Patents

Literature

55 results about "Speed skating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Speed skating is a competitive form of ice skating in which the competitors race each other in travelling a certain distance on skates.Types of speed skating are long track speed skating, short track speed skating, and marathon speed skating.In the Olympic Games, long-track speed skating is usually referred to as just "speed skating", while short-track speed skating is known as "short track".

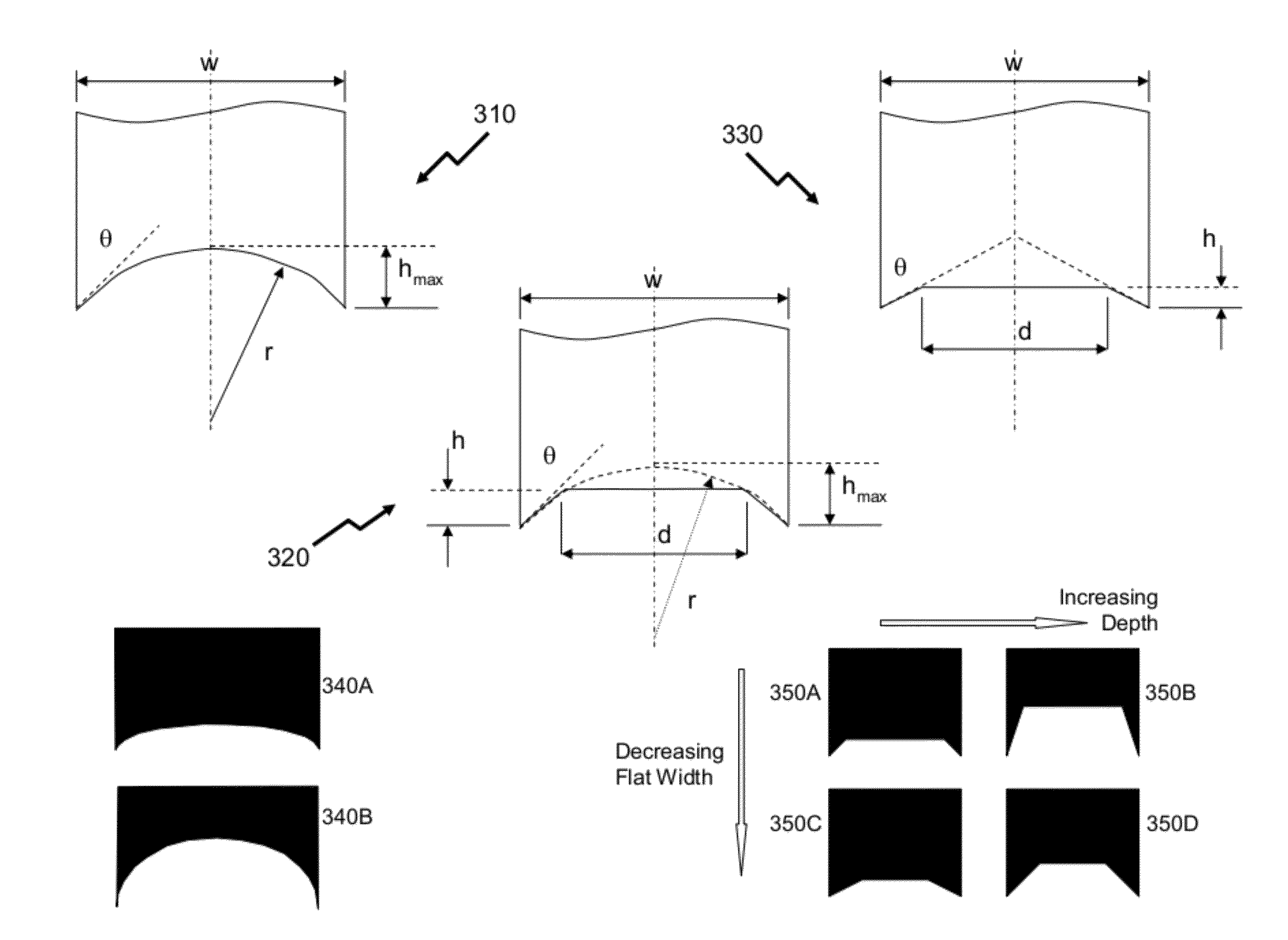

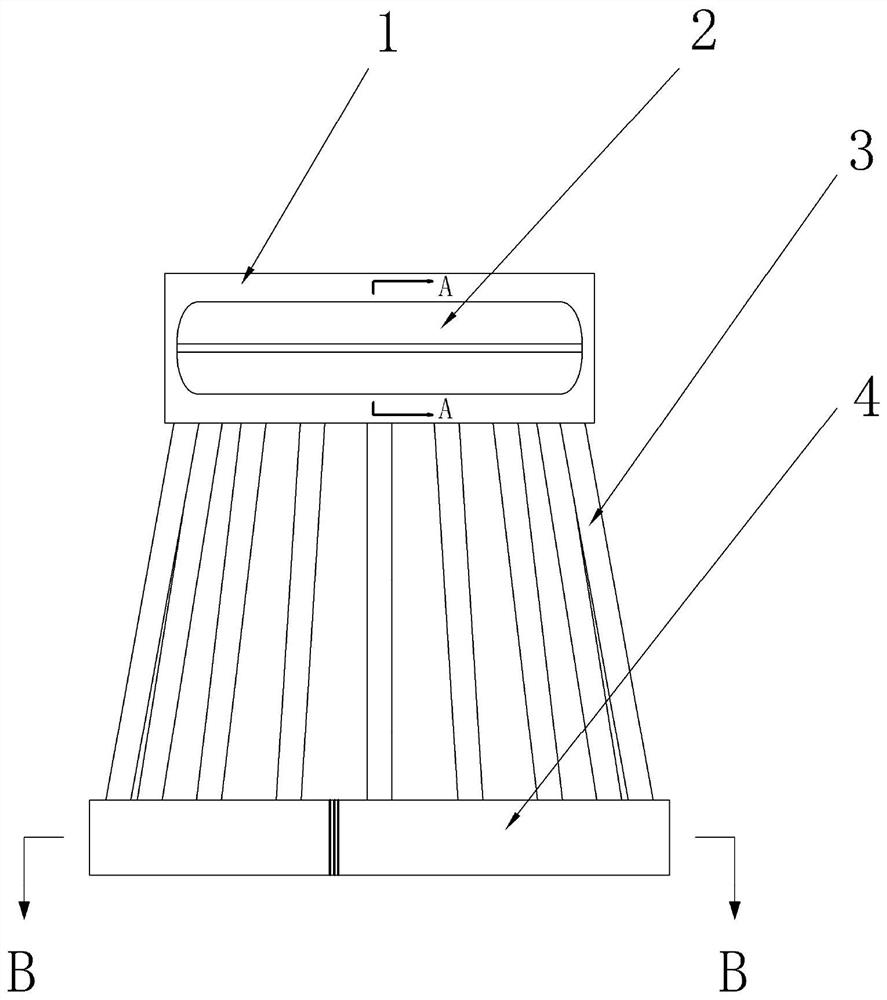

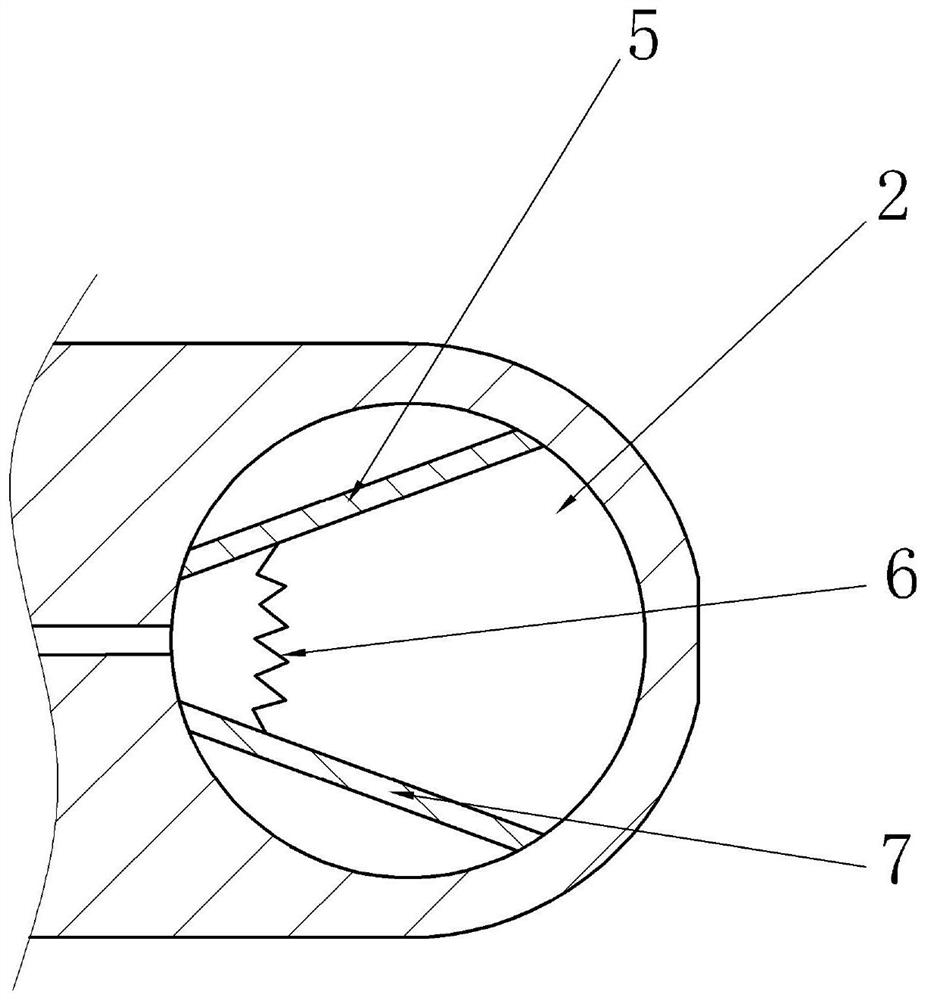

Multiple Blade Sharpening Apparatus and Method

The competitive and technological evolution of sports with ice skates such as ice hockey, speed skating, and figure skating as well as the conditioning and training of these athletes places increased demands on their equipment. Amongst these are the ability to vary the blade profile at different points to increase speed, agility, acceleration, etc according to the sport and the athlete's personal preferences. In many instances matching left and right blades is also important. In contrast in amateur sports where users access retail skate sharpening services speed or service and cost of service is important. A system and method are taught for simultaneously profiling both blades of user for increasing speed and reducing cost in retail environments whilst aligning there profiles in more professional applications. The method further allows for profiles to vary in cross-section along the length of the blade.

Owner:SWIST JASON

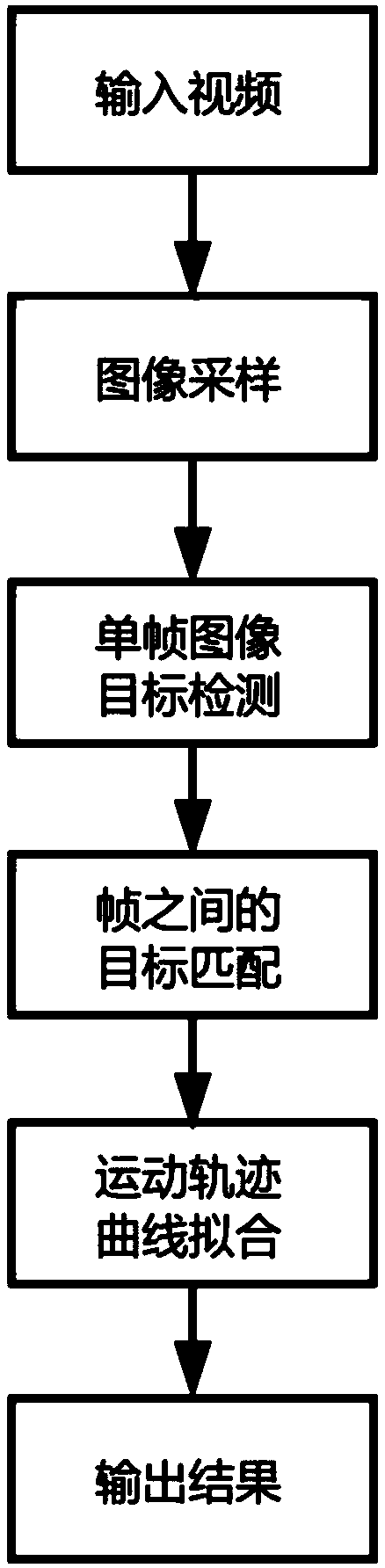

An automatic tracking and track modeling method for short-track speed skating athletes in videos

InactiveCN109448025AReduce consumptionQuick feedbackImage enhancementImage analysisKinematicsMotion parameter

The invention discloses an automatic tracking and track modeling method for short-track speed skating athletes in videos. The method comprises the steps of using a high-speed camera for collecting athlete training or competition videos from a boundary line overlook view angle; sampling the image in the video according to a specific frequency to obtain a group of single-frame images; carrying out target detection on the athletes in the single-frame image, and determining the positions of the athletes by using a square frame; matching the target detection results belonging to the same athlete among the frames to obtain a tracking result belonging to the same athlete target; mapping the tracking result of each athlete to the ice surface, carrying out curve fitting, and drawing a smooth motiontrack; estimating and outputting the motion parameters of the athlete according to the track equation. The short-track speed-skating game analysis system has no interference on games, can directly collect and analyze the positions of athletes, greatly improves the automation level, reduces the manpower consumption, can quickly feed back related kinematics parameters after games, improves the speed, and provides possibility for real-time short-track speed-skating game analysis.

Owner:CHINA INST OF SPORT SCI

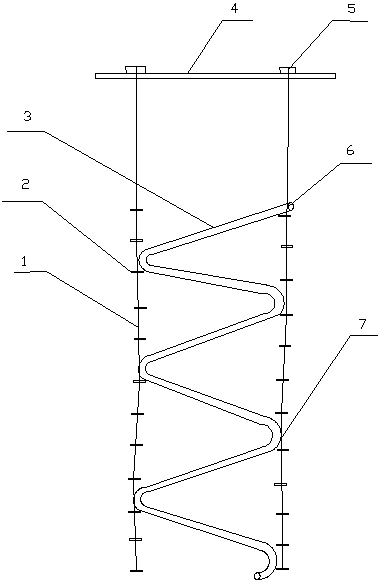

Bottom layer flexible speed skating escape device

The invention discloses a bottom layer flexible speed skating escape device which comprises a channel and a fixing frame, wherein the channel is a zigzag channel knitted from an inflaming retarding fabric and is supported between two groups of vertical flexible supports, the upper ends of the flexible supports are connected with the fixing frame which is arranged on the roof of the building, a channel inlet is connected to an escape exit of the building, and a control device with a high performance fiber rope is arranged on the fixing frame. The bottom layer flexible speed skating escape device can ensure that the trapped people rapidly and safely escape a scene, and has the advantages of simple structure, good safety, and capability of enabling continuous groups to pass through.

Owner:徐纯中

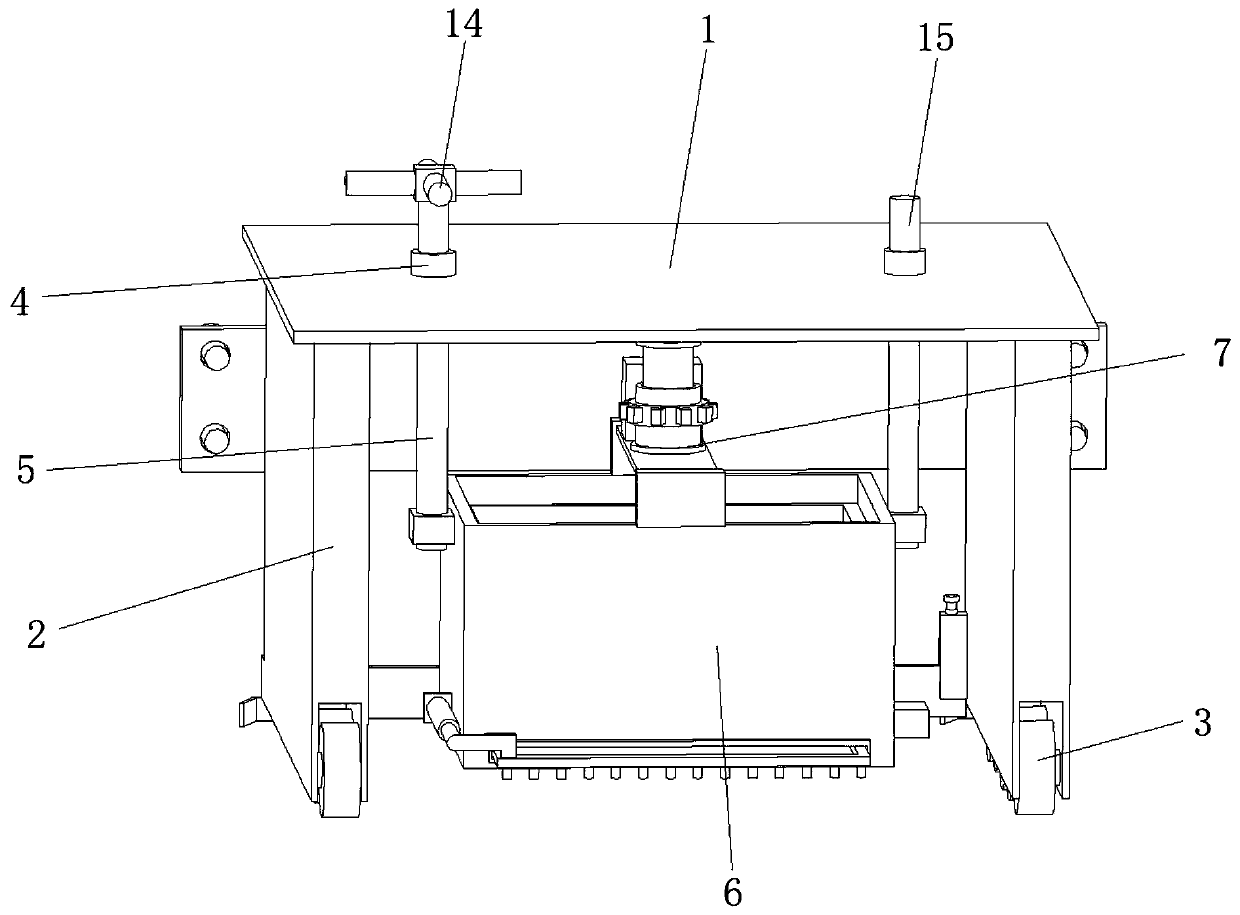

Vehicle-mounted ice surface repairing device based on dry ice refrigeration for short-track speed skating

The invention discloses a vehicle-mounted ice surface repairing device based on dry ice refrigeration for short-track speed skating. The device comprises a supporting top plate; walking side plates are fixedly connected to the left and right sides of the top of the supporting top plate; a transmission sleeve rod is fixedly connected to the left side of the top of the supporting top plate; a transmission screw rod penetrates through the transmission sleeve rod and is in threaded connection with the transmission sleeve rod; the bottom end, located below the supporting top plate, of the transmission screw rod is fixedly connected with a limiting repairing mechanism; an ice layer pretreatment mechanism is fixedly connected to the middle position of the top of the limiting repairing mechanism;a filling and leveling scraping plate is fixedly connected to the bottom of the supporting top plate and located on the back face of the walking wheel; limiting inner rails are fixedly connected to the inner sides of the back faces of the walking side plates; and ice scraping knives are slidably connected into the limiting inner rails. According to the vehicle-mounted ice surface repairing devicebased on dry ice refrigeration for short-path speed skating, which relates to the technical field of short-track speed skating ice tracks, the firmness of a repaired ice layer is improved, rapid ice surface repairing is achieved, and consumption of ice surface repairing is reduced.

Owner:杨健

Preparation method of chromium-molybdenum-vanadium type speed skating ice skate blade material

InactiveCN111283204AExtend your lifeExtended cycleTurbinesOther manufacturing equipments/toolsTemperingIce hockey

The invention discloses a preparation method of a chromium-molybdenum-vanadium type speed skating ice skate blade material, and belongs to the field of metal materials. The preparation method comprises the following steps that spherical metal powder comprising the components of, by mass, 2.3% to 2.7% of C, less than 0.1% of Mn, less than 0.1% of Si, 5.7% to 6.0% of Cr, 3.5% to 4.0% of Mo, 8.5% to9.0% of V, 0.5% to 1.0% of Nb, 1.5% to 2.0% of Co, 0.05% to 0.1% of N, less than 0.005% of O and the balance Fe, is prepared by adopting a gas atomization powder making technology, wherein the ratio of Nb to N is 10: 1 and the particle size of the powder is controlled within the range of 45-270 microns; the powder is loaded into a cuboid carbon steel can, then is subjected to vacuumizing to reach10<-3> Pa, and then is placed in a hot isostatic pressing furnace for sintering to achieve densification; the sintered and densified block body is machined to remove the carbon steel can on the surface, and then hot rolling is conducted to form a plate blank, wherein the hot rolling temperature is 1150-1200 DEG C, and the thickness of the hot-rolled plate blank is 2-3 mm; and quenching and tempering are carried out on the hot-rolled plate blank to obtain a speed skating ice skate blade plate blank material which meets the requirement in performance, then cutting is carried out according to therequirement, and the surface is ground to obtain a speed skating ice skate blade. The preparation method is simple in process, low in cost and suitable for mass production, and meanwhile the materialcan serve as figure and ice hockey ice skate blade materials by adjusting the performance by means of the adjustment of the heat treatment process.

