Method and special device for implementing tobacco leaf product online cooling in threshing and re-drying production

A technology of threshing and re-roasting and leaves, which is applied in packaging, application, packaging by pressurization/gasification, etc. It can solve the problems of limited processing effect, increasing the gap between tobacco blanks and mantles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

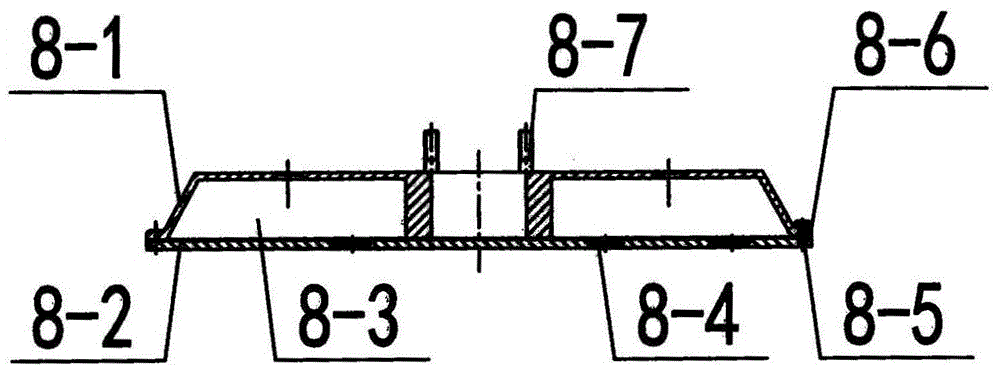

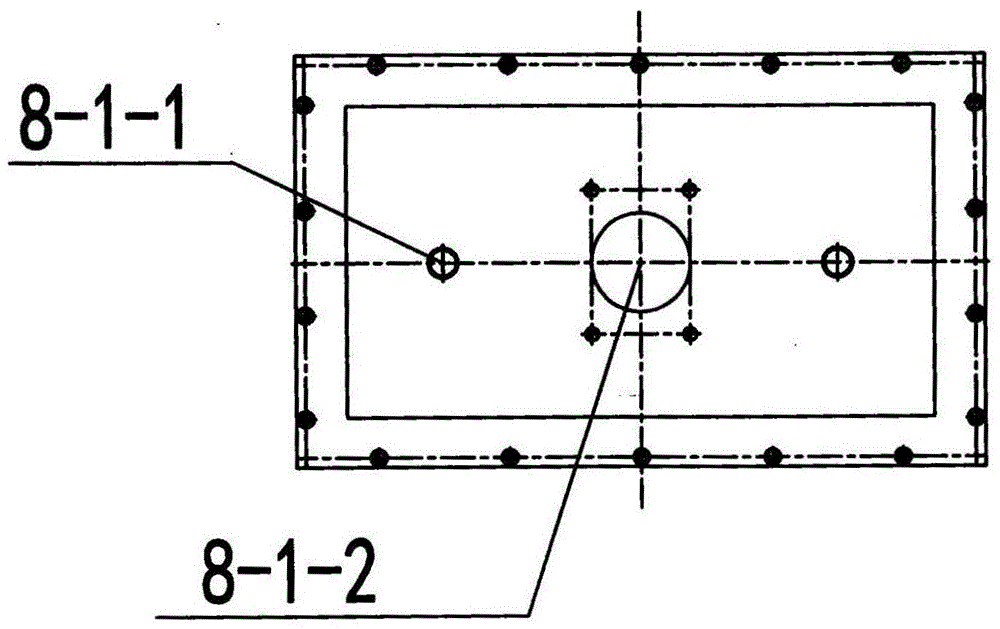

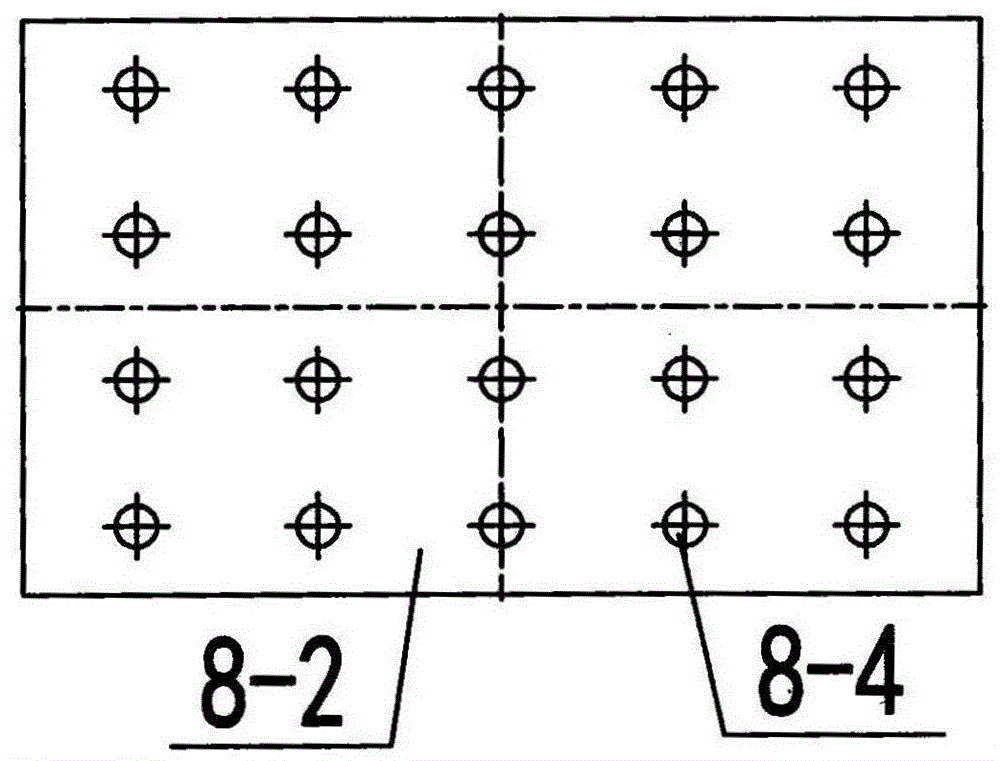

[0022] see figure 1 : A method for realizing online cooling of leaf products in the production of leaf threshing and rebaking. The plastic film packaging box with tobacco blanks is pre-pressed and re-weighed and then enters the packaging process. Vacuumize the billet to reduce the temperature of the cigarette package and eliminate the gap between the billet and the plastic casing. The specific method is as follows: After re-baking, pre-pressing, and re-weighing, the tobacco base C packed with carton A and plastic film B is formed. At the same time, the vacuum pump 13 is started, and the tobacco billet is vacuumed through the special online vacuuming device for the vane bag. When the vacuuming of the system reaches the set temperature, the temperature sensor 11 in the suction channel feeds back information to the system, and the system stops. Vacuuming, the pressure head 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com