Dead weight Rockwell hardness machine adopting screw type weight gradation loading technology

A technology of graded loading and Rockwell hardness, applied in the direction of testing material hardness, analyzing materials, strength characteristics, etc., can solve the problems of rare Rockwell hardness standard machine, large friction force of lifting spindle, low work efficiency, etc., to achieve Meet the requirements of value transfer and traceability, improve measurement accuracy and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

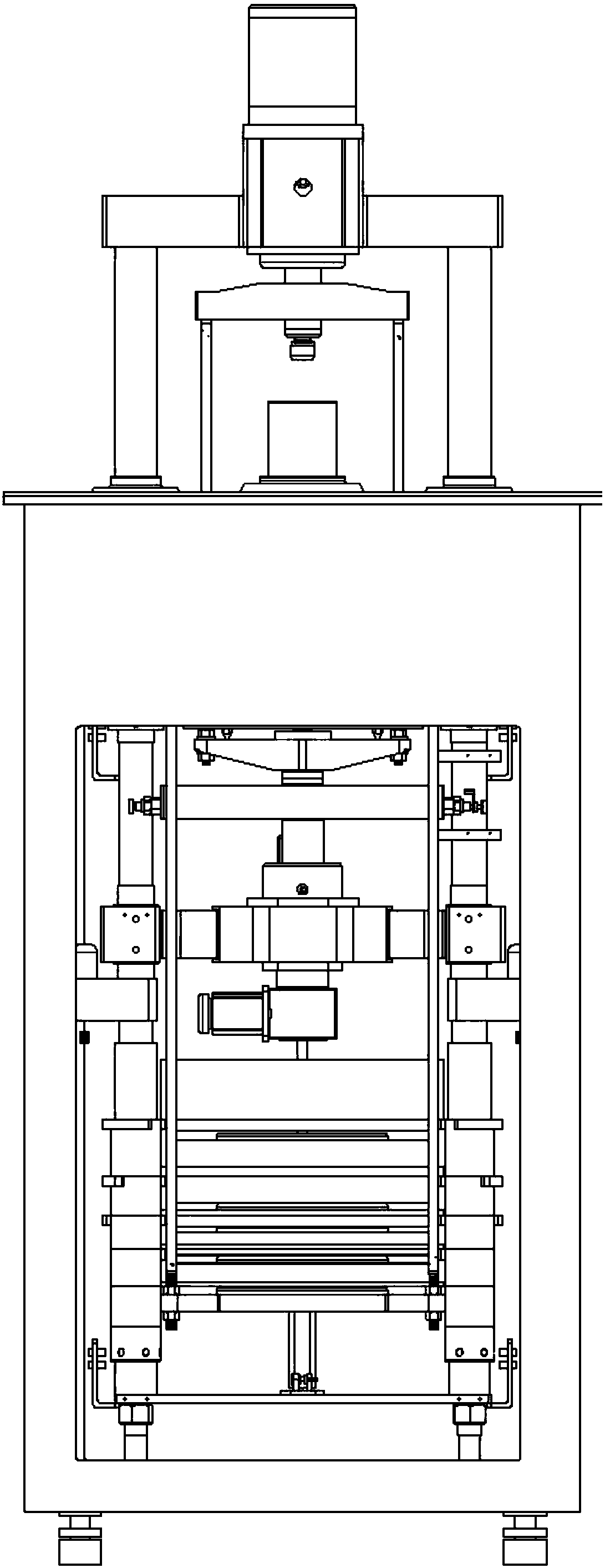

[0029] A static weight Rockwell hardness machine adopting spiral weight staged loading technology, such as figure 1 As shown, it mainly includes a main shaft, a frame, an upper hanger, a lower hanger, weights, a guide mechanism, a test force drive and a spiral weight loading device.