Owner:UNIV OF SCI & TECH BEIJING

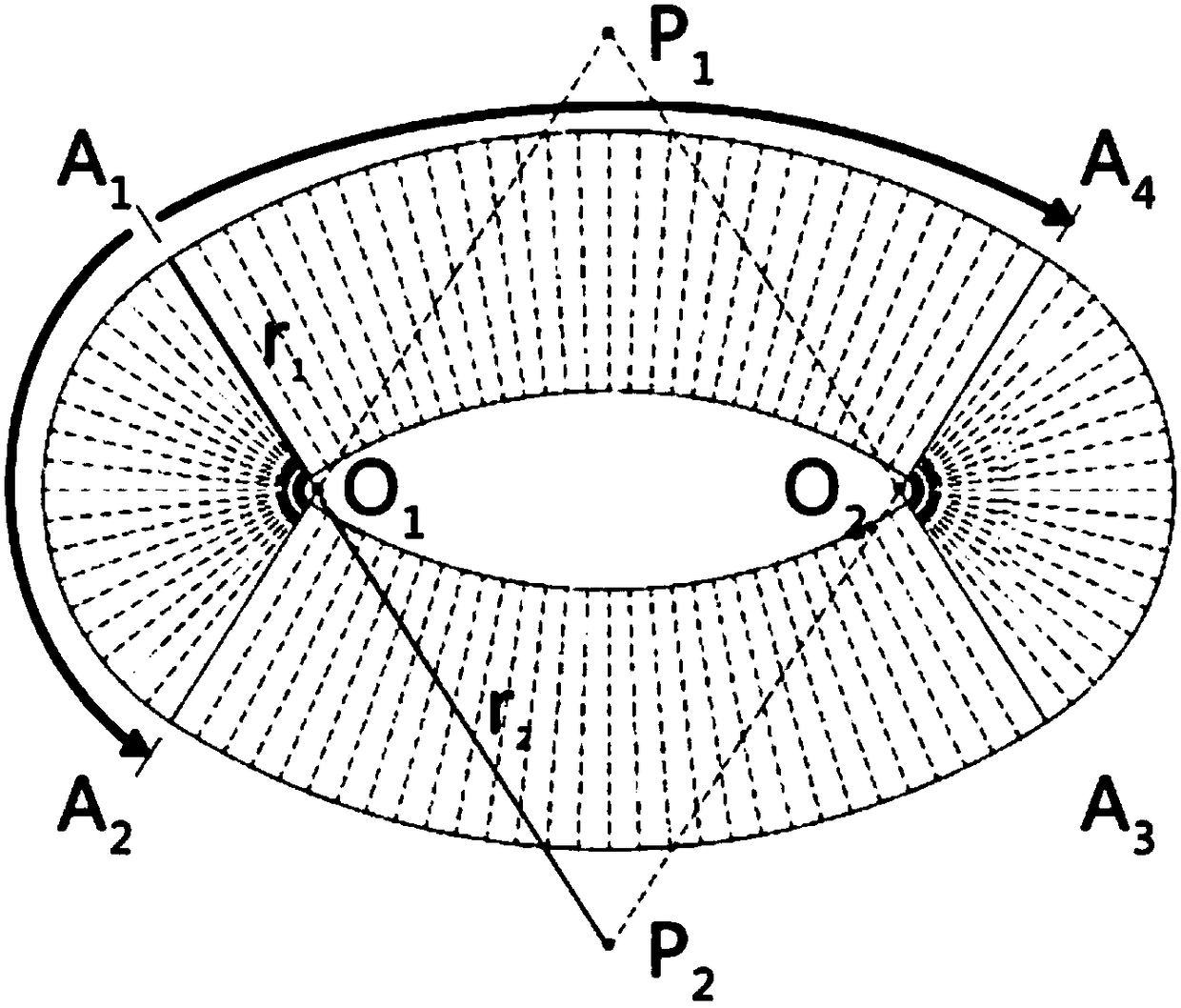

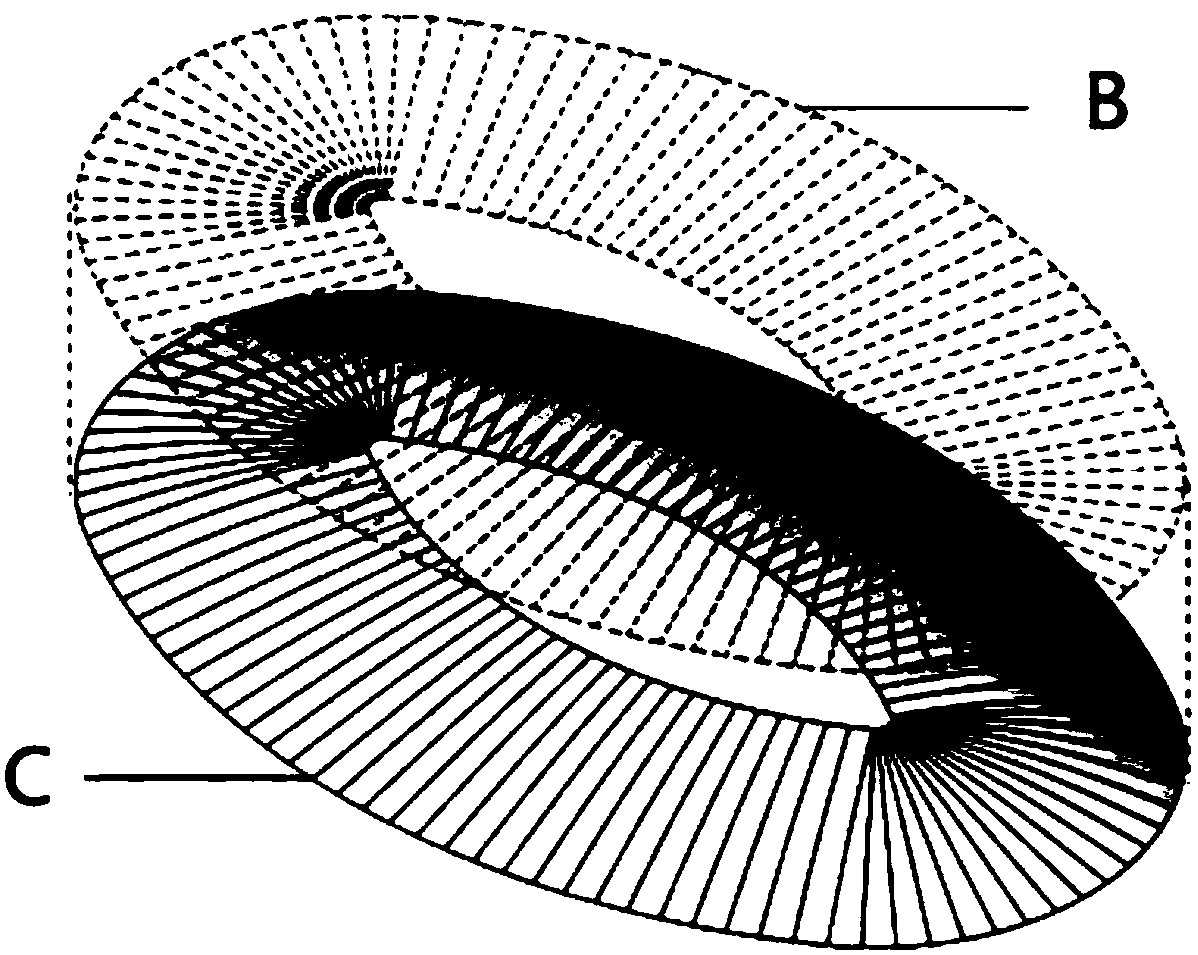

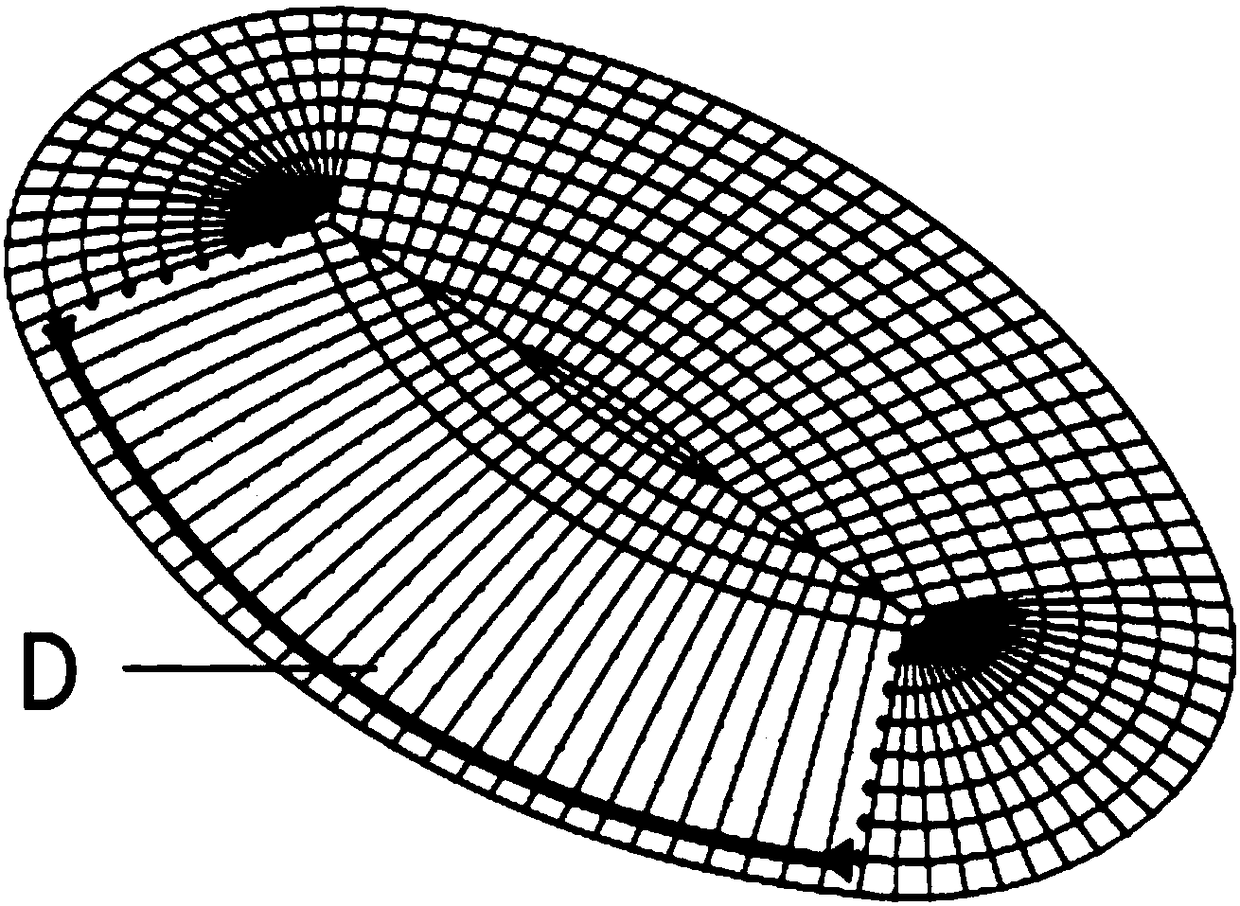

Method for calculating double-hearted elliptical speed skating roof cover system based on Kiewitt grid layout principle and construction method

ActiveCN108153969AReduce in quantityImprove project qualityGeometric CADBuilding material handlingNetwork generationCovering system

Disclosed are a method for calculating a double-hearted elliptical speed skating roof cover system based on a Kiewitt grid layout principle and a construction method. The invention relates to the method for calculating the double-hearted elliptical speed skating roof cover system and the construction method, and aims at solving the problems of complex structural component layout, low component standardized degree, large processing amount and high construction difficulty in the prior art. The calculation method comprises the steps of step 1, standardized design of a plane grid system; step 2, generation of basic projection lines; step 3, generation of a circumferential network; step 4, generation of combined grids; step 5, generation of a structural grid system. The construction method comprises the steps that assembly of a fusiform circular truss is conducted at a ground site center; circumferential installation at lowered positions of lower cables and supporting rods is conducted; prestressing force is exerted through the lower cables, overall elevation of the fusiform circular truss is conducted, and elevation of the lower cables and the supporting rods is conducted synchronously; after the fusiform circular truss, the lower cables and the supporting rods are elevated in place, and circumferential rod members and longitudinal rod members are installed; outer circular steel beams are installed and reinforcement of the overall structure is completed; a roof grid structure is installed.

Owner:BUILDING DESIGN RES INST HARBIN INST OF TECH

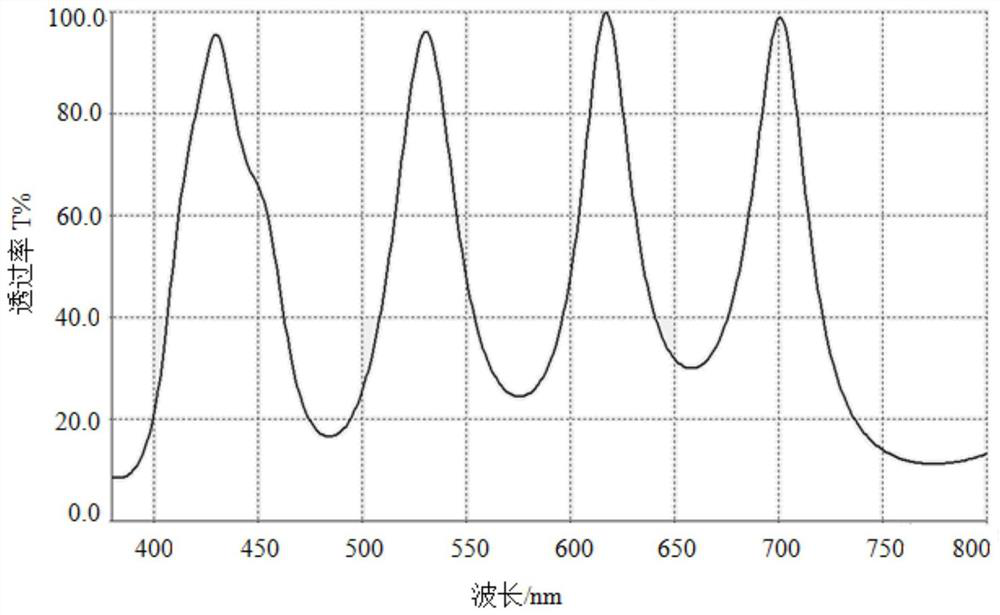

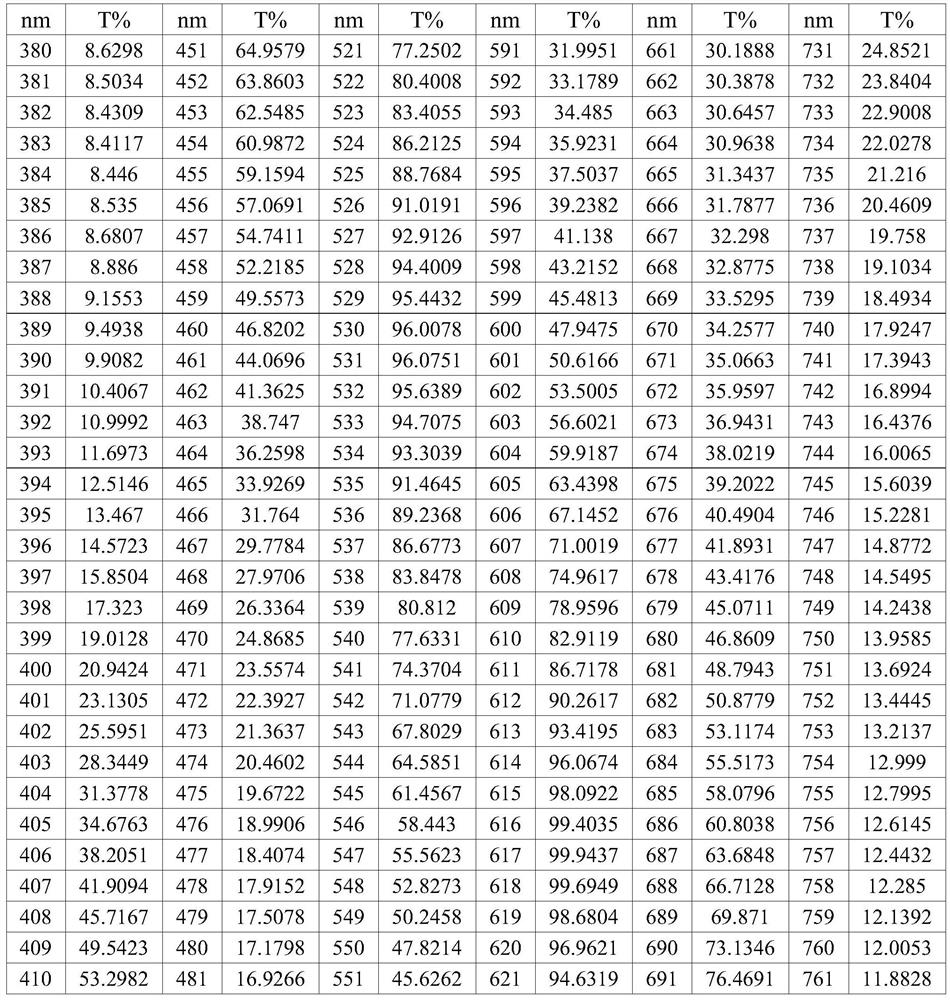

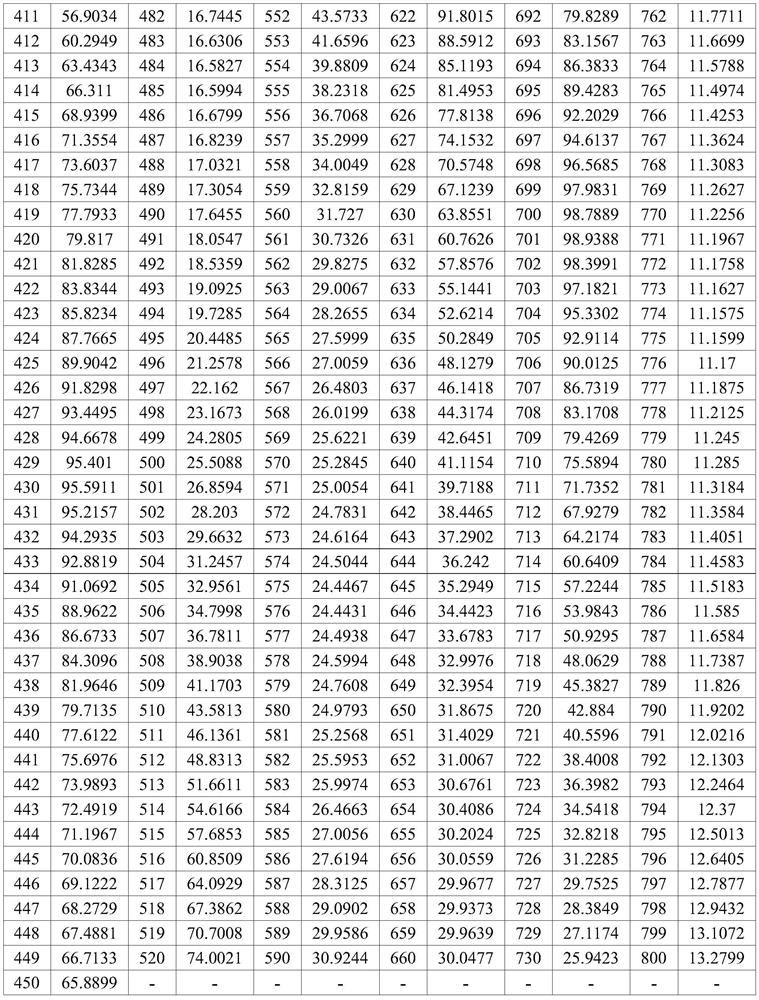

Lens capable of improving color contrast and saturation and preparation method thereof

The invention belongs to the technical field of functional lenses, and relates to a lens capable of improving color contrast and saturation and a preparation method thereof. The lens comprises a substrate, a priming coat and a plurality of film layers, wherein the priming coat and the plurality of film layers are sequentially arranged on the outer surface of the substrate, the plurality of film layers are formed by alternately stacking low-refractive-index layers and high-refractive-index layers, and the high-low transmittance difference values of the plurality of film layers in blue, green, red and yellow spectral regions are all more than 50%. The lens provided by the invention has relatively large high-low transmittance difference values in blue, green, red and yellow spectral regions,and can improve the identification degree and definition of blue, green, red and yellow colors at the same time, so that the visual stereoscopic impression can be improved in an omnibearing manner; byadopting the same lens, the requirements of athletes in different sports scenes such as skiing, bicycles, speed skating and the like can be met at the same time, universality is achieved, the purposeof protecting the eyes and the bodies of the athletes is finally achieved, and meanwhile the competitive sports performance can be improved.

Owner:厦门美澜光电科技有限公司

Speed skating simulation training system using wind tunnel

The invention provides a speed skating simulation training system using a wind tunnel. The system comprises the wind tunnel, a sliding plate device and a camera monitoring device. The wind tunnel generates an adjustable wind speed to blow towards the direction where a user is located, the camera monitoring device is fixedly installed on the inner wall of the wind tunnel in a multi-position mode and carries out multi-angle real-time shooting on the user, the sliding plate device simulates the smooth ice surface of speed skating, the user wears shoe covers on the feet, and movement operation of speed skating is carried out on the sliding plate device. And the camera monitoring device records a real-time motion video of the user. According to the speed skating simulation training system using the wind tunnel, the motion state of speed skating is simulated by utilizing the wind speed in the wind tunnel, coaches and athletes are helped to carry out posture optimization and intensive training of key technical actions, and technicians are helped to carry out research and development of high-performance sports equipment.

