Lens capable of improving color contrast and saturation and preparation method thereof

A technology for color contrast and saturation, applied in the field of lenses and their preparation for improving color contrast and saturation, can solve problems such as inability to meet the needs of patients, single color weakness, etc. visual stereo effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

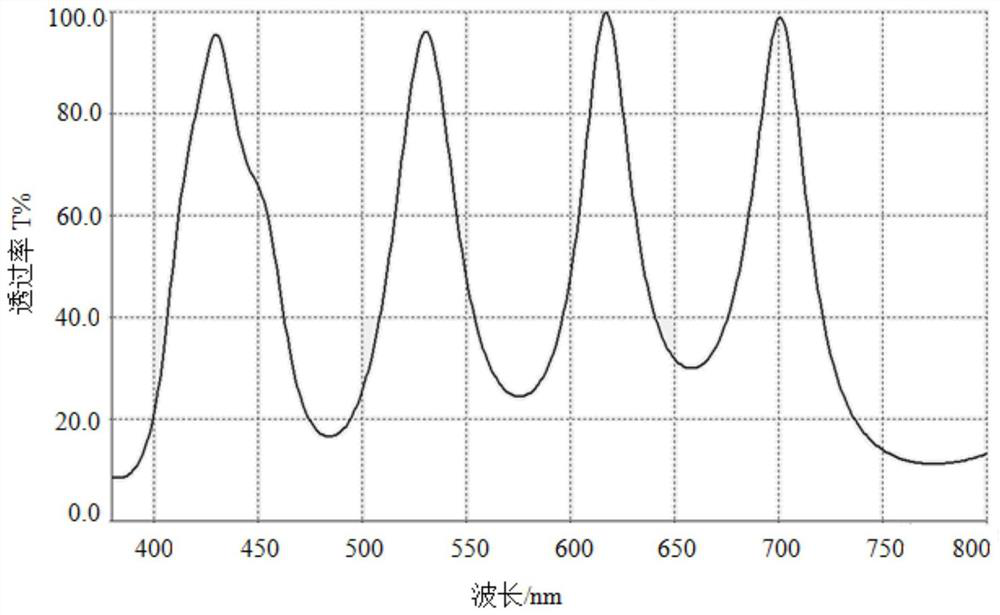

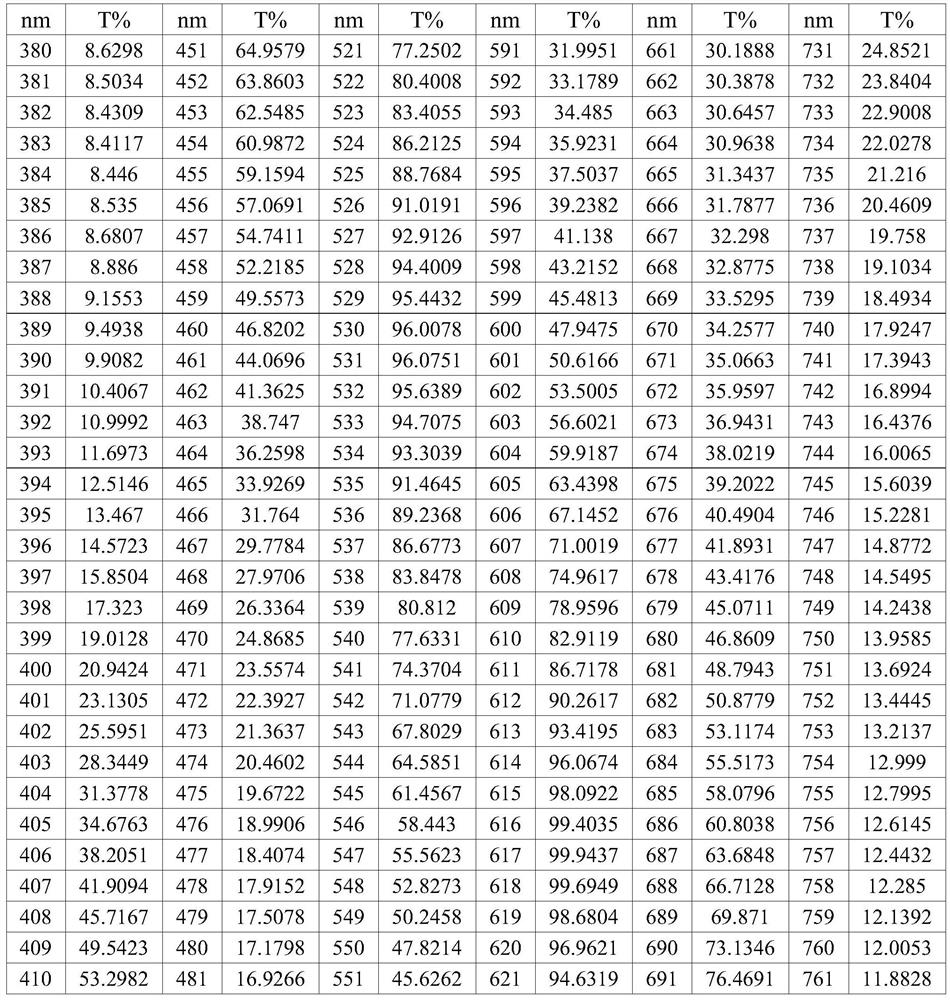

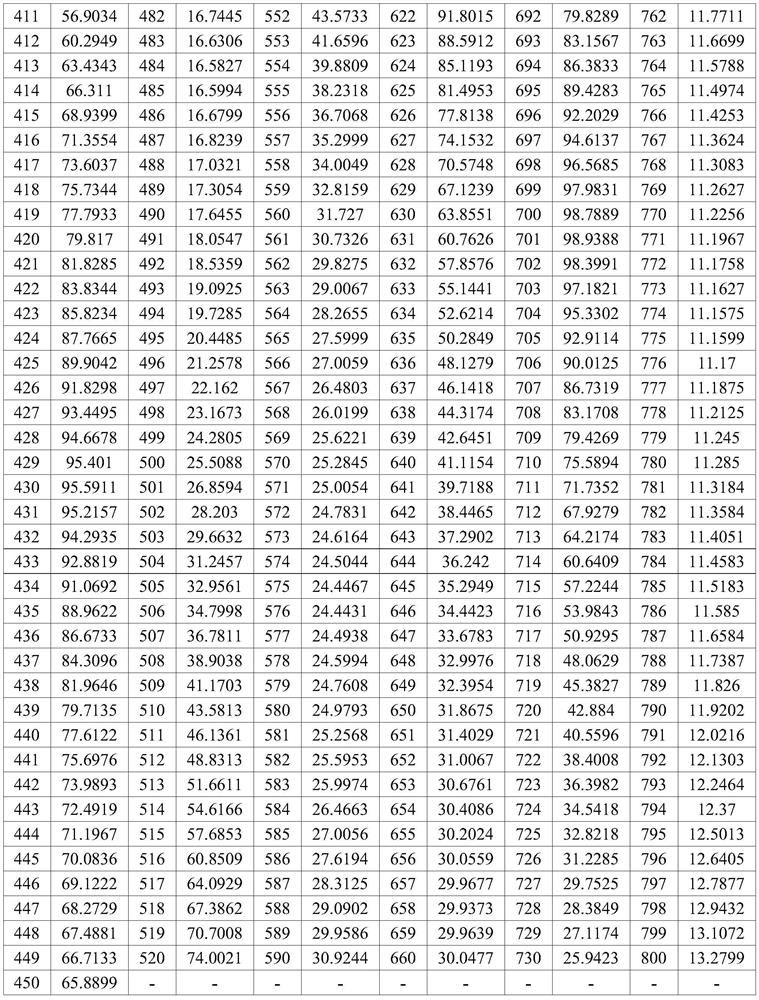

Image

Examples

Embodiment 1

[0031] S1. Clean the acrylic substrate with a thickness of 1mm and dry it to obtain a clean acrylic substrate;

[0032] S2. Place the clean acrylic substrate on the jig, send it into the vacuum coating chamber and evacuate it. When the vacuum degree in the vacuum chamber reaches 5*10 -5 When the Torr is below, turn on the ion source and clean the surface of the acrylic substrate. When the vacuum degree in the vacuum chamber reaches 2*10 -5 When the Torr is below, the temperature in the vacuum chamber is controlled at 40-60°C and the evaporation rate is controlled at Use an electron gun to bombard the bottom layer and several film layer materials in order to form the bottom layer and several film layers sequentially on the outer surface of the substrate;

[0033] S3, keep the vacuum degree in the vacuum chamber at 2*10 -5 Below Torr, control the temperature in the vacuum chamber at 40-60°C and control the evaporation rate at A tungsten boat is used to heat the waterproof m...

Embodiment 2

[0040] S1. Clean the acrylic substrate with a thickness of 1mm and dry it to obtain a clean acrylic substrate;

