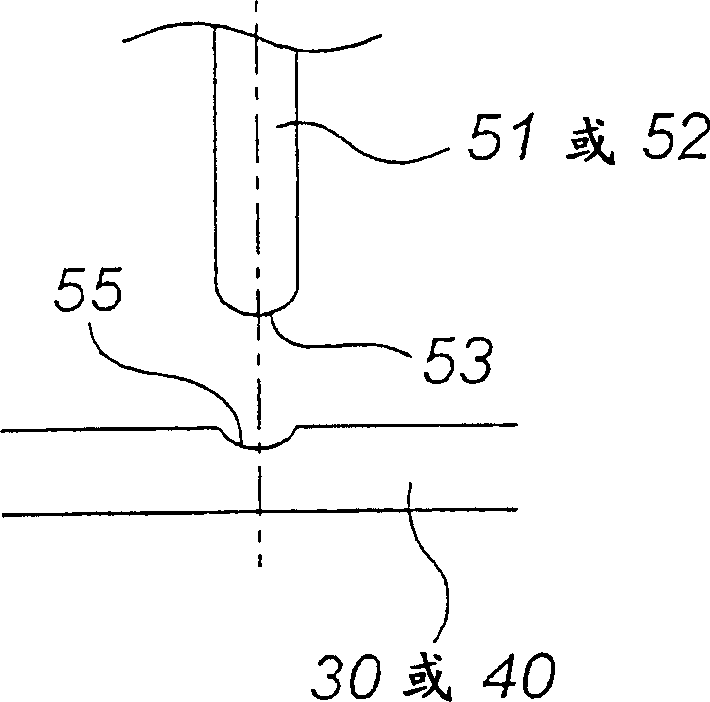

Inflator

ActiveCN1914068AGreat penetration depthImprove the fixing strengthPedestrian/occupant safety arrangementElectrical and Electronics engineeringEngineering

Stud bolts 51, 52 are fixed by welding to the side faces of a first closure 30 and a second closure 40, which are connected to a cylindrical housing 20. When connecting a gas introduction port of the air bag to a diffuser portion 43, the stud bolts 51, 52 do not cause an obstruction, and hence the attachability of an inflator 10 to a module case using the stud bolts 51, 52 is not impaired.

Owner:DAICEL CHEM IND LTD

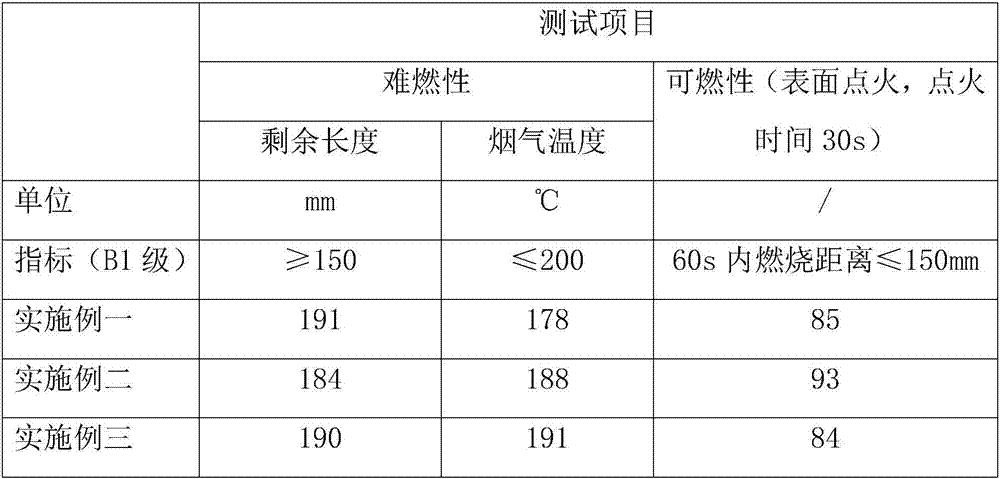

Environment-friendly flame-retardant polyurethane foam material for interior trim sealing strip of limo and preparation method thereof

The invention discloses an environment-friendly flame-retardant polyurethane foam material for an interior trim sealing strip of a limo and a preparation method thereof. The foam material comprises isocyanate and a mixture, wherein the ratio of the isocyanate to the mixture in parts by mass is: isocyanate: mixture=1:1.5; the mixture comprises the following raw materials in parts by weight: 55 to 65 parts of JTM polyether 4110, 23 to 28 parts of polyether 4110, 2.5 to 2.8 parts of a stabilizer, 9 to 13 parts of diethanolamine, 3 to 4 parts of a catalyst APM9, 35 to 38 parts of a flame retardant and 3.5 to 3.8 parts of water. The foam material prepared from the raw materials which are reasonably proportioned has efficient flame retardancy, and is safe and environmentally friendly, the interior trim sealing strip of the limo prepared from the foam material is high in fire safety and stability, and hazards to the environment and human bodies are avoided.

