High-stability lifting mechanism

A high-stability, frame technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can save maintenance and repair costs, reduce frictional resistance, and drive smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

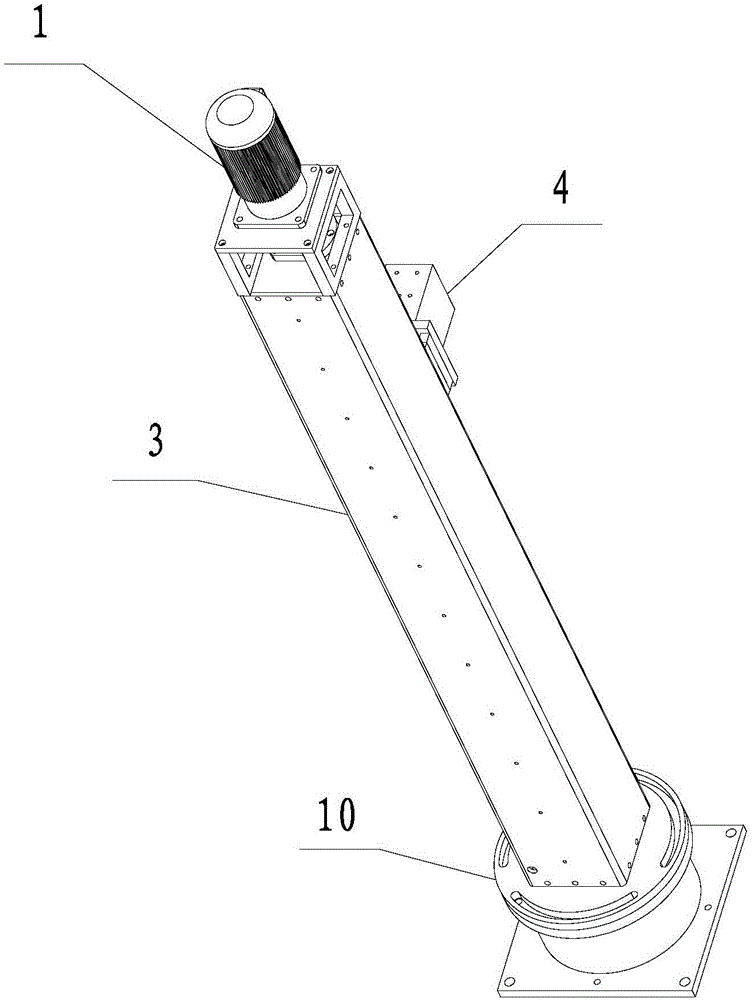

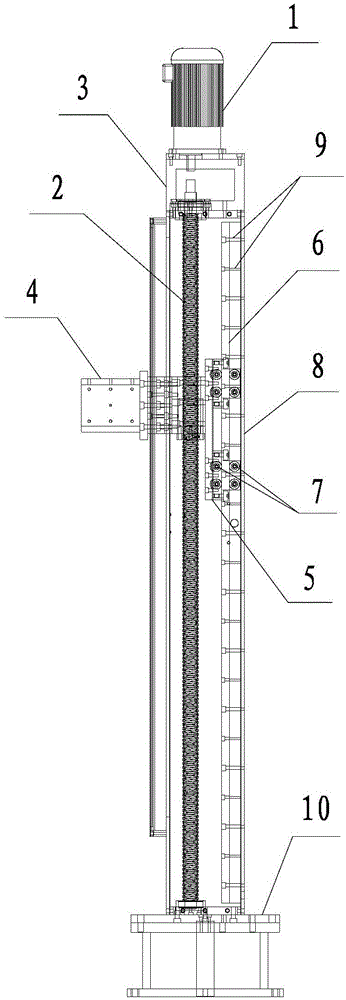

[0023] Example: Combine figure 1 and figure 2 As shown, it is a specific embodiment of the high-stability lifting mechanism of the present invention, which has a motor 1, a screw rod 2, a frame 3, and a nut movable block 4. The screw rod 2 is arranged longitudinally, and the motor 1 is fixed on the frame 3 is connected to and drives the screw mandrel 2 to rotate, the nut movable block 4 is threadedly matched with the screw mandrel 2, and the frame 3 is provided with longitudinal slots for the threaded movable block 4 to move up and down, and the threaded movable block 4 It is clamped in the longitudinal slot.

[0024] The improvement of the present invention lies in the addition of a support and guide mechanism, which is composed of a guide trolley 5, a guide plate 6 and a support plate 8. The guide trolley 5 and the nut movable block 4 are fixed by screws, the guide plate 6 is fixed in the frame 3 and arranged in parallel with the screw mandrel 2, and the guide trolley 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com