New Drill and Blast Shaft Drilling Rig

A drilling and blasting method and a technology for vertical wells, which are applied in the field of drilling rig machinery, can solve the problems of difficulty in improving the working environment and further improving the construction efficiency, and achieve the effects of improving the working environment of workers, reliable connection between equipment, and stable operation of equipment up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

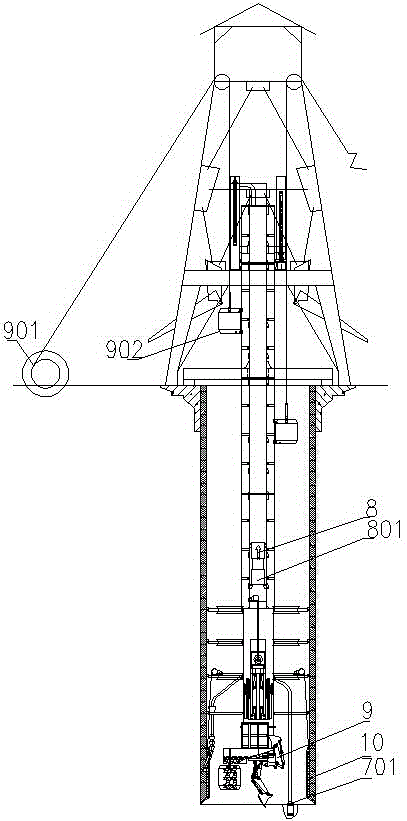

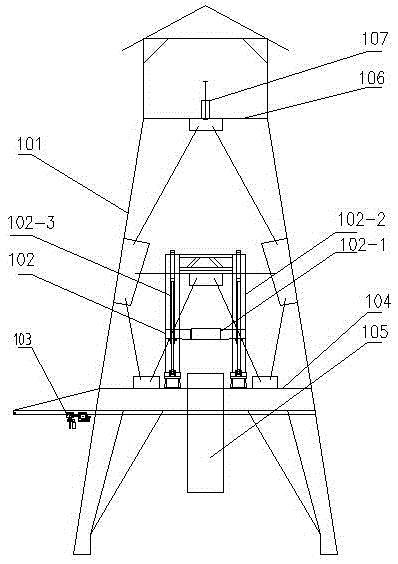

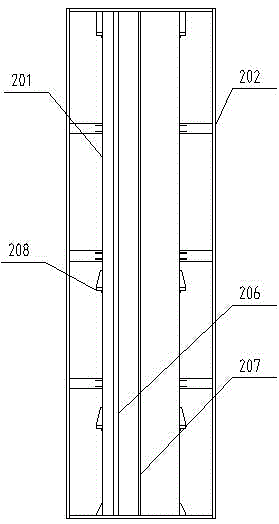

[0023] A new drilling and blasting shaft drilling rig, including a derrick 1, a central column 2, a sealing flat car 3, a well bottom suspension plate 4, a numerically controlled umbrella drill 5, a loader 6, a drainage system 7, a ventilation system 8, a slag discharge system 9, Well wall pouring system 10 , hydraulic station 11 and control room 12 . The derrick 1 and the sealing flat car 3 are fixed on the wellhead, and the sealing flat car 3 is arranged in the bottom of the derrick 1 . A column lifting mechanism 102 is installed on the derrick 1, the central column 2 is connected with the column lifting mechanism 102, the central column 2 extends to the downhole, and the central column 2 middle part is connected with several well bottom hanging pans 4. The central column 2 passes through the suspension pan 4 at the bottom of the shaft, and a loader 6 is installed at the bottom, and a numerically controlled umbrella drill 5 is installed inside the lower end of the central co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com