Waste gas purification equipment for medical waste incinerator and using method of waste gas purification equipment

A technology for exhaust gas purification and purification equipment, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, which can solve the problems of reduced utilization rate of adsorbents, large safety hazards, and environmental pollution, so as to reduce loss rate and improve purification effect, easy adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

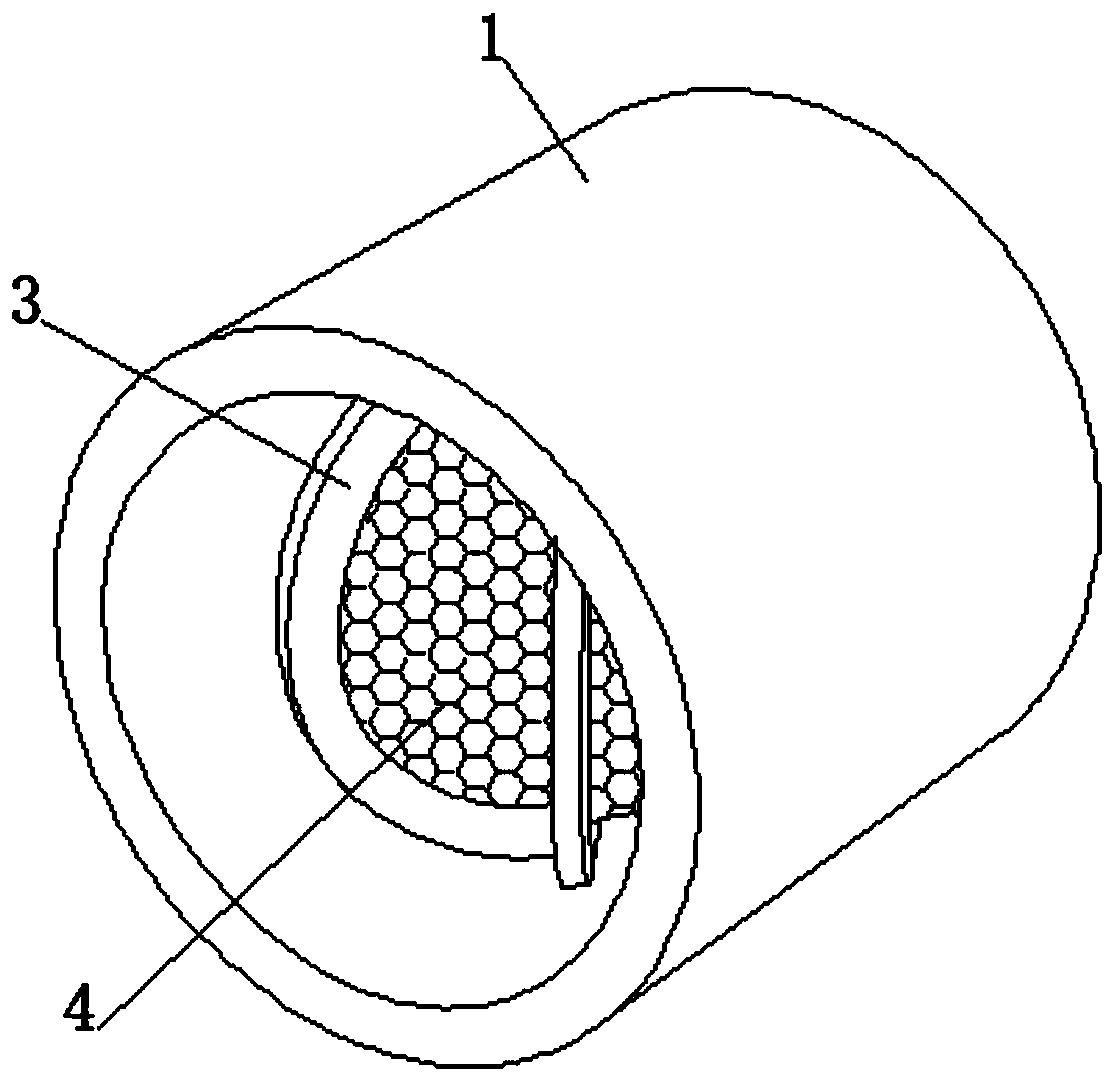

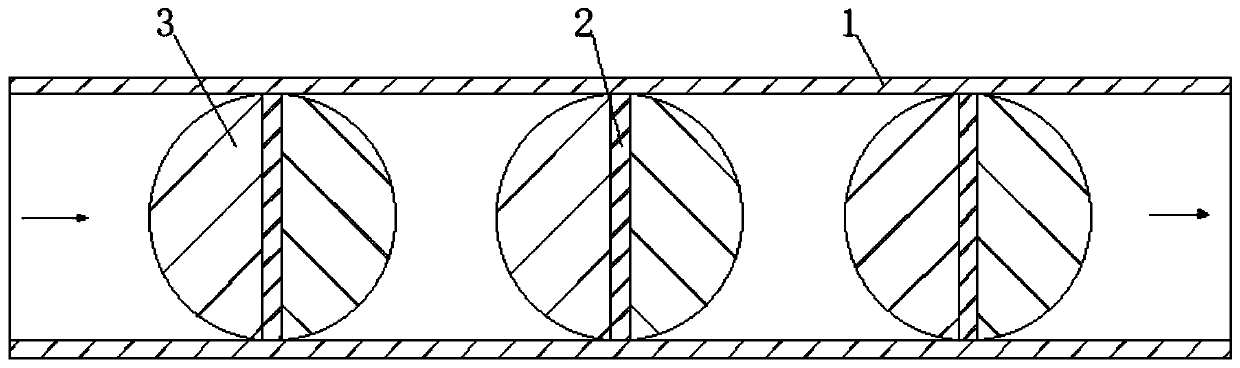

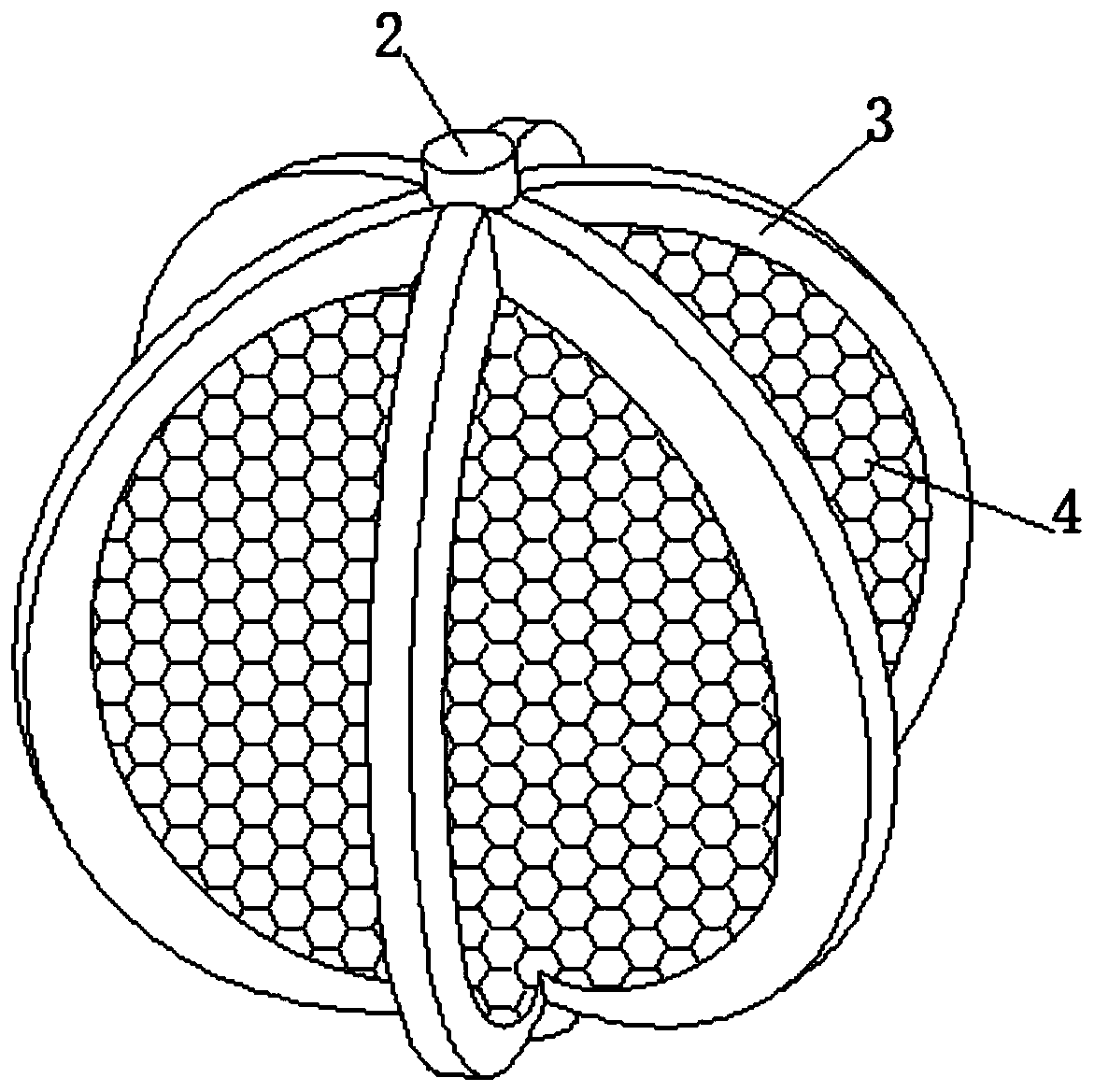

[0048] see Figure 1-2 , an exhaust gas purification device for medical waste incinerators, comprising a purification device body 1, the purification device body 1 is installed at the exhaust port of the incinerator, and a plurality of evenly distributed spherical adsorption bodies are arranged in the purification device body 1 The ball-transfer adsorption body is in contact with the inner wall of the purification equipment body 1. The ball-transfer adsorption body includes a transfer shaft 2 that is rotatably connected to the inner wall of the purification device body 1. The outer end of the transfer shaft 2 is fixedly connected with a plurality of evenly distributed semicircular rotor blades 3.

[0049] see Figure 3-4 , between every adjacent two semicircular rotating blades 3, an inner filter 4 and an outer filter 5 are connected, the inner filter 4 is located in the outer filter 5, and the diameter of the concentric circles where the plurality of outer filter 5 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com