All-aluminum van vehicle ribbed floor and manufacturing and mounting method thereof

A manufacturing method and technology for vans, which are applied in the directions of transportation and packaging, vehicle components, and connections between upper structure sub-assemblies, etc., can solve the problem of unrecyclable carbon fiber floors, cumbersome foam aluminum floor heads, and embossed aluminum plates. Insufficient rigidity and other problems, to achieve the effect of obvious weight reduction, convenient assembly, and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

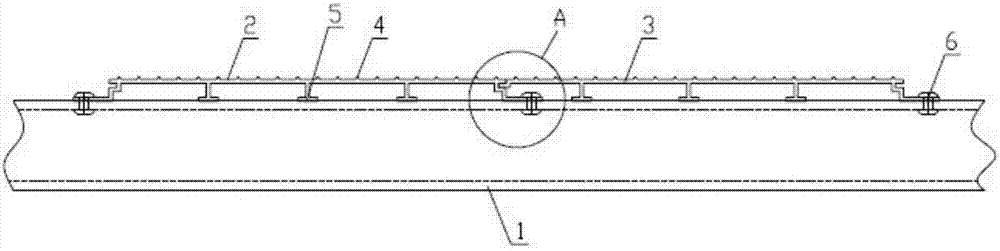

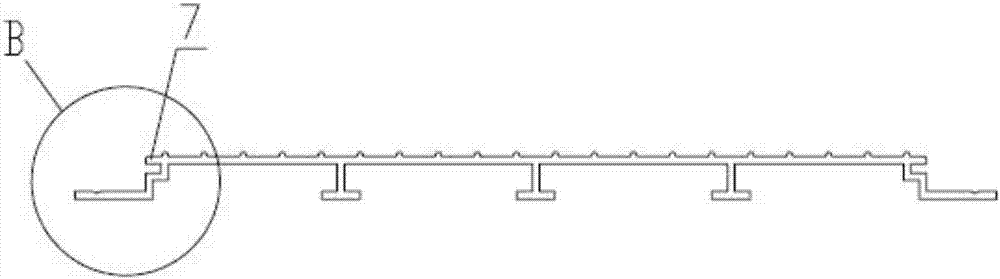

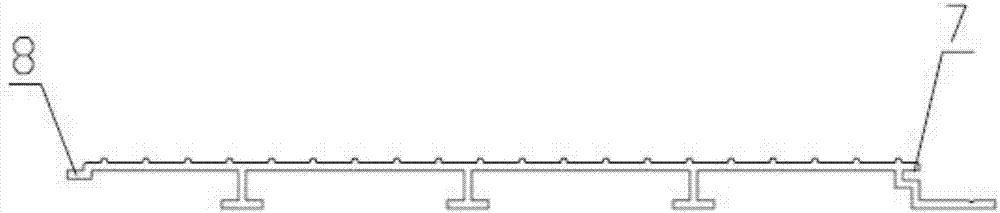

[0040] Such as Figure 1-5 As shown, a ribbed floor of an all-aluminum van includes a symmetrical floor unit 2 and an asymmetrical floor unit 3, and the symmetrical floor unit 2 and the asymmetrical floor unit 3 are respectively fixedly connected to the crossbeam 1 of the carriage chassis by rivets 6 The bottoms of both the symmetrical floor unit 2 and the asymmetrical floor unit 3 are provided with a number of reinforcing ribs 5, both ends of the symmetrical floor unit 2 are provided with a plug-in mechanism 7, and one end of the asymmetrical floor unit 3 is provided with a plug-in mechanism 7, The other end of the asymmetric floor unit 3 is provided with a first connecting plate 8, and the first connecting plate 8 of the asymmetric floor unit 3 is plugged with the plug-in mechanism 7 of the symmetrical floor unit 2 to form a structural connection, and the plug-in mechanism 7 A connecting slot 9 and a second connecting plate 10 are provided, the second connecting plate 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com