Air outlet panel assembly and vertical air conditioner

A vertical air conditioner and air outlet panel technology, which is applied to air conditioning systems, heating methods, air flow control elements, etc., can solve the problems of complex connection structures and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

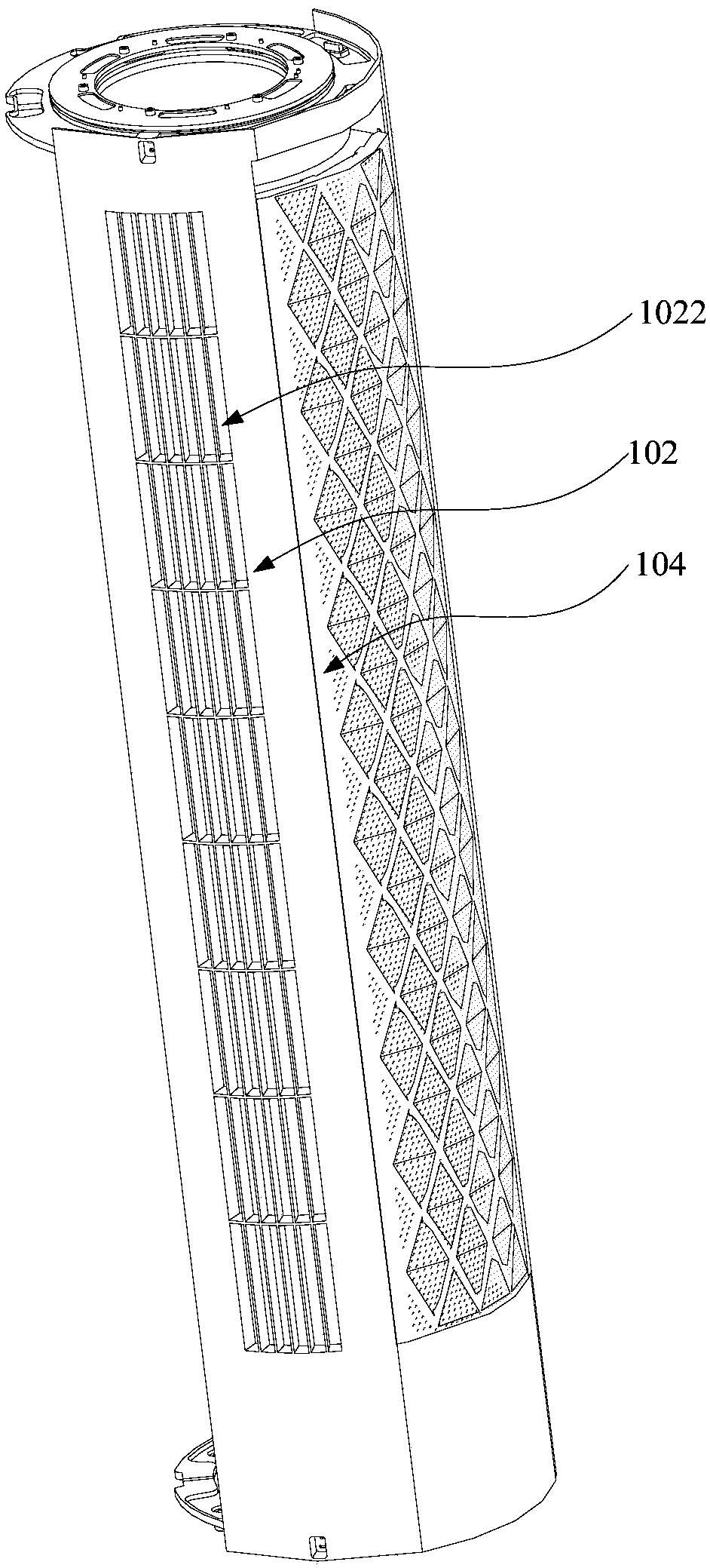

[0089] Such as figure 1 and figure 2 As shown, in the above-mentioned embodiment, preferably, the wind guiding panel 102, the breeze panel 104 and the shielding panel 106 are all configured as arc-shaped panels, and are smoothly connected sequentially along the circumferential direction.

[0090] In this embodiment, the first combination of the wind guide panel 102, the breeze panel 104 and the shielding panel 106 is defined. The angle is the viewpoint, and they are smoothly connected sequentially along the circumference, which can be connected clockwise or counterclockwise. With this setting method, after the air conditioner is turned on, the correspondence between the air outlet and the breeze panel 104 can be realized first, so as to quickly Enter the windless operation mode.

Embodiment 2

[0092] At the same time, it is also possible to adopt the second combination of the wind guide panel 102, the breeze panel 104 and the shielding panel 106 to exchange the setting positions of the wind guide panel 102 and the breeze panel 104, that is, the wind guide panel 102, the breeze panel 104 and the shielding panel 106 Set up in turn along the circumferential direction. With this setting method, after the air conditioner is turned on, it can first use the air guide mode to achieve rapid cooling or heating. Microhole 1044B vents air to improve user comfort.

[0093] Wherein, the wind guiding panel 102 , the shielding panel 106 and the breeze panel 104 may be separate arc-shaped panels, which are fixed and assembled to form a wind outlet panel assembly.

[0094] In addition, the wind guiding panel 102 , the shielding panel 106 and the breeze panel 104 can also be prepared by integral molding.

Embodiment 3

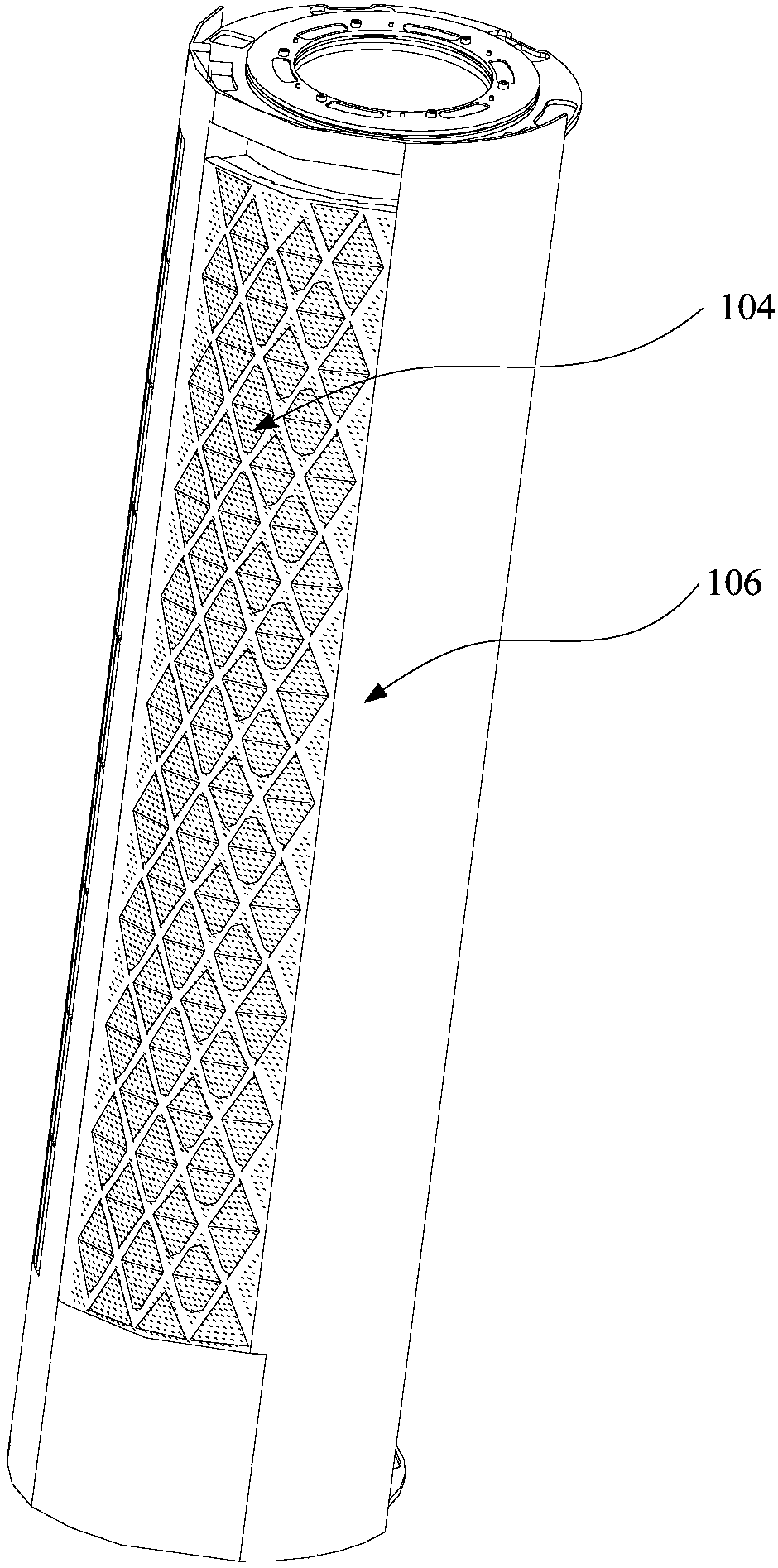

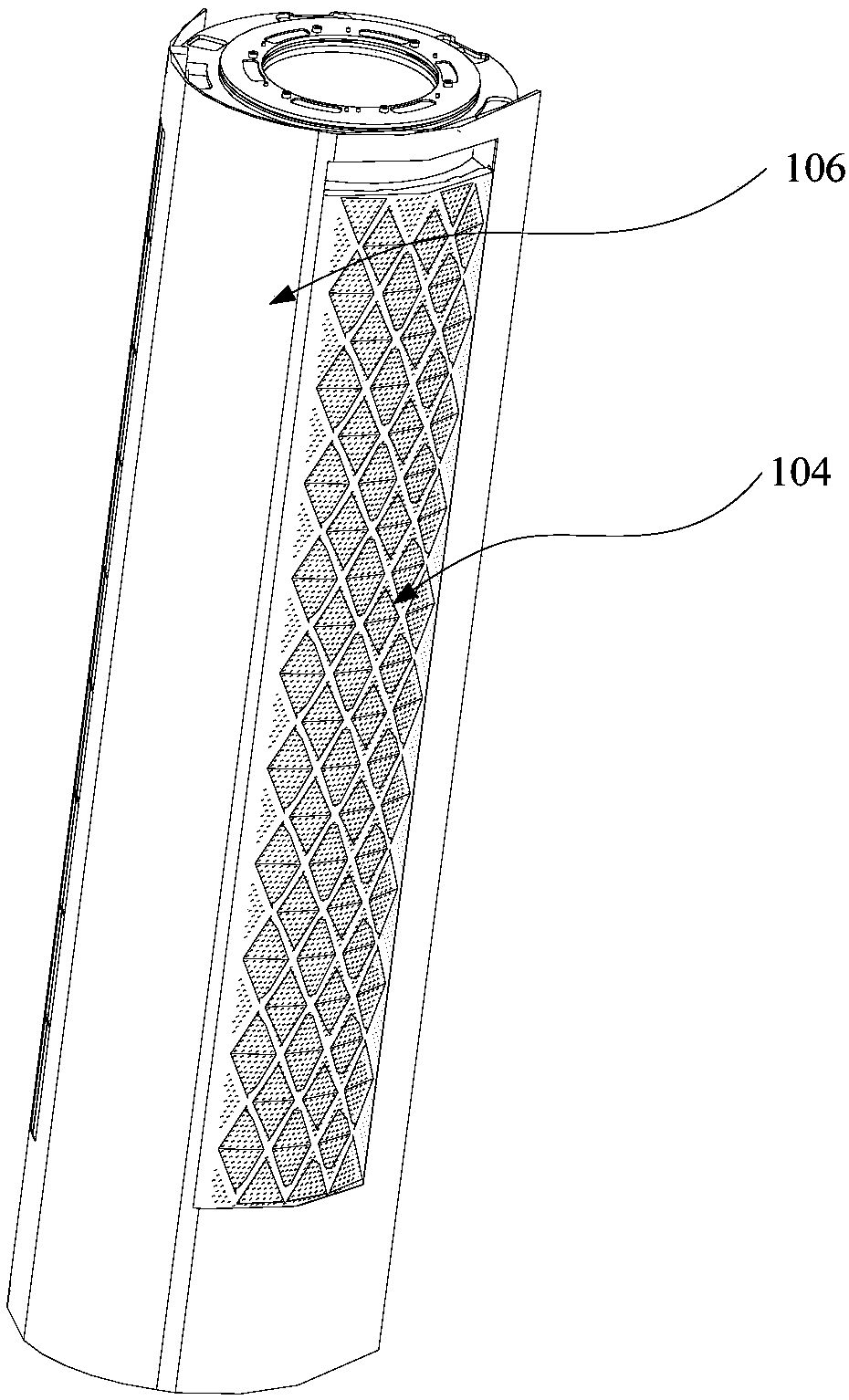

[0096] Such as image 3 and Figure 4 As shown, in any of the above-mentioned embodiments, preferably, the wind guiding panel 102 , the shielding panel 106 and the breeze panel 104 are all configured as arc-shaped panels, and are smoothly connected successively along the circumferential direction.

[0097] In this embodiment, a third combination of the wind guide panel 102, the breeze panel 104 and the shielding panel 106 is defined. By setting the shielding panel 106 between the wind guide panel 102 and the breeze panel 104, in the off state, The shading panel 106 corresponds to the air outlet. After the power is turned on, the air outlet panel module can be rotated clockwise or counterclockwise according to the user's choice to enter the wind guide mode or the breeze panel 104 mode. In a single-mode use environment, the The rotation stroke minimization setting is set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com