Owner:BEIJING JIAOTONG UNIV

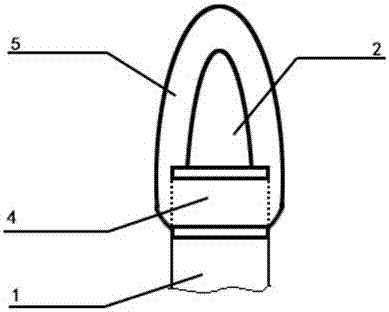

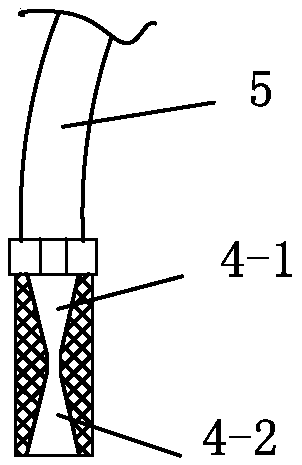

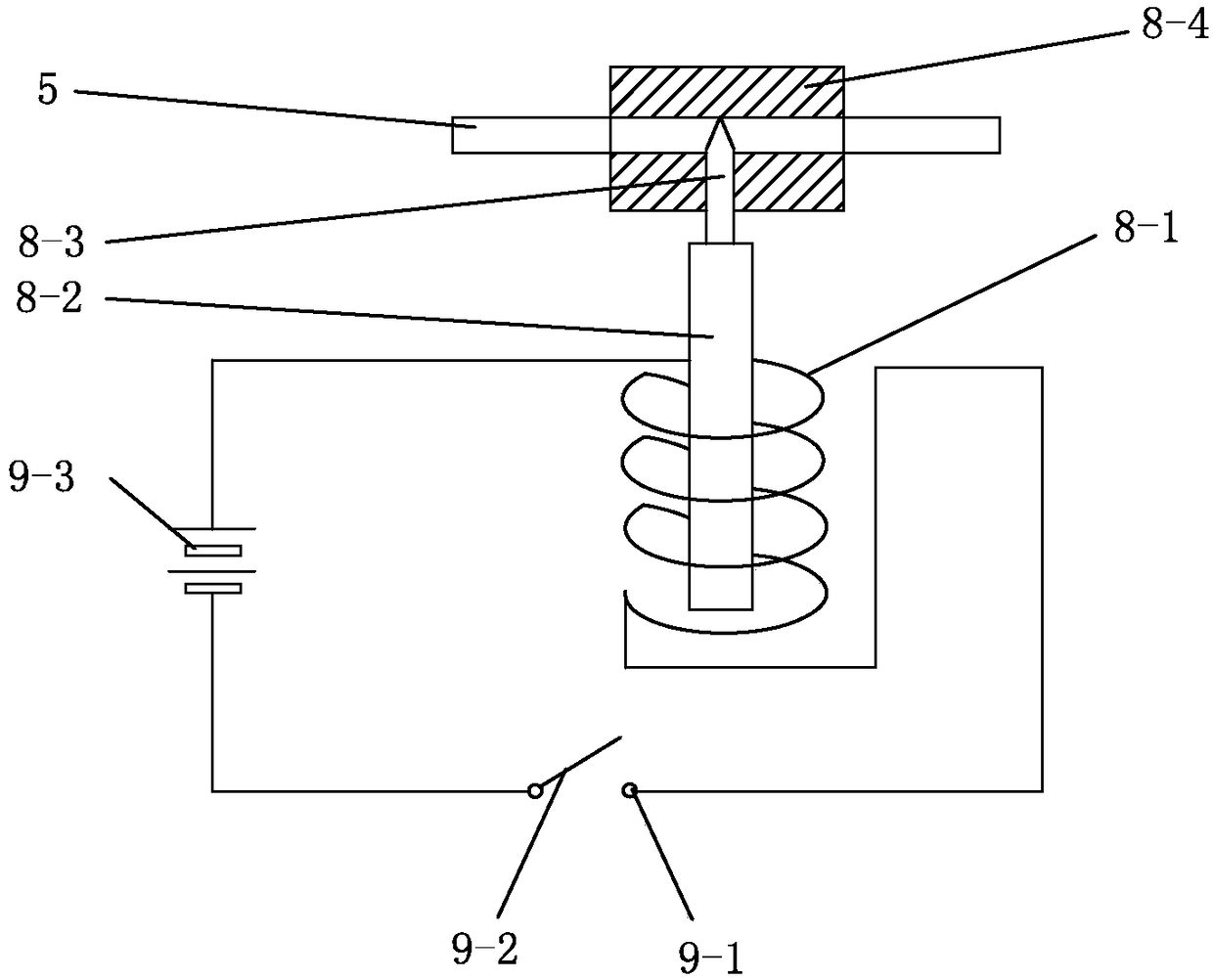

Speed skating boots

The invention relates to a pair of speed skating boots, and belongs to the field of sports instruments. The pair of speed skating boots solves the problem that ice skate blades of existing speed skating boots are unreliable in lubricating effect obtained purely in virtue of human body pressure intensity. Each speed skating boot comprises a boot body, a connecting rack and a blade body; the blade body is fixedly onto the bottom surface of the boot body through the connecting rack. Each speed skating boot also comprises a spray head, a connecting pipe, a water storage tank and a hand switch; the spray head is fixed at the position of the upper surface of the front end of the blade body; a spray nozzle of the spray head faces the front part of the front end of the blade body; a water inlet of the spray head is connected onto a water outlet of the water storage tank through the connecting pipe; and the hand switch is arranged on the connecting pipe. During ice skating of a speed skating person, water is sprayed by the spray head in front of the blade bodies, a water film is formed on an ice surface, and the friction force between the blade bodies and the ice surface is reduced, so that the skating speed can be increased. Due to the fact that the sprayed water cannot be frozen instantly, the problem that a stable water lubricating effect cannot be formed by the human body pressure intensity after the temperature is reduced is solved.

Owner:王茵

Preparation method of high-performance speed skating ice skate blade

ActiveCN113770361AReduce coefficient of frictionImprove performanceSolid state diffusion coatingProcess efficiency improvementMetallic materialsIce skating

The invention discloses a preparation method of a high-performance speed skating ice skate blade material, and belongs to the field of metal materials. The preparation method comprises the following steps that firstly, spherical metal powder with the mass ratio of 1.20% to 1.30% of C, 0.3% to 0.5% of Si, 0.65% to 1.00% of Mn, 4.8% to 5.2% of Cr, 4.8% to 5.2% of Mo, 4.8% to 5.2% of V, 4.8% to 5.2% of Co, 4.8% to 5.2% of W, O less than or equal to 0.005%, 0.03% to 0.05% of N and the balance Fe is prepared by adopting a vacuum gas atomization powder preparation technology, 0.3 to 0.5 percent of Si; mn: 0.65 to 1.00%; 4.8 to 5.2 percent of Cr; 4.8% to 5.2% of Mo; v: 4.8 to 5.2%; 4.8% to 5.2% of Co; 4.8% to 5.2% of W; o < = 0.005%; wherein the particle size range of the powder is 10-250 microns, then hot isostatic pressing sintering densification is carried out to obtain a hot isostatic pressing ingot, then forging cogging and hot rolling are carried out on the hot isostatic pressing ingot to obtain a plate blank with a certain thickness, then welding is carried out on the plate blank and a knife back material with the same thickness to obtain a bimetal blade blank; and then performance heat treatment is carried out, then the plate blank subjected to heat treatment is machined into a semi-finished product bimetallic blade with a required size, and finally, glow particle nitriding treatment is carried out on a cutting edge part of the bimetallic blade to form a carbonitride layer with the thickness of 0.11-0.12 mm on the surface. The ice skate blade prepared by the method has excellent wear resistance and toughness; and meanwhile, the friction coefficient with the ice surface is lower, and the movement efficiency can be further improved.

Owner:UNIV OF SCI & TECH BEIJING +1

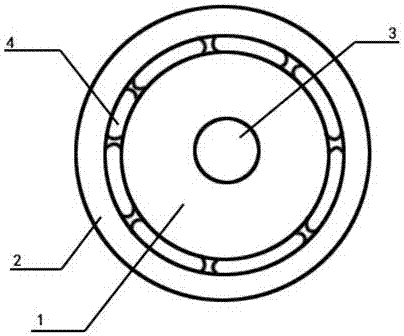

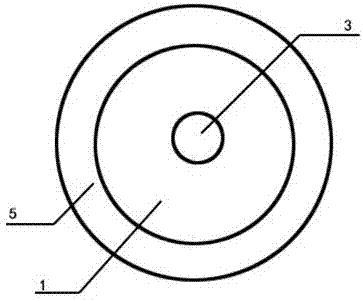

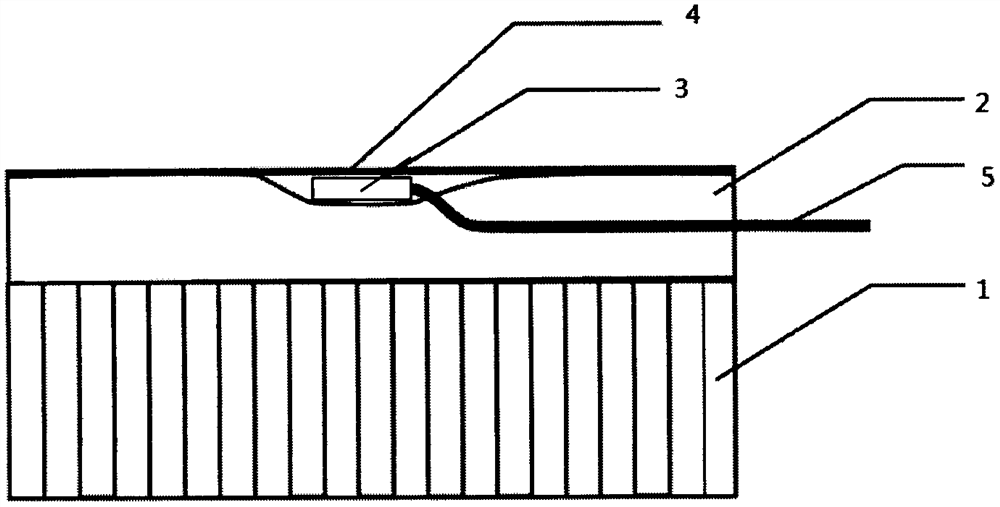

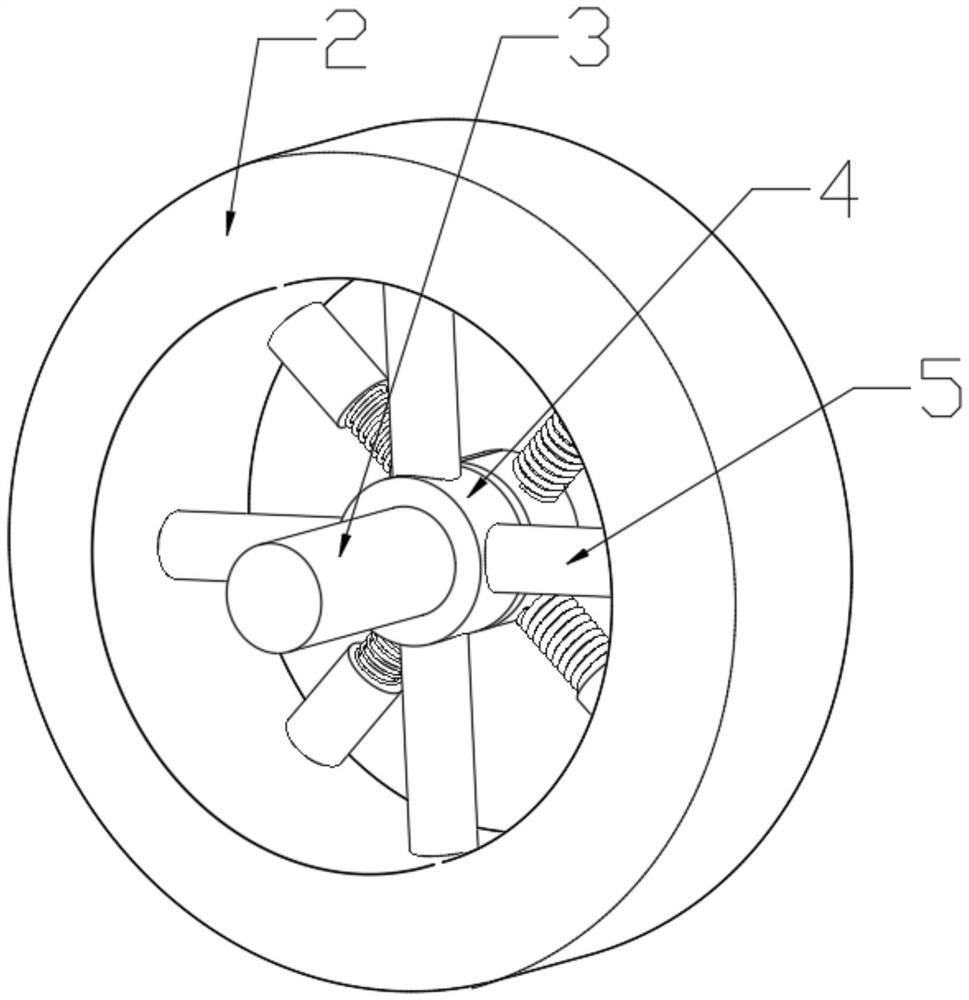

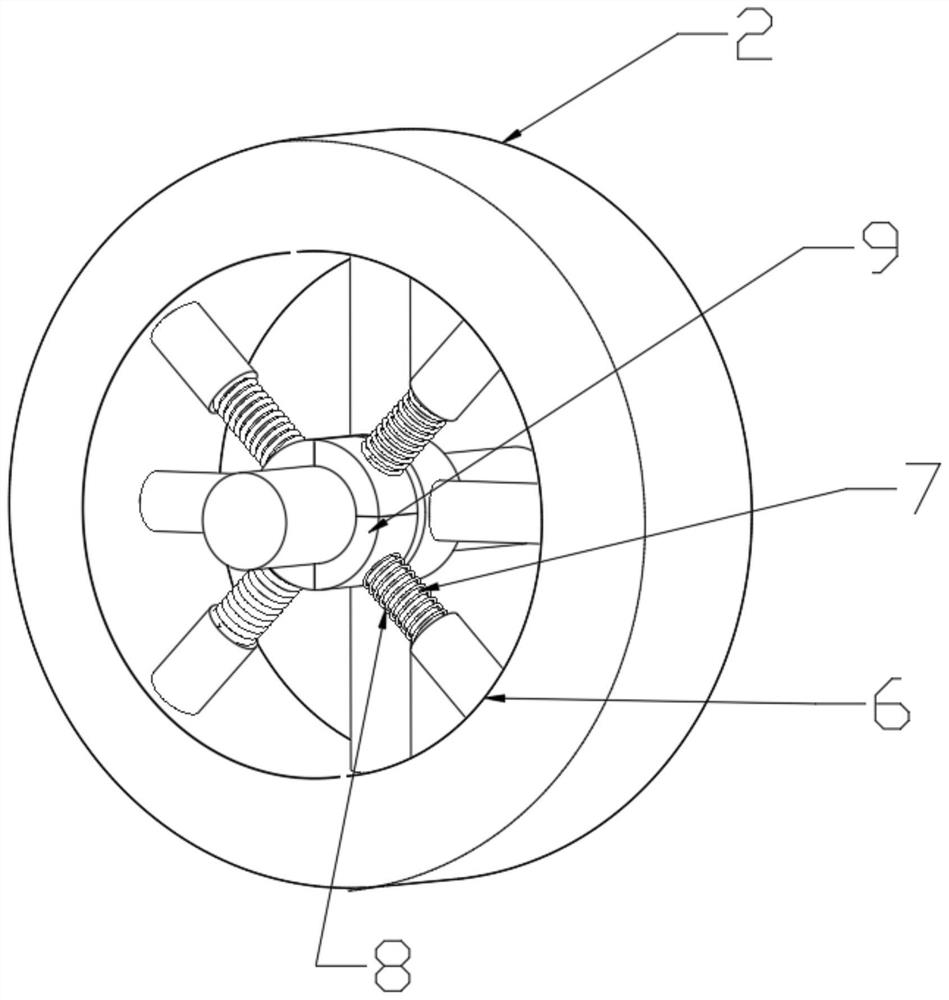

Double-layered speed skating wheel

The invention relates to a double-layered speed skating wheel. The double-layered speed skating wheel comprises an inner core, an inner container and an outer container, wherein the inner core is in around shape; a circle of kidney-shaped holes are additionally formed in the edge of the inner core; an axial hole for mounting is designed in the center of the inner core; the inner container is designed on the outer side of the inner core; the inner container is in a circular ring shape and is fixedly connected with the outer side edge of the inner core through injection molding; the outer container is positioned on the outer side of the inner container and is in a circular ring shape; the outer container covers the inner container; the inner side of the outer container covers the kidney-shaped holes formed in the edge of the inner core through injection molding; the outer container, the inner container and the inner core are fixedly connected with each other. The double-layered speed skating wheel has the advantages that a double-layered structure is adopted; due to the kidney-shaped holes formed in the edge of the speed skating wheel, air exhaustion is facilitated; a circle of inner container of the speed skating wheel is prepared from a soft polyurethane material through injection molding, and the hardness reaches Shore hardness A-level of 65A, so that when wheels incline forturning and steering, the double-layered speed skating wheel has good road holding property, no loss of speed is ensured, and the double-layered speed skating wheel is controlled more easily.

Owner:JIANGSU YAOZHANG SPORTING GOODS

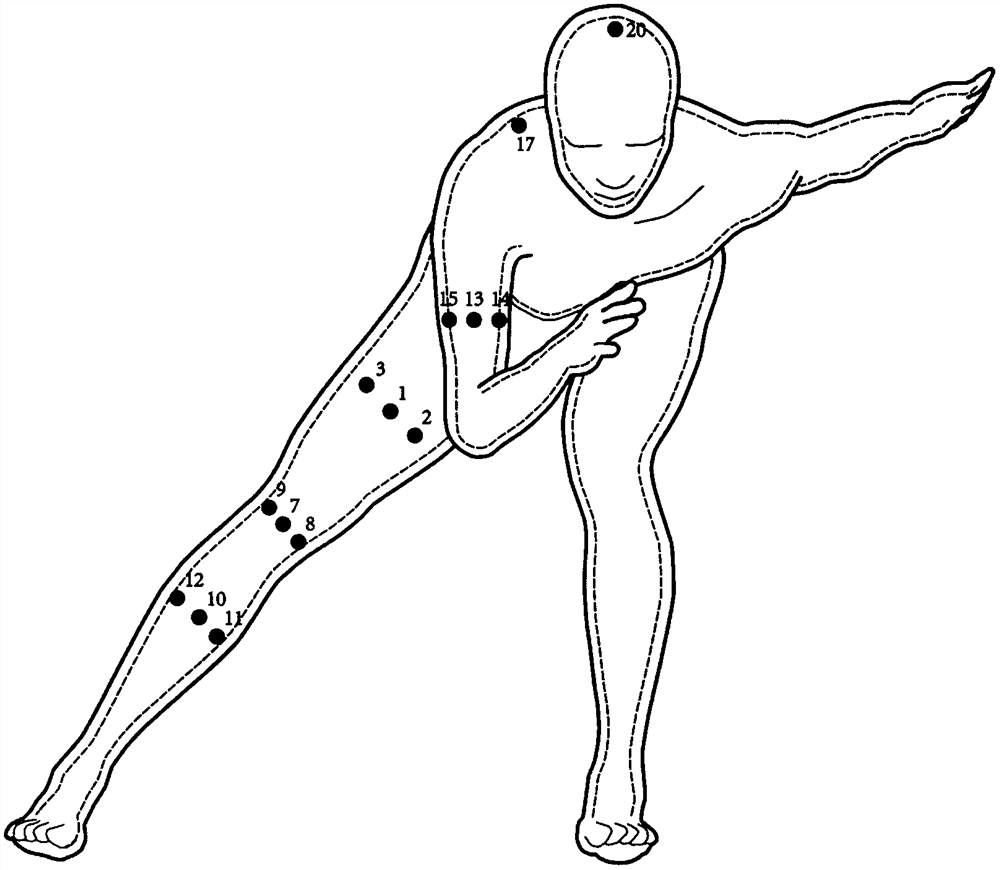

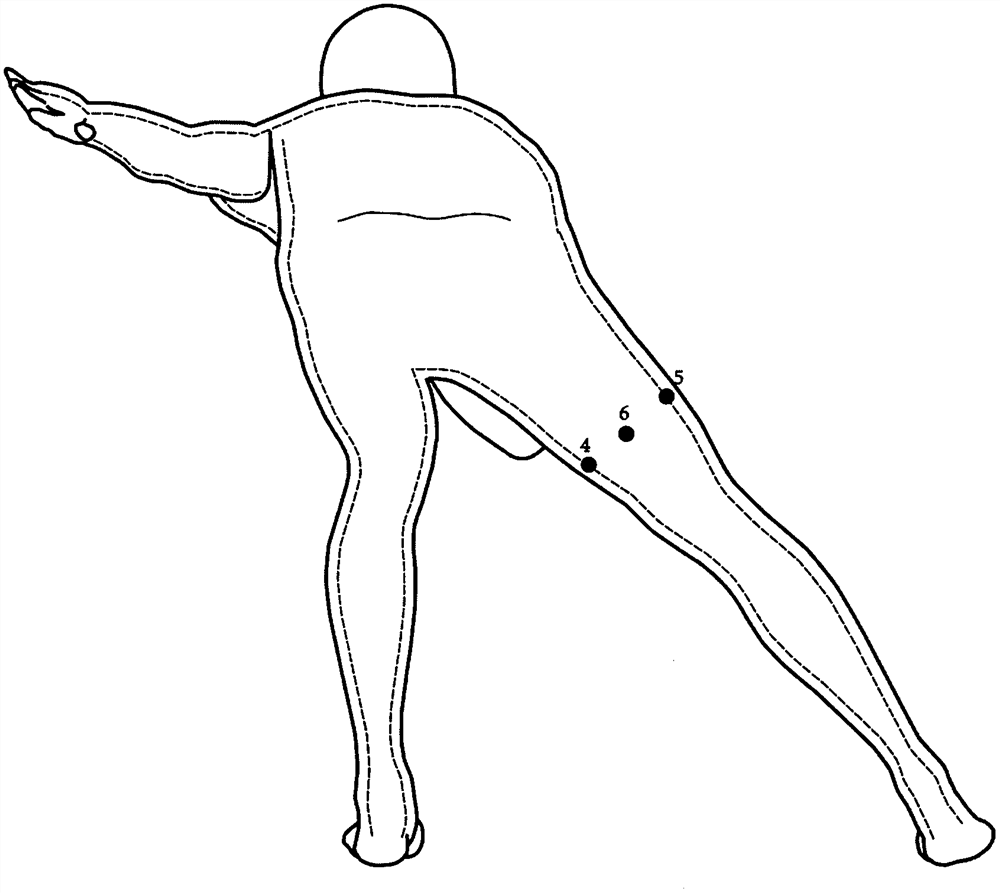

Wind tunnel test short-track speed skating mannequin and test position determination method thereof

The invention provides a wind tunnel test short-track speed skating mannequin which comprises a mannequin body, a simulated human body liquid silica gel layer and simulated human body liquid silica gel layer. The dynamic posture of the mannequin body is consistent with that of short-track speed skating, the mannequin body is composed of a right leg part, a left leg part, a hip part, a left arm, a right arm, an upper body and a head part, and all the parts are connected and fixed through magnetic disk buckles and screws; the simulated human body liquid silica gel layer covers the outer surface of the mannequin body; and the simulated human body liquid silica gel layer are embedded into the simulated human body liquid silica gel layer, and the surfaces of the twenty flexible force sensors are fixed by using simulated skin adhesive tapes. The invention also provides a method for determining the position of the short-track speed skating mannequin pressure test point in the wind tunnel test, and the position is determined through calculation of a Reynolds number formula. The device can realize simultaneous measurement of multi-point pressure, and can be conveniently and effectively used for wind tunnel air resistance testing.