Owner:YANGZHONG TIANZHENG SYNTHETIC MATERIAL RES CENT

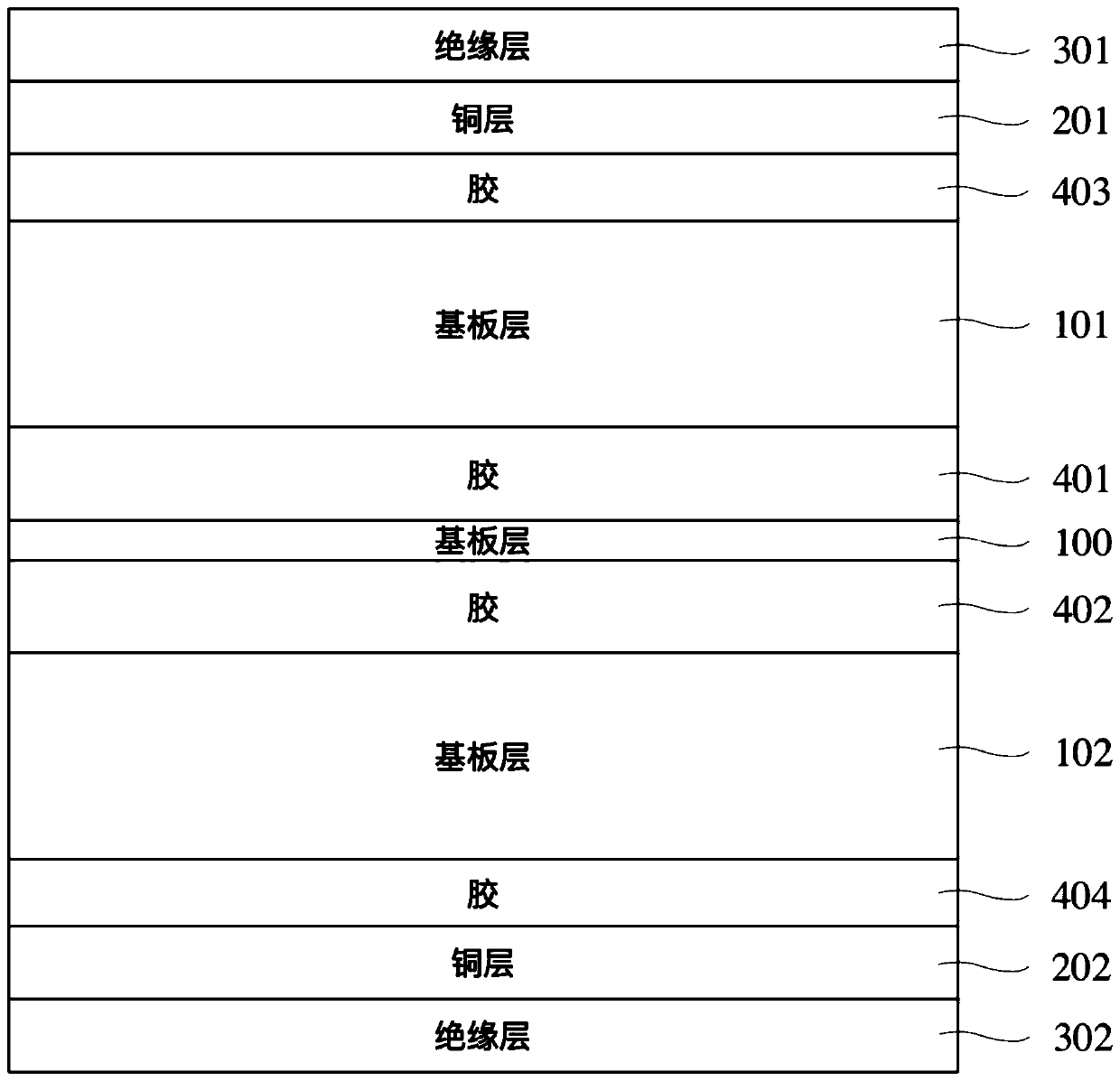

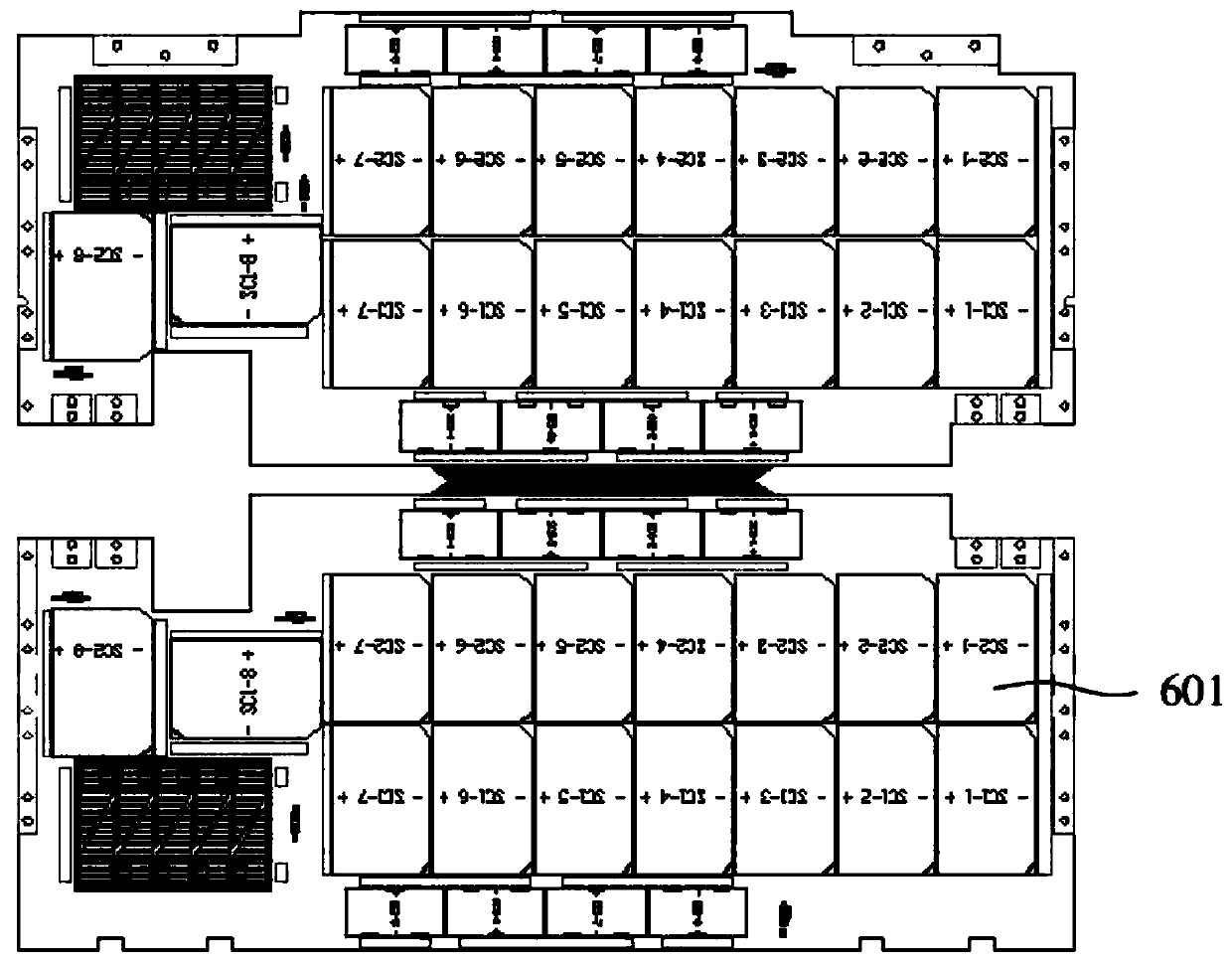

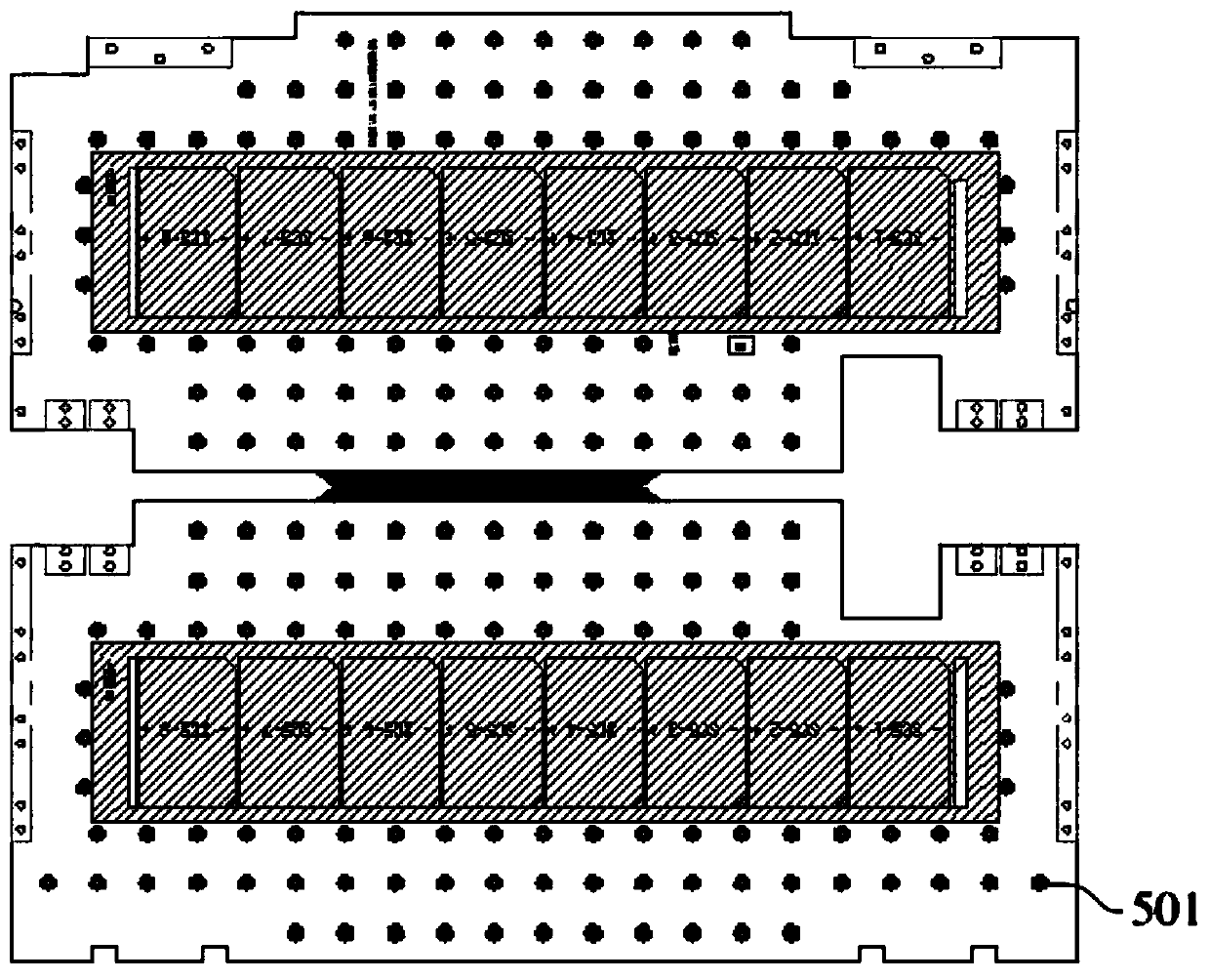

Overall isothermal solar cell array PCB substrate

PendingCN109714884AReduce the temperatureImprove efficiencyPrinted circuit detailsPhotovoltaic energy generationComposite substrateCopper

The invention provides an overall isothermal solar cell array PCB substrate, which comprises a composite substrate layer, copper layers covering the upper and lower surfaces of the composite substratelayer, and insulating layers covering the copper layers, wherein the composite substrate layer is formed by a combination of a multi-layer epoxy fiberglass fabric substrate and copper layers, and thefunction of the copper layers is heat conduction. The overall isothermal solar cell array PCB substrate has the beneficial effects of adopting a thermal control design method of integrating the copper layers inside the substrate, satisfying the requirements of a whole satellite on weight, reducing the temperature of solar cells so that the efficiency of converting optical energy into electric energy is increased, and satisfying requirements of the small satellite pair on energy.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

