Suspension controller of magnetic suspension train

A levitation controller and maglev train technology, applied in the field of converter devices, can solve the problems of light weight levitation controller design difficulty, high purchase cost, high power, etc., to optimize electromagnetic compatibility performance, reduce manufacturing cost, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

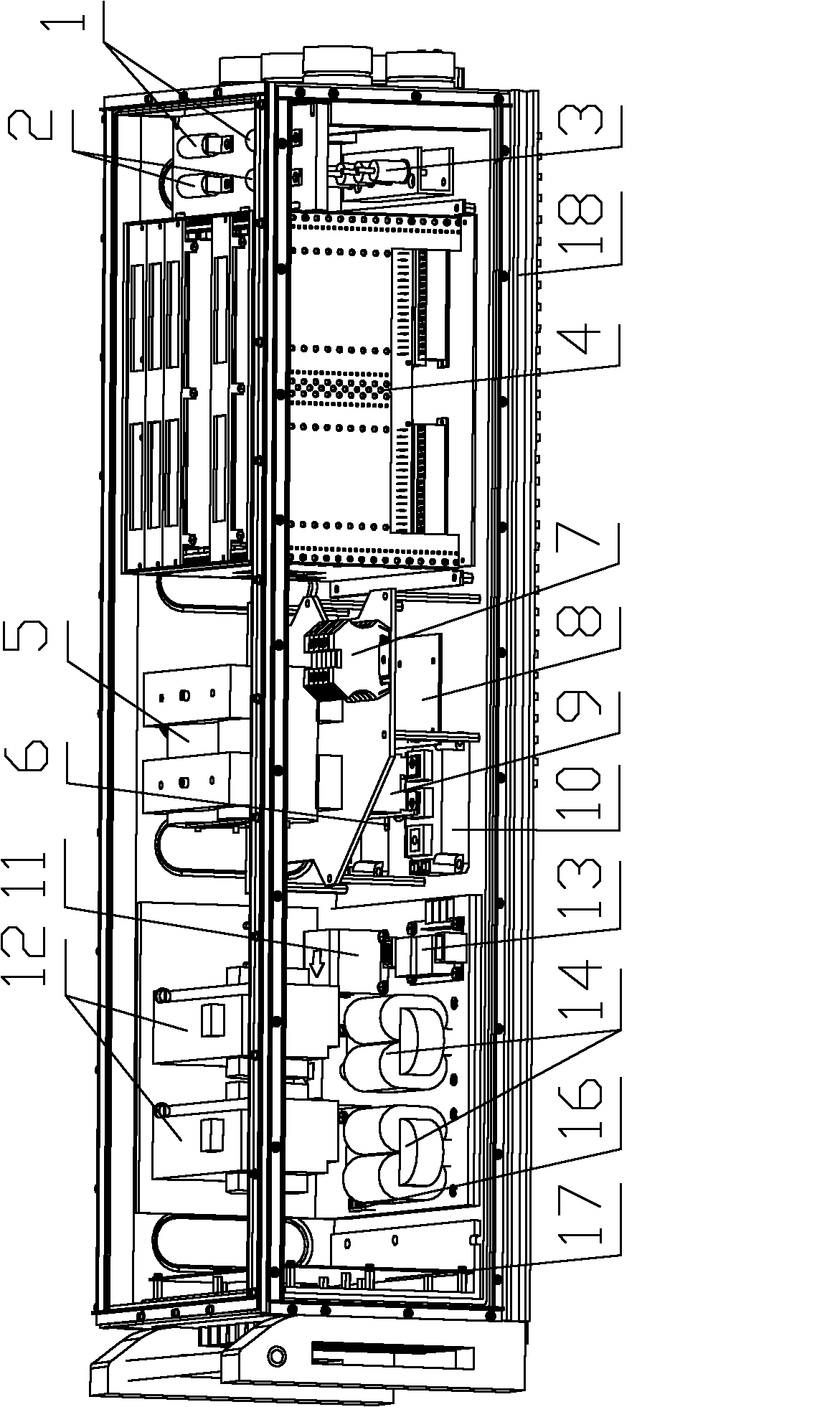

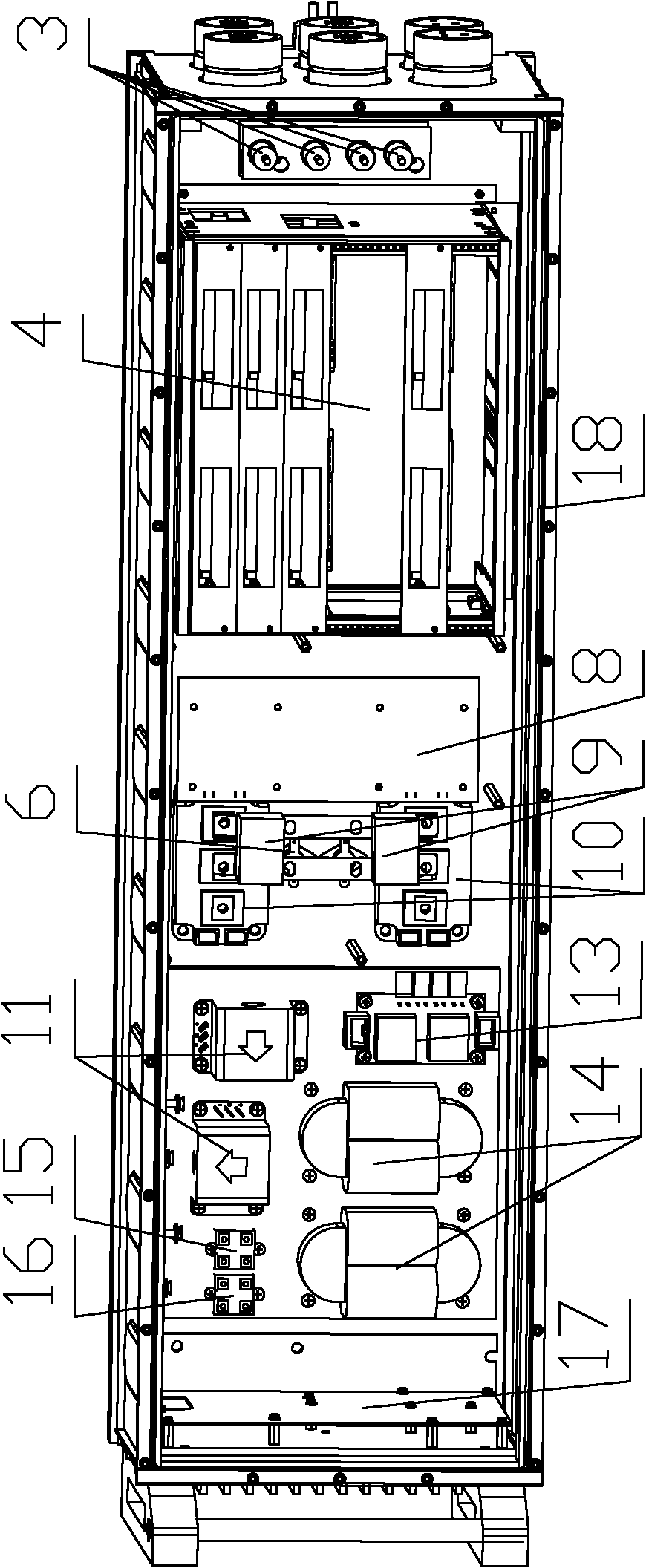

