Bearing system

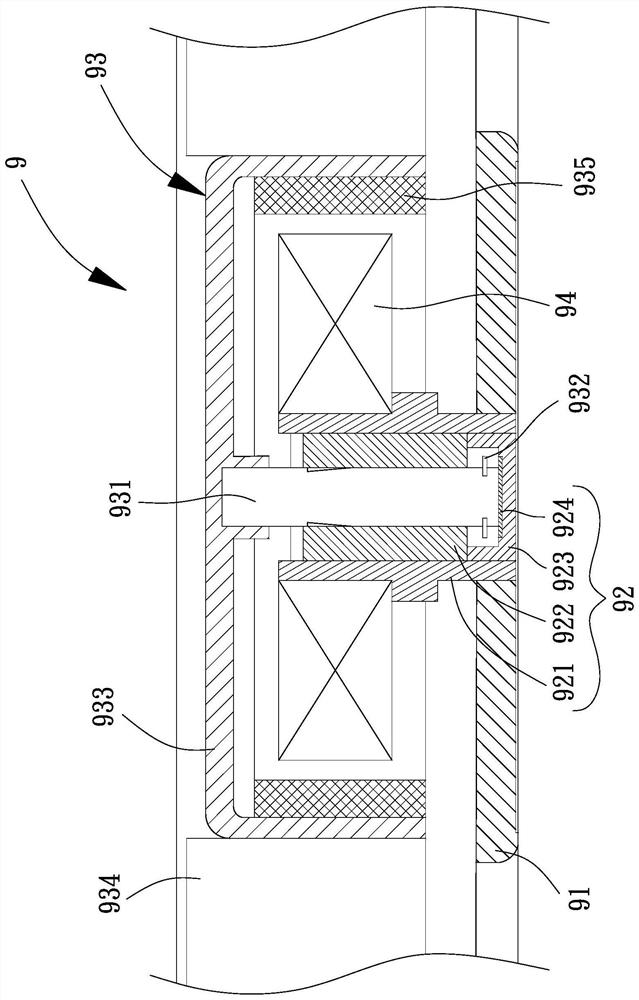

A bearing and shaft hole technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of unstable rotation of rotor 93 and noise, and achieve the effect of improving quality and reducing operating noise and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