Owner:TIANJIN POLYTECHNIC UNIV

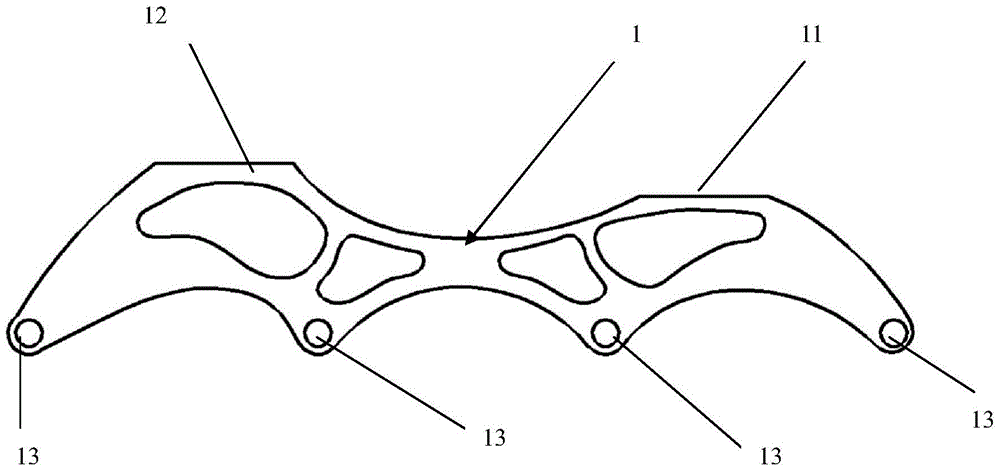

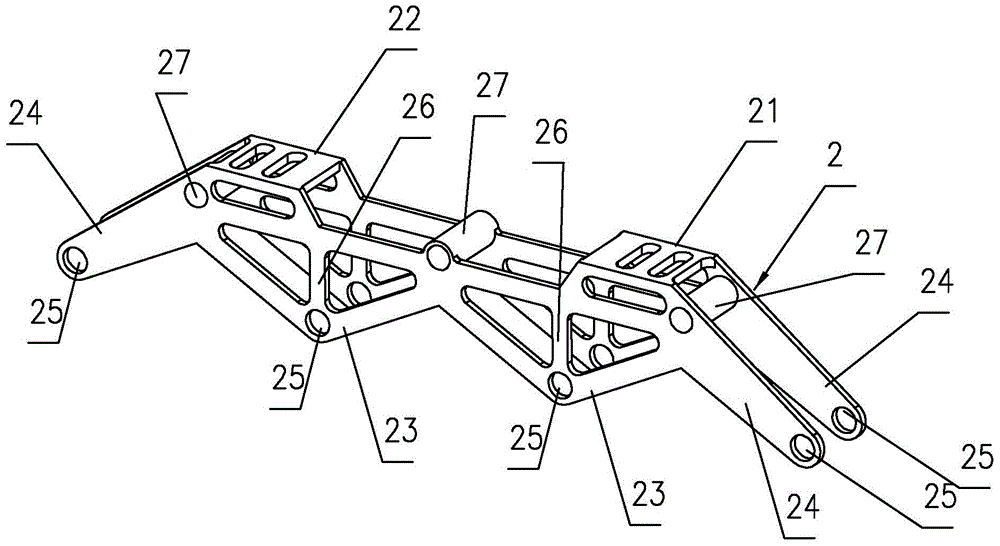

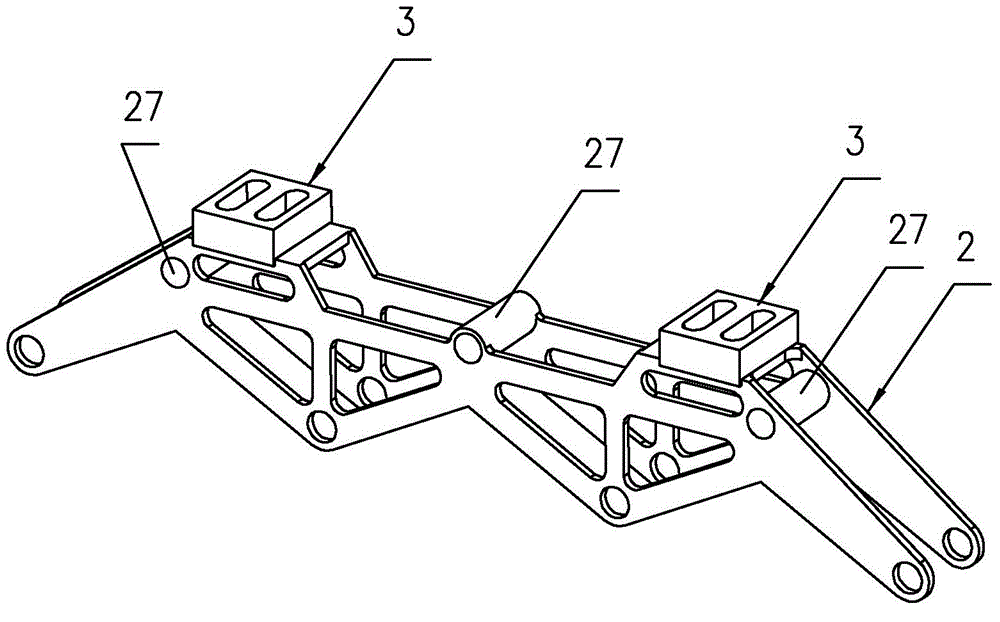

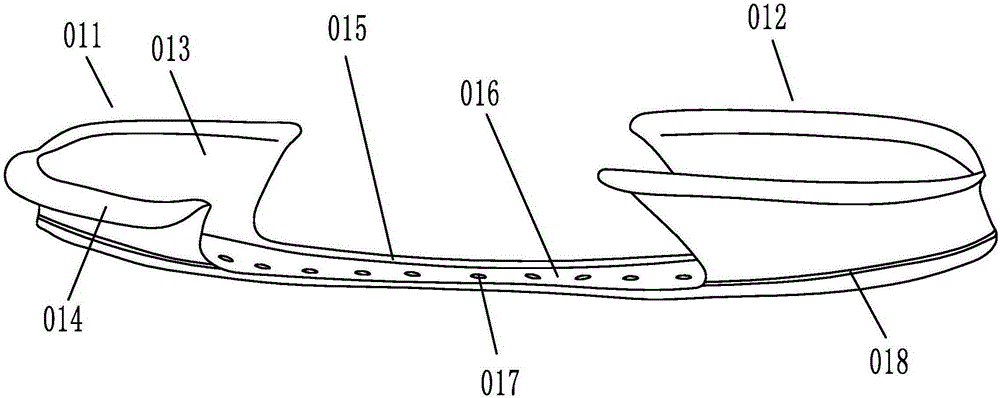

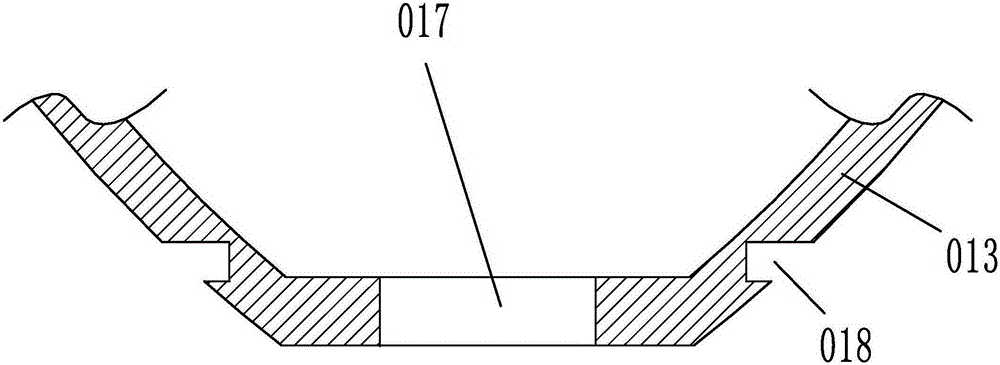

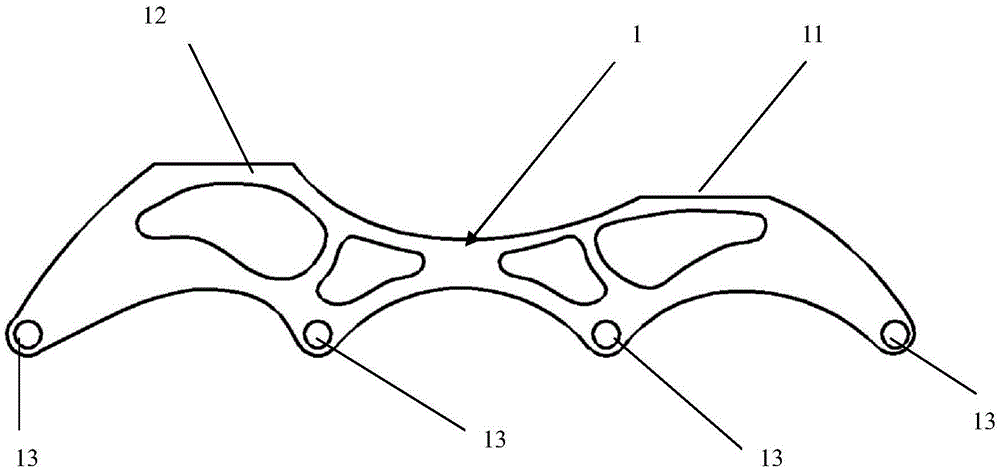

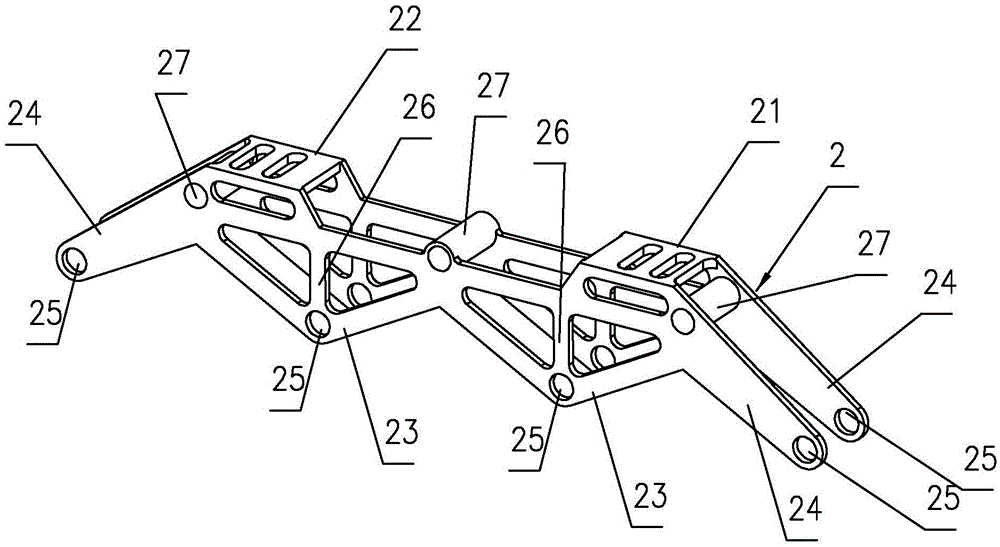

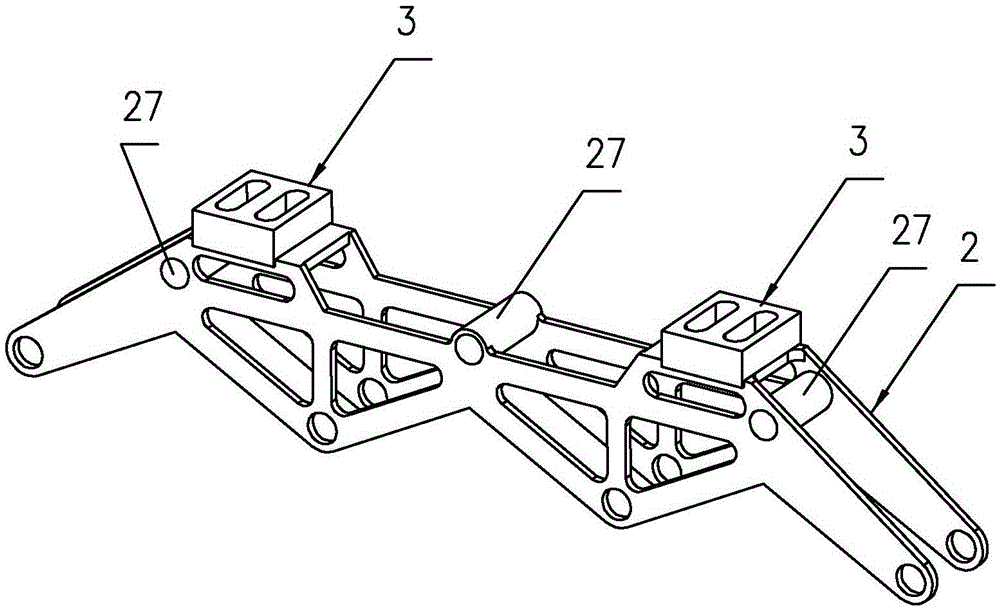

Multifunctional speed skating shoes blade frame

The invention discloses a multifunctional speed skating shoes blade frame including a blade frame main body; the top end of the blade frame main body is provided with mounting surfaces; the mounting surfaces comprise a front mounting surface and a rear mounting surface which are respectively distributed on the front part and the rear part of the top end of the blade frame main body, the front mounting surface and the rear mounting surface are located on a same horizontal plane, and according to speed skating functions required to be achieved, cushion blocks are selectively mounted on the front mounting surface and the rear mounting surface. The front mounting surface and the rear mounting surface are each not provided with the cushion block. The rear mounting surface is provided with the cushion block, the cushion block is detachably mounted, and the front mounting surface is not provided with the cushion block. The front mounting surface and the rear mounting surface are respectively provided with the cushion blocks, and the cushion blocks have the same height and are detachably mounted. The multifunctional speed skating shoes blade frame has simple and compact structure and low cost, allows the front mounting surface and the rear mounting surface to be selectively provided with the mounting blocks, is simple in adjustment, can achieve various speed skating functions, and is beneficial for Asian to exert the muscle explosive force and improve speed skating results.

Owner:东莞市启键体育用品有限公司

speed skates

The invention relates to a pair of speed skating boots, and belongs to the field of sports instruments. The pair of speed skating boots solves the problem that ice skate blades of existing speed skating boots are unreliable in lubricating effect obtained purely in virtue of human body pressure intensity. Each speed skating boot comprises a boot body, a connecting rack and a blade body; the blade body is fixedly onto the bottom surface of the boot body through the connecting rack. Each speed skating boot also comprises a spray head, a connecting pipe, a water storage tank and a hand switch; the spray head is fixed at the position of the upper surface of the front end of the blade body; a spray nozzle of the spray head faces the front part of the front end of the blade body; a water inlet of the spray head is connected onto a water outlet of the water storage tank through the connecting pipe; and the hand switch is arranged on the connecting pipe. During ice skating of a speed skating person, water is sprayed by the spray head in front of the blade bodies, a water film is formed on an ice surface, and the friction force between the blade bodies and the ice surface is reduced, so that the skating speed can be increased. Due to the fact that the sprayed water cannot be frozen instantly, the problem that a stable water lubricating effect cannot be formed by the human body pressure intensity after the temperature is reduced is solved.

Owner:王茵

Ice skate blade three-dimensional rigid bridge force measuring table and system

PendingCN113008530AImprove technical effectMachine part testingMarine engineeringStructural engineering

The invention provides an ice skate blade three-dimensional rigid bridge force measuring table. The three-dimensional rigid bridge force measuring table comprises an upper rigid bridge, a lower rigid bridge, two three-dimensional force sensors and a motion measuring unit. The rigid bridge force measuring table is fixedly connected to the ice skate blade through the upper rigid bridge and the lower rigid bridge, and a front three-dimensional force sensor and a rear three-dimensional force sensor are fixedly installed between the upper rigid bridge and the lower rigid bridge and used for detecting the stress of the ice skate blade; and the motion measurement unit is used for detecting the spatial position of the rigid bridge force measuring table and is fixedly arranged at the rear part of the upper rigid bridge. The force measuring table can monitor the size and direction of three-dimensional ice pedaling force of an athlete, the position of a counter-acting force acting point and the opening and closing state of an ice skate blade in real time, and fills the blank of three-dimensional force measurement of speed skating sports in China.

Owner:SHANGHAI UNIV OF SPORT

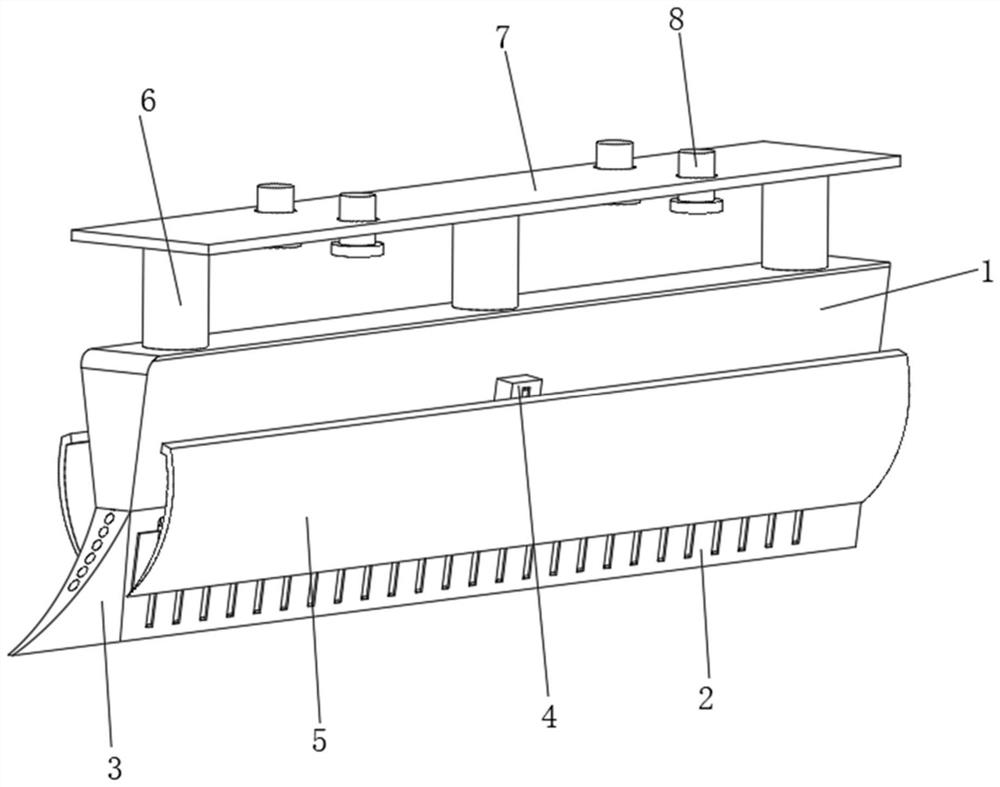

Safe speed skate ice skate blade based on blade tip ice shoveling and drag reduction

InactiveCN112516571AReduce harmEnabling Secure PackagesSkatesMarine engineeringStructural engineering

The invention discloses a safe speed skate ice skate blade based on blade tip ice shoveling and drag reduction. The safe speed skate ice skate blade comprises a blade body support, a touch pressing blade is fixedly connected to the bottom of the blade body support, a shoveling arc blade is fixedly connected to the end face of the left side of the touch pressing blade, and the top of the shovelingarc blade is sunken inwards to be in an arc shape. Adsorption driving mechanisms are fixedly connected to the middle positions of the front side and the rear side of the outer portion of the knife body support, the output ends of the adsorption driving mechanisms are fixedly connected with protective baffles, the protective baffles are in an outwards-protruding arc shape, and the bottoms of the protective baffles make contact with the outer side surfaces of the touch pressing blades. Micro-motion supporting rods evenly penetrate through the top of the cutter body support and are connected withthe top of the cutter body support in a sliding mode, and a mounting carrier plate is fixedly connected to the tops of the ends, away from the cutter body support, of the micro-motion supporting rods. The invention relates to the technical field of sports devices. According to the safety type speed skating shoe ice skate blade based on knife point ice shoveling resistance reduction, a knife edgeis safely wrapped, meanwhile, normal skating use is not affected, and harm of the knife edge to personnel during falling is reduced.