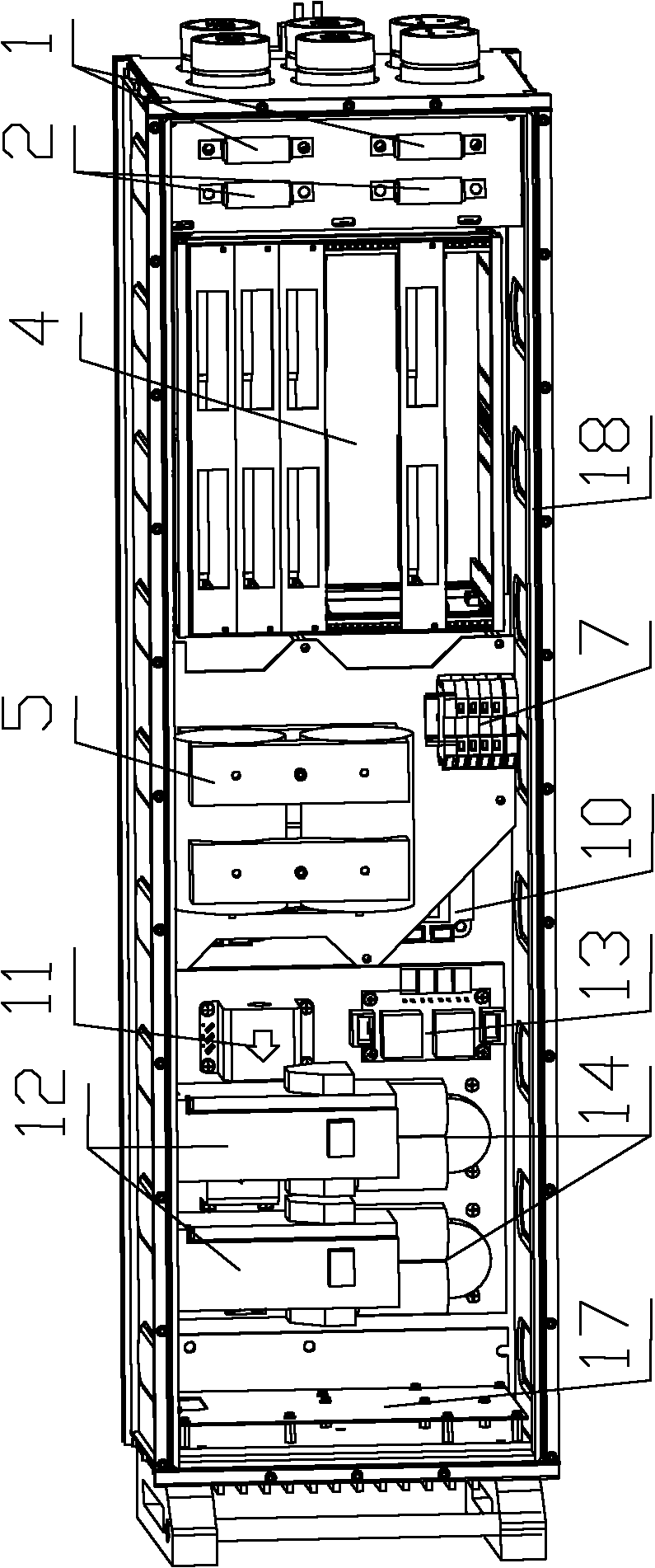

[0019] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a levitation controller for a maglev train includes a box body 18, a main circuit input terminal protection fuse 1, a control circuit input terminal protection fuse 2, a main circuit input terminal filter 3, a control cabinet 4, and a support capacitor 5 , temperature relay 6, terminal 7, drive circuit board 8, surge absorbing capacitor 9, IGBT10, current sensor 11, charging contactor and main contactor 12, voltage sensor circuit board 13, output filter reactor 14, charging resistor 15 , discharge resistor 16 and power supply board 17, the box body 18 is cast from aluminum material, and has cooling fins at the bottom; the main circuit input filter 3 is installed on the "U"-shaped groove aluminum, "U" The grooved aluminum is installed on the bottom surface of the box body 18, and the control cabinet 4 is installed on the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com