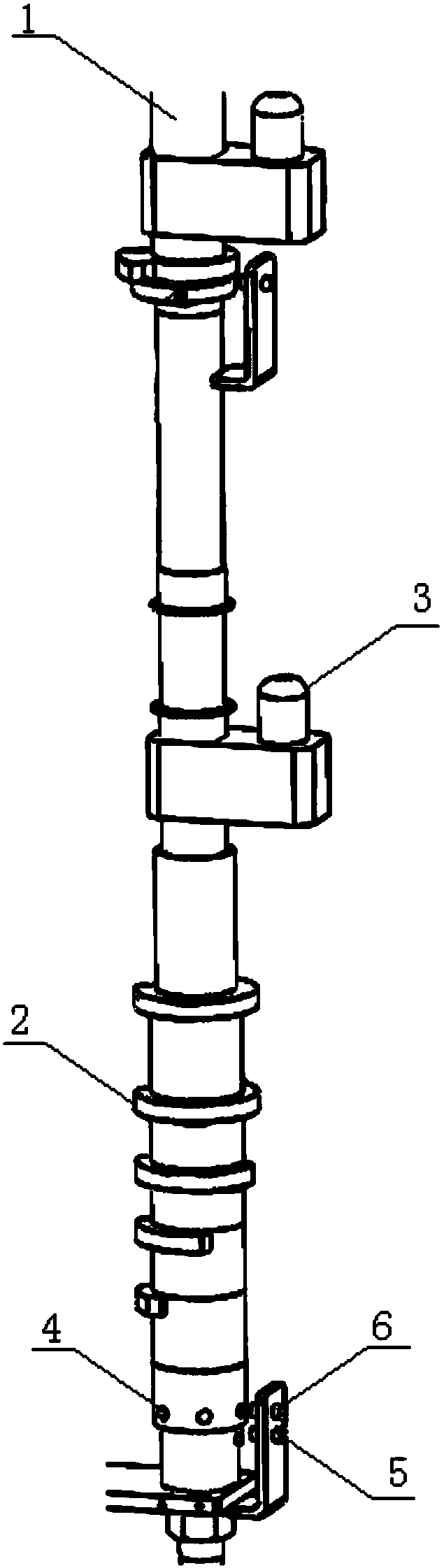

[0030] Such as figure 2 As shown, the spiral weight loading device includes: a sleeve 1, a fan-shaped support block 2, a screw mechanism drive 3, a strong induction magnet 4, a zero sensor 5 and a displacement sensor 6;

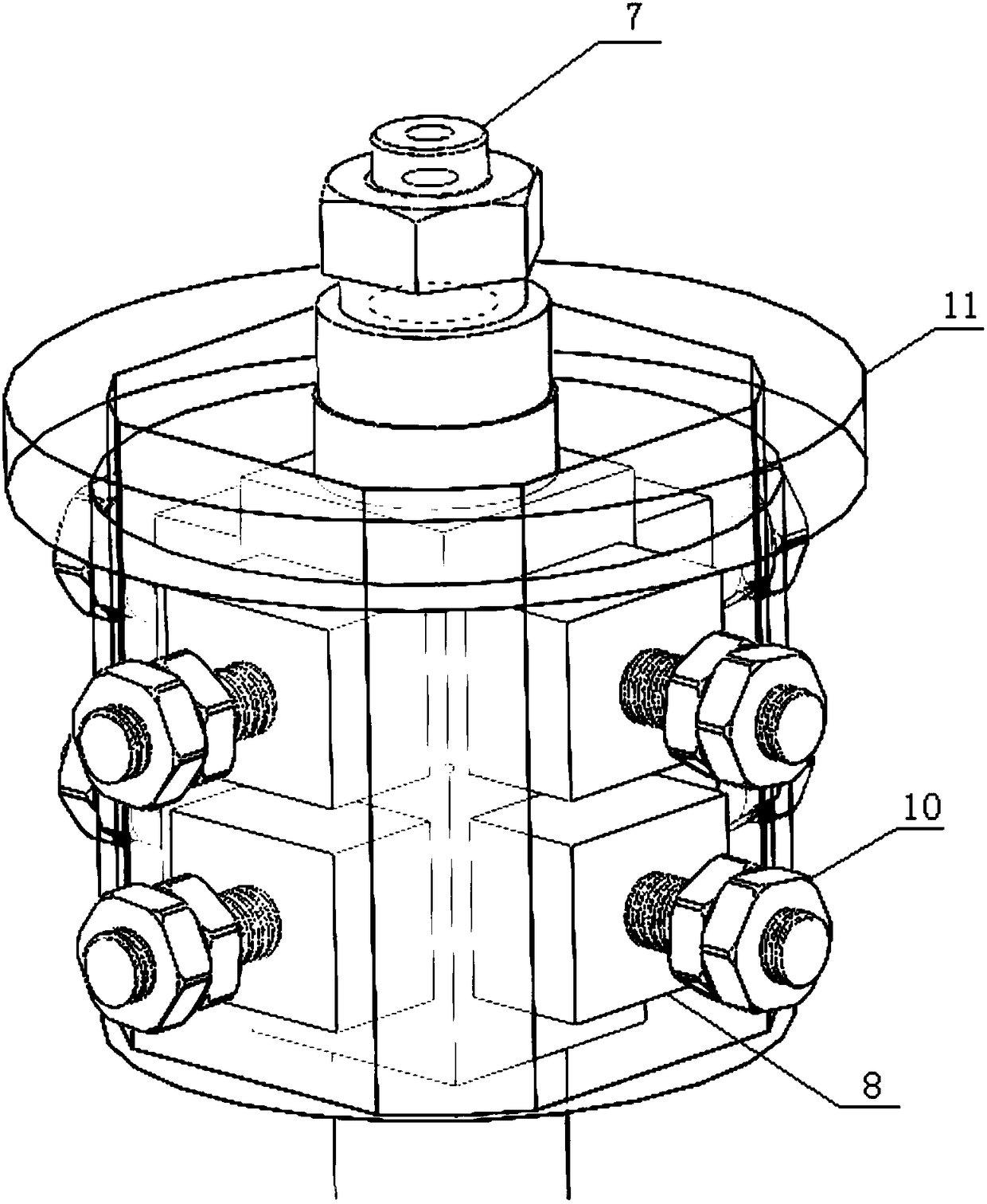

[0031] The 6 fan-shaped brackets are fixedly installed on the sleeve, and the fan-shaped brackets are located under the weight, contact with the weight, and support the weight of the weight; the sleeve is set on the cylinder of the hardness tester; the screw mechanism is used for driving It is used to control the rotation of the sleeve; 6 powerful magnets are evenly distributed at the bottom of the sleeve for the induction of the main load position sensor, and another strong m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com