Owner:赵微

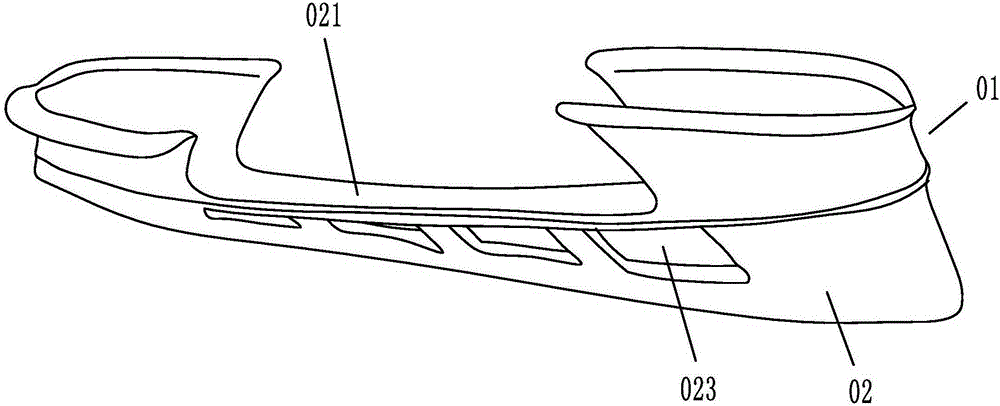

Combined type ice skate bracket

The invention relates to ice skates, and in particularly relates to a combined type ice skate bracket. The combined type ice skate bracket comprises a bracket body, wherein the bracket body comprises a shoe rack and a knife rest, the shoe rack comprises a toe support base, a heel support base, and a connecting bar for connecting the toe support base and the heel support base, the shoe rack is made of carbon fibers, the knife rest is made of plastic, the knife rest and the shoe rack are connected and fixed through pouring, the cross section of the connecting bar is in the shape of a Chinese character 'ao', an accommodating groove is arranged on the inner bottom surface of the shoe rack, a plurality of connecting holes are formed in the bottom of the accommodating groove at intervals, the accommodating groove is filled with a pressure plate, and the pressure plate and the knife rest are integrally formed. The combined type ice skate bracket has the beneficial effects that elasticity and toughness can be increased, the energy of the pressure applied to feet can be buffered and stored, the speed skating performance of the ice skates is improved, the support strength of the ice skate blade is guaranteed, the integral firmness of the bracket is guaranteed, and the cost of the material is greatly reduced.

Owner:吴有权

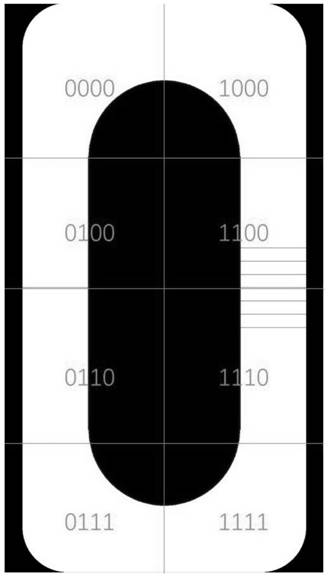

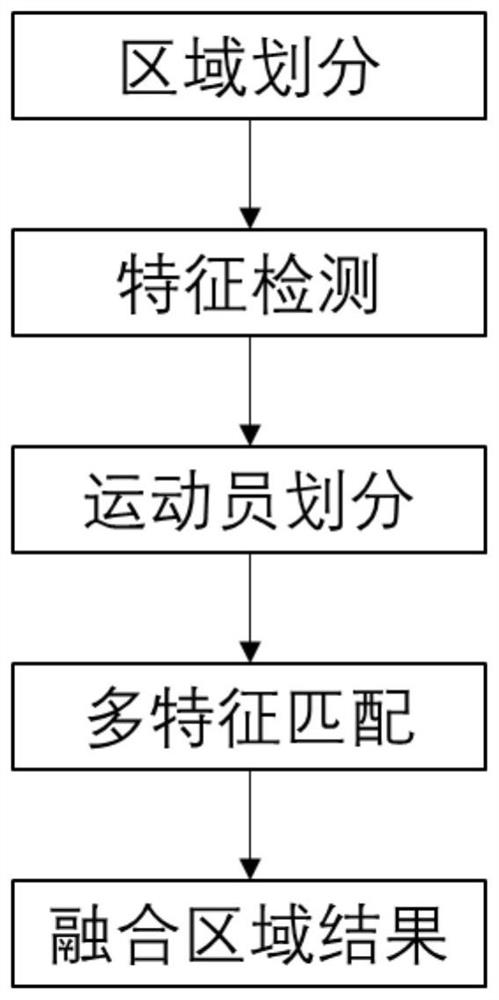

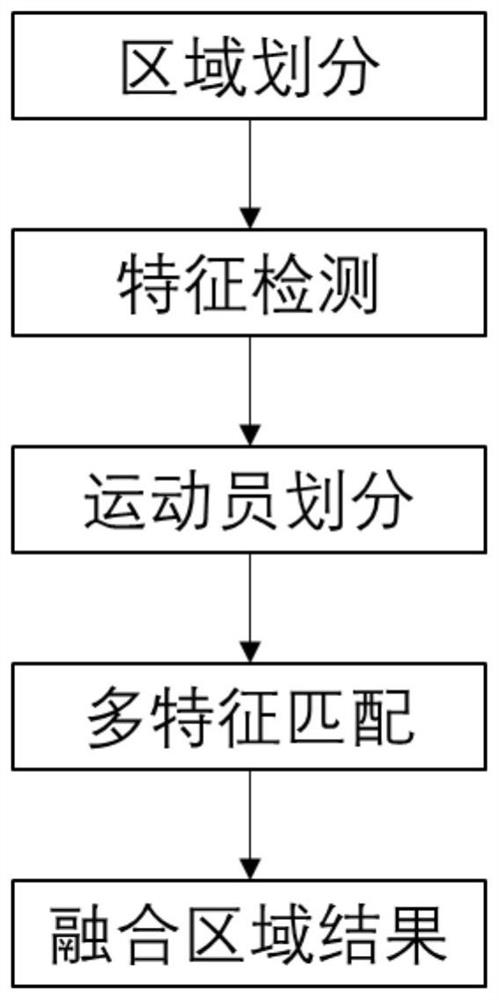

Region-based multi-feature matching speed-skating athlete multi-target tracking method

PendingCN113963375AImprove matching accuracyGood for multi-target tracking tasksImage enhancementImage analysisMulti target trackingEngineering

The invention combines deep learning and a computer vision algorithm, and particularly discloses a region-based multi-feature matching speed-skating athlete multi-target tracking method, which comprises the following steps: s1, dividing a current region according to a speed skating field; s2, detecting speed skating athlete information in the picture according to a target detection algorithm; s3, carrying out regional division on the speed skating athlete information detected in the s2 according to the division regions in the s1; s4, matching the speed skating athletes in each region by using the multi-feature information; and s5, according to the tracking result of the speed skating athlete in each region, performing matching among the regions to form a final tracking result. According to the method, multi-target tracking of the speed-skating athletes is carried out more robustly in modes of region segmentation, multi-feature matching and the like according to feature information such as the competition duration and the speed skating field of the speed skating athletes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

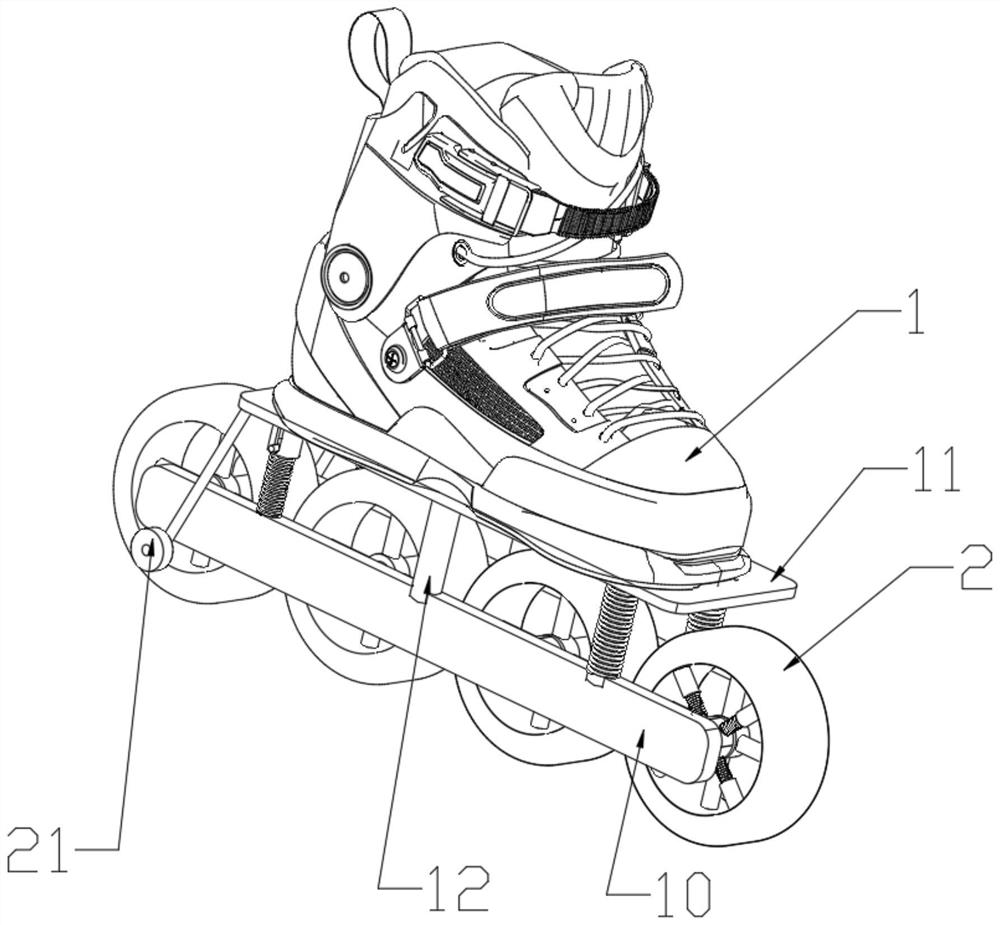

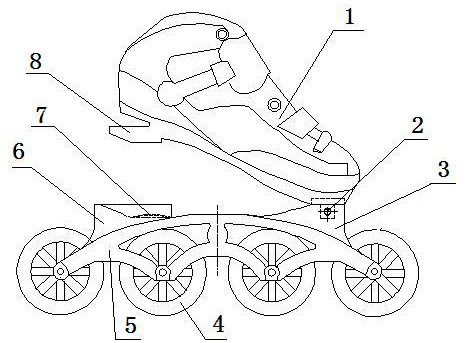

A roller skating structure and speed skating shoes that are convenient for starting and accelerating

The invention discloses a roller skating structure and speed skates which are convenient for starting and accelerating. The roller skating structure includes two installation frames parallel to each other and oppositely arranged, a pulley assembly, and a starting roller whose rotational friction force decreases as the speed increases. Acceleration assembly, auxiliary acceleration assembly, the pulley assembly is rotatably installed between two installation frames, the start acceleration assembly is installed on the pulley assembly, and the auxiliary acceleration assembly will be installed on the two installation frames, by adding The starting friction of the speed skating shoes makes the initial speed the smallest and the frictional force is the largest. As the ring roller of the speed skating shoes rotates, the centrifugal force increases, the friction force decreases, and the speed increases, so as to achieve the purpose of speed skating.

Owner:CHONGQING UNIV OF EDUCATION

A kind of skating shoe with active anti-knee feet for speed skating beginners

ActiveCN112369753BCooperate wellImprove comfortFootwearPhysical medicine and rehabilitationEngineering

The invention discloses an active anti-sprain skate for beginners in speed skating, which comprises a support sole plate, the top of the support sole plate is fixedly connected with a front groove of the shoe body, and the left side of the support sole plate is rotationally connected with a movable sole plate. The top of the sole plate is fixedly connected with a root restraint groove, the top between the root restraint groove and the front groove of the shoe body is fixedly connected with an ankle sleeve, and the front of the ankle sleeve is fixedly connected with a restraint zipper to support the middle position of the bottom of the sole plate A blade mounting carrier plate is fixedly connected, a supporting blade is fixedly connected to the middle position of the bottom surface of the blade mounting carrier plate, and an inflatable rubber bag is fixedly connected to the inner surface of the ankle sleeve, the root restricting groove and the supporting shoe sole plate. Slippery technical field. The active anti-sprain skates for beginners in speed skating can support the ankle when a large torque is generated, and fit the ankle under normal conditions to improve the coordination of different ankles.

