Fiber Bragg grating array type oil tank liquid level sensing system

A technology of fiber optic Bragg and Bragg grating, which is applied in liquid level indicators, liquid/fluid solid measurement, instruments, etc. It can solve the problems of poor adaptability to oily environment, low measurement accuracy, small measurement range, etc., so as to facilitate maintenance and inspection And the effects of replacement, high measurement accuracy, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the above technical solution, the above-described technical scheme will be described in detail below in conjunction with the drawings and specific embodiments.

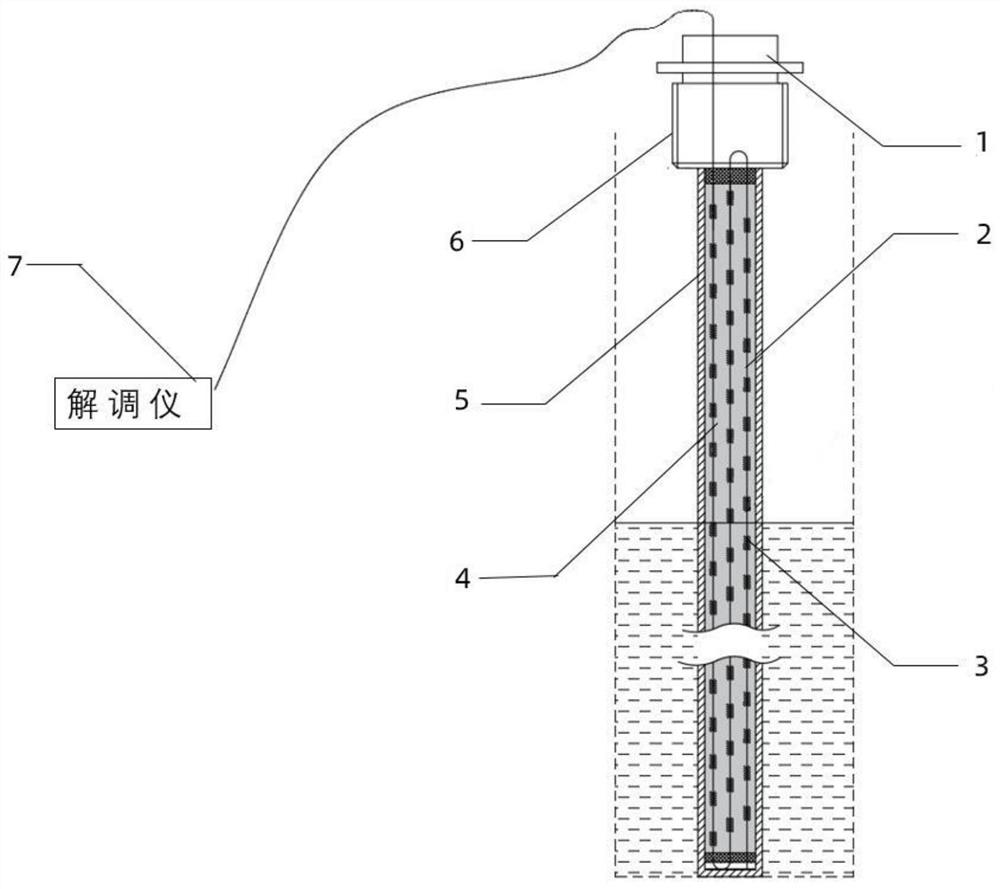

[0026] This embodiment provides a fiber-backer grating array fuel tank liquid level sensor system, including: fiber Bragg grating array tank liquid level sensor and fiber grating demodulator. Among them, the fiber Bragg grating array tank liquid level sensor includes: fiber, Prague grating measurement point, capillary tube; the optical fiber is placed within the capillary tube; several of the Prague grating measuring point is disposed in the optical fiber The measuring point array is formed; the fiber Bragg grating array fuel tank liquid level sensor is accessed into the fiber grating demodulator by the optical fiber.

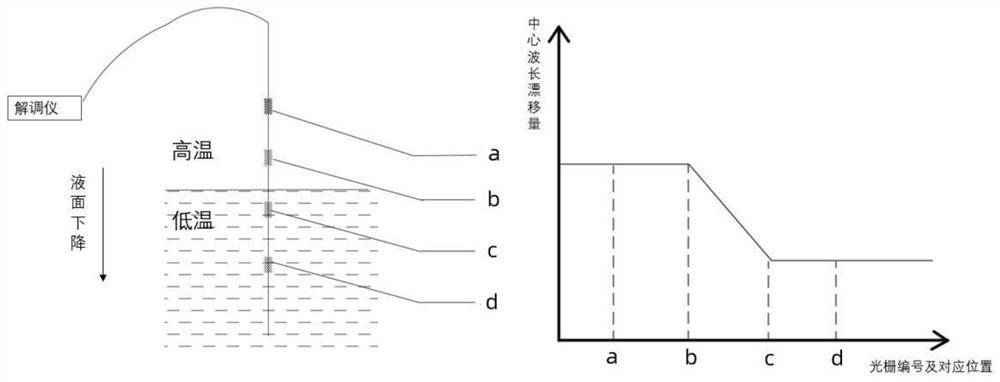

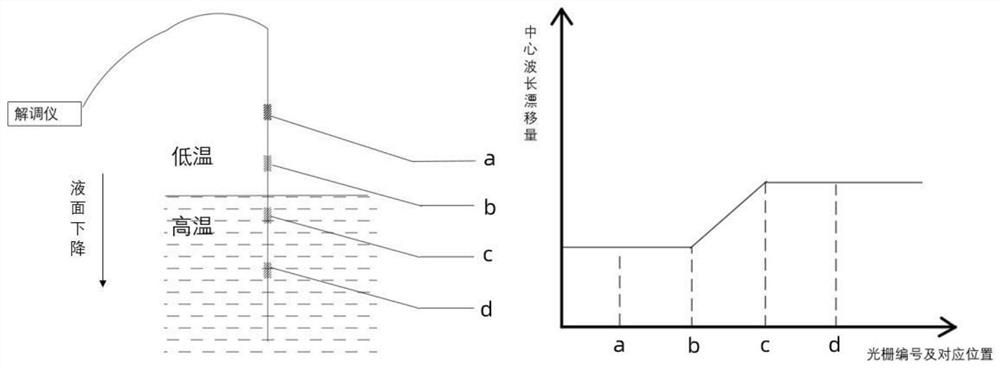

[0027] The fiber grating demodulator is used to observe the wavelength drift information of all of the Prague grating points, and obtain the liquid level position infor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com