A pipe cutting device for self-positioning pipes

A pipe cutting device and self-positioning technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of uneven pipe cuts, increased production costs, and self-heavy pipes, so as to prolong the service life, improve production efficiency, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

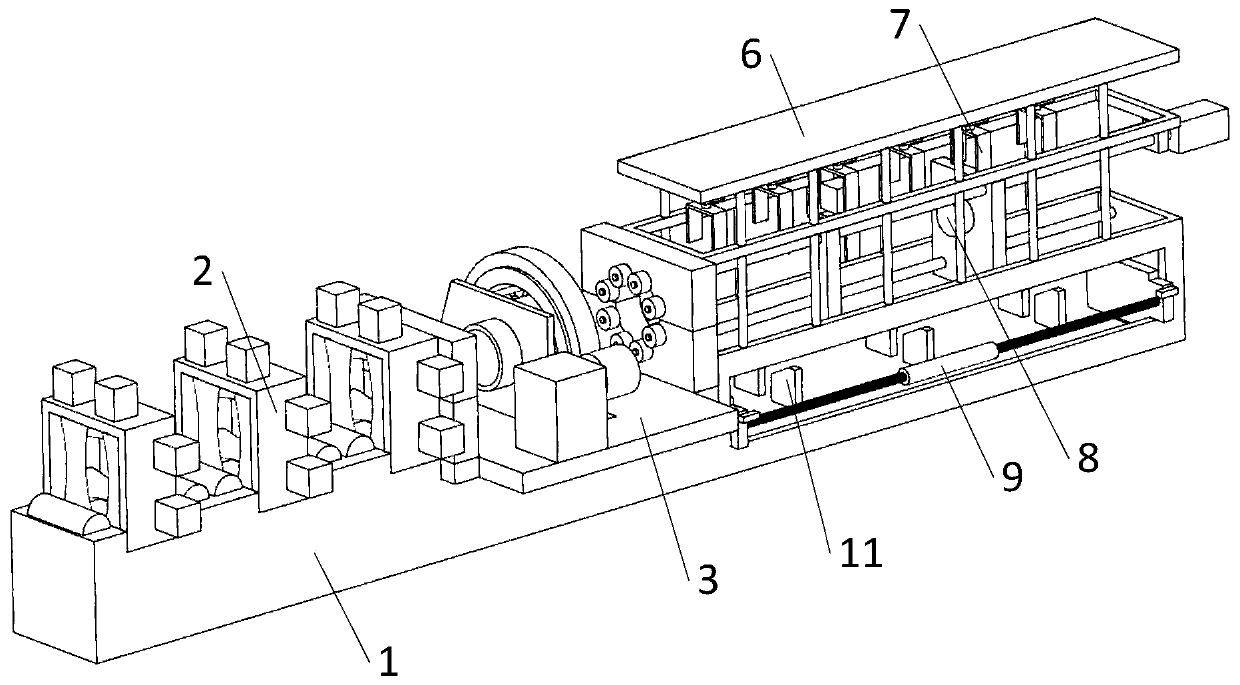

[0033] Such as figure 1 As shown, the self-positioning pipe cutting device provided in this embodiment includes a frame 1 and multiple sets of straightening devices 2 , cutting machines 3 and positioning devices 6 sequentially installed on the top of the frame 1 along the processing direction.

