Rotating assembly and floor air conditioner

A technology of vertical air conditioners and rotating components, which is applied to air conditioning systems, heating methods, airflow control components, etc., and can solve problems such as no driving scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

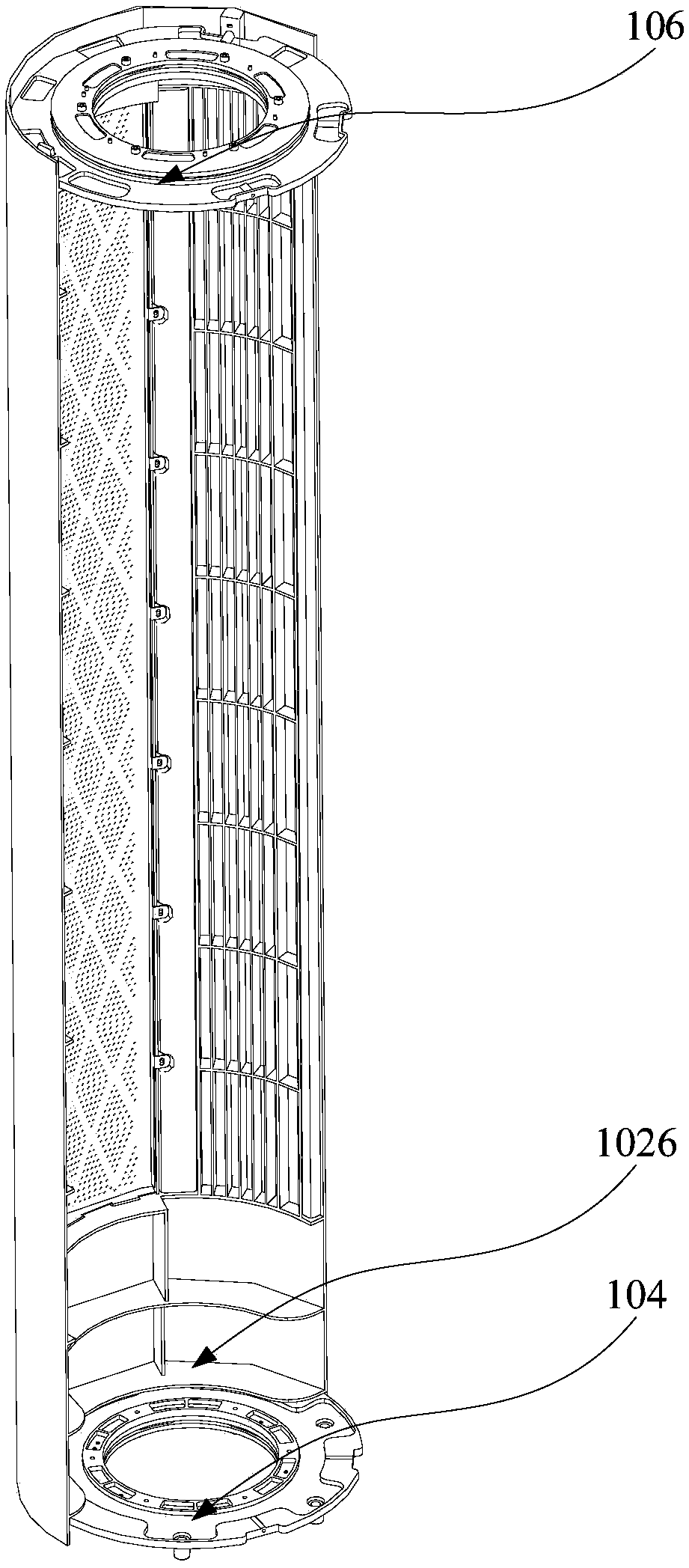

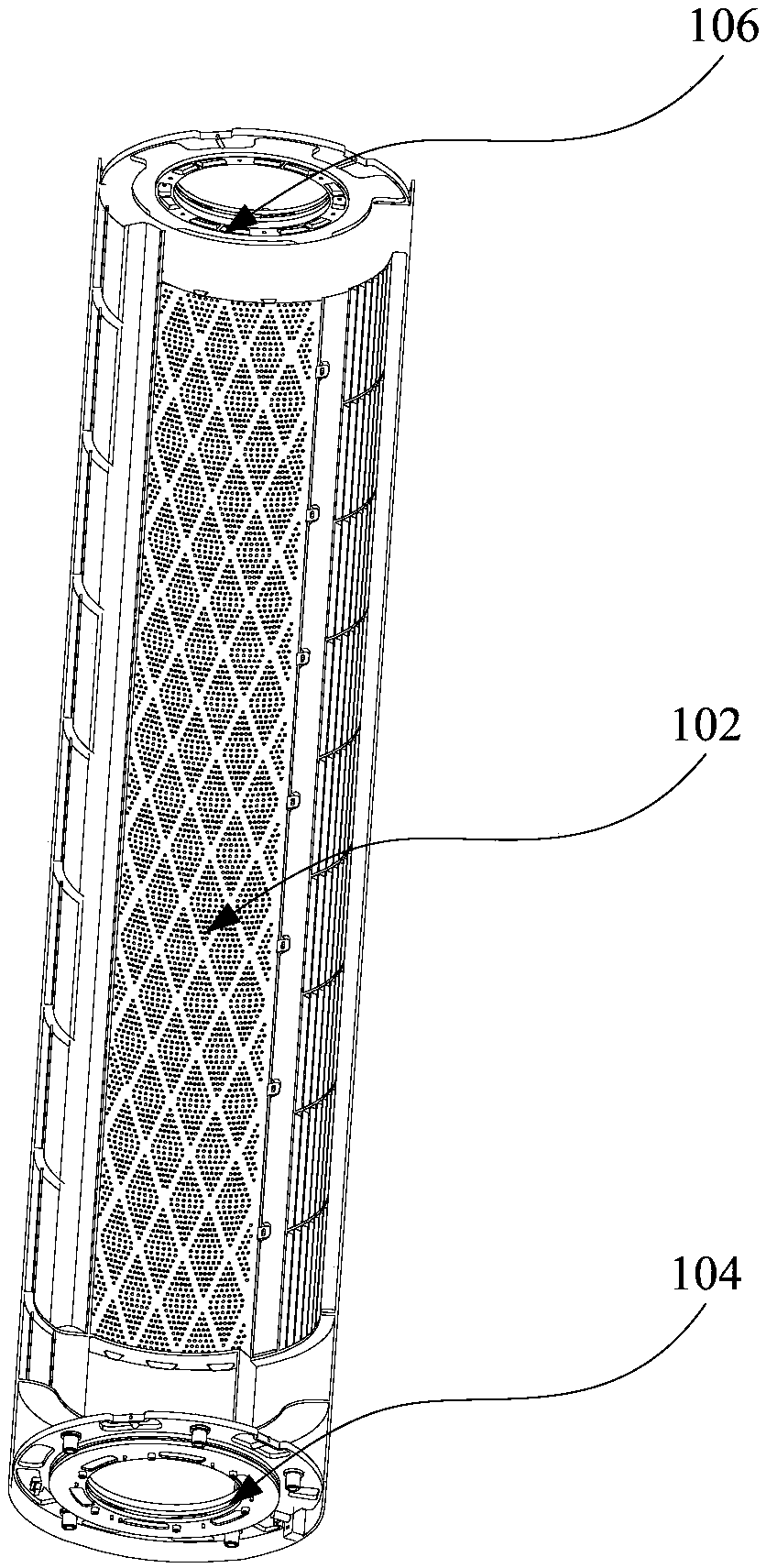

[0095] Such as figure 1 and Figure 4 As shown, the rotating assembly according to the embodiment of the present invention is suitable for a vertical air conditioner. The rotating assembly includes: an arc-shaped air outlet panel 102, on which a micro-hole area 104 is arranged; an arc-shaped air inlet panel, and an arc-shaped air inlet panel, The air outlet panel can be detachably docked and assembled; the driving mechanism 106 is assembled on the bottom and / or top of the air inlet panel, and the driving mechanism 106 is used to drive the arc-shaped air inlet panel and the arc-shaped air outlet panel to rotate.

[0096] In this embodiment, by cooperating with the arc-shaped air inlet panel to assemble the driving device, the automatic rotation of the corresponding air outlet assembly is realized to achieve different modes of air outlet, and the rotation of the drive mechanism 106 drives the arc-shaped air outlet panel to rotate, so that Realize that when the air guide area 10...