Owner:濉溪野草信息科技有限公司

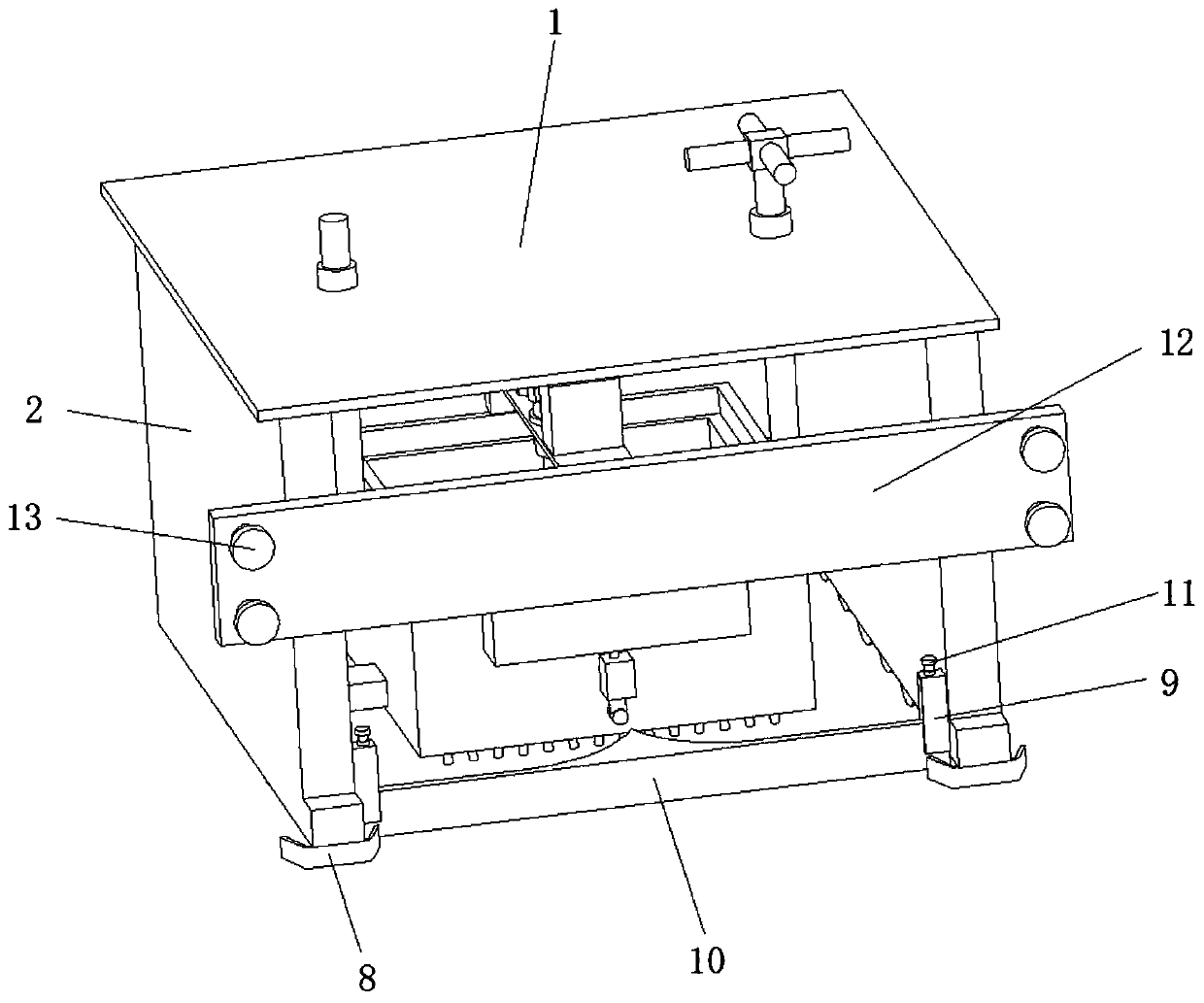

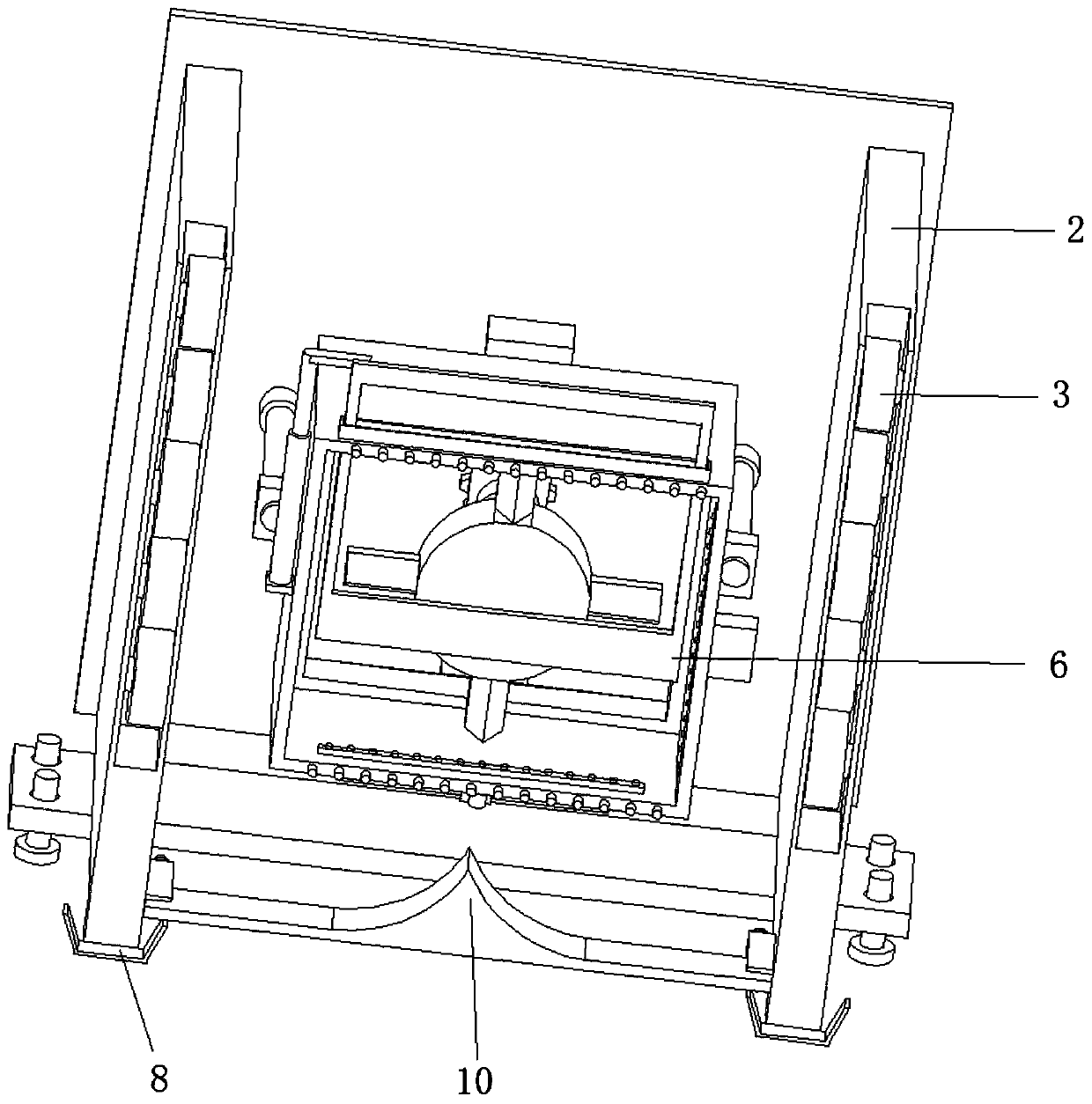

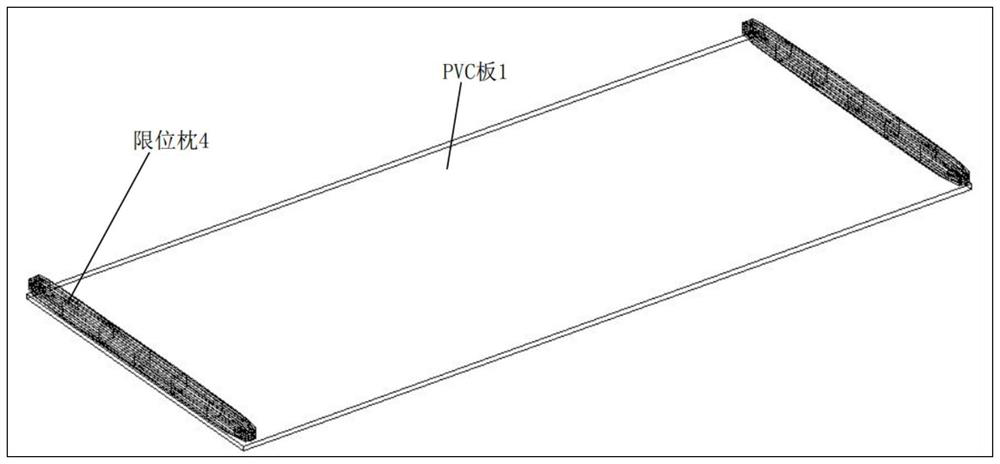

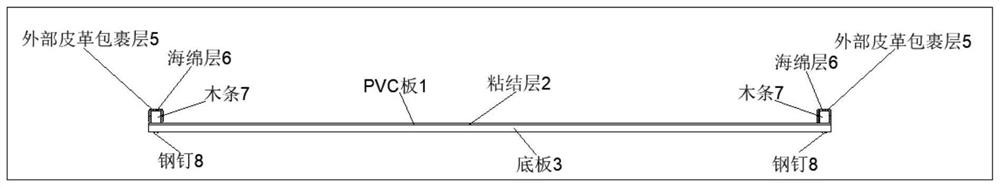

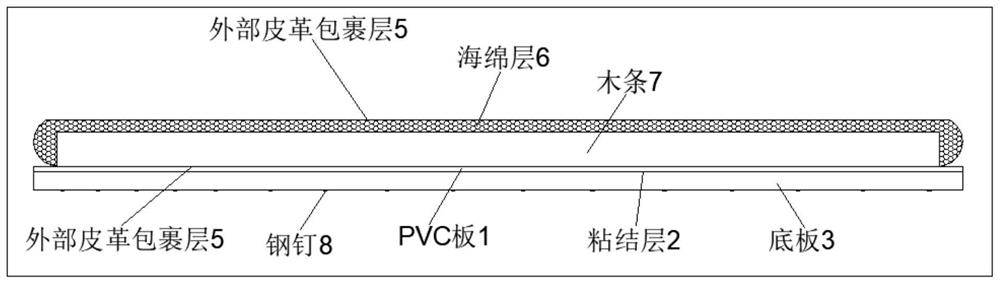

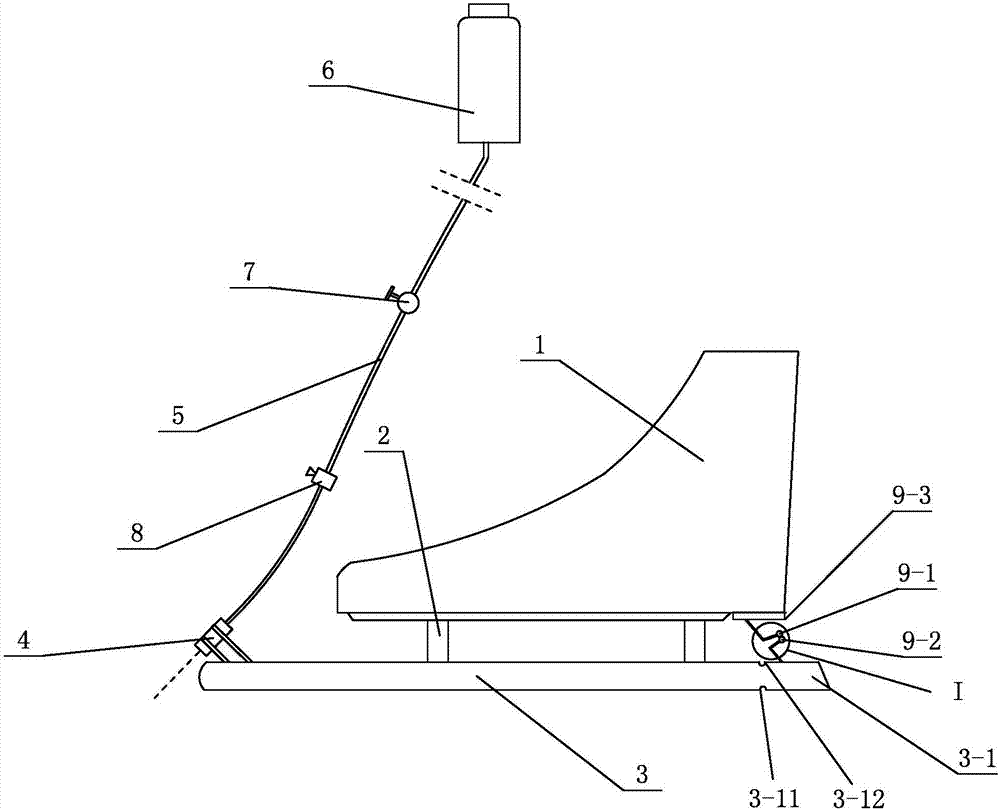

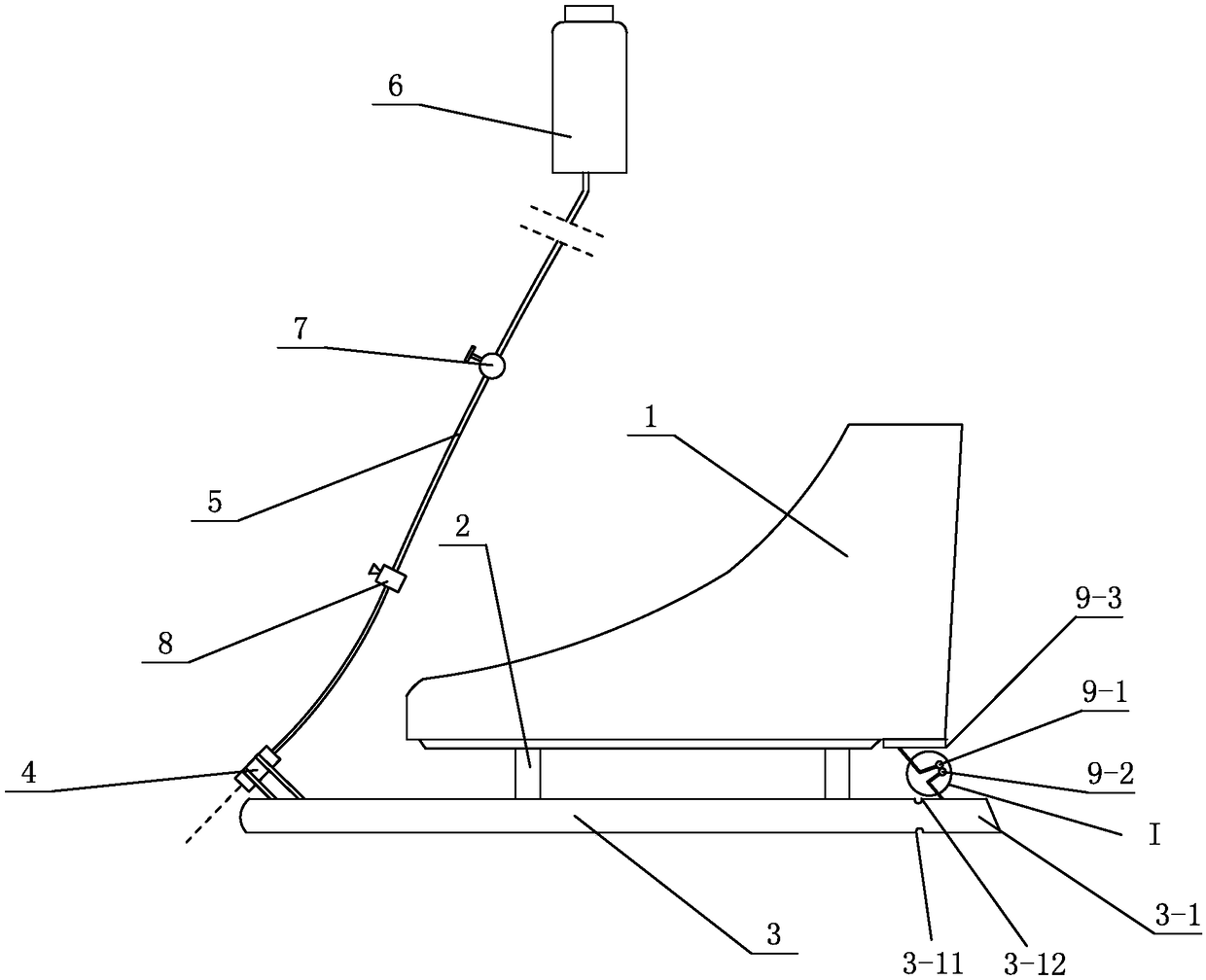

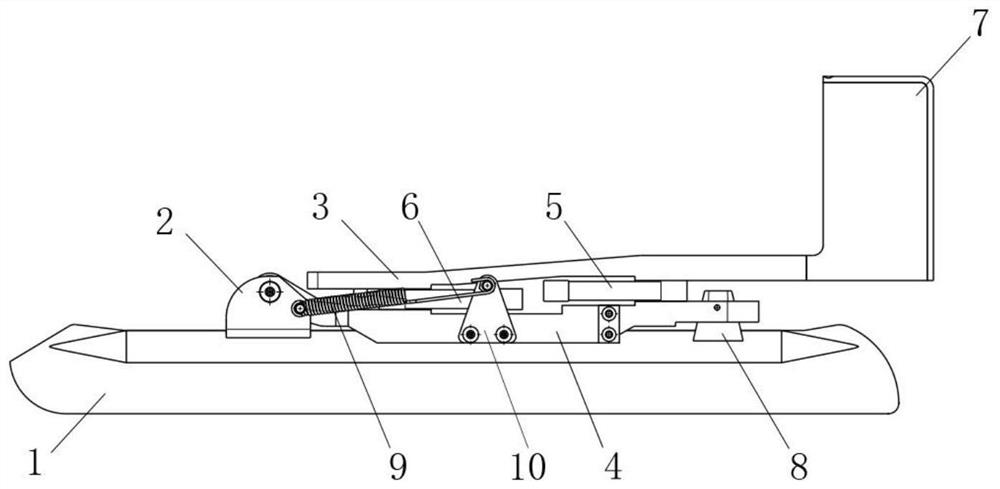

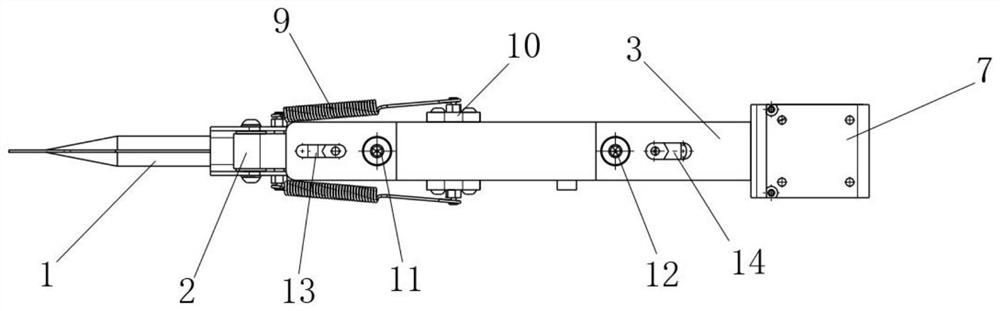

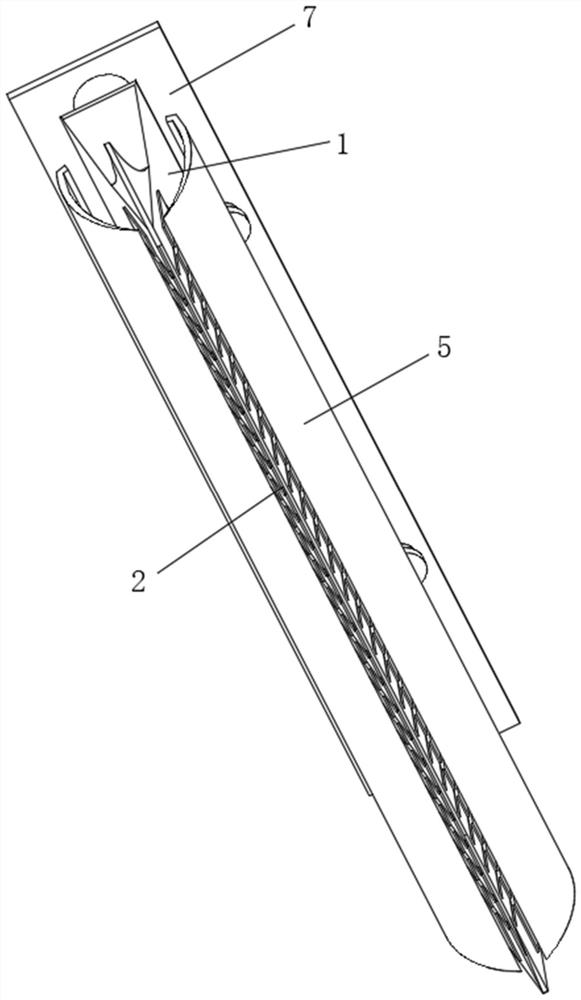

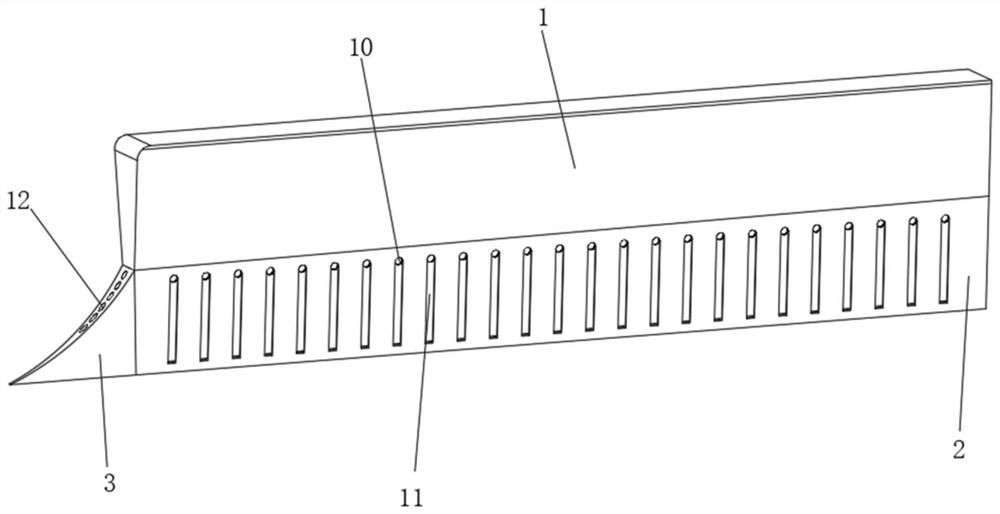

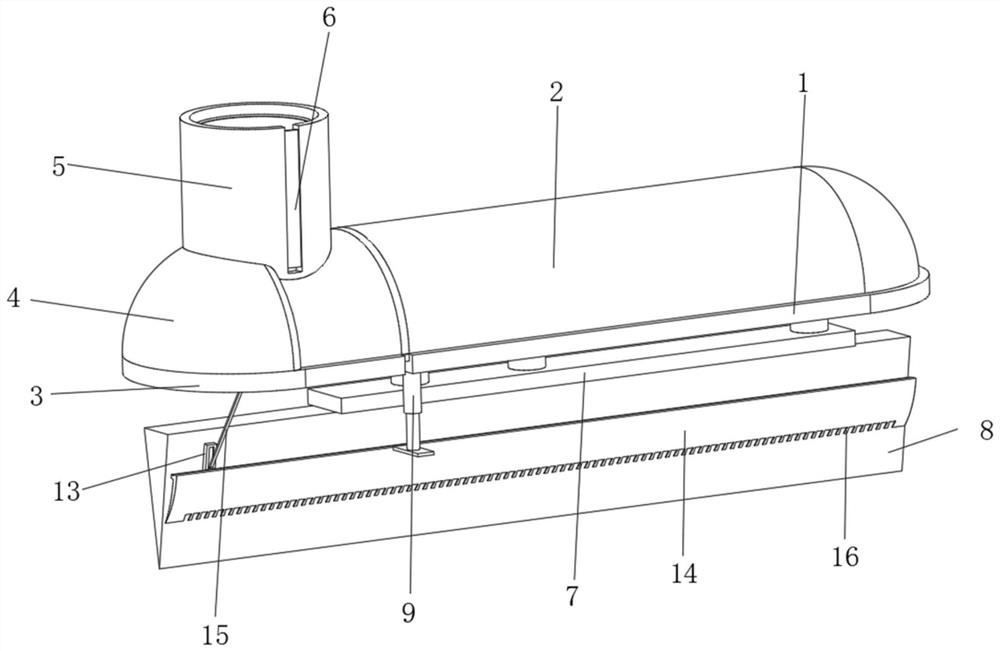

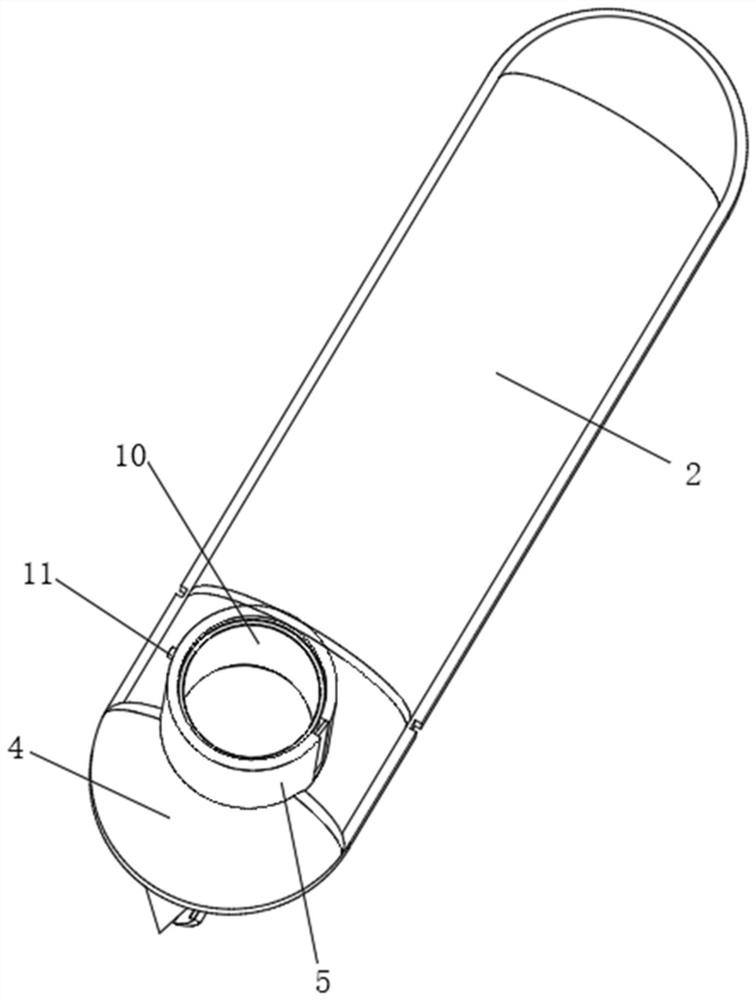

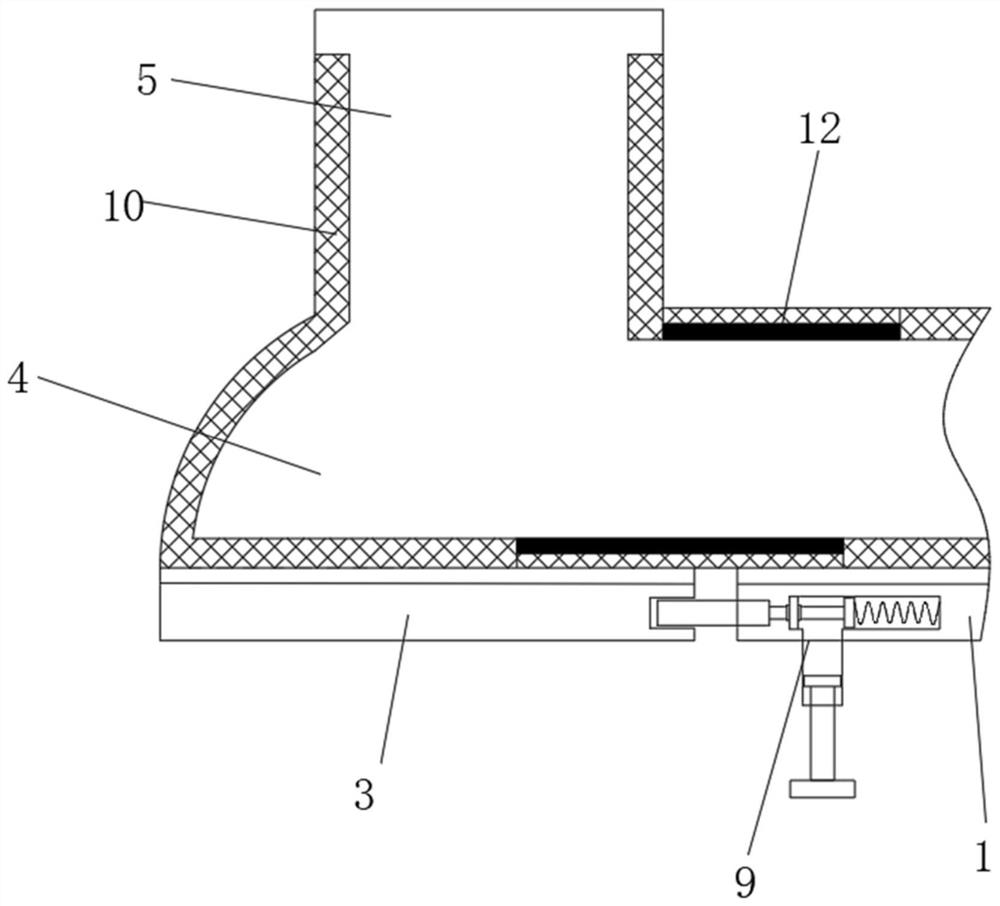

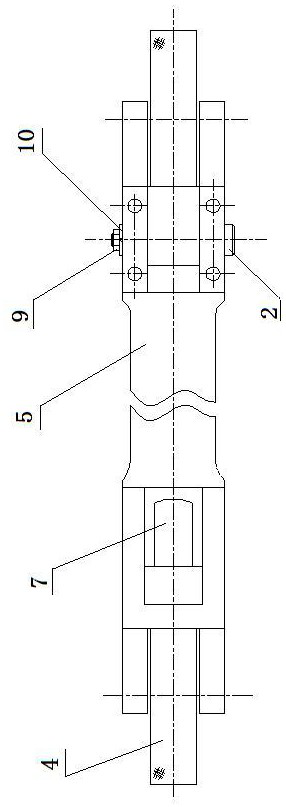

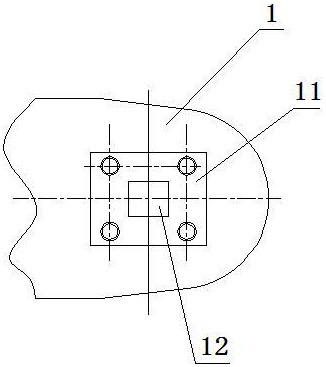

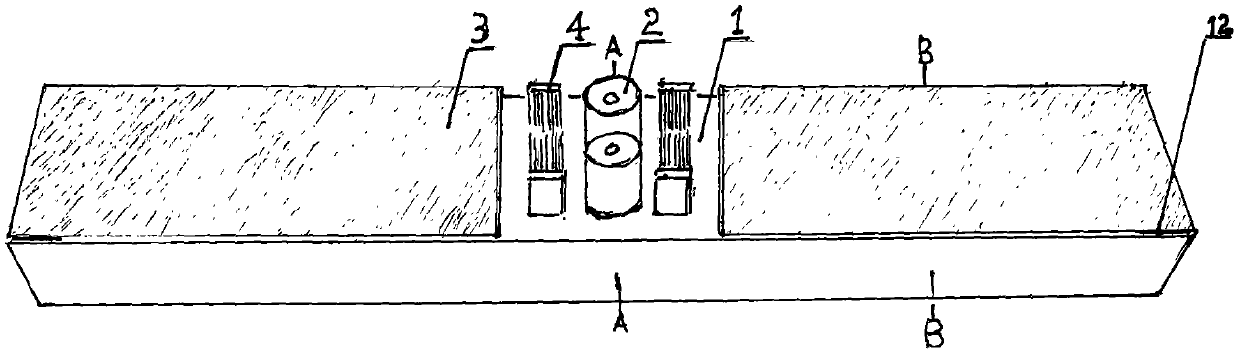

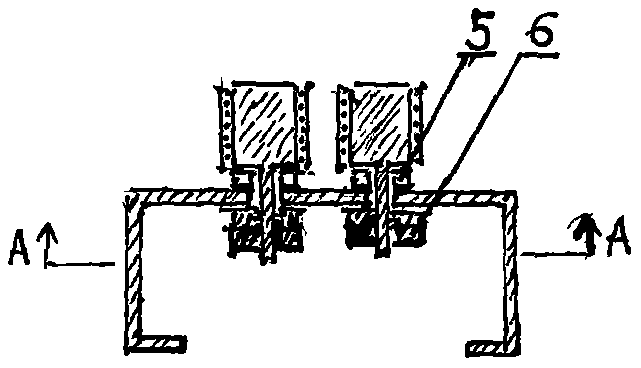

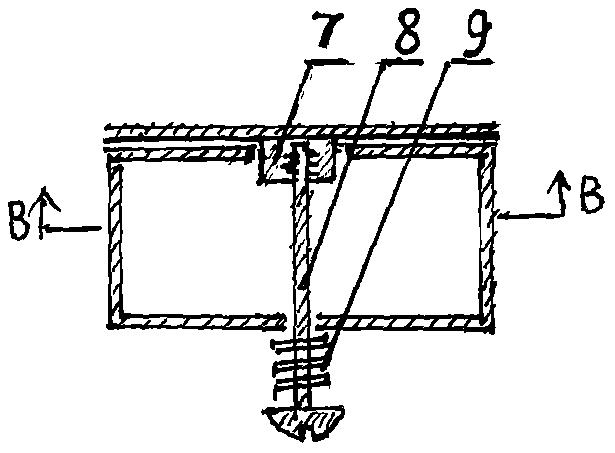

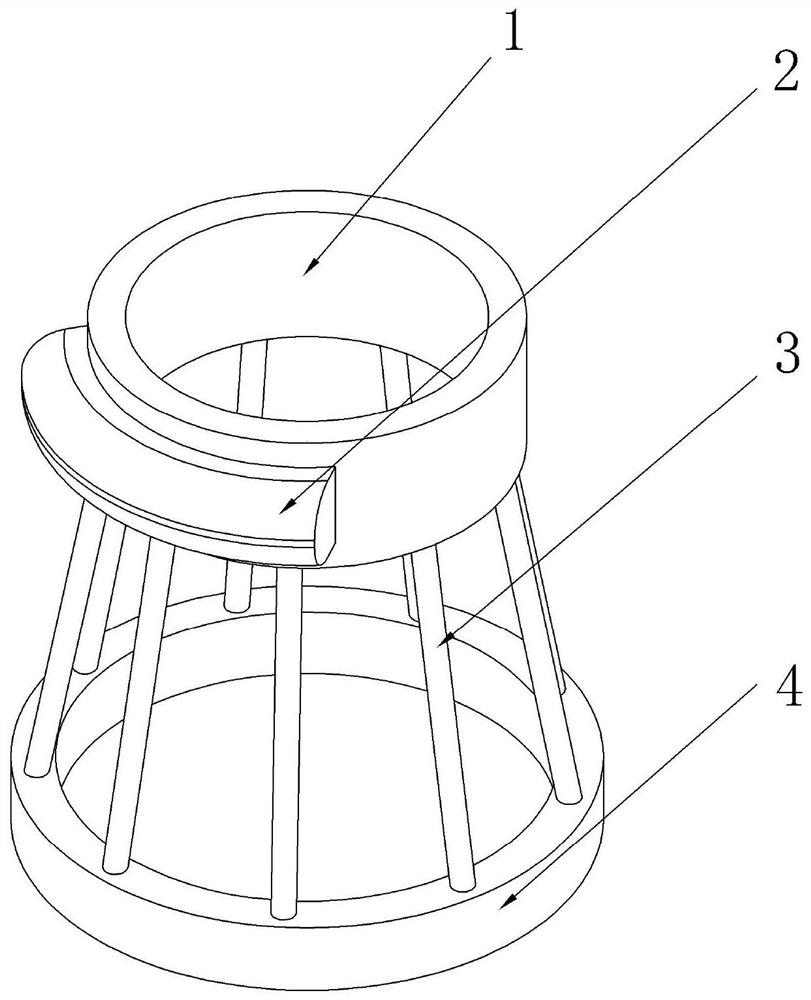

Simulation training device for land speed skating and use method

PendingCN114733172AMeet the characteristicsImprove teaching qualitySport apparatusStructural engineeringWasher

The invention relates to a simulation training device for land speed skating and a use method. Existing teaching equipment is not provided with a land simulation training device matched with the existing teaching equipment, shoes worn by students in daily land skating simulation training are not matched with speed skating knives, and the teaching quality of simulation training is directly affected. The device comprises a speed skate (1), a fixing plate (11) is embedded in a sole at the front end of the speed skate, the fixing plate is provided with a protruding square limiting column (12), the square limiting column is installed in a groove of a front end connecting base (3), a pin shaft (2) penetrates through the square limiting column on the two sides and in the middle of the front end connecting base and is connected with the square limiting column through a spring washer (10) and a thin nut (11), the front end connecting base is provided with a set of unthreaded holes, and the thin nut (11) is connected with the pin shaft (2). The pin penetrates through the unthreaded hole and is connected with the fixing plate through threads, the rear end of the speed skating shoe is provided with an elastic heel (8), the bottom face of the elastic heel is provided with an inclined face, and the inclined face is attached to an inclined face in a rear end connecting base (6). The invention is used for the land speed skating simulation training device.

Owner:HARBIN INST OF PHYSICAL EDUCATION

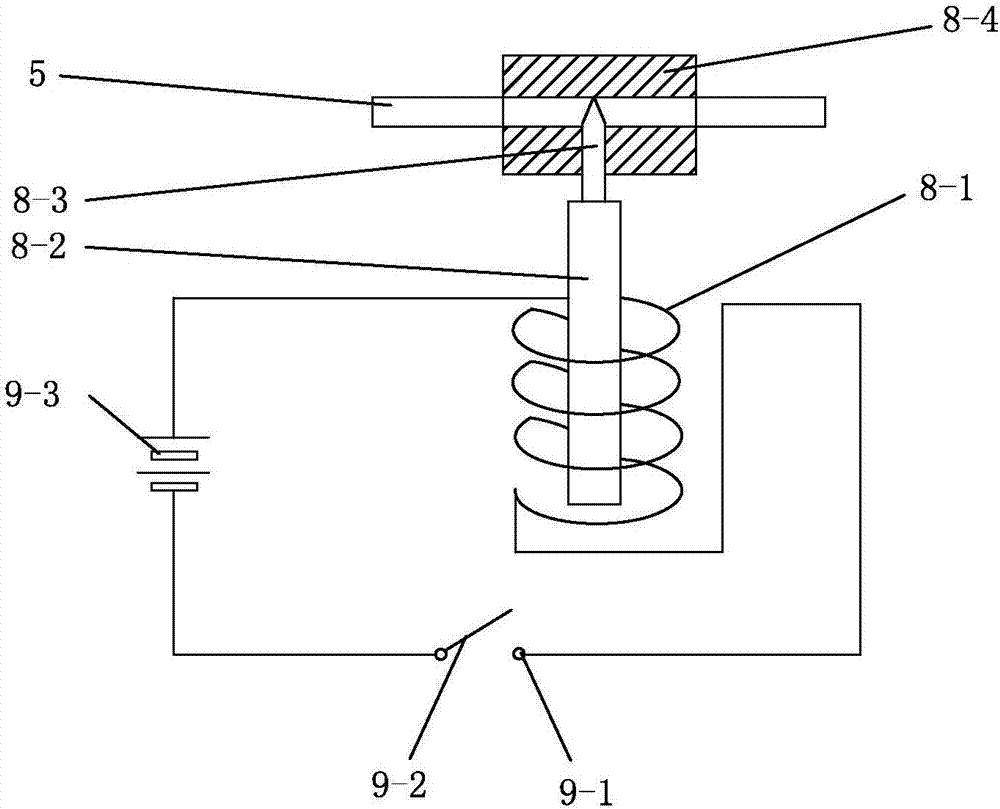

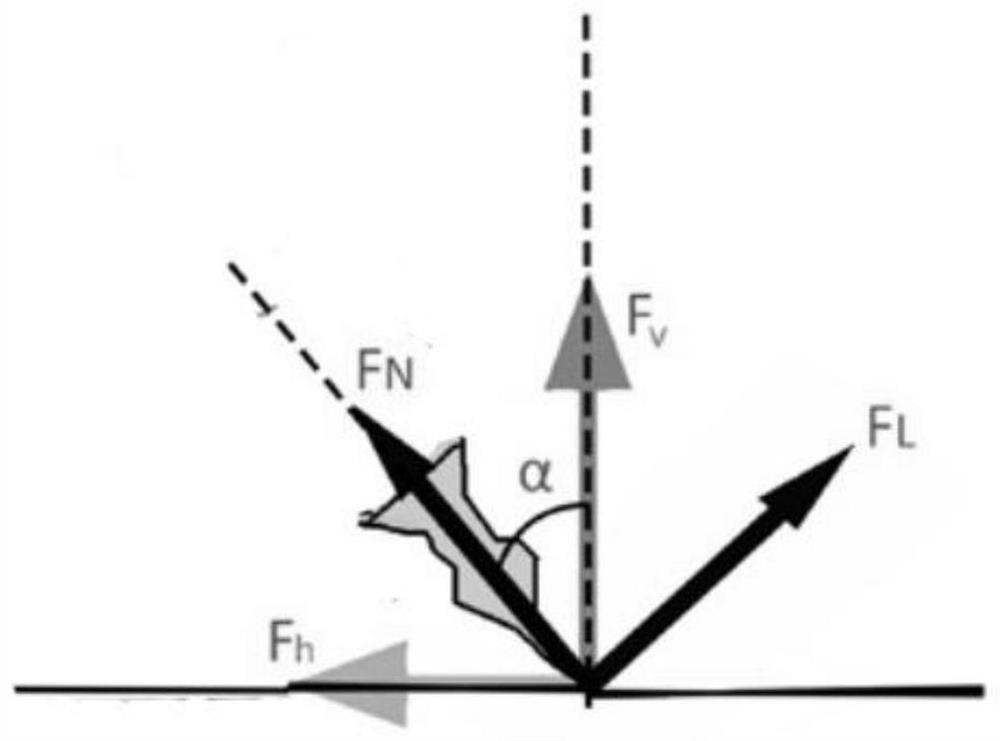

Special strength training device for speed skating at land curve

InactiveCN103285571AImprove training effectSmall footprintSport apparatusLiquid-crystal displayEngineering

A special strength training device for speed skating at a land curve relates to a special strength training device and specifically to a special strength training device for speed skating at a land curve. The special strength training device for the speed skating at the land curve is invented to solve the problems that resistance applied to an athlete is completely controlled by the virtue of an auxiliary training member, exact quantification and supervisory control are deficient, and the training effect is not good enough in the conventional special strength training process of the speed skating at the land curve. The