Metal structural buoyancy pontoon type inner floating tray for storage tank

A metal structure, buoy-type technology, used in containers, packaging, transportation and packaging, etc., can solve the problems of heavy weight, difficult replacement, and large friction coefficient of the floating plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

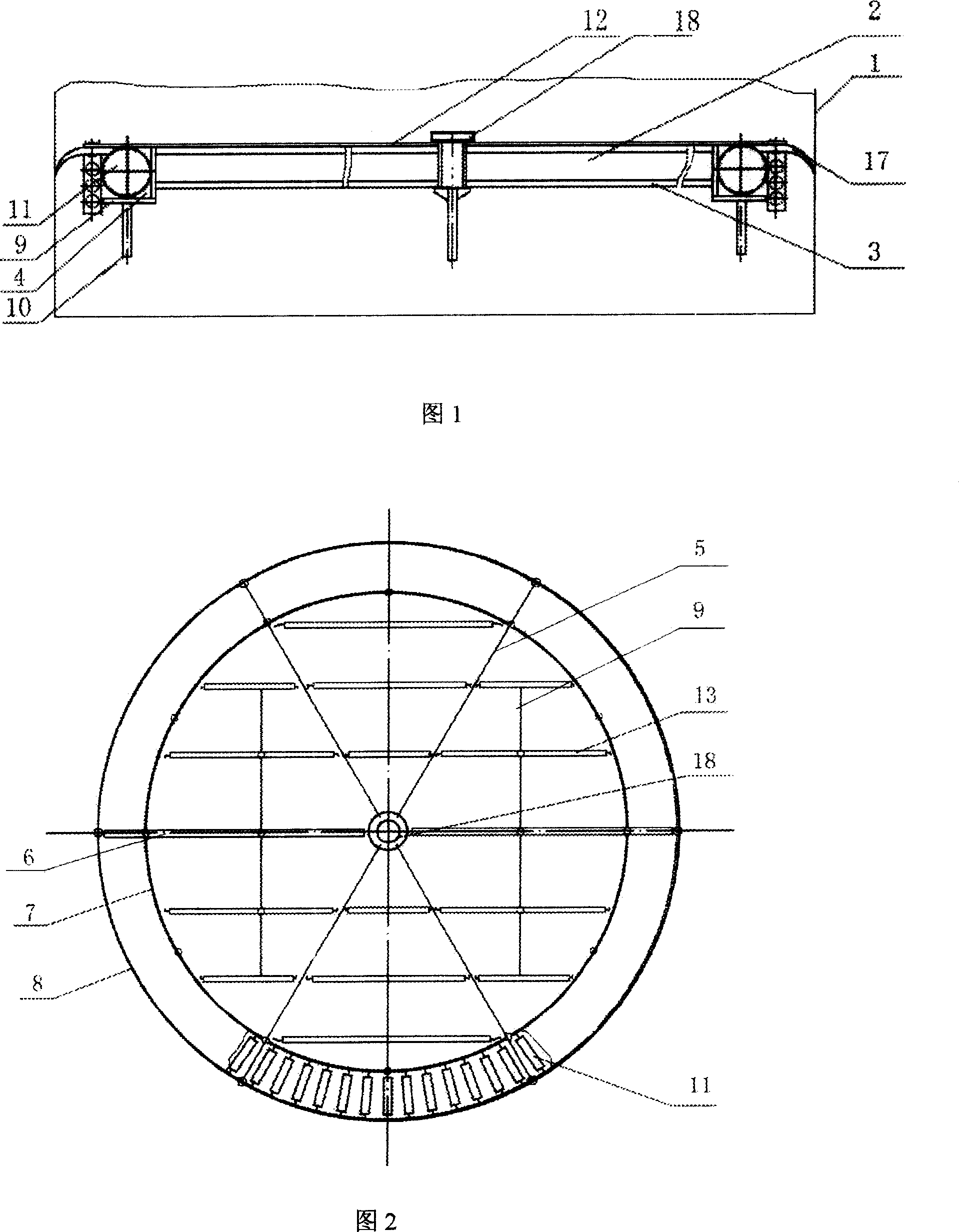

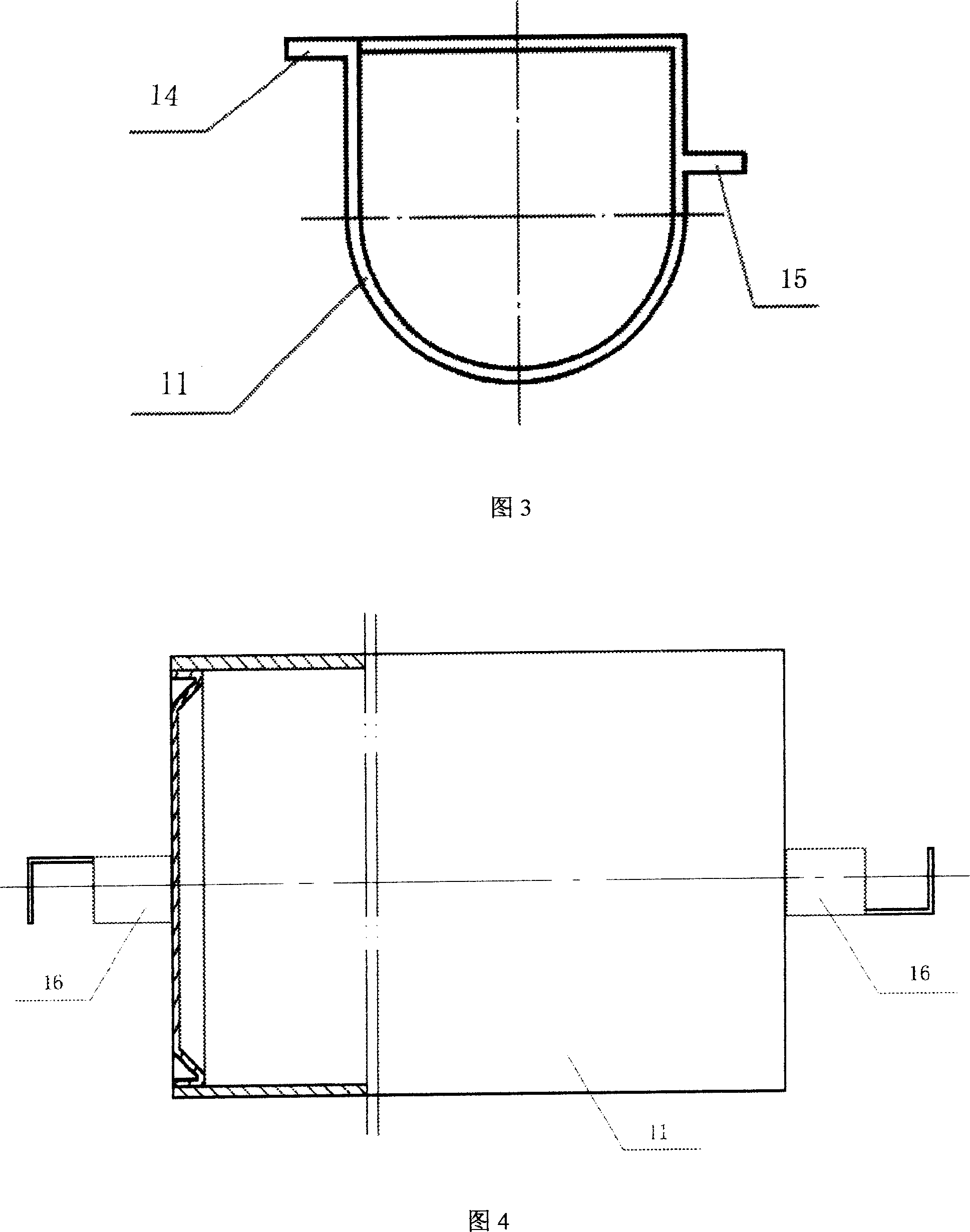

[0010] The floating disc 2 is installed in the storage tank shell 1. It can be seen from Figure 1 that it consists of a radioactive metal framework and a buoy in the metal framework. The floating plate 2 is installed in the storage tank shell 1 filled with medium, floats above the liquid surface, and floats up and down with the liquid surface. . The floating disc 2 is composed of two parts, the middle part of the floating disc is the middle floating disc 3 , and the peripheral part of the floating disc is the peripheral cabin 4 . The middle floating plate (3) is made up of U-shaped buoys (13), and is fixed on the inner ring beam 7, and the inner ring beam 7 of the surrounding cabin 4 is formed by connecting the ribs 9 and the cylindrical buoys 11. Various accessories are installed on the floating plate 2, such as sealing device, static electricity der...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com