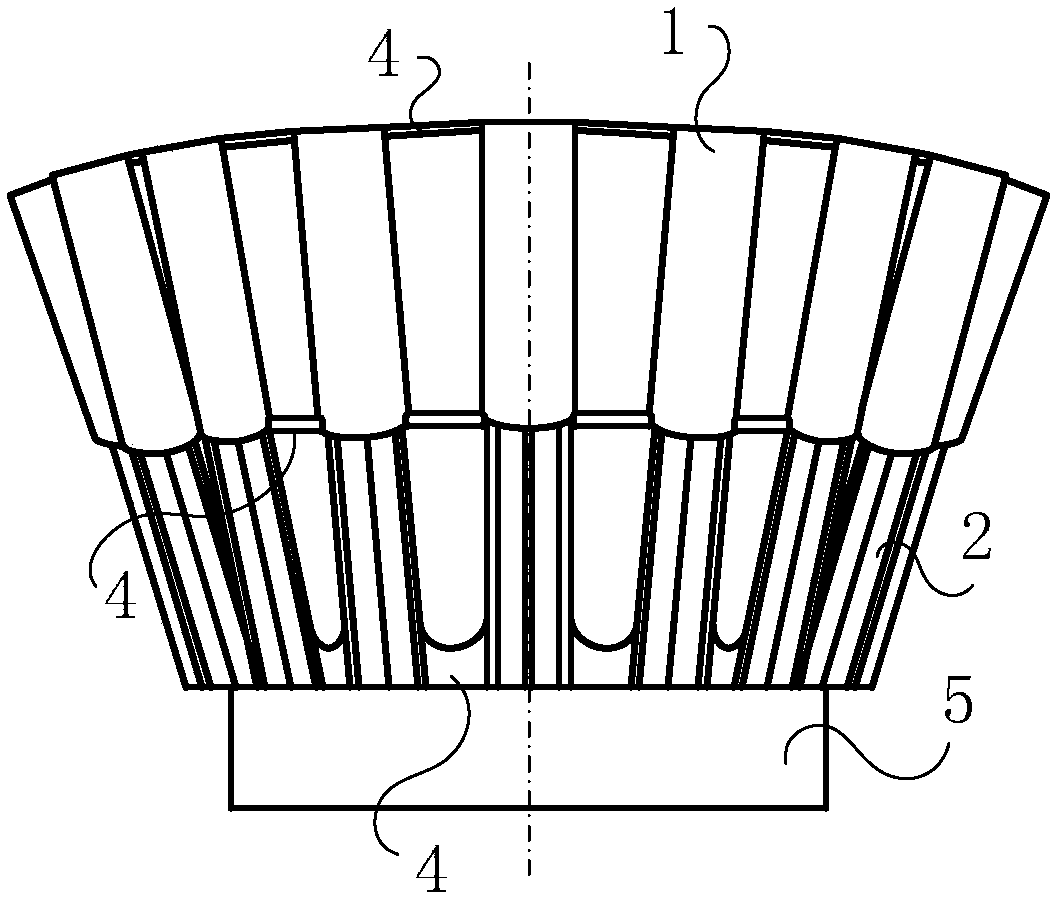

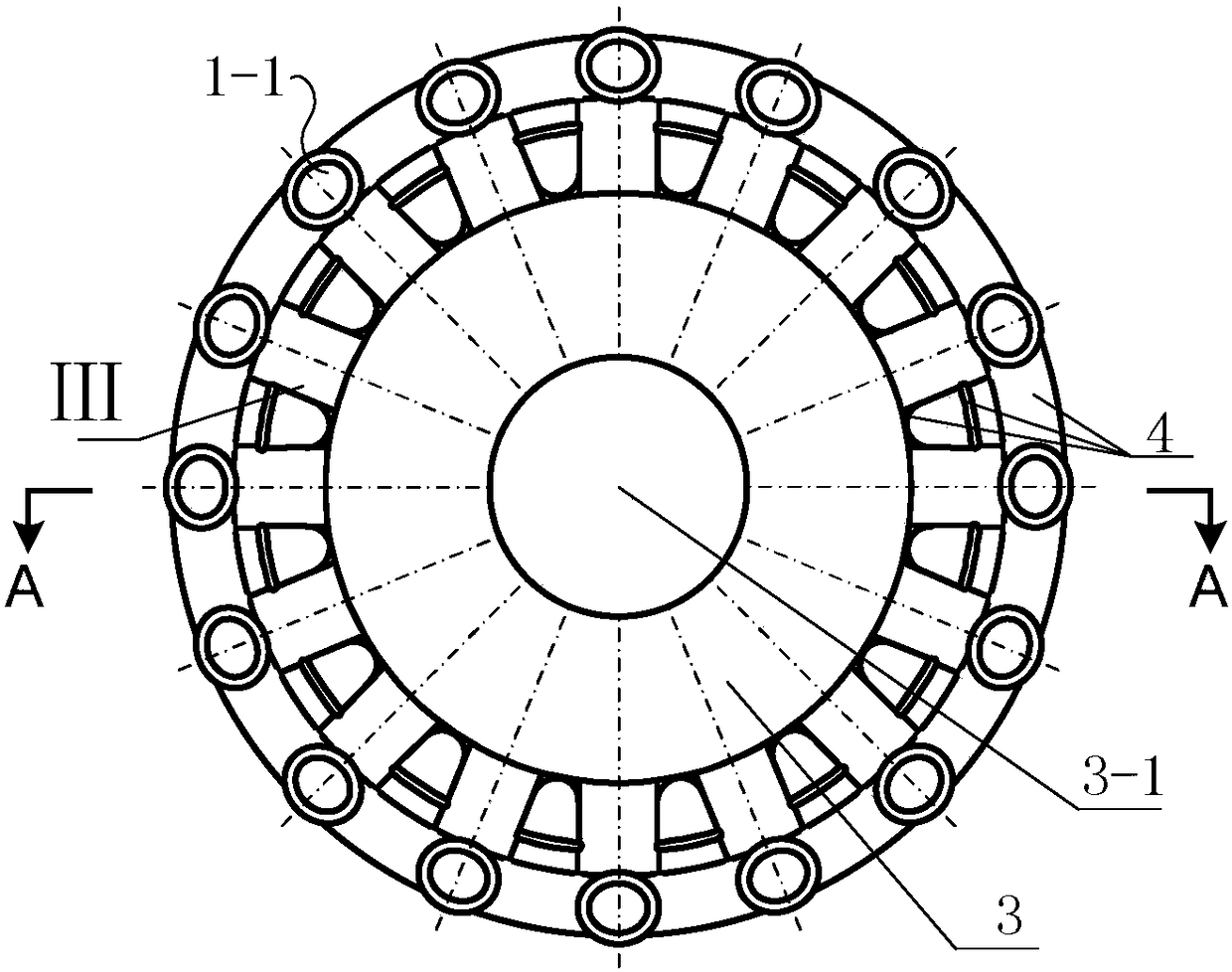

Three-section type badminton hair planting frame

ActiveCN108096802AReduce weightWarranty Strength RequirementsAgriculture gas emission reductionRacket sportsStructural engineeringUltimate tensile strength

The invention relates to a three-section type badminton hair planting frame. An existing product easily deforms, and difference exists between the hand feeling of badminton made by the frame and the hand feeling of a traditional badminton. The three-section type badminton hair planting frame includes hair planting pipes, hair planting rods, a bottom plate, reinforcing ribs and a connection base. One hair planting pipe and one hair planting rod form one connector clip, the several connector clips are uniformly distributed on the periphery of the edge of the bottom plate, and an inverted circular-truncated-cone connector clip combination. The adjacent connector clips are connected through the reinforcing ribs, connection ribs on the same plane form the reinforcing ribs, the area of the crosssection of the middle of each reinforcing rib is larger than that of the end portion of the reinforcing rib, and the shapes of the reinforcing ribs adopt various kinds of design. Through optimizing the design of the badminton hair planting frame, the badminton hair planting frame increases the rigidity of the hair planting frame, the strength and the anti-fatigue degree of the reinforcing ribs ofthe hair planting frame are improved, and the service life of the integrally formed hair planting frame is then prolonged.

