Cold extrusion blanking die for cross shaft blanks

A technology of blanking die and cross shaft, which is applied in the field of cold extrusion billet blanking die, can solve problems such as unreasonable structure, achieve the effect of improving blanking precision, reasonable shearing gap, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

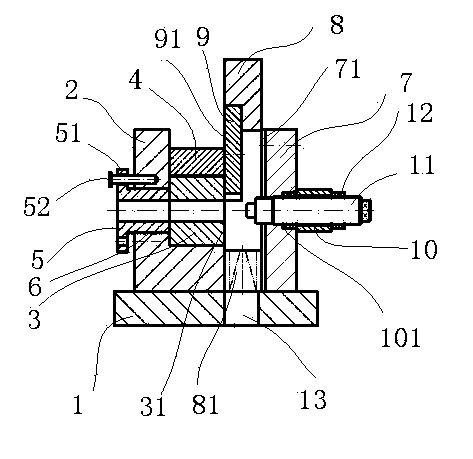

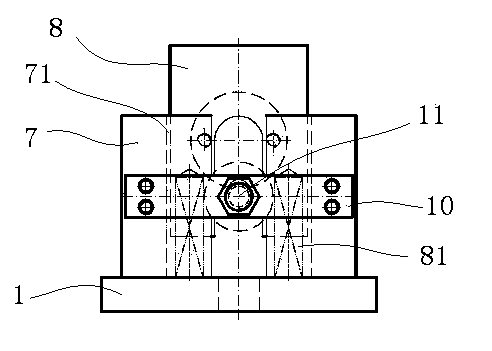

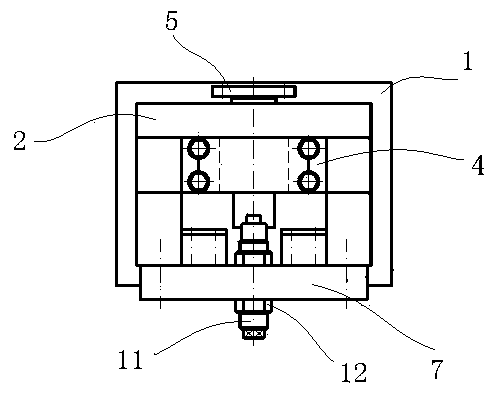

[0032] Embodiment 1: as Figure 1~3 As shown, a cold extrusion cross axis billet blanking mold includes a backing plate 1, a mold base 2 is fixed on the backing plate 1, a lower knife plate 3 is arranged on the mold base 2, and the lower knife plate 3 is connected to the mold through a gland 4. The seat 2 is connected, the rear end of the lower knife plate 3 bears on the adjusting screw 5, the adjusting screw 5 cooperates with the adjusting screw hole 6 on the mold base 2, the rear end of the adjusting screw 5 is provided with a shoulder 51, and the shoulder 51 Lock with the mold base 2 through the pin 52; a guide rail seat 7 is arranged at a certain distance from the front end of the mold base 2, and the bottom of the guide rail base 7 is fixedly connected with the backing plate 1 through screws, and a guide rail 71 is provided on the back of the guide rail base 7. 71 slips are equipped with movable formwork 8, and upper cutter plate 9 is embedded in movable formwork 8, and i...

Embodiment 2

[0039] Embodiment 2: The circular crescent structure is a double crescent structure, that is, two arc-shaped notches 92 are evenly distributed on the circumference of the circular plate, and the two notches can be exchanged for use. When the blade of one of the notches is worn blunt, the upper knife plate can be removed and turned 180° and reinstalled, and another notch can be used to continue blanking, which can save the man-hours of grinding the knife edge, and the rest of the structure is the same as that of embodiment 1, such as Figure 8 shown.

[0040] Applying the mold of the present invention, blanking of round steel with a diameter of ≤φ18mm, the inclination of the end surface of the blank is ≤1°30′, the quality of the incision is significantly improved, and the weight deviation can be controlled to ≤0.0005kg. After data retrieval and comparison, it has reached the advanced level of industrially developed countries , fully meet the weight requirements of high-precisio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com