special strength training device for the speed skating at the land curve comprises a first intermediate stretching belt, a second intermediate stretching belt, a force sensor, a first endless belt and a second endless belt, wherein one end of the first intermediate stretching belt is connected to the first endless belt; the other end of the first intermediate stretching belt is connected to one end of the second intermediate stretching belt through the force sensor; the other end of the second intermediate stretching belt is connected to the second endless belt; and the force sensor is provided with a liquid crystal display screen and a sounder. The special strength training device for the speed skating at the land curve is used for special strength training for the speed skating at the land curve.

Owner:HARBIN NORMAL UNIVERSITY

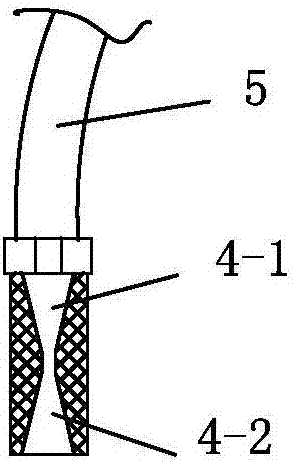

Portable speed skating blade sharpener

PendingCN111251203AEasy to operateMiniaturizationGrinding/polishing hand toolsBlade plateKnife sharpener

The invention provides a portable speed skating blade sharpener and aims at providing a sharpener which is convenient to carry on a skating site and can also be used for sharpening skating blades. Meanwhile, by using the portable speed skating blade sharpener, a skater can learn how to sharpen the blades through simple operation. The portable speed skating blade sharpener comprises a base, rollingbearings, bearing height adjusting washers, bearing fixing nuts, chip removal brushes, grinding boards, grinding board fixing nuts, compression springs, grinding board fixing screw rods, grinding board gaskets, a bearing fixing and adjusting window and a handle. When the portable speed skating blade sharpener is in use, a user handholds a single skating blade with a cutting edge upwards, the rolling bearings of the sharpener downwards clamp a blade board to make the cutting edge attached to the grinding boards, the user slightly exerts pressure to press the skating blade downwards and slidesthe skating blade front and back, and then the grinding boards can grind the cutting edge into a specific skating blade cutting edge with the two straight sides of 90 degrees.

Owner:宁福胜

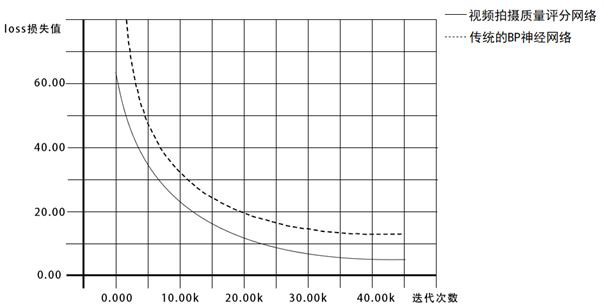

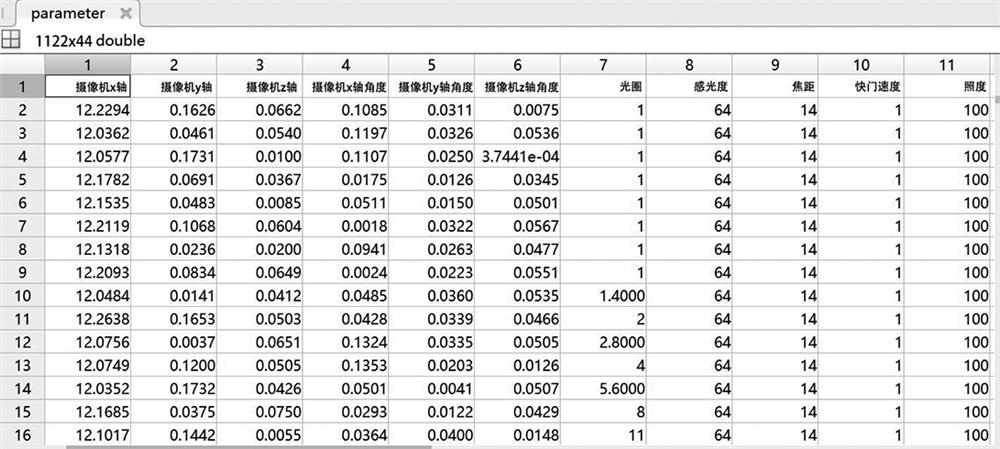

A method for quality assessment of multi-camera video

ActiveCN113794874BShorten the timeImprove scoring accuracyTelevision systemsData setComputer graphics (images)

The invention discloses a method for evaluating the quality of video shot by multiple cameras, comprising: collecting shooting data of four adjustable cameras through a short-track speed skating virtual simulation module, and making a data set; and constructing a video shooting quality scoring network based on the data set ; calculate the error of the output layer of the video shooting quality scoring network, and train the video shooting quality scoring network in combination with the error and the bat optimization strategy. The video is input into the trained video shooting quality scoring network for video quality scoring; the present invention enhances the optimization ability by optimizing the bat algorithm, and uses it as an optimizer to optimize the video shooting quality scoring network to improve the video shooting quality The scoring accuracy rate of the scoring network saves the cost and time of manual evaluation of video shooting.