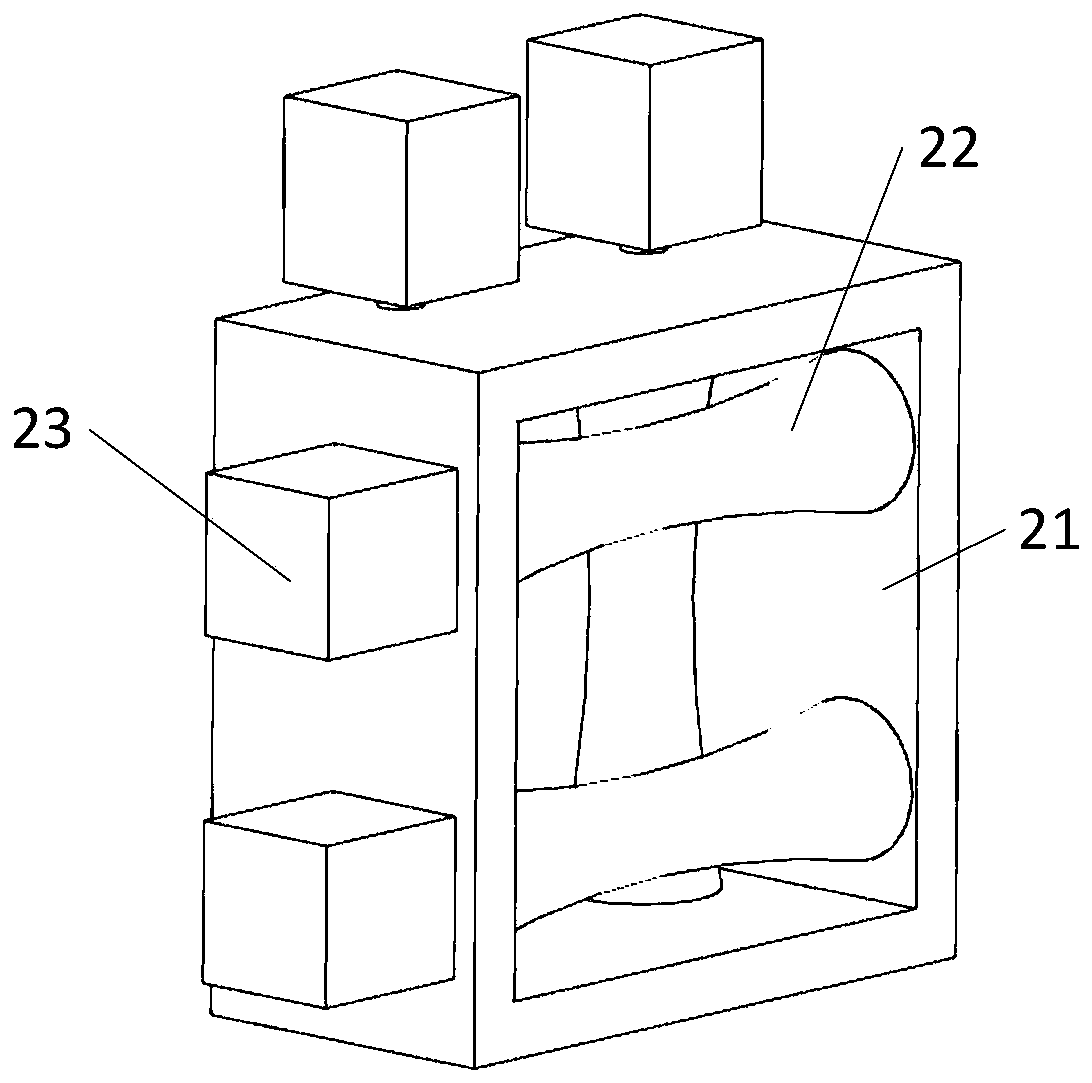

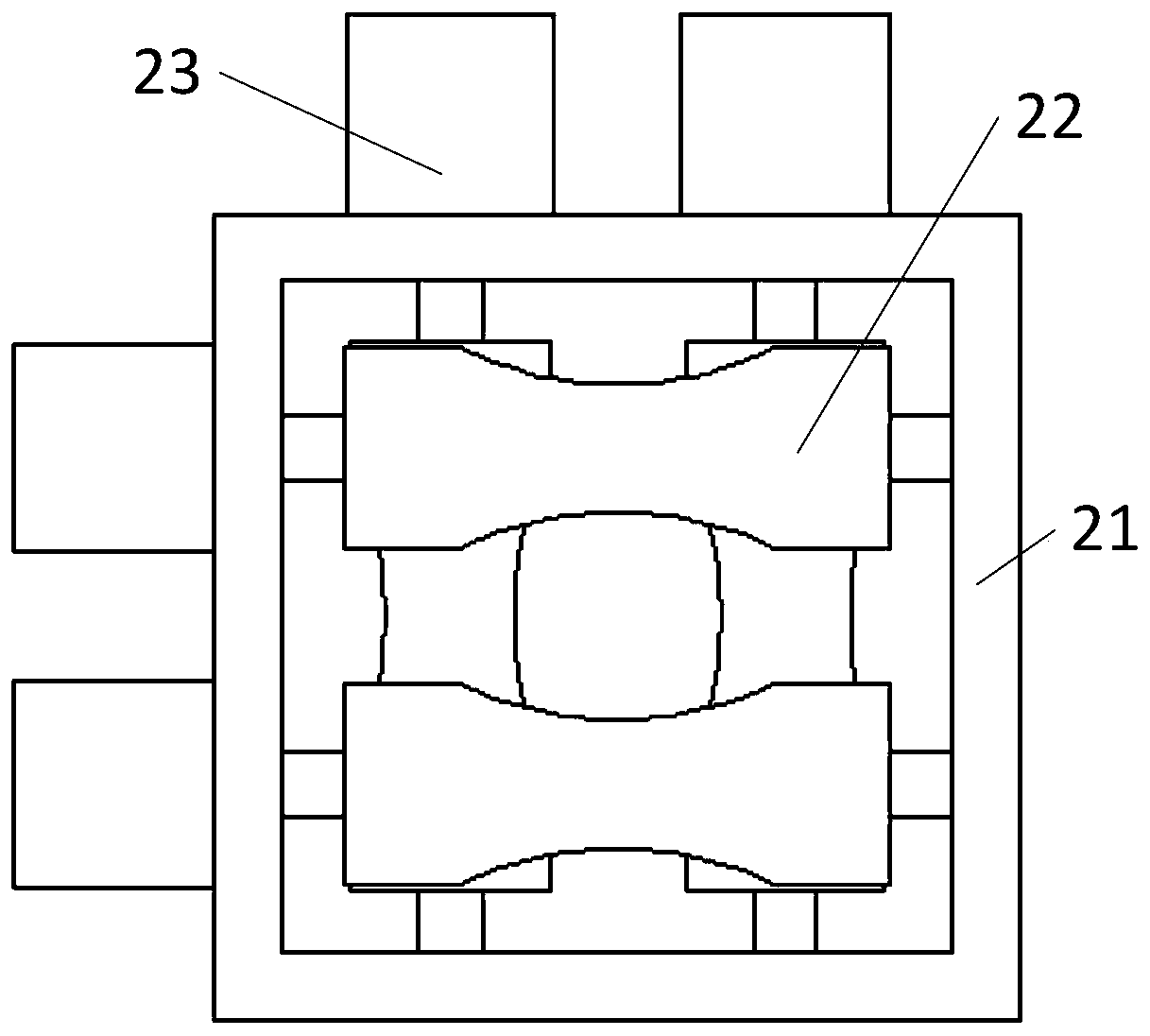

[0034] Such as figure 2 , image 3 As shown, the straightening device 2 includes a straightening frame 21, a pressure roller 22 and a reduction motor 23, and the straightening frame 21 is installed on the top of the frame 1, and two groups of pressure rollers 22 are arranged in the straightening frame 21, and a group of pressure rollers 22 is arranged horizontally, and another group of pressure rollers 22 is vertically arranged. Two groups of pressure rollers 22 form the straightening portion of the straightening device 2, and each group of pressure rollers 22 passes through the straightening frame 21 and is connected with the output shaft of the reduction motor 23.

[0035] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com