[0041] S2. Place the clean acrylic substrate on the jig, send it into the vacuum coating chamber and evacuate it. When the vacuum degree in the vacuum chamber reaches 5*10 -5 When the Torr is below, turn on the ion source and clean the surface of the acrylic substrate. When the vacuum degree in the vacuum chamber reaches 2*10 -5 When the Torr is below, the temperature in the vacuum chamber is controlled at 40-60°C and the evaporation rate is controlled at Use an electron gun to bombard the bottom layer and several film layer materials in order to form the bottom layer and several film layers sequentially on the outer surface of the substrate;

[0042] S3, keep the vacuum degree in the vacuum chamber at 2*10 -5 Below Torr, control the temperature in the vacuum chamber at 40-60°C and control the evaporation rate at A tungsten boat is used to heat the waterproof m...

Embodiment 3

[0046] S1. Clean the acrylic substrate with a thickness of 1mm and dry it to obtain a clean acrylic substrate;

[0047] S2. Place the clean acrylic substrate on the jig, send it into the vacuum coating chamber and evacuate it. When the vacuum degree in the vacuum chamber reaches 5*10 -5 When the Torr is below, turn on the ion source and clean the surface of the acrylic substrate. When the vacuum degree in the vacuum chamber reaches 2*10 -5 When the Torr is below, the temperature in the vacuum chamber is controlled at 40-60°C and the evaporation rate is controlled at Use an electron gun to bombard the bottom layer and several film layer materials in order to form the bottom layer and several film layers sequentially on the outer surface of the substrate;

[0048] S3, keep the vacuum degree in the vacuum chamber at 2*10 -5 Below Torr, control the temperature in the vacuum chamber at 40-60°C and control the evaporation rate at A tungsten boat is used to heat the waterproof m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com