High-efficiency high-temperature-resistant heat-insulating coating and preparation and coating methods thereof

A heat-insulating coating and high-temperature-resistant technology, which is applied in the direction of fire-proof coatings, coatings, and devices for coating liquid on the surface, can solve the problems that heat-insulating coatings cannot meet the requirements of temperature, space, and weight at the same time, and achieve short preparation cycles , high temperature resistance, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

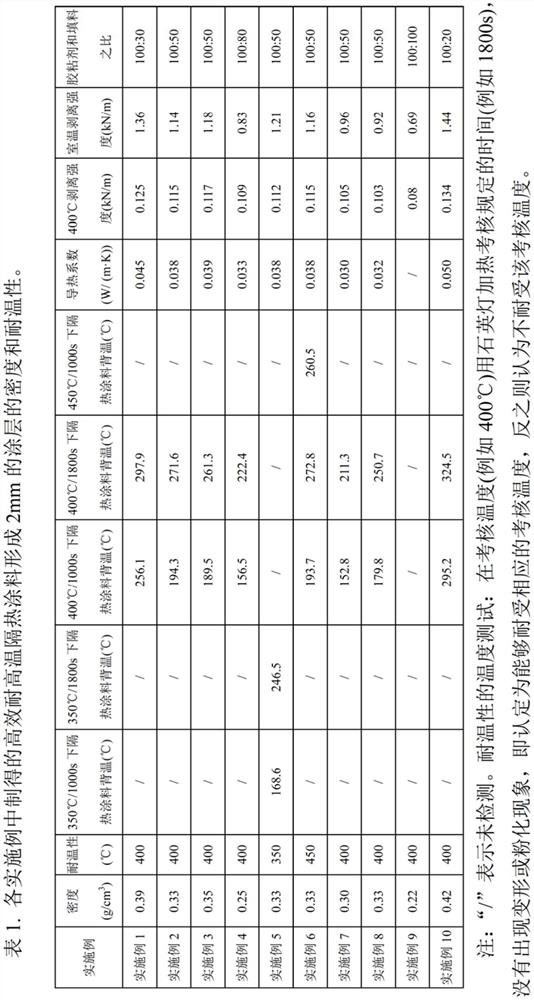

Examples

preparation example Construction

[0035] The second aspect of the present invention provides a preparation method of high-efficiency high-temperature-resistant heat-insulating coating, and the preparation method includes the following steps:

[0036] (1) Provide silicone rubber adhesive;

[0037] (2) Add heat-insulating fillers and optional diluents into the adhesive solution, and stir evenly to obtain the high-efficiency high-temperature-resistant heat-insulating coating.

[0038] The third aspect of the present invention provides a coating method of high-efficiency high-temperature-resistant heat-insulating paint, and the coating method is a spraying method or a brushing method.

[0039] In some preferred embodiments, the spraying method comprises the steps of:

[0040] (1) Cleaning: clean the substrate to be coated to make its surface clean;

[0041](2) Paint spraying: spray the high-efficiency high-temperature-resistant heat-insulating paint on the surface of the cleaned substrate, wherein the mass ratio...

Embodiment 1

[0052] (1) Weigh 1000g of KH-HP-RTV silicone rubber adhesive, add 1800g of cyclohexane diluent, and use a mechanical stirrer to stir at 1000rpm for 5min to form a uniform adhesive solution;

[0053] (2) Add 300g of hollow glass microspheres, use a mechanical stirrer to stir at 100rpm for 2min, and then stir at 500rpm for 15min to mix evenly to obtain a high-efficiency high-temperature-resistant heat-insulating coating.

[0054] Put the prepared high-efficiency high-temperature-resistant and heat-insulating coating into a watering can, connect the compressed air pipeline to adjust the pressure to 0.5MPa, spray the coating on the surface of a 2mm thick metal plate, and spray 50 times to obtain a heat-insulating coating thickness of about 2mm, put the sprayed product at room temperature for 48 hours.

[0055] After testing, the high-efficiency high-temperature-resistant heat-insulating coating has a density of 0.39g / cm 3 , Quartz lamp 400°C / 1000s heating 256.1°C, quartz lamp 400...

Embodiment 2

[0057] (1) Weigh 1000g of KH-HP-RTV silicone rubber adhesive, add 3000g of cyclohexane diluent, and use a mechanical stirrer to stir at 1000rpm for 5min to form a uniform adhesive solution;

[0058] (2) Add 500 g of hollow glass microspheres, and use a mechanical stirrer to stir at 100 rpm for 2 minutes, and then stir at 500 rpm for 15 minutes to mix evenly to obtain a high-efficiency high-temperature-resistant heat-insulating coating.

[0059] Put the prepared high-efficiency high-temperature-resistant and heat-insulating coating into a watering can, connect the compressed air pipeline to adjust the pressure to 0.5MPa, spray the coating on the surface of a clean and clean 2mm thick metal plate, and spray 50 times to obtain a heat-insulating coating thickness of about 2mm, let the sprayed product stand at room temperature for 48 hours.

[0060] After testing, the high-efficiency high-temperature-resistant heat-insulating coating has a density of 0.33g / cm 3 , quartz lamp 400°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com