Owner:ANHUI SANCAI SPORTS GOODS

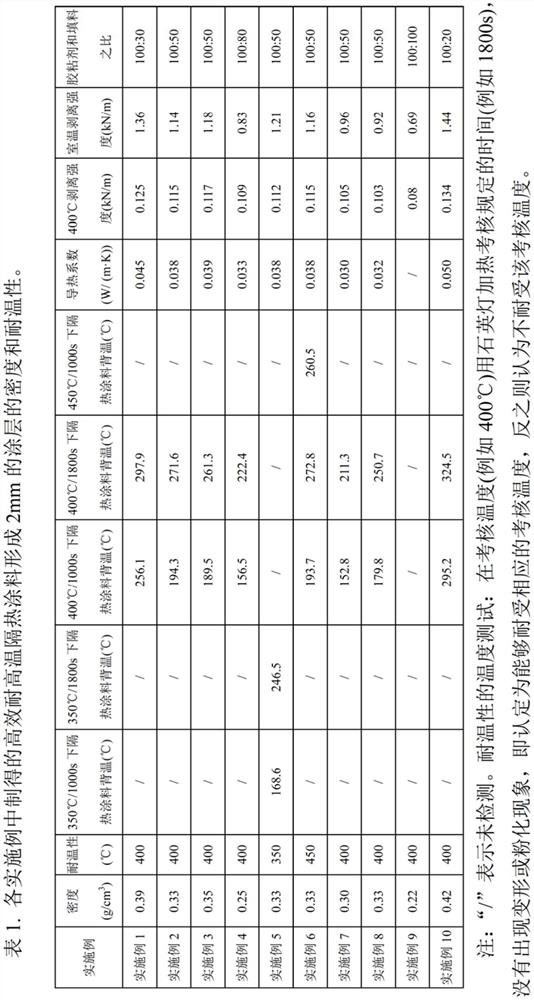

High-efficiency high-temperature-resistant heat-insulating coating and preparation and coating methods thereof

InactiveCN113736363ALow densityGood heat insulationFireproof paintsSpecial surfacesAdhesive cementThermal insulation

The invention relates to a high-efficiency high-temperature-resistant heat-insulating coating and a preparation method and a coating method thereof. The heat-insulating coating comprises a silicone rubber adhesive and a thermal insulation filler, wherein the mass ratio of the silicone rubber adhesive to the heat insulation filler is 100: (30-80). The high-efficiency high-temperature-resistant heat-insulating coating prepared by the invention can resist the temperature of 350-450 DEG C for a long time. Compared with an existing heat insulation coating technology, the efficient high-temperature-resistant heat-insulating coating is small in density, good in heat insulation performance and higher in adhesive capacity. The method can be applied to the fields of industrial kilns, metallurgy, heat supply network pipelines, aerospace and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Automobile trimming vertical column environmental-friendly flame-retardant foamed material and preparation method thereof

