High tensile cable electrical transmission device for hydraulic grab bucket

An electrical transmission and hydraulic grabbing technology, applied in the direction of insulated cables, electrical components, coupling devices, etc., can solve the problems of inoperable cleaning work, entry into the cable, small winding force, etc., so that it is not easy to hang. , Reliable work, the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

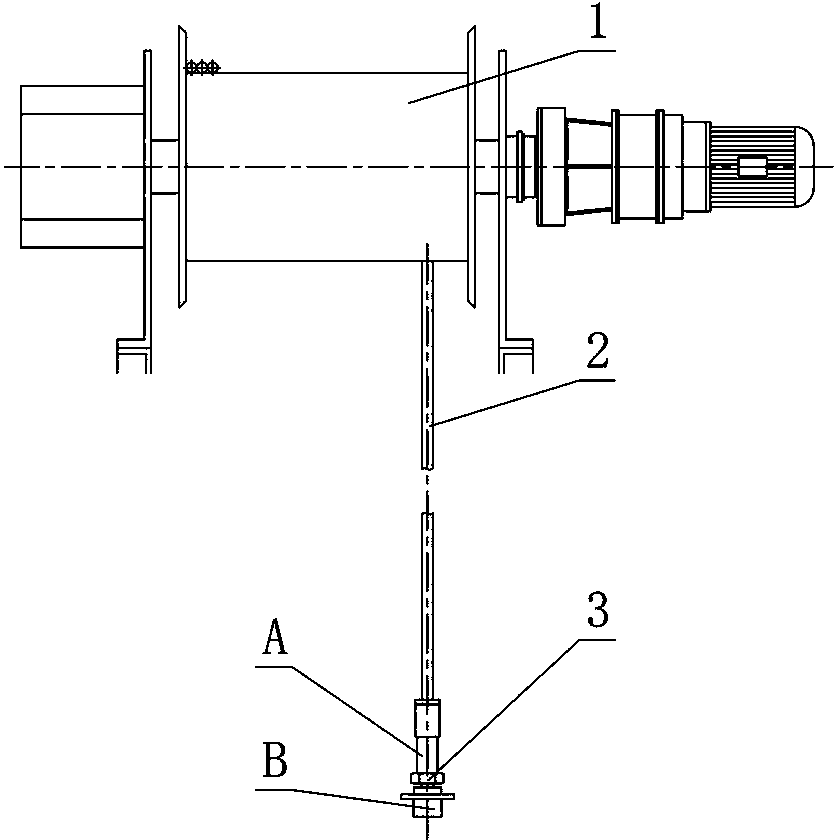

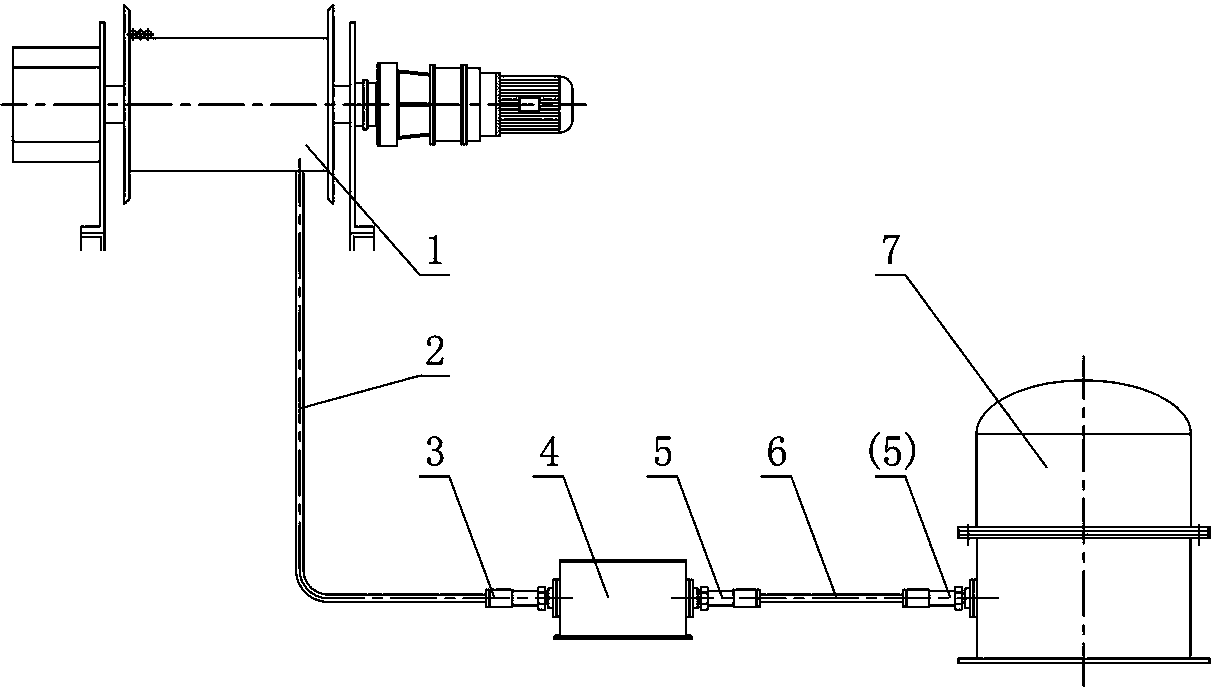

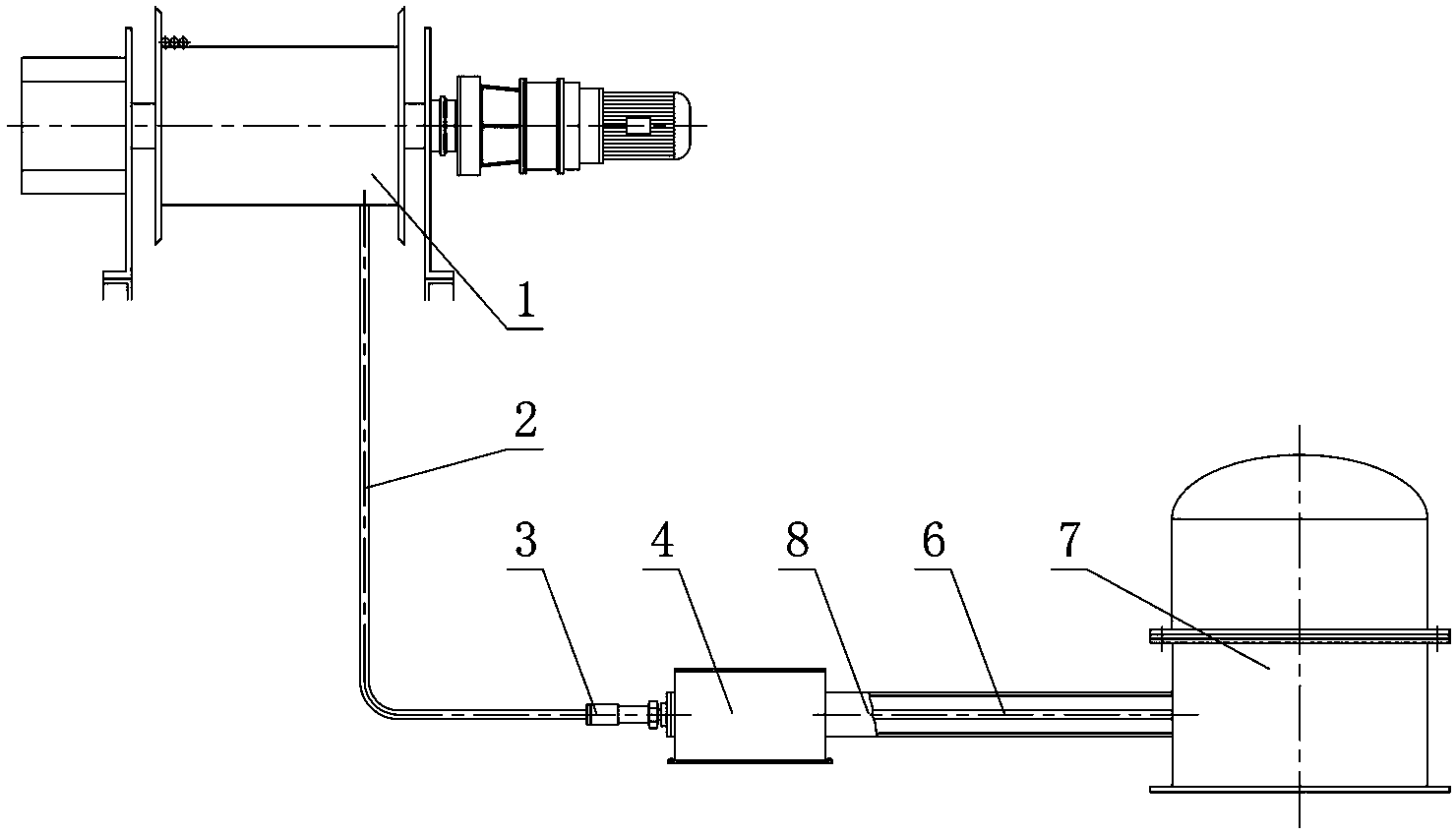

[0021] figure 1 It is a schematic diagram of Embodiment 1 of a high-tension cable electrical transmission device for a hydraulic grab of the present invention. The device is composed of a cable reel 1, a composite steel wire cable 2, and a waterproof electrical connection device 3. Wherein, the waterproof electrical connection device 3 is an electrical plug-in device, which is composed of a water pressure-resistant sealing plug A and a water pressure-resistant sealing socket B. Among them, the water pressure-resistant sealing plug A is connected to the end of the cable 2, and the water pressure-resistant sealing socket B is installed on the electrical equipment of the cleaning bucket. Generally, the water pressure-resistant sealing socket B is installed on the oil tank of the hydraulic grab. Equipped with hydraulic pump station. Different from the electrical transmission device of the hydraulic cleaning grab bucket in the prior art, the cable 2 is a cable with a steel wire ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com