Owner:南京理工大学紫金学院

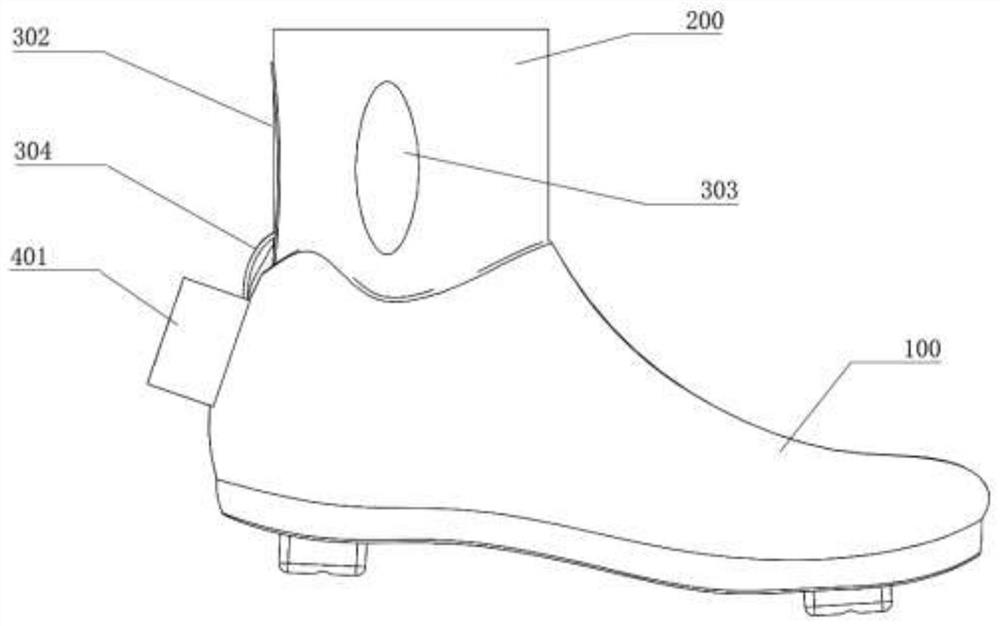

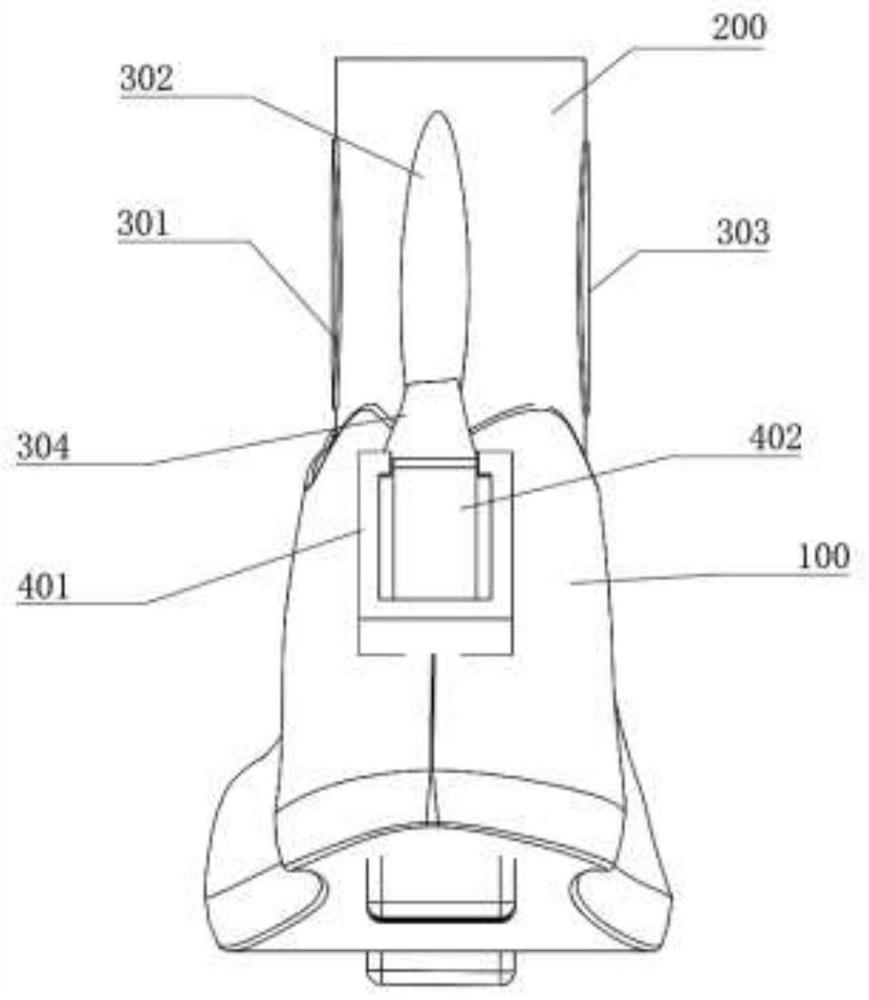

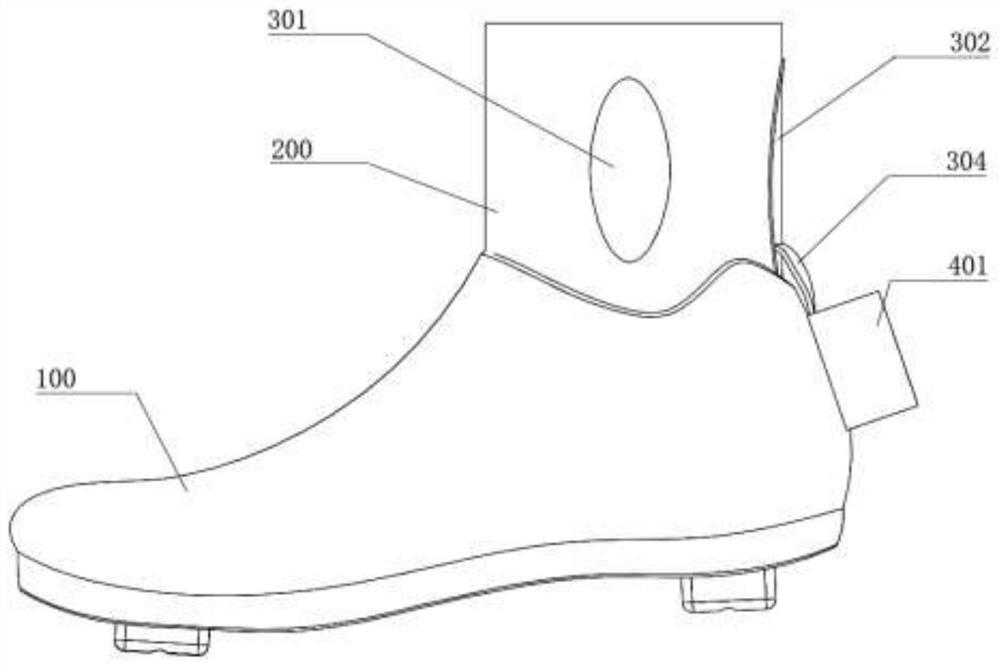

Speed skate for testing

PendingCN113827940AReduce distractionsHigh precisionSkatesPhysical medicine and rehabilitationData acquisition

The invention relates to sports goods, in particular to a speed skate for testing. The invention provides a device capable of performing continuous monitoring in daily training of speed skating athletes. The speed skate for testing comprises a skating shoe body, a sock connected to the upper portion of the skating shoe body and a detachable data acquisition box attached to the heel position of the skating shoe, different from existing speed skating shoes, the sock is connected to the upper portion of the skating shoe body, and according to the testing requirement for ankle joint angle changes of athletes, the sock sleeve is provided with three data acquisition areas, and the three data acquisition areas correspond to three kinds of motion of the ankle joint, namely, ankle dorsal flexion, ankle entropion and ankle ectropion. By means of the method, detailed whole-course action analysis data can be provided for speed skating athletes, and data support is provided for finite element simulation and later equipment improvement and manufacturing.

Owner:BEIJING SPORT UNIV

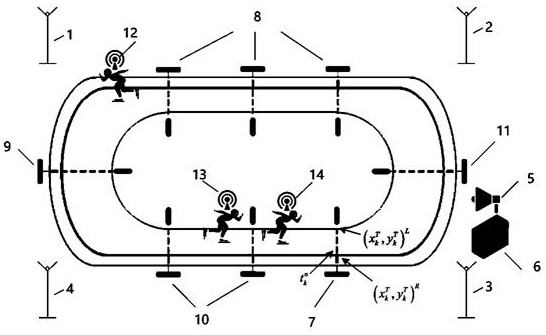

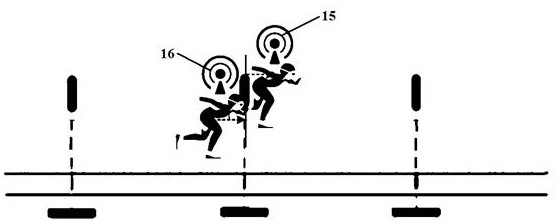

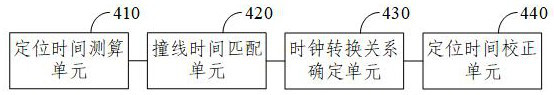

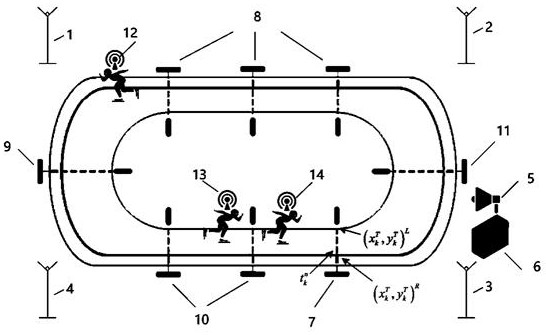

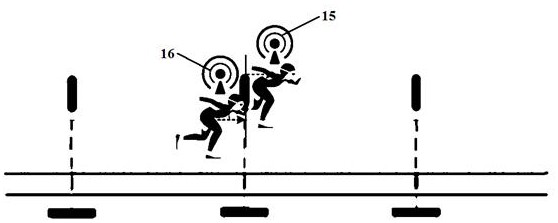

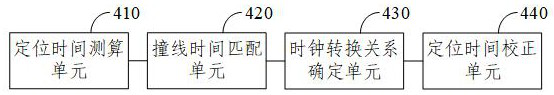

Segment tracking timing method and device for short track speed skating or speed skating events

ActiveCN112687024BReduce track direction timing errorsHigh precisionRegistering/indicating time of eventsUltra-widebandStopwatch

The present invention provides a segment tracking timing method and device for short-track speed skating or speed skating events, wherein the method includes: based on the positioning information of any athlete collected by an ultra-wideband positioning device, calculating the time when the athlete passes through two adjacent laser beams The first positioning time and the second positioning time of the timer; based on the first positioning time and the second positioning time, query the first line-crossing time and the second line-crossing time collected by the laser timer; based on the first positioning time, the second 2. Positioning time, the first line-crossing time and the second line-crossing time, determine the conversion relationship between the positioning clock and the laser timer clock between the first laser timer and the second laser timer; The positioning time collected while moving between the first laser timer and the second laser timer is corrected. The invention reduces the track direction timing error of the ultra-broadband positioning device, and realizes significant improvement of track point timing measurement accuracy under high-speed and fierce racing conditions.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

A multifunctional speed skating shoe knife holder

ActiveCN104001322BEasy to adjustCompact structureSkatesSkate-boardsExplosive forceMechanical engineering

The invention discloses a multifunctional speed skating shoes blade frame including a blade frame main body; the top end of the blade frame main body is provided with mounting surfaces; the mounting surfaces comprise a front mounting surface and a rear mounting surface which are respectively distributed on the front part and the rear part of the top end of the blade frame main body, the front mounting surface and the rear mounting surface are located on a same horizontal plane, and according to speed skating functions required to be achieved, cushion blocks are selectively mounted on the front mounting surface and the rear mounting surface. The front mounting surface and the rear mounting surface are each not provided with the cushion block. The rear mounting surface is provided with the cushion block, the cushion block is detachably mounted, and the front mounting surface is not provided with the cushion block. The front mounting surface and the rear mounting surface are respectively provided with the cushion blocks, and the cushion blocks have the same height and are detachably mounted. The multifunctional speed skating shoes blade frame has simple and compact structure and low cost, allows the front mounting surface and the rear mounting surface to be selectively provided with the mounting blocks, is simple in adjustment, can achieve various speed skating functions, and is beneficial for Asian to exert the muscle explosive force and improve speed skating results.

Owner:东莞市启键体育用品有限公司

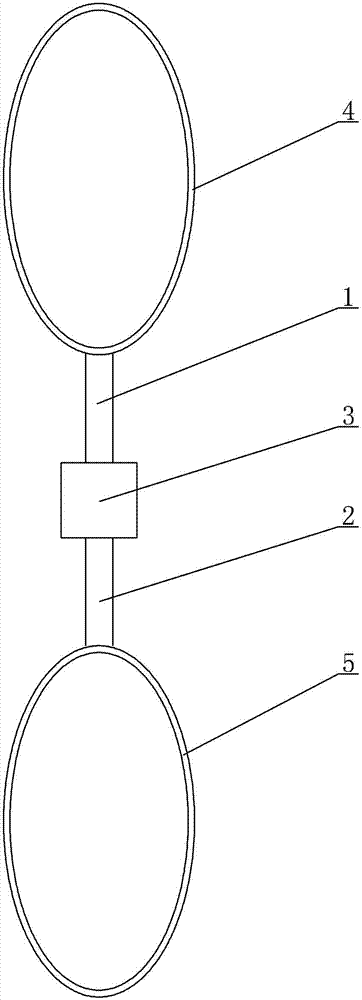

A monitoring device for physical function changes of speed skating athletes

The invention belongs to the field of auxiliary sports equipment, and particularly discloses body function change monitoring equipment for special speed skating athletes. The monitoring equipment comprises a detection sensor; an elastic air bag is fixedly connected to a side surface of an elastic fixing band; a plurality of ventilation hoses communicate with the elastic air bag; a detection band comprises an outer layer band and an inner layer band; the sensor is fixed between the inner layer band and the outer layer band; one end of a first V-shaped piece is fixedly connected to one end of anon-elastic band; one end of a second V-shaped piece is fixedly connected to the other end of the non-elastic band; the middle of the first V-shaped piece is connected with the middle of the second V-shaped piece in a relative rotation manner; an oval air bag is arranged between one end, far away from the non-elastic band, of the first V-shaped piece and one end, far away from the non-elastic band, of the second V-shaped piece; one end of the oval air bag is fixed to a first V-shaped band, and the other end of the oval air bag is fixedly connected with a second V-shaped band; and the ventilation hoses communicate with the oval air bag. According to the scheme, the problem that the measurement is not accurate due to the fact that the burden of muscles is increased in existing detection equipment is solved.

Owner:WUHAN SPORTS UNIV

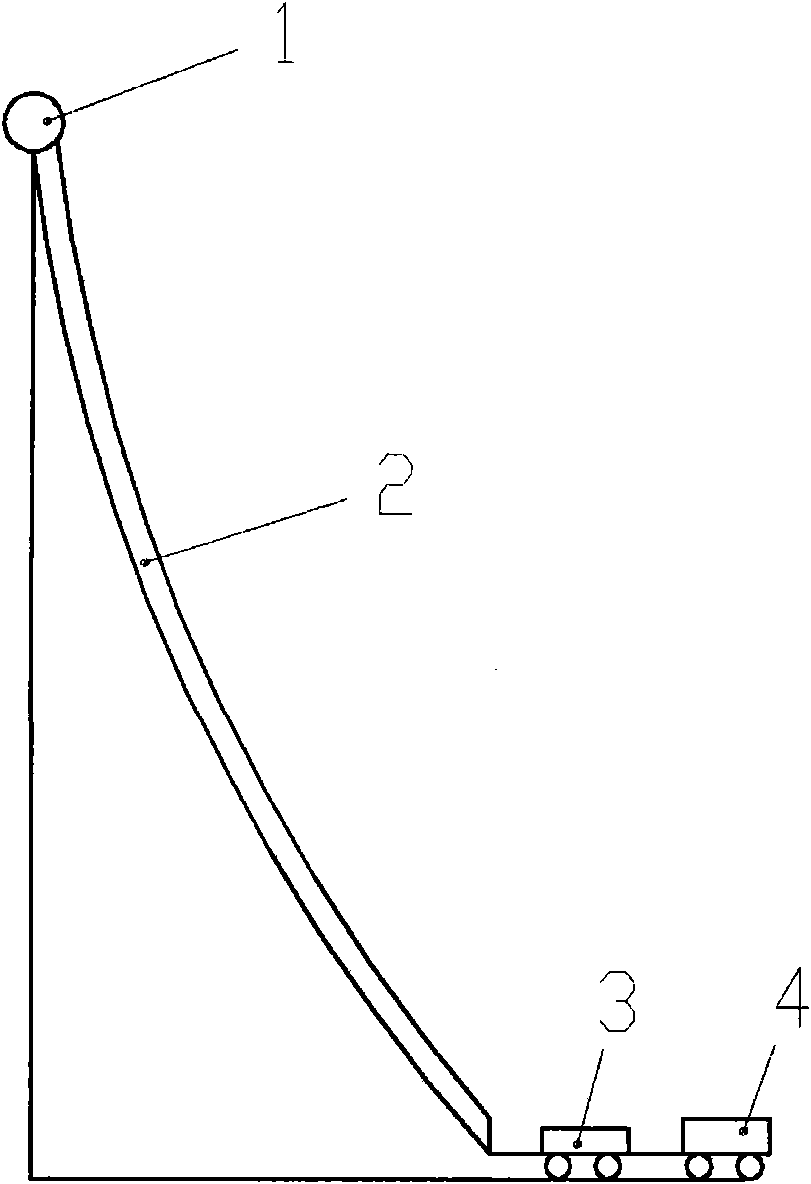

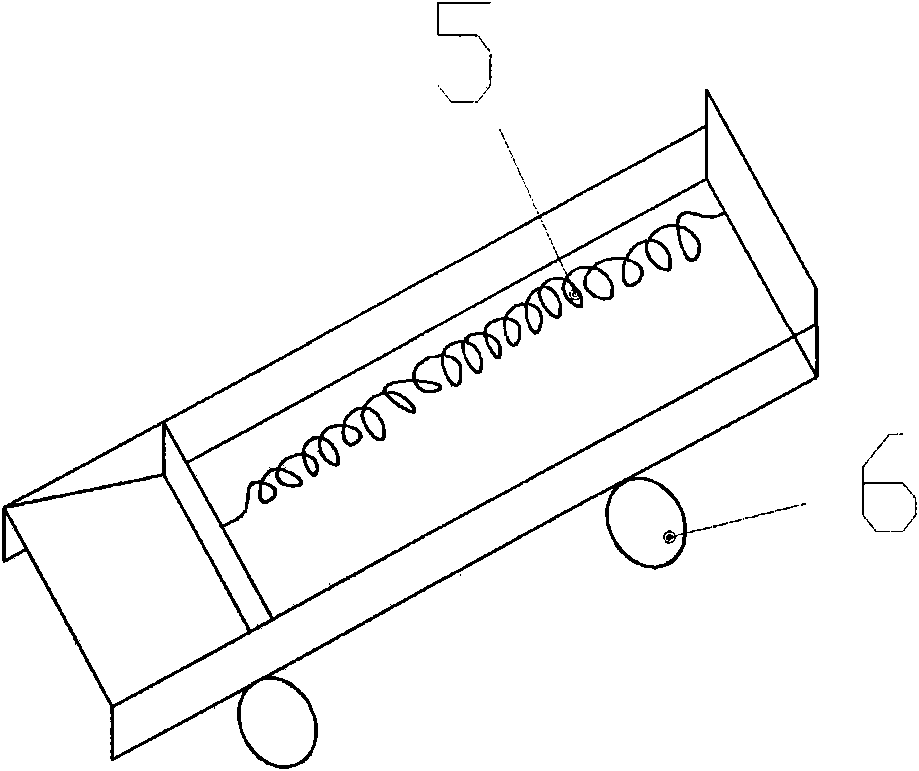

High building escape system

The invention relates to a high building escape system which comprises a speed skating bag, a slide plate and a reduction vehicle. One end of the speed skating bag is fixed on a high building, the other end is connected with the slide plate, and the slide plate is connected with the reduction vehicle. The maximum tension which can be borne by the speed skating bag is 1000 kg, and the diameter of the speed skating bag is 1 m. The length of the slide plate is 3 m, a pulley is installed at the bottom of the slide plate, and a spring is arranged on the plate surface of the slide plate. The reduction vehicle is provided with a current condenser, an engine and a speed change device. Through the structure, people are not influenced by smoke and fire of a building body when leaving the building body through the speed skating bag, have no glaring visual impact when sliding in the speed skating bag, and can utilize the invention no matter how physical constitution is. The invention does not need to be controlled by a survivor, and is not influenced by a state of the survivor. But when a human body achieves the ground and enters the slide plate, the slide plate slides supporting the human body to protect skins against bruising, and speed can be regulated through the reduction vehicle, therefore, the invention is safe, has short time, and is beneficial to multi-person escape.

Owner:ADOLESCENT SCI & TECH GUIDE STATION BAOSHAN DISTRICT SHANGHAI CITY

Segmented tracking and timing method and device for short-track speed skating or speed skating project

ActiveCN112687024AReduce track direction timing errorsHigh precisionRegistering/indicating time of eventsUltra-widebandStopwatch

The invention provides a segmented tracking and timing method and device for a short-track speed skating or speed skating project, and the method comprises the steps: calculating the first positioning time and second positioning time of an athlete when the athlete passes through two adjacent laser timers based on the positioning information, collected by an ultra-wideband positioning device, of any athlete; based on the first positioning time and the second positioning time, querying first line collision time and second line collision time collected by the laser timer; based on the first positioning time, the second positioning time, the first line collision time and the second line collision time, determining a conversion relation between a positioning clock and a laser timer clock between the first laser timer and the second laser timer; and based on the conversion relationship, correcting the positioning time collected by the athlete when the athlete moves between the first laser timer and the second laser timer. According to the invention, the track direction timing error of the ultra-wideband positioning device is reduced, and the track point timing measurement precision under high-speed and fierce racing conditions is significantly improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com