Wheel core capable of preventing tread from peeling off and roller skate

A wheel core and tread technology, which is applied to roller skates, ice skating, skateboards, etc., can solve the problems of inline skates not being lightweight, difficult to meet product testing requirements, and cumbersome wheel waste disposal. Achieve the effect of reducing material cost, reducing weight and being competitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

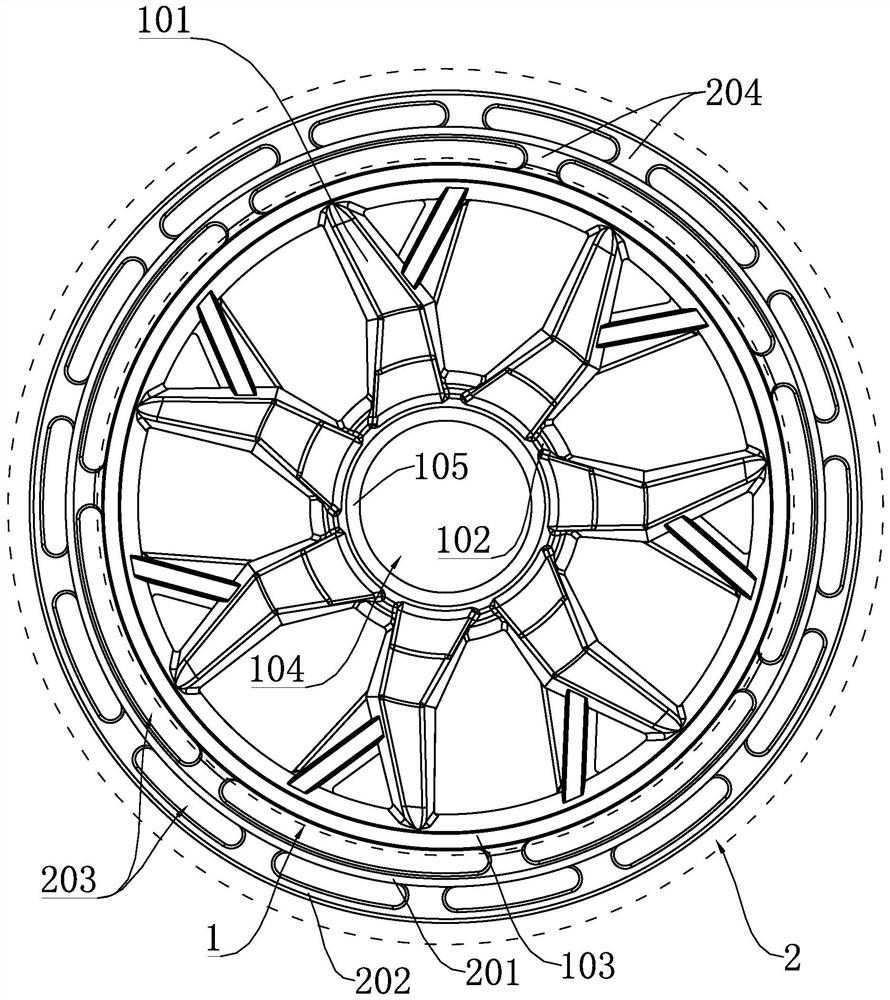

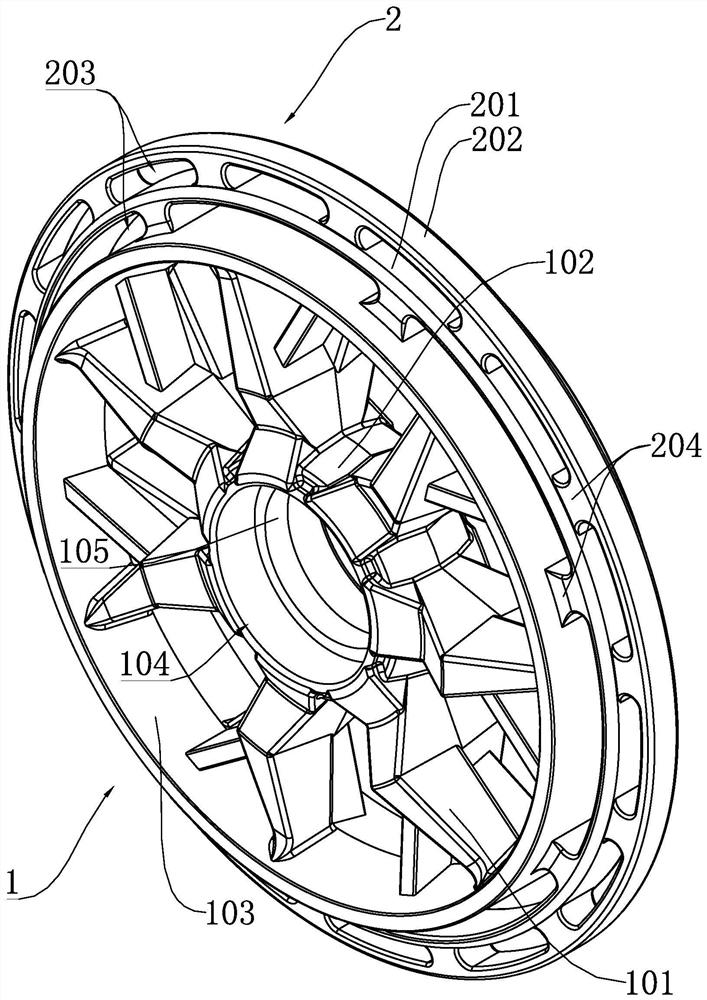

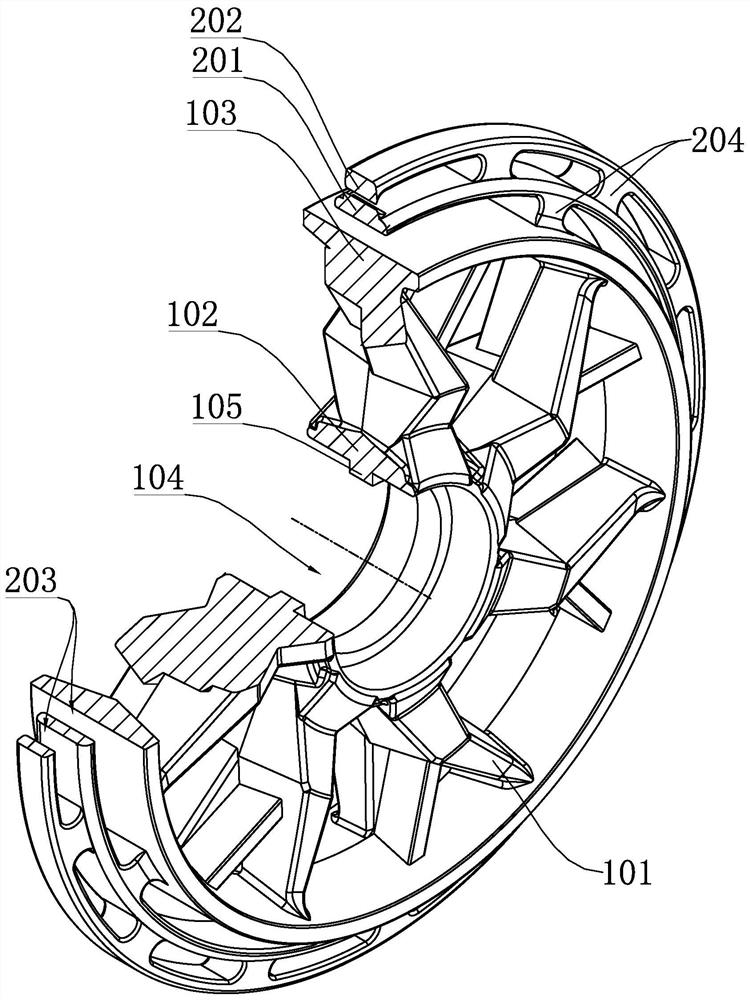

[0038] Such as figure 1 As shown, the present invention provides a wheel core with anti-tread peeling, comprising a main body 1 and a fastening structure 2. The fastening structure 2 is arranged on the outer contour of the main body 1 and configured to prevent polymer materials from being caused by lateral force. Peel off. In this embodiment, the length along the axis of the main body 1 is referred to as thickness.

[0039] The development of the roller skating industry has gradually matured, and the product of roller skating has also become stable; this has caused all roller skates to be the same. Although the appearance is constantly changing, the core, such as the thickness of the roller and the bearings used, etc. , There has been no major improvement for a long time.

[0040] The qualification verification of roller pulleys needs to go through a set of specific tests to check whether the key performances such as life and wear resistance meet the requirements; due to the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com