Counter balance for turbine high-speed dynamic balance

A high-speed dynamic balance and balance block technology, which is applied in the static/dynamic balance test, machine/structural component test, measuring device, etc., can solve the problems of small weight of balance block, low work efficiency, on-site grinding, etc. Achieve the effect of improving installation speed, installation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

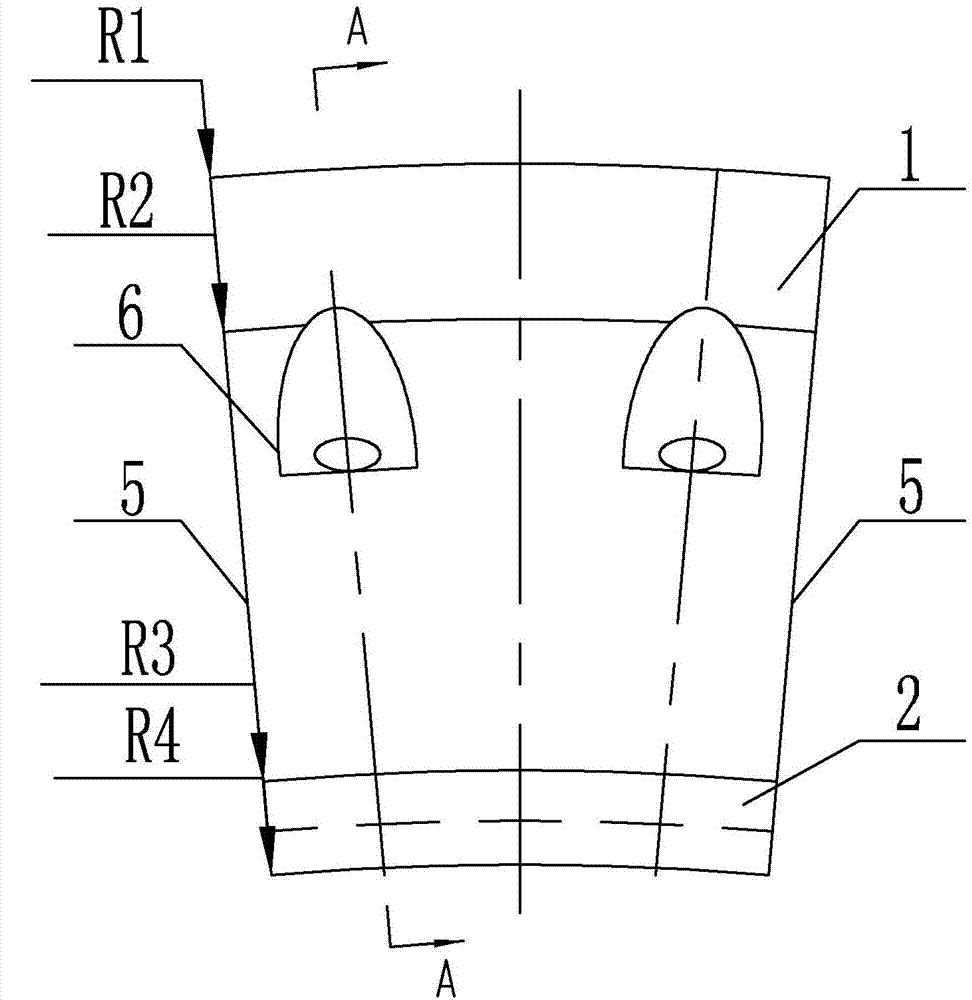

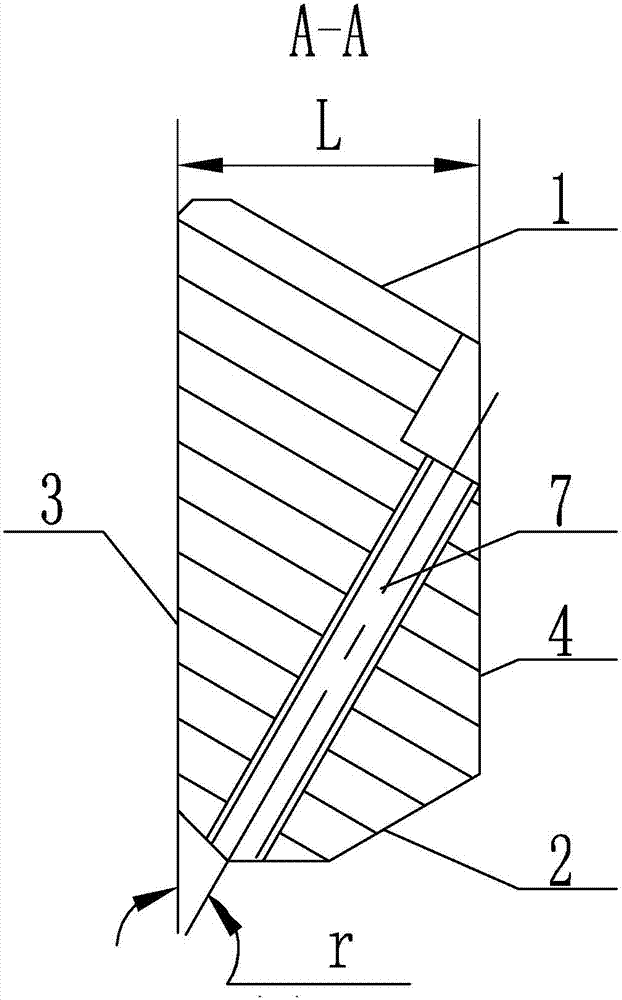

[0007] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, a kind of balance block for steam turbine high-speed dynamic balance described in this embodiment, the balance block has six faces, and the six faces are top face 1, bottom face 2, front face 3, back face 4 and two faces respectively. 5 sides, the top surface 1 is an upwardly convex oblique surface, the bottom surface 2 is an upwardly concave oblique surface, the front side 3, the back side 4 and the side side 5 are all planes, and the intersection of the top side 1 and the back side 4 is processed with two The notch 6 is processed with a threaded hole 7 along the bottom of the notch 6 to the intersection of the front face 3 and the bottom face 2, the angle formed by the center line of the threaded hole 7 and the front face 3 is r, r is an acute angle, and the radius of the top arc of the top face 1 R1, the radius of the bottom arc of top 1 is R2, the radius of the top arc of bottom 2...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, the high-speed dynamic balance of steam turbine described in this embodiment is a balance weight, the value range of the r is 25 ° ~ 40 °, within this angle range, the two jacking wires of the balance weight can be effectively Fixing the balance weight can make the top of the top wire fully contact with the bottom of the balance groove, and firmly fix the balance weight through friction, and the other is the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, the balance weight for high-speed dynamic balancing of a steam turbine described in this embodiment, 3. The balance weight for high-speed dynamic balance of a steam turbine according to claim 1, characterized in that: the value of R1 is 516.3mm , the value of R2 is 506.3mm, the value of R3 is 496.3mm, the value of R4 is 486.3mm, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com