Widening mechanism of cable shielding network using rolling steel brush

A cable shielding and steel brush technology, applied in the direction of online network, application, household appliances, etc., can solve the problem that the braided shielding network is not easy to widen, and achieve the effect of improving the adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

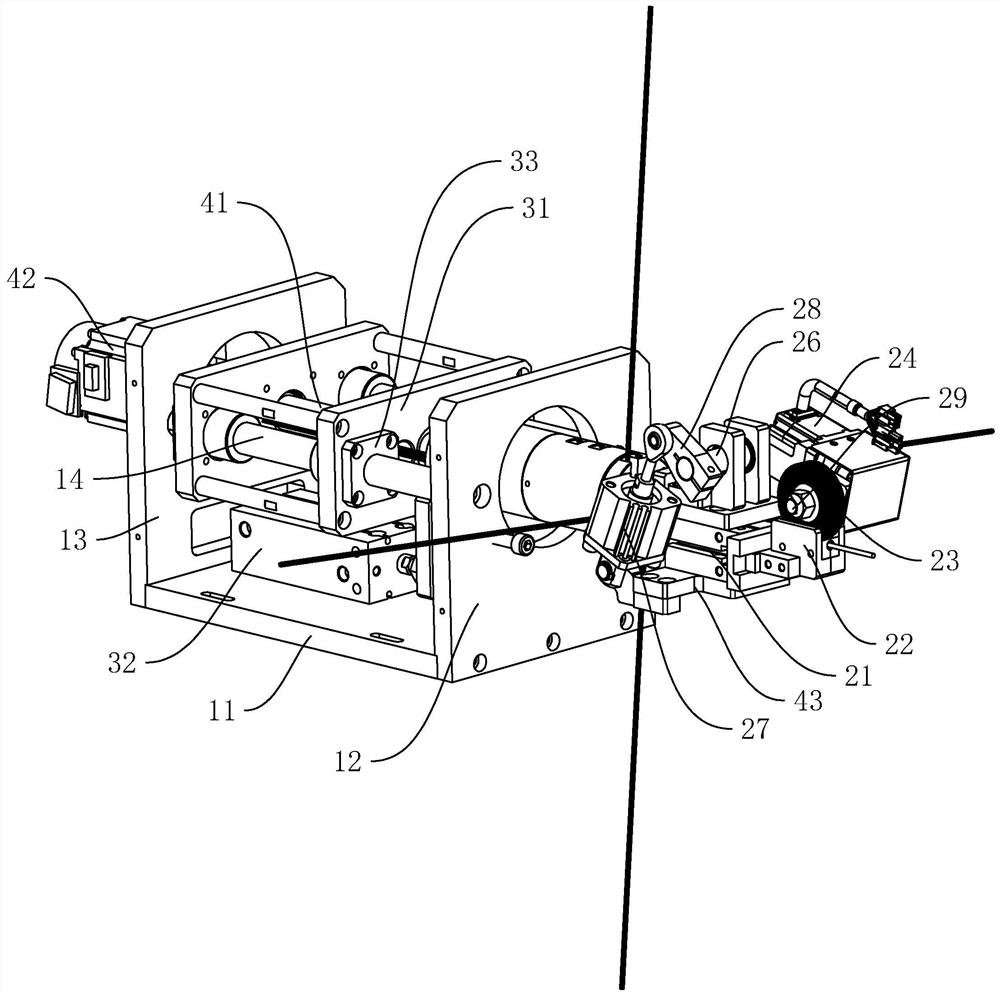

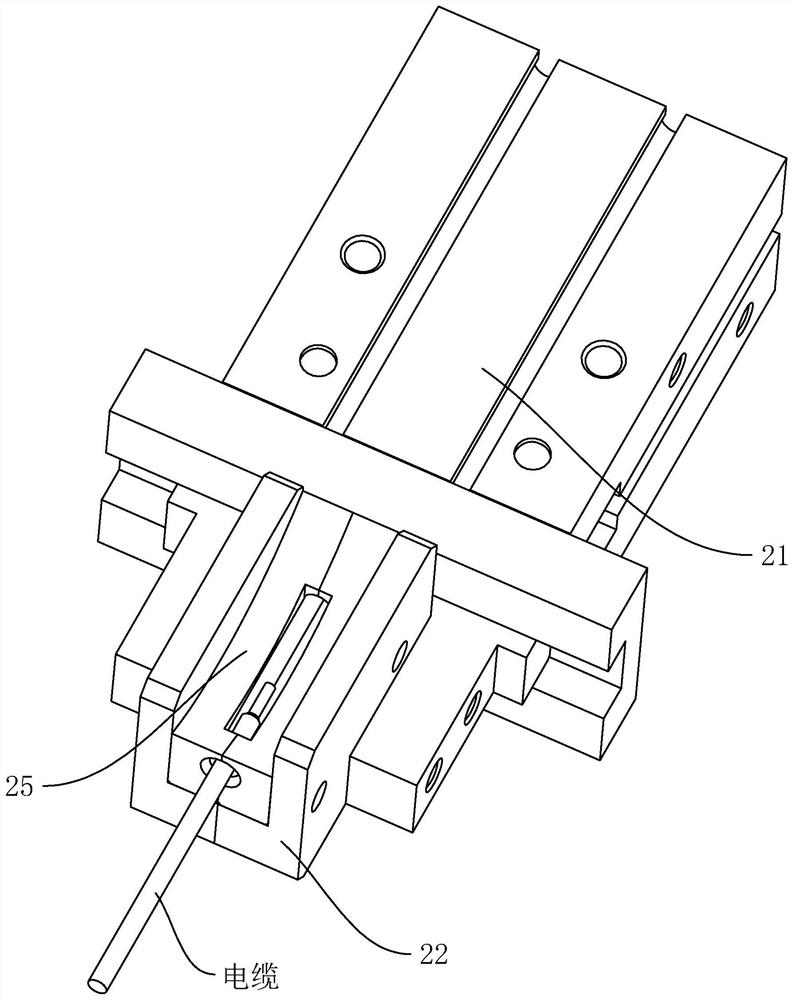

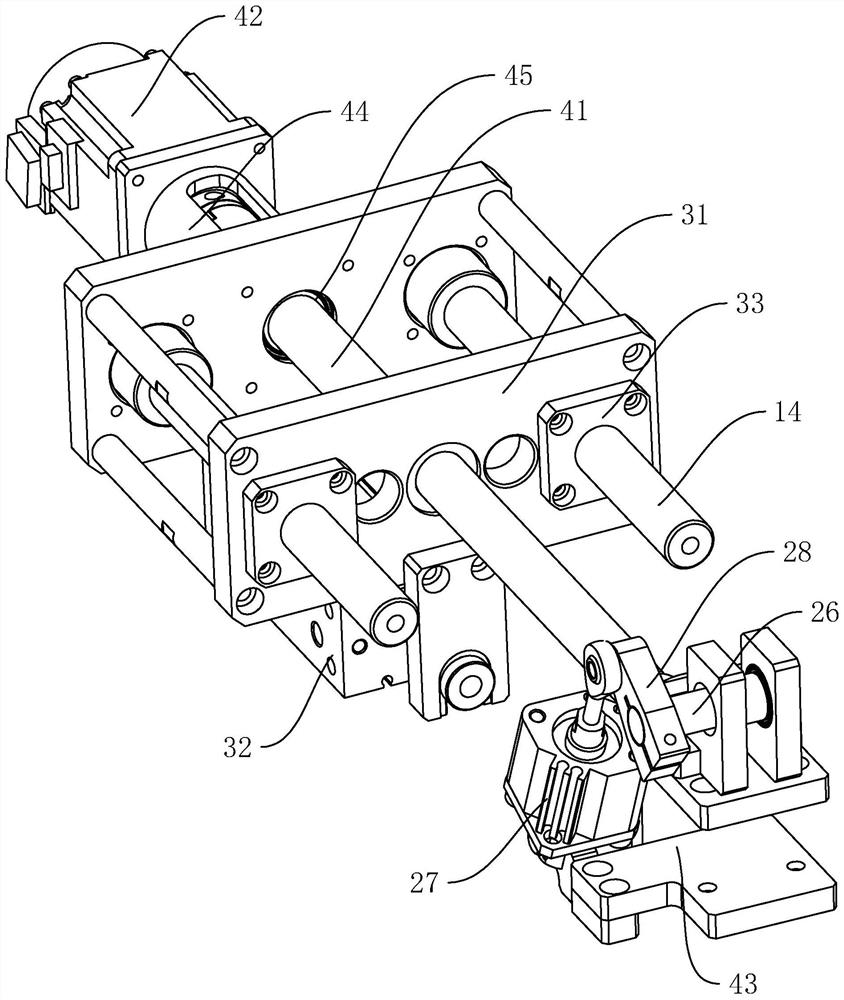

[0028] Cable shielding network widening mechanism using rolling steel brush, such as figure 1 , figure 2As shown, it includes a support assembly, an execution assembly, a telescopic assembly and a rotation assembly; the execution assembly includes an air claw 21, two gap clamping blocks 22 bolted to the air claw 21, a steel brush wheel 23, and a steel brush wheel 23 for driving The steel brush motor 24, the two gap clamping blocks 22 are provided with circular arc grooves 25 for the cables to be exposed and for the steel brush wheel 23 to be embedded. 24 and the rotating shaft 26 that is rotatably connected to the air claw 21, and the swing cylinder 27 that is rotatably connected to the air claw 21, the piston rod end of the swing cylinder 27 is hinged with a holding block 28, and the holding block 28 is clamped on the other end of the rotating shaft 26 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com