Array structure and realization method of MEMS electro-spray thruster

An array structure and thruster technology, applied in the field of electrospray thruster preparation, can solve the problems of inapplicability to micro-nano satellite applications, difficult array expansion, large volume and weight, etc., to achieve precise control tasks, simple composition and structure, and improved thrust The effect of the level of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

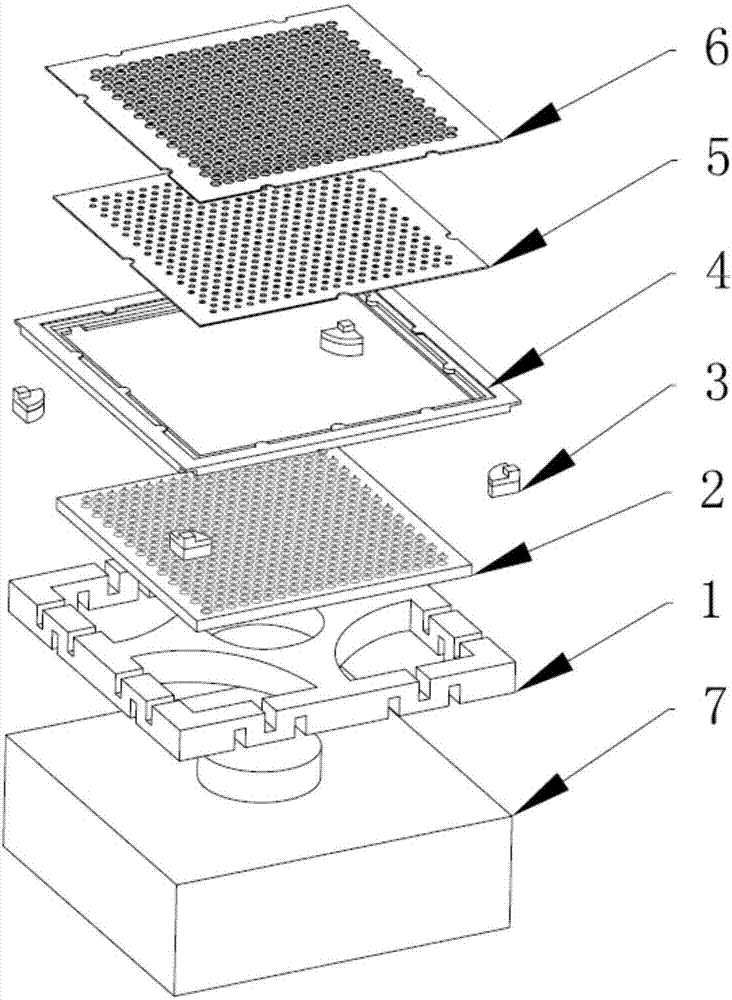

[0046] The invention provides a MEMS electrospray thruster array structure, which can be as figure 1 As shown, the structure is firstly explained below:

[0047] The MEMS electrospray thruster array structure provided by the present invention includes, from bottom to top, an installation base 1, an emitter 2, a positioning and insulating layer 3, an electrode installation frame 4, an extraction pole 5, an acceleration pole 6, and a storage tank 7 ; The emitter 2 is placed in the middle of the installation base 1, and is bonded by epoxy resin; the positioning and insulating layer 3 is located at the four corners of the installation base 1, and is bonded to the installation base 1, electrically isolating the described The emitter 2 and the extractor 5; the electrode mounting frame 4 and the positioning and insulating layer 3 are aligned and then bonded; the extractor 5 and the accelerating pole 6 are placed on the electrode mounting frame 4 in sequence, and the extracting pole 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com