Automobile trimming vertical column environmental-friendly flame-retardant foamed material and preparation method thereof

A foamed material and column technology, which is applied in the field of environmentally friendly flame-retardant foamed materials for vehicle interior columns and its preparation, can solve the problems of low environmental protection performance of foamed material raw materials, reduced fire safety of automobiles, poor flame retardancy and stability, etc. problems, to avoid harm to the environment and human body, light weight, high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

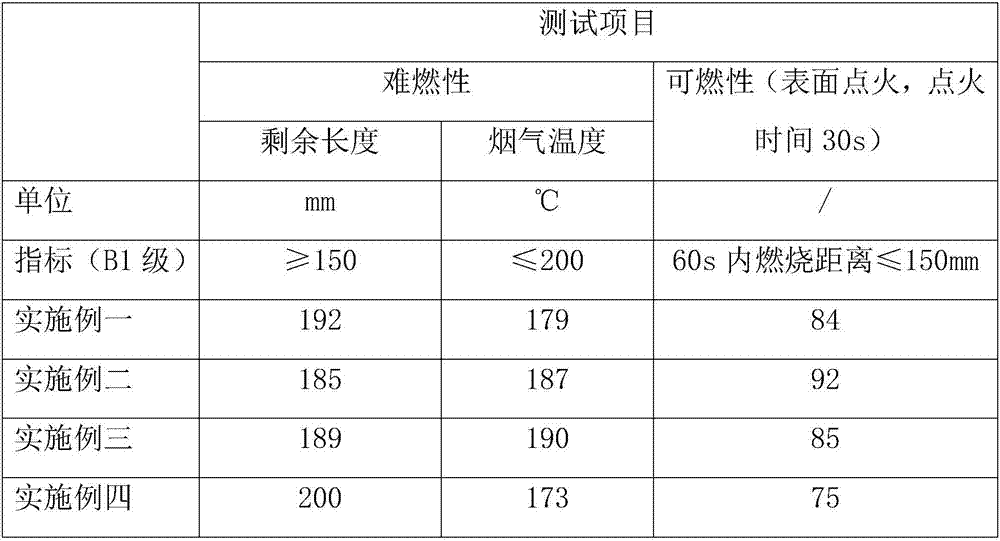

Examples

Embodiment 1

[0014] A preparation method of the above-mentioned environment-friendly flame-retardant foaming material for the upright column of the vehicle interior, comprising the following preparation steps:

[0015] (1) Raw material treatment: Dry polyether 4110, JTM polyether 403, polyether 200 and isocyanate at a drying temperature of 40°C and a drying time of 6 hours;

[0016] (2) Weighing ratio: According to the mass ratio, weigh 2.5 parts of silicone oil AK7760, 1.6 parts of catalyst AFM300, 38 parts of flame retardant TCPP and 3.5 parts of water, and dry polyether 4110: 55 parts, JTM Polyether 403: 20 parts and Polyether 200: 20 parts;

[0017] (3) Prepare the mixture: add the weighed polyether 4110, JTM polyether 403, polyether 200, silicone oil AK7760, catalyst AFM300, flame retardant TCPP and water into the reaction kettle in order to fully stir, and the stirring time is 0.5 h, the stirring temperature is 50°C, and the stirring speed is 250r / min, the mixture can be obtained; ...

Embodiment 2

[0020] A preparation method of the above-mentioned environment-friendly flame-retardant foaming material for the upright column of the vehicle interior, comprising the following preparation steps:

[0021] (1) Raw material treatment: Dry polyether 4110, JTM polyether 403, polyether 200 and isocyanate at a drying temperature of 40°C and a drying time of 8 hours;

[0022] (2) Weighing ratio: According to the mass ratio, weigh 3 parts of silicone oil AK7760, 1.9 parts of catalyst AFM300, 42 parts of flame retardant TCPP and 4.2 parts of water, and polyether 4110 after drying: 65 parts, JTM Polyether 403: 26 parts and Polyether 200: 25 parts;

[0023] (3) Prepare the mixture: add the weighed polyether 4110, JTM polyether 403, polyether 200, 3 parts of silicone oil AK7760, 1.9 parts of catalyst AFM300, 42 parts of flame retardant TCPP and 4.2 parts of water into the reaction kettle in sequence Thoroughly stir, the stirring time is 1.5h, the stirring temperature is 80°C, and the st...

Embodiment 3

[0026] A preparation method of the above-mentioned environment-friendly flame-retardant foaming material for the upright column of the vehicle interior, comprising the following preparation steps:

[0027] (1) Raw material treatment: Dry polyether 4110, JTM polyether 403, polyether 200 and isocyanate at a drying temperature of 40°C and a drying time of 7 hours;

[0028] (2) Weighing ratio: according to the mass ratio, weigh 2.75 parts of silicone oil AK7760, 1.75 parts of catalyst AFM300, 40 parts of flame retardant TCPP and 3.85 parts of water, and dry polyether 4110: 60 parts, JTM Polyether 403: 23 parts and Polyether 200: 22.5 parts;

[0029] (3) Prepare the mixture: Add the weighed polyether 4110, JTM polyether 403, polyether 200, silicone oil AK7760, catalyst AFM300, flame retardant TCPP and water into the reaction kettle in turn for full stirring, and the stirring time is 1h , the stirring temperature is 65°C, and the stirring speed is 265r / min, the mixture can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com