Express delivery terminal warehouse machine and automatic service method

An automatic service and warehouse technology, applied in the field of machinery and electronics, can solve the problems of weak speed and service at the end of express delivery, delay, affecting delivery time, etc., and achieve the effect of being locked when it is inserted well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

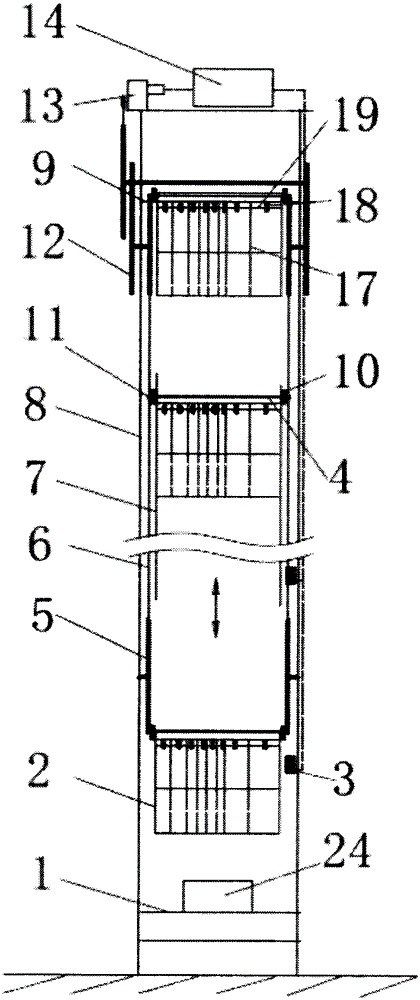

[0037] Embodiment 1: The working process and principle of the automatic service system of the express terminal warehouse machine.

[0038] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 .