Embodiment 2

[0103] In any of the above-mentioned embodiments, preferably, the driving mechanism 106 further includes: a fan-shaped top plate, the inner side wall of the fan-shaped top plate is fixedly assembled with the outer peripheral wall of the top fixing member, and a plurality of bar-shaped teeth are arranged on the fan-shaped top plate along the circumferential direction. , the bar-shaped teeth can be connected with the angle sensor, wherein, when the top fixing piece drives the fan-shaped top plate to rotate, the angle sensor detects the number of the bar-shaped teeth passing by to determine the rotation angle of the arc-shaped air outlet panel.

[0104] In this embodiment, by setting the fan-shaped top plate and a plurality of bar-shaped teeth on the upper end surface of the fan-shaped top plate, the plurality of bar-shaped teeth form an arc profile, and an angle sensor can be set correspondingly on the upper part of the arc profile. During the rotation of the curved air outlet pa...

Embodiment 3

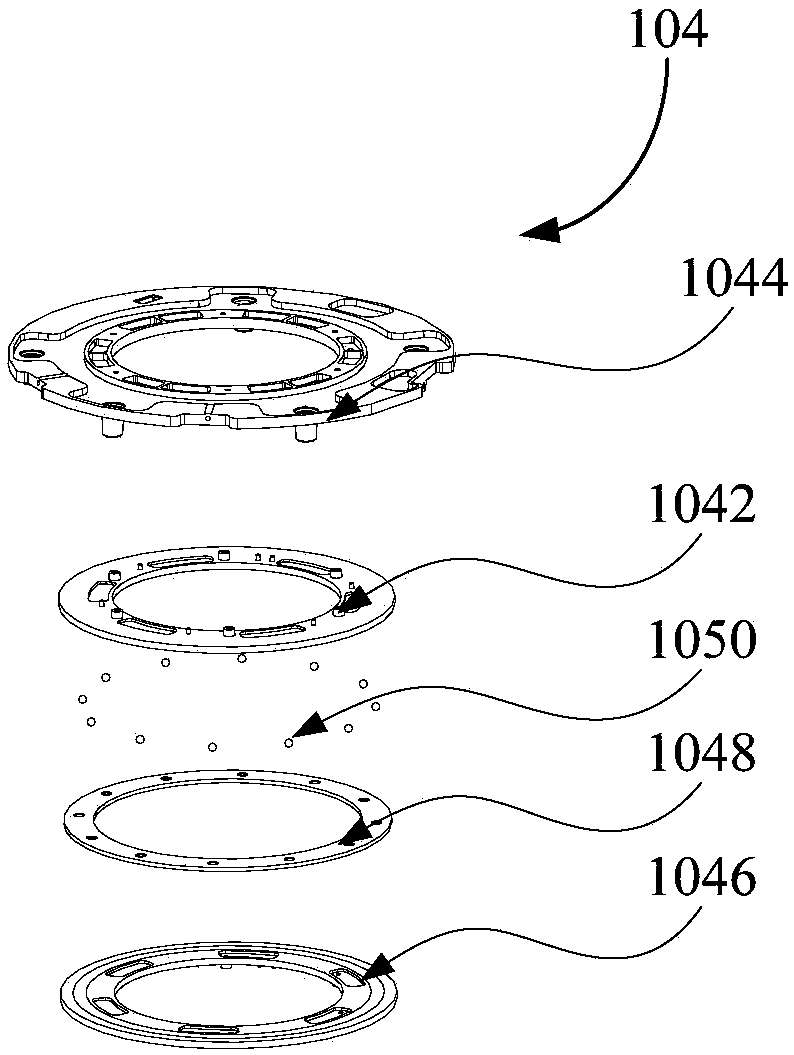

[0106] Such as Figure 2 to Figure 5 , Figure 10 and Figure 13As shown, when the rotating mechanism 104 includes the second rolling bearing 1042, in the above embodiment, preferably, the arc-shaped air outlet panel 102 further includes: a first fan-shaped plate 1026, which is horizontally arranged on the inner side of the bottom of the arc-shaped air outlet panel 102 , the fan-shaped base plate is provided with a first group of connecting holes; the second fan-shaped plate 1036 is arranged above the first fan-shaped plate 1026 and is arranged in parallel with the first fan-shaped plate 1026; the rotating mechanism 104 includes: rotating the water receiving tray 1044, rotating The upper end surface of the water receiving tray 1044 is attached to the lower end surface of the first fan-shaped plate 1026. The rotating water receiving tray 1044 is provided with a drainage groove 1044A. The drainage groove 1044A is provided with a plurality of drainage holes along the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com