The invention discloses an automobile trimming vertical column environmental-friendly flame-retardant foamed material and a preparation method thereof. The foamed material consists of isocyanate and a mixed material, wherein the mass part ratio of the isocyanate to the mixed material is 1:1.5; the mixed material comprises the following raw materials in parts by weight: 55-65 parts of polyether 4110, 20-26 parts of JTM polyether 403, 20-25 parts of polyether 200, 2.5-3 parts of silicon oil AK7760, 1.6-1.9 parts of a catalyst AFM300, 38-42 parts of a flame retardant TCPP and 3.5-4.2 parts of water. Due to reasonable proportioning of the raw materials, the foamed material is good in flame retardancy and stability, an automobile trimming vertical column made of the foamed material is not only high in fireproof security, but also long in service life, the foamed material and the automobile trimming vertical column prepared from environmental-friendly raw materials in reasonable proportioning do not release harmful substances, and thus the environment and human bodies are not damaged.

Owner:YANGZHONG TIANZHENG SYNTHETIC MATERIAL RES CENT

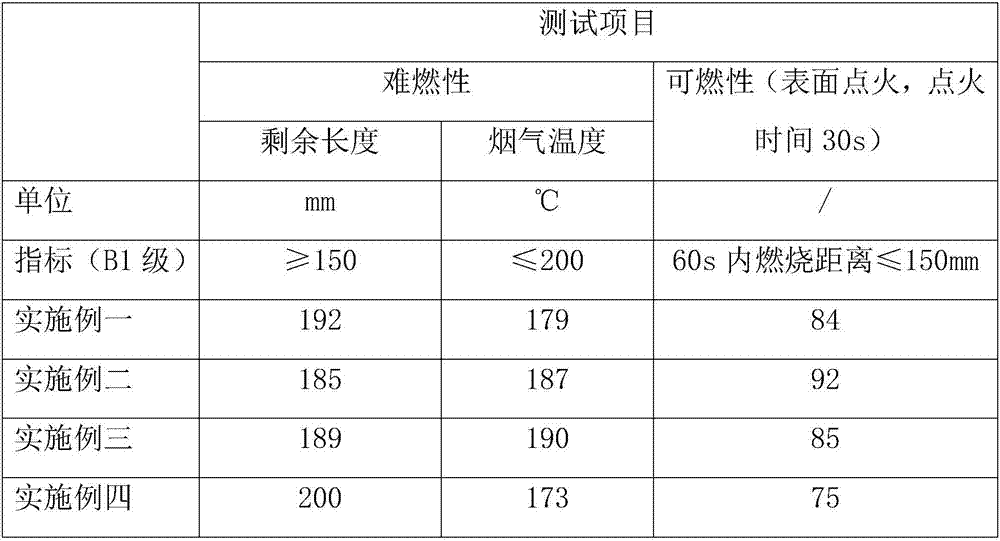

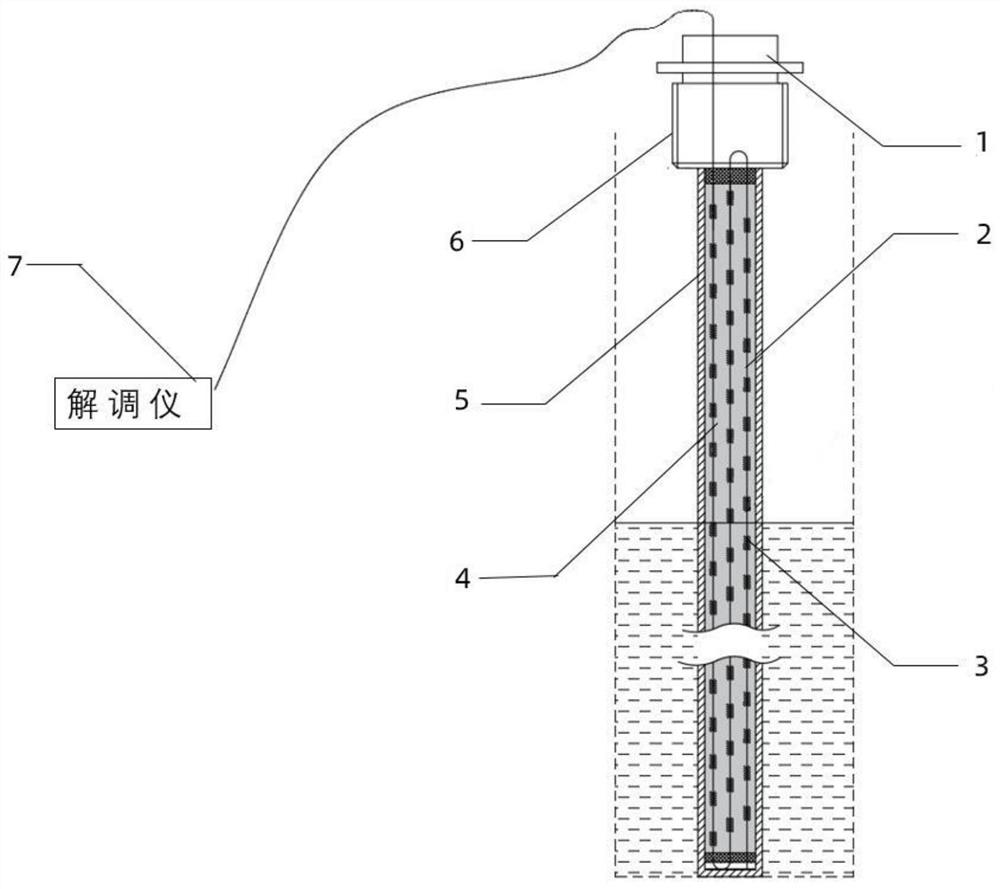

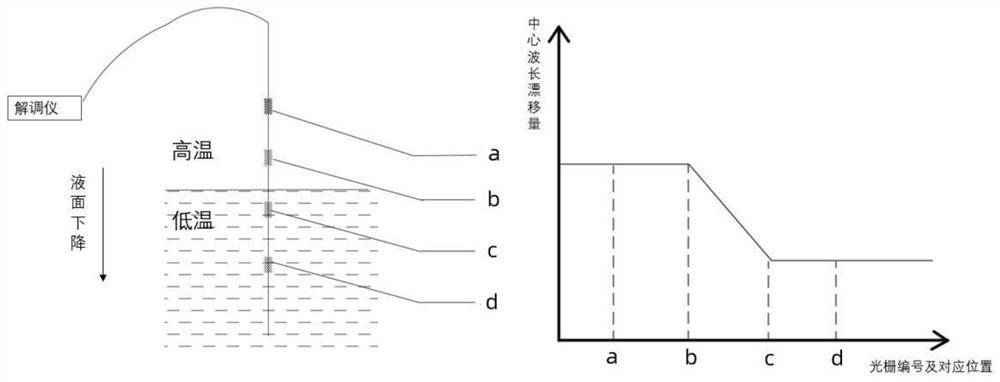

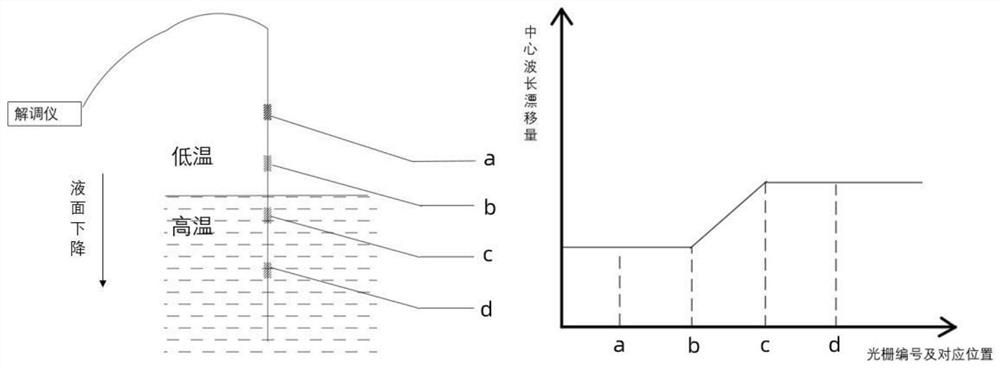

Fiber Bragg grating array type oil tank liquid level sensing system

InactiveCN113137999ASmall sizeImprove applicabilityMachines/enginesLevel indicatorsFiberFiber gratings

The invention belongs to the technical field of optical fiber sensing, and discloses a fiber bragg grating array type oil tank liquid level sensing system which comprises a fiber bragg grating array type oil tank liquid level sensor and a fiber bragg grating demodulator. The optical fiber Bragg grating array type oil tank liquid level sensor comprises an optical fiber, a Bragg grating measuring point and a capillary sleeve. The optical fiber is placed in the capillary sleeve; a plurality of Bragg grating measuring points are arranged on the optical fiber and form a measuring point array; and the fiber bragg grating array type oil tank liquid level sensor is connected to the fiber bragg grating demodulator through an optical fiber. The system can solve the problems that in the prior art, an optical fiber grating liquid level sensor is complex in device, low in measurement precision, small in measurement range, poor in oil contamination environment adaptability and the like, and has the advantages of being high in applicability, high in measurement precision, high in response speed, high in stability, small in dimension and small in size.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com