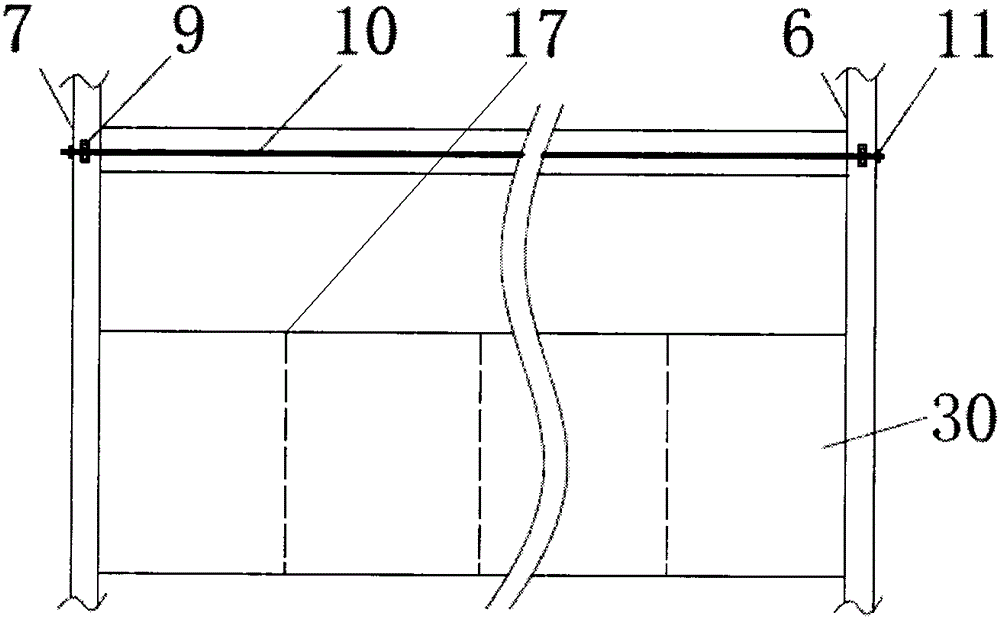

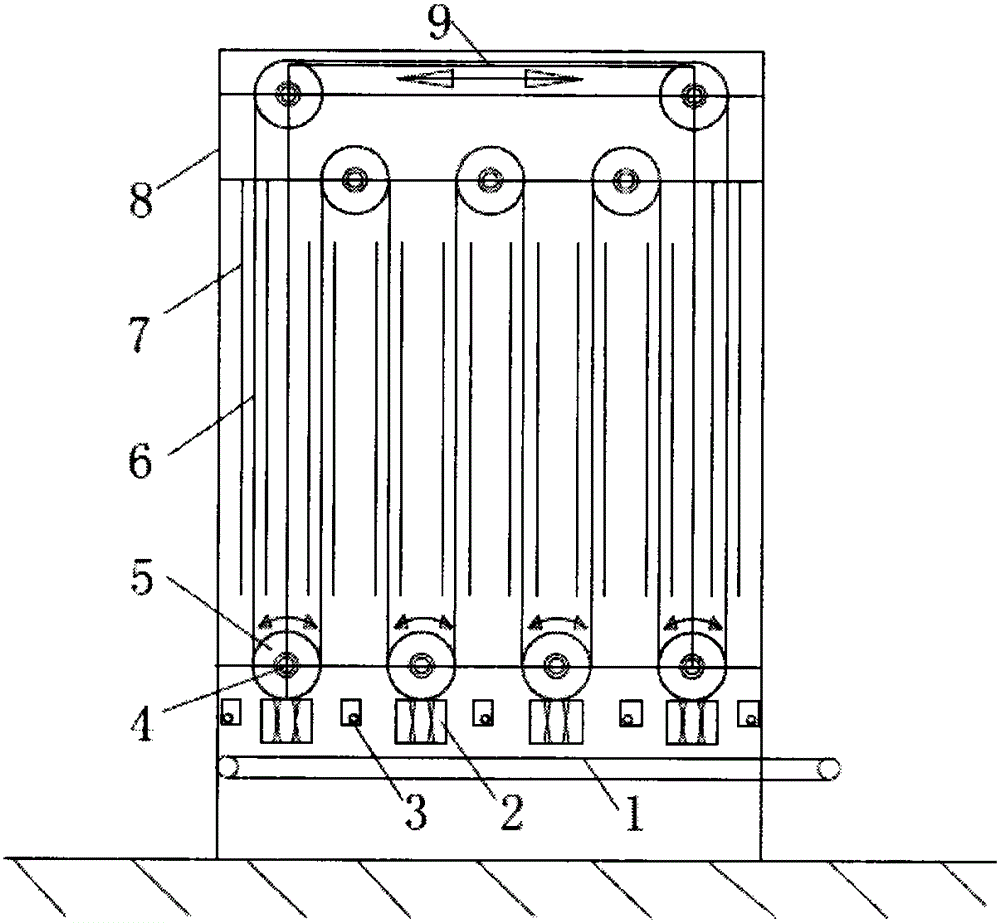

[0039] figure 1 It is a group of mechanical transmission diagrams on one side of the warehouse machine. In order to keep the drawing clear and easy to read and see the intention of the diagram, most of the hanging cargo boxes 2 with different heights above the minimum limit position and disorderly disorder are omitted in the figure. Warehouse machine There is a group on the left and right sides of the inside with figure 1 The same synchronous mechanical transmission system, the light-load chain rope 6 is a closed-loop power transmission part, which is formed by the transmission guide and dynamic load bearing of multiple chain rope wheels 5, multiple sets of vertical restraint slide rails 7 and container restraint grooves 15 A set of...

Embodiment 2

[0043] Embodiment 2: an automatic service system for luggage storage and retrieval warehouse machines at airports, stations, large-scale exhibitions, etc.

[0044] see picture figure 1 , figure 2 , Figure 9 .

[0045] Luggage storage and retrieval services at airports, stations, large-scale exhibitions, etc., can also be completed by using the automatic service system of the warehouse machine above. It is only necessary to install a lifting device on the horizontal conveyor belt 1, because the luggage does not have shockproof and drop-proof packaging. When placing a luggage bag, the horizontal conveyor belt 1 must first rise to a position very close to the bottom of the hanging cargo rail box 2 for acceptance, and then fall down for "placement" and convey to the customer. This example shows two equal-length parallel conveyors. The rotary rod type lifting device is powered by the pneumatic piston rod 28, and the conveyor belt 1 is lifted to the bottom of the hanging cargo ...

Embodiment 3

[0046] Embodiment 3: Automatic service system for machine parts and machine material warehouse machines in factories and enterprises.

[0047] See figure 1 , figure 2 , Figure 10 .

[0048] In the normal production of factories and enterprises, a large number of machine materials and machine accessories are used in large quantities. To use the automatic service system of the micro warehouse machine, it is only necessary to slightly change the partial door parts of the above warehouse machine and the use method of the entire warehouse machine. There are three main ways to easily realize automatic service: one is to change the two sets of restraint strips to the top corners of the diagonal line of the hanging cargo box, or the front and rear box panels of the original cargo box, and the other is to remove the hanging shaft and partition Plates and lock hooks and the conveyor belt at the bottom, the bottom plate of the box is added, and the lower side of the received goods i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com