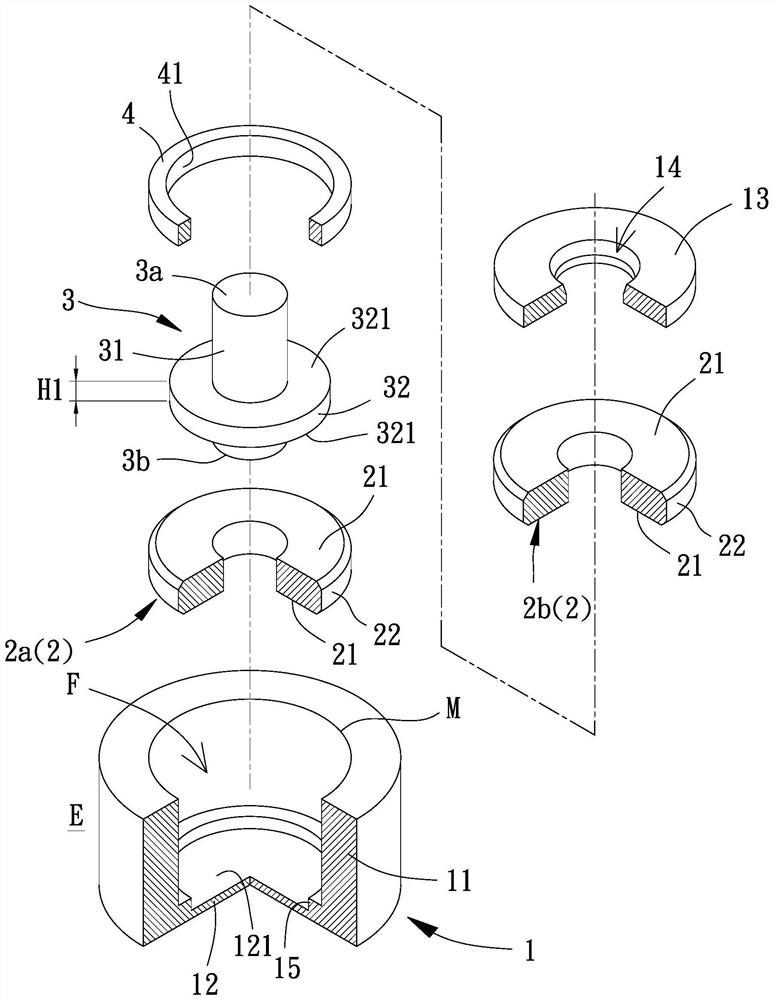

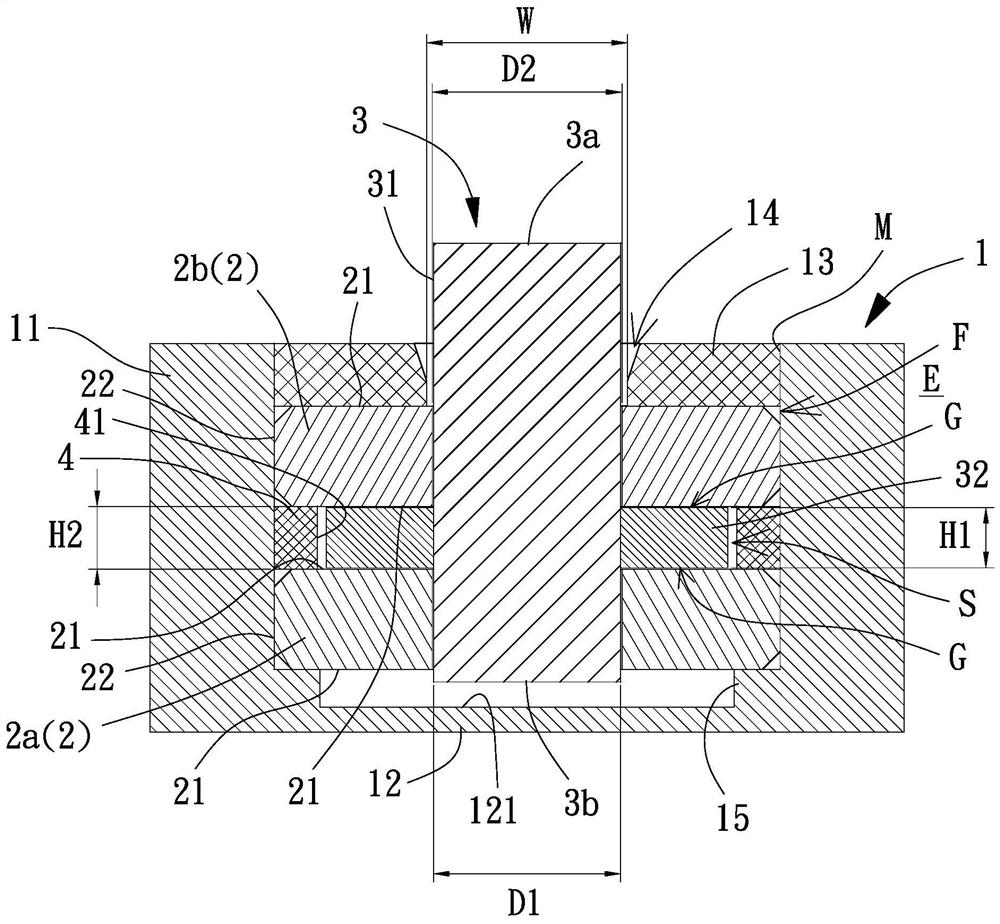

[0096] Please refer to figure 2 , 3 As shown, it is the first embodiment of the bearing system of the present invention, including a bushing 1, two bearings 2 and a rotating shaft 3, the two bearings 2 are located inside F of the bushing 1, and the rotating shaft 3 runs through the two A bearing 2 with one end protruding from the bush 1.

[0097] The bushing 1 has a ring wall 11 connected to the sealing bottom 12, so that the bottom end of the ring wall 11 is closed by the sealing part 12, and a space where the two bearings 2 can be arranged is formed inside the bushing 1 F. Wherein, the sealing portion 12 can be assembled and combined with the ring wall 11, for example, tightly fit and laser welded at the junction; The top end has an opening M, and the bottom end is completely closed to effectively prevent lubricating oil from leaking inside F of the bushing 1 . In addition, the bushing 1 can be provided with an end plate 13 adjacent to the